Material Science - LMT Cachan - ENS Cachan

Material Science - LMT Cachan - ENS Cachan

Material Science - LMT Cachan - ENS Cachan

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

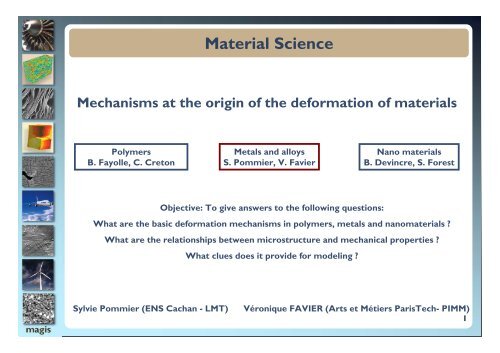

<strong>Material</strong> <strong>Science</strong><br />

Mechanisms at the origin of the deformation of materials<br />

Polymers<br />

B. Fayolle, C. Creton<br />

Objective: To give answers to the following questions:<br />

What are the basic deformation mechanisms in polymers, metals and nanomaterials ?<br />

What are the relationships between microstructure and mechanical properties ?<br />

Sylvie Pommier (<strong>ENS</strong> <strong>Cachan</strong> - <strong>LMT</strong>)<br />

Metals and alloys<br />

S. Pommier, V. Favier<br />

What clues does it provide for modeling ?<br />

Nano materials<br />

B. Devincre, S. Forest<br />

Véronique FAVIER (Arts et Métiers ParisTech- PIMM)<br />

1

Introduction – Why ?<br />

Why are we interrested in the deformation mechanisms of materials ?<br />

� to design new materials for new problems<br />

Lighter cars<br />

� Increase material strength<br />

more secure cars<br />

� increase material ductility<br />

2

Introduction – Why ?<br />

3

Elongation (%)<br />

Introduction – Why ?<br />

Tensile strength (MPa)<br />

4

Introduction – Why ?<br />

5

Introduction – Why ?<br />

� design a material considering its entire life<br />

It includes :<br />

•Production,<br />

•forming processes,<br />

•assembly processes,<br />

•operating,<br />

•recycling<br />

A geometrical defect created during metal forming may induce a<br />

premature failure in operating conditions<br />

6

� We need to open the black box<br />

Introduction – Why ?<br />

in order to understand the mechanisms<br />

7

� We need to open the black box<br />

Introduction – Why ?<br />

in order to model mechanisms and simulate<br />

8

vacancy<br />

intertitial<br />

Introduction – <strong>Material</strong> scales<br />

substitution<br />

Macroscopic scale (~ mm)<br />

Scale of computational mechanics<br />

Phases (~10 µm)<br />

Scale of metallurgy<br />

Grain (~µm)<br />

Scale of cristallography<br />

Coherent domain<br />

(~10 nm)<br />

Scale of diffraction<br />

Crystallographic lattice<br />

(~ Å)<br />

Scale of « Transmission Electronic Microscope »<br />

9

Introduction – <strong>Material</strong> scales<br />

� We need to open the black box<br />

in order to<br />

understand,<br />

model,<br />

characterize,<br />

and simulate<br />

material behaviour<br />

at various scales from nanometer to meter<br />

10

1 Basic mechanisms: crystals<br />

nuclear<br />

electronic<br />

total<br />

A B<br />

E = − + m n<br />

r r<br />

A material tends to<br />

crystallize to<br />

minimize its energy<br />

11

1 Basic mechanisms : crystals<br />

Body centered cubic (BCC)<br />

For metals and alloys<br />

Face centered cubic (FCC)<br />

hexagonal compact (HC)<br />

12

1 Basic mechanisms : crystals<br />

Miller indices for planes and directions<br />

(orthotropic systems)<br />

OA = x A .a = a/h,<br />

OB = y B .b = b/k<br />

OC = z C .c = c/l<br />

Be careful : if the system is not cubic [h,k,l] is not orthogonal to (h,k,l)<br />

OM = x.<br />

a.<br />

e + y.<br />

b.<br />

e + z.<br />

c.<br />

e<br />

x<br />

a, b, c interatomic distances<br />

Equation of the plane<br />

hx + ky + lz = 1<br />

Index : (h,k,l)<br />

Direction : [h,k,l]<br />

y<br />

z<br />

13

1 Basic mechanisms : crystals<br />

Most metals and alloys are<br />

polycristalline<br />

14

1 Basic mechanisms : crystals<br />

X-Ray diffraction<br />

15

BRAGG’s law<br />

Sinθ<br />

=<br />

1 Basic mechanisms : crystals<br />

nλ<br />

2d<br />

16

BRAGG’s law<br />

Sinθ<br />

=<br />

1 Basic mechanisms : crystals<br />

nλ<br />

2d<br />

17

1 Basic mechanisms : crystals<br />

Keep the angle θ constant<br />

And vary<br />

the diffraction vector g<br />

versus<br />

the vector n normal to the sample<br />

Incoming<br />

X-Ray beam<br />

diffracted<br />

X-Ray beam<br />

18

Stereographic projection<br />

1 Basic mechanisms : crystals<br />

19

Stereographic projection<br />

1 Basic mechanisms : crystals<br />

20

1 Basic mechanisms : crystals<br />

Stereographic projection : pole figures<br />

21

1 Basic mechanisms : crystals<br />

Metal forming : the material is not isotropic<br />

DL<br />

22

1 Basic mechanisms: elasticity<br />

nuclear<br />

electronic<br />

total<br />

A B<br />

E = − + m n<br />

r r<br />

23

1 Basic mechanisms: elasticity<br />

nuclear<br />

electronic<br />

total<br />

Elastic behaviour : asymptotic behaviour of atomic bonds<br />

around r=ro<br />

24

551<br />

482<br />

413<br />

DL<br />

1 Basic mechanisms: elasticity<br />

loading / rolling directions angle<br />

Youngs modulus<br />

loading / rolling directions angle<br />

25

2<br />

Evidences of plastic<br />

deformation in metals<br />

26

2 Evidences of plastic deformation in metals<br />

σ<br />

ε p<br />

Non recoverable deformation<br />

inelastic – plastic deformation<br />

ε<br />

Hanriot, 1993 (from S. Forest)<br />

Slip lines, Slip bands<br />

Single slips<br />

Crystallographic slip<br />

27

2 Evidences of plastic deformation in metals<br />

CROSS SLIP<br />

28

3<br />

crystallographic slip,<br />

slip systems<br />

29

A slip system consists in :<br />

•A slip plane<br />

•A slip direction<br />

A B<br />

E =<br />

− + m n<br />

r r<br />

3: crystallographic slip<br />

30

structure<br />

FCC<br />

BCC<br />

HCP<br />

Slip planes<br />

{111}<br />

{110}, {112},<br />

{123}<br />

{0001}, {1010}<br />

3: crystallographic slip<br />

Slip directions<br />

<br />

<br />

<br />

Examples of<br />

metals<br />

Al, Fe γ, Cu, Ni,<br />

Au, Ag<br />

Fe α, Nb, Mo<br />

Mg, Ti, Zn, Zr<br />

α, Be<br />

31

structure<br />

FCC<br />

BCC<br />

HCP<br />

3: crystallographic slip<br />

{110}, {112}, {123}<br />

basal<br />

pyramidal<br />

Slip planes<br />

{111}<br />

{0001}, {1010}<br />

Slip directions<br />

<br />

<br />

<br />

Examples of metals<br />

Al, Fe γ, Cu, Ni, Au, Ag<br />

Fe α, Nb, Mo<br />

Mg, Ti, Zn, Zr α, Be<br />

prismatic<br />

32

3: crystallographic slip : slip systems in FCC crystals<br />

33

3: crystallographic slip : slip systems in FCC crystals<br />

34

3: crystallographic slip : slip systems in FCC crystals<br />

35

3: crystallographic slip : slip systems in FCC crystals<br />

36

3: crystallographic slip : slip systems in FCC crystals<br />

37

3: crystallographic slip : slip systemms in FCC crystals<br />

Octaedra<br />

38

4<br />

When is a slip system active ?<br />

Yield strength<br />

39

10<br />

µm<br />

When is a slip system active ?<br />

One, two, or more slip systems can be activated<br />

10<br />

µm<br />

Single crystal of aluminium<br />

40

τ<br />

s<br />

When is a slip system active ? Schmid law<br />

For any stress tensor<br />

s s<br />

= Rij<br />

ij<br />

τ σ<br />

1<br />

R n m n m<br />

2<br />

( )<br />

s<br />

ij = i j + i j<br />

Schmid tensor<br />

( n)<br />

⋅ m<br />

= σ<br />

Resolved shear stress on the slip system (s)<br />

n<br />

n<br />

χ<br />

F<br />

m Elastic if<br />

θ<br />

F<br />

τ<br />

m<br />

τ = σ 0 cos θ cosχ<br />

Schmid factor<br />

τ < τ c<br />

Plastic if<br />

τ = τ c<br />

Schmid criterion<br />

41

When is a slip system active ? Tensile strength for single crystals<br />

n<br />

χ<br />

F<br />

θ<br />

F<br />

τ<br />

Elastic if<br />

τ < τ c<br />

Plastic if<br />

τ = τ c<br />

Schmid criterion<br />

m<br />

Yield strength σ o<br />

τ = σ 0 cos θ cosχ<br />

cos θ cosχ<br />

τ = 0.5×<br />

σ<br />

max 0<br />

⇒ σ = 2τ<br />

y c<br />

42

When is a slip system active ? Yield stress of polycrystals<br />

Austenitic stainless steel 316L<br />

σ 0<br />

σ 0 500 µm<br />

43

When is a slip system active ? Yield stress of polycrystals<br />

τ σ sinθcosθ =<br />

0<br />

Austenitic stainless steel 316L<br />

σ 0<br />

τ = τ when θ=45° ⇒ τ = 0.5×<br />

σ<br />

max max 0<br />

⇒ σ = 2× τ<br />

= 2× k<br />

y critical( macroscopic )<br />

σ 0 500 µm<br />

44

When is a slip system active ? Yield stress of polycrystals<br />

⇒ σ =<br />

2τ<br />

y c<br />

⇒ σ = 2× τ<br />

= 2× k<br />

y critical(macroscopic)<br />

45

When is a slip system active ? Scale transition from grain to polycrystal<br />

σ<br />

b) The Sachs model (1928)<br />

σ τ<br />

Heterogenous stress and strain fields in polycrystals !!<br />

The stress field is assumed uniform and one single slip system per grain is active.<br />

Uniaxial tensile test<br />

a) The static model (Batdorf and Budiansky, 1949)<br />

The stress field is assumed uniform and<br />

Uniaxial tensile test<br />

σlocal,grain ≠σ<br />

y = 2.24 c<br />

Isotropic F.C.C<br />

( s ) s ( )<br />

Max R σ = Max R σ = τ<br />

grains,slip systems ij ijlocal,grain grains,slip systems ij ij c<br />

σ = 2τ<br />

y c<br />

σlocal,grain =<br />

σ<br />

46

When is a slip system active ? Scale transition from grain to polycrystal<br />

σ<br />

d) The Taylor-Lin Taylor Lin model (Lin, 1957)<br />

Heterogenous stress and strain fields in polycrystals !!<br />

local ,grain E<br />

ε ≠<br />

c) The Taylor model (1938)<br />

The elastic deformation is neglected (and so internal stresses) and<br />

the strain field is assumed uniform.<br />

Uniaxial<br />

tensile test<br />

σ = 3.06τ<br />

y c<br />

Isotropic F.C.C<br />

The strain field is assumed uniform and one single slip system per grain is active.<br />

Many other scale transition models … see course on Heterogeneous media : large scale behaviour<br />

47

Tensile<br />

tests<br />

iron single<br />

crystals<br />

After the onset of plastic yielding ?<br />

HARDENING IS A KEY PHENOMENON<br />

48

To summarize<br />

•Plastic deformation in metals<br />

•Slip systems (plane and directions)<br />

•Schmid law in single cristal (critical shear stress on slip systems)<br />

•Various models for polycristals<br />

49