24 - Zuidberg Frontline Systems

24 - Zuidberg Frontline Systems

24 - Zuidberg Frontline Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The new ECO-TWIN PTO<br />

The ECO-TWIN PTO was designed with the vision that the<br />

engines of current tractors can supply the same power<br />

even with a lower rpm.<br />

Virtually all tractors have the ability to switch off the rear Pto<br />

between 1000 revolutions and what is known as a ‘low-power<br />

mode’. In that case, 1000 revolutions of the rear power take-off<br />

shaft is achieved with a reduced engine rpm of approximately<br />

1600 rpm. With Eco-tWIN Pto, this is now also possible in<br />

the front Pto. the Eco-tWIN Pto has been designed for<br />

tractor classes of 100-250 hp.<br />

Two clutches<br />

the mechanics in the Pto are based on the tried<br />

and tested <strong>Zuidberg</strong> technique with a wet lamella<br />

clutch and an separate hydraulic circuit. However,<br />

two clutches are incorporated in this housing. the<br />

first clutch works as it does in any other <strong>Zuidberg</strong><br />

housing, by connecting the outgoing axle directly to<br />

the lowest gear from the housing; the so-called drive<br />

cup. the second clutch connects the outgoing axle<br />

with the drive cup via a planetary gear system. the<br />

planetary gear system provides the extra deceleration<br />

between the gear and axle. Due to its compact design,<br />

the housing uses only 32 mm more space than, for<br />

example, a standard PN housing and uses 54 mm more<br />

space than a PA3/4, which is mounted on these tractors in<br />

the current <strong>Zuidberg</strong> range.<br />

In its programme, <strong>Zuidberg</strong> already has a gearbox with<br />

adapted transmission ratio, with which a lower<br />

engine rpm can be realised. If you would also<br />

like to use the normal 1:2 ratio, the gearbox<br />

must be changed. that is now a thing of the<br />

past with the Eco-tWIN Pto.<br />

Use<br />

As regards use, imagine duties where the required<br />

power of the front and rear Pto allow it to operate<br />

with lower revolutions. for example, when mowing.<br />

Another use is when the front machine needs to<br />

operate at 1000 revolutions and the rear machine<br />

can operate with fewer revolutions. the user can set<br />

the front Pto electronically to 1000E from the<br />

ZuIDbERG fRoNtLINE SYStEMS bV <strong>24</strong><br />

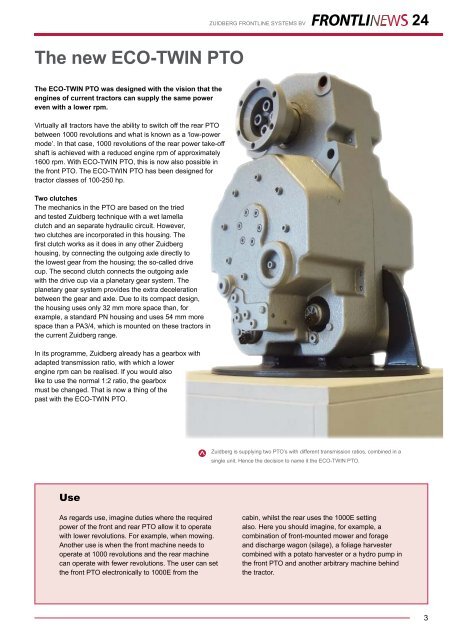

<strong>Zuidberg</strong> is supplying two Pto’s with different transmission ratios, combined in a<br />

single unit. Hence the decision to name it the Eco-tWIN Pto.<br />

cabin, whilst the rear uses the 1000E setting<br />

also. Here you should imagine, for example, a<br />

combination of front-mounted mower and forage<br />

and discharge wagon (silage), a foliage harvester<br />

combined with a potato harvester or a hydro pump in<br />

the front Pto and another arbitrary machine behind<br />

the tractor.<br />

3