4-day WebCast/OnsIte auCtIOn - Hilco Industrial

4-day WebCast/OnsIte auCtIOn - Hilco Industrial

4-day WebCast/OnsIte auCtIOn - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

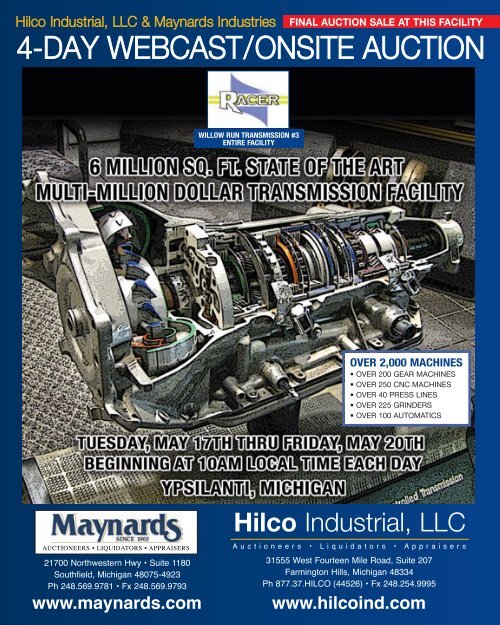

<strong>Hilco</strong> <strong>Industrial</strong>, LLC & Maynards Industries<br />

4-<strong>day</strong> <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong><br />

Auctioneers • LiquidAtors • ApprAisers<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

WillOW run TransMissiOn #3<br />

enTire FaciliTy<br />

Final auction Sale at thiS Facility<br />

Over 2,000 Machines<br />

• Over 200 Gear Machines<br />

• Over 250 cnc Machines<br />

• Over 40 Press Lines<br />

• Over 225 Grinders<br />

• Over 100 autOMatics<br />

hilco <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 877.37.HILCO (44526) • Fx 248.254.9995<br />

www.hilcoind.com

2<br />

HILCO IndustrIaL, LLC<br />

& Maynards IndustrIes<br />

<strong>auCtIOn</strong> dates<br />

tues<strong>day</strong>, May 17 tH tHru FrI<strong>day</strong>, May 20 tH<br />

beGInnInG at 10aM LOCaL tIMe eaCH <strong>day</strong><br />

PrevIeW date<br />

May 12 tH , 13 tH & 16 tH<br />

9aM tO 4PM ea. <strong>day</strong> & MOrnInG OF saLe<br />

For earlier inspection, please contact ken planet<br />

at 248.254.9999 x33 or email kplanet@hilcoind.com<br />

<strong>auCtIOn</strong> & PrevIeW LOCatIOn<br />

2930 eCOrse rOad<br />

yPsILantI, MI 48198<br />

<strong>day</strong>s IteMs<br />

WILL be sOLd<br />

WillOW run<br />

TransMissiOn #3<br />

enTire FaciliTy<br />

4-<strong>day</strong> <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong><br />

<strong>day</strong> 1<br />

Gear, CenterLess<br />

GrInders, rObOts, CnC<br />

dIreCtIOns<br />

FrOM detrOIt MetrOPOLItan aIrPOrt (dtW): exIt tO I-94. traveL West On I-94 FOr<br />

11 MILes tO exIt FOr WILLOW run aIrPOrt (exIt #186). FOLLOW exIt FOr WILLOW run<br />

aIrPOrt and MerGe OntO WIard rd. traveL On WIard rd FOr 1 MILe and take exIt<br />

FOr aIrPOrt rd. Make IMMedIate LeFt OntO W. HydraMatIC dr tO enter FaCILIty.<br />

Must use W. HydraMatIC entranCe On West sIde OF PLant at FLaG POLes.<br />

FurtHer InFOrMatIOn<br />

• a buyers PreMIuM OF 16% FOr aLL <strong>WebCast</strong> saLes and 13.5% FOr aLL<br />

<strong>OnsIte</strong> saLes WILL be In eFFeCt. <strong>auCtIOn</strong> WILL be COnduCted In enGLIsH,<br />

aCCePtInG u.s. CurrenCy OnLy.<br />

• PleaSe note: ReMoVal DeaDline Will Be DeteRMineD PRioR to auction.<br />

equiPMent ReMoVal ReStRictionS aPPly. PleaSe ViSit ouR WeBSite at<br />

WWW.hilcoinD.coM FoR MoRe inFoRMaiton.<br />

• FOr FurtHer InFOrMatIOn On MaCHInery & equIPMent, PLease COntaCt<br />

ken PLanet at 248.254.9999 x33 Or eMaIL kPLanet@HILCOInd.COM Or<br />

MarIO MazzuCa at 248.569.9781 Or MarIO@Maynards.COM<br />

• FOr PayMents PLease COntaCt terrI terPstra at 248.596.9781 Or eMaIL<br />

tterPstra@Maynards.COM<br />

• CustOMer servICe, PLease COntaCt sandI neeLy at 248.254.9999 x16 Or<br />

eMaIL sneeLy@HILCOInd.COM<br />

<strong>day</strong> 2<br />

Press LInes, sCreW<br />

MaCHInes, InsPeCtIOn,<br />

FabrICatInG, tOOLrOOM<br />

<strong>day</strong> 3<br />

WeLdInG, Heat treat,<br />

Cranes, rOLLInG stOCk<br />

<strong>day</strong> 4<br />

asseMbLy, transFer<br />

LInes, kItCHen, OFFICes,<br />

MIsCeLLaneOus<br />

(30) cnc Gear hOBBinG Machines<br />

2 – MITSUBISHI GND10A 6-AxIS CNC GEAR HOBBERS; S/Ns 1104C6, 1105C6 (Both 2004); Fanuc<br />

180i MB Control; Max. Dia. 100mm; Automatic Loader & Unloader; Magnetic Chip Conveyor<br />

1 – SAMPUTENSILI S 100 5-AxIS CNC GEAR HOBBER; S/N 180604 (2006); Siemens 840D<br />

Control; Max. Dia. 100mm; Automatic Loader & Unloader; Magnetic Chip Conveyor<br />

2 – MITSUBISHI GB15CNC 5-AxIS CNC GEAR HOBBERS; (1) Max. Dia. 200mm; (1) Max. Dia. 100mm;<br />

Automatic Load & Unload; Both With Fanuc O-M Controls; Coolant Tank w/ Magnetic Conveyor<br />

5 – PFAUTER PE 150 6-AxIS CNC GEAR HOBBERS; Automatic Load & Unload; GE Fanuc<br />

15M Controls; Magnetic Chip Conveyor; Nominal Workpiece Diameter 5.9”<br />

20 – PFAUTER PE 80 6-AxIS CNC GEAR HOBBERS; (1) w/ GE Fanuc 15-M Control;<br />

(19) w/ Allen Bradley Series 9 Control; All With Parts Carousel w/ Auto Load & Unload;<br />

Coolant w/ Magnetic Chip Separator; Nominal Workpiece Diameter 3.15”, (4) Parts Machines<br />

PLEASE NOTE: Equipment Removal Restrictions Apply.<br />

Please Visit www.hilcoind.com for More Information.<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

CnC Gear HObbers, sHavers & sHaPers • burnIsHers & InsPeCtIOn<br />

(10) cnc Gear shavers<br />

1 – SICMAT RASO 200 5-AxIS CNC GEAR SHAVER; S/N 3948 (2006); Siemens 840D<br />

Control; Max. Dia. 200mm; Automatic loader & Unloader; Magnetic Chip Seperator<br />

8 – HURTH ZS 240T CNC GEAR SHAVERS; S/Ns 44482, -477, -479, -485 (All 1993);<br />

44523, -522, -521 (All 1994); S/N 44515 (1994) Parts Machine; Allen Bradley Series 9<br />

Control; Automatic Loader & Unloader; Max Wheel Diameter 390mm (15.36”); Max<br />

Work Module 8, Max Gear Width 50mm (1.97”)<br />

(106) cnc Gear shaPers<br />

38 – FELLOWS (MTD) 10-2 CNC GEAR SHAPERS; 14” Dia Table; Allen Bradley Panel<br />

View Plus 1000 Control; Coolant Tank w/ Magnetic Separator (2 Disassembled)<br />

14 – FELLOWS 10-2 GEAR SHAPERS; 14” Dia Table; Allen Bradley “Panel View” CRT<br />

Control Panel; Magnetic Chip Conveyor; Coolant System<br />

54 – FELLOWS 10-2 GEAR SHAPERS; 14” Dia Table; SPM Driven Sheave; Spindle Motor 7 1/2 HP;<br />

Hydraulic Pump 5 HP<br />

Gear hOBBers<br />

5 – CLEVELAND MODELS 1886-606-223, -290, -154, -252, -340 GEAR HOBBERS;<br />

Magnetic Chip Conveyor<br />

1 – BOURNE & KOCH 50-7 GEAR HOBBER; Automatic Load & Unload; Motor 5 HP; Coolant<br />

Tank w/ Magnetic Chip Separator<br />

(22) Gear shavers<br />

15 – RED RING GCU GEAR SHAVERS; 9” Cutter Head; Coolant w/ Magnetic Separator<br />

2 – NATIONAL BROACH GCU GEAR SHAVERS; 9” Cutter Head; (1) w/ Automatic Load &<br />

Unload; (1) w/ Allen Bradley Panel View Control; Magnetic Chip Separator<br />

4 – NATIONAL BROACH GFF GEAR SHAVERS; Allen Bradley Panel View Control; 9” Cutter<br />

Head; (1) w/ Automatic Load & Unload, (3) w/ Coolant Tank w/ Magnetic Chip Separator<br />

1 – NATIONAL BROACH GEAR SHAVER; Parts Machine<br />

(11) Gear Burnishers & insPecTiOn Machines<br />

11 – NUMRATROL II, KRUEGER, RED RING & ITW HEARTLAND GEAR BURNISHING MACHINES<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 3

4<br />

brOaCHes • CnC brOaCH, tOOL & Cutter GrInders<br />

(31) BrOaches<br />

3 – FEDERAL 50-TON HyDRAULIC VERTICAL BROACHES; Model<br />

50T-48-VPU; Stroke 48”; Coolant Tank w/ Magnetic Chip Conveyor; Models<br />

50T13X15 & 10X15DRBS Blind Side Dual Ram; Allen Bradley Panel View;<br />

16-Position Rotary Index Table; Automatic Load & Unload<br />

1 – AMERICAN BROACH APPROx 50-TON VERTICAL HyDRAULIC<br />

ExTERNAL BROACH; Approx 66” Stroke; Pick and Place Part<br />

Loader/Unloader; 25 HP Hydraulic Pump; Allen Bradley SLC500<br />

Programmable Controller; Approx 8” Dia Press Cylinder Bore; 2 Cutting Heads<br />

1 – NATIONAL VBB 15-TON HyDRAULIC VERTICAL BROACH<br />

2 – GENERAL BROACH GBVPD 11-TON HyDRAULIC VERTICAL BROACHES<br />

2 – AMERICAN BROACH 4-TON HyDRAULIC VERTICAL BROACHES;<br />

Stroke 36”; 500 Lb. Jib Crane; Parts Hopper w/ Conveyor & Vibratory Feeder<br />

4 – NACHI 4T40E VERTICAL BROACHES; S/Ns BVT-298, -299, -300, N/A<br />

(All 2000); With Allen Bradley Panel View 1400e Control; Pump Motor 15<br />

HP; Coolant Tank w/ Magnetic Chip Separator; Turmoil Model OC-1000<br />

BI-WC Chiller; Electric Hoist; (N/A w/ No Control)<br />

1 – NATIONAL BROACH HyDRAULIC VERTICAL BROACH; (3) Heads; (2) Hydraulic Pumps;<br />

Coolant Tank w/ Magnetic Separator; Magnetic Chip Conveyor; Budgit 1-Ton Electric Hoist<br />

4 – NATIONAL BROACH HyDRAULIC VERTICAL BROACHES; Allen Bradley PanelView 1200<br />

Control; Pump Motor 40 HP; Coolant Pump w/ Magnetic Chip Separator<br />

8 – NATIONAL BROACH BVT HyDRAULIC VERTICAL BROACHES; (7) w/ Allen Bradley Panel<br />

View Control; Hydraulic Pump 20 HP; Coolant Tank (1 Parts Machine)<br />

1 – COLONIAL VFS 4-18 VERTICAL HyDRAULIC BROACH; S/N 86021<br />

2 – US BROACH HyDRAULIC VERTICAL BROACHES; Allen Bradley PanelView Control; Magnetic Chip Conveyor<br />

2 – AMERICAN BROACH 15x60 POT 15-TON HyDRAULIC VERTICAL BROACHES;<br />

Allen Bradley Panel View Control; Capacity 15-Ton; Stroke 60”; Coolant Tank w/ Magnetic Chip<br />

Separator; 2-Ton Electric Hoist<br />

2 – DETROIT BROACH 14-STATION HyDRAULIC INLINE SHAPERS; (2) Rams<br />

cnc BrOach GrinDers<br />

2 – AMERICAN BROACH CNC BROACH GRINDERS; (2) w/ GE Fanuc O-M Control; Spindle<br />

Speed 7200 RPM; Monroe Environmental Dust Collector; (1) w/ Allen Bradley Series 9 Control<br />

1 – THOMPSON BROACH GRINDER; S/N FM 53542; Table 9” x 96”; 6” x 32” Permanent<br />

Magnetic Chuck<br />

cnc TOOl & cuTTer GrinDer<br />

1 – WALTER HELITRONIC POWER BG 6-AxIS CNC BROACH GRINDER; S/N 6531 (1997);<br />

Control HMC 400 WWM; Spindle Speed 9500 RPM; 8” x 24” Electro-Magnetic Chuck; Coolant<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Gear sHaver Cutter GrInders • sPLIne rOLLers • rObOts<br />

(6) Gear shaver cuTTer GrinDers<br />

2 – GLEASON-HURTH SRS-405 9-AxIS & SRS-400 11-AxIS CNC SHAVING CUTTER GRINDERS<br />

(Both 1998); Control GE Fanuc 16-M<br />

4 – HURTH SRS-400, -401 & -402 SHAVING CUTTER GRINDERS<br />

hOB GrinDers<br />

6 – ILLITRON TyPE A62/0 “MIKRON” HOB GRINDERS; Coolant System<br />

1 – KAPP & CO AS203 GEAR HOB SHARPENER; 8” x 12” c.c.; Coolant System; Magnetic<br />

Particle Separator<br />

(6) sPline rOllers<br />

3 – ANDERSON COOK 450 48” SPLINE ROLLERS; Index Feeder; Pump Motor 40 HP<br />

1 – MICROMATIC ROTO-FLO 3251 SPLINE ROLLER; 60 HP Hydraulic Pump; Automatic<br />

Load & Unload<br />

2 – GROB ZRM 12-NC-A SPLINE ROLLERS; GE Fanuc Controls; Automatic Load & Unload; Hydraulic<br />

Pump 3 HP<br />

cnc FlOW FOrMers<br />

3 – LEICO DW 326 CNC FLOW FORMERS; Allen Bradley Series 9 Control; Alpha Chiller; Pump<br />

Motor 50 HP<br />

(17) cnc rOBOTs<br />

4 – FANUC MODEL M710iB 6-AxIS RAIL MOUNTED ROBOT CELLS; All With (2) Fanuc M710iB 70T<br />

Robots w/ R-J3iB Controls & Teach Pads; S/N TP 004177 (2005); Rail 85’; 92” Under Rail; S/Ns TP<br />

004001, TP 00480 (2004); Rail 75’; 94” Under Rail; S/N TP 00435 (2003); Rail 75’; 120” Under Rail<br />

13 – FANUC 6-AxIS CNC ROBOTS: (6) R-2000iA (2004); R-J3iB Control; (3) M-16iB (2004-2005); R-J3iB<br />

Control; (4) S-420iF; R-J2 Control; All With Teach Pad<br />

PLEASE NOTE: Equipment Removal Restrictions Apply.<br />

Please Visit www.hilcoind.com for More Information.<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 5

6<br />

CnC HOrIzOntaL & vertICaL MaCHInInG Centers<br />

(56) cnc hOriZOnTal MachininG cenTers<br />

13 – NTC MODEL N5H-868 CNC HORIZONTAL MACHINING<br />

CENTERS; (2006-2007); GE Fanuc 18i-MB; Spindle<br />

Motor 30-HP; 26 Position ATC; Travels: X-80mm;<br />

Y-600mm; Z-800mm; Set for In-Line Production Machining<br />

29 – NTC MODEL N4q-555 CNC HORIZONTAL MACHINING<br />

CENTERS; (2004-2007); GE Fanuc 18i-MB; Spindle<br />

Motor 22-HP; 13-Position ATC; Travels: X-500mm;<br />

Y-500mm; Z-500mm; Set for In-Line Production Machining<br />

12 – ENSHU JE50S CNC HORIZONTAL MACHINING<br />

CENTERS, (2006); Fanuc 18i-MB; Spindle Motor<br />

20-HP; Travels: X-19.7”; Y-19.7”; Z-19.7”; Set for In-Line<br />

Production Machining<br />

2 – TOyODA FA550 CNC HORIZONTAL MACHINING<br />

CENTERS; Dual Pallet; 4-axis with GE Fanuc Series<br />

15-M Computer Control; including (2) 22” x 22” Pallets;<br />

Pallet Changer; 48 Tool Capacity Auto Tool Changer;<br />

Indexable 4th Axis<br />

(8) cnc verTical MachininG cenTers<br />

1 – ENSHU ES450 COMPACT BRIDGE STyLE CNC<br />

VERTICAL MACHINING CENTER, S/N 05C448 (2006);<br />

Fanuc Control; Spindle Motor 20-HP; Travels: X-25.6”;<br />

Y-17.7”; Z-18.1”; Set for In-Line Production Machining<br />

1 – CINCINNATI MILACRON SABRE 500 CNC VERTICAL<br />

MACHINING CENTER; GE Fanuc O-M Control; Cutler<br />

Hammer Panel Mate Control<br />

6 – ARCOLOC CNC 4-AxIS VERTICAL MACHINING<br />

CENTERS; GE Fanuc O-M Controls<br />

(44) 2-aXis cnc hOriZOnTal TurninG cenTers<br />

6 – HARDINGE CONqUEST T51 2-AxIS CNC TURNING CENTERS; 12 Station Turret; Tailstock; Fanuc 18-T<br />

Control; Light Curtains; Chip Conveyor<br />

28 – HARDINGE CONqUEST T51 2-AxIS CNC TURNING CENTERS; GE Fanuc 32 Bit O-TC CNC Control,<br />

(28) With Chip Conveyor<br />

7 – HARDINGE CONqUEST 42 2-AxIS CNC TURNING CENTERS; GE Fanuc O-T Controls; 10-Positon<br />

Turret; Hydraulic Tailstock; Magnetic Chip Conveyor<br />

3 – MONARCH 2-AxIS CNC TURNING CENTERS; (1) w/ 10” Chuck; (1) w/ 12” 3-Jaw Chuck; Hydraulic<br />

Tailstock; 6-Position Turret; Chip Conveyor; (1) w/ 18” Chuck; All With General Electric Mark Century 2000<br />

Control; 8 or 6-Position Turrets; Chip Conveyor<br />

(67) cnc verTical TurninG cenTers<br />

40 – OLOFSSON CNC TWIN SPINDLE VERTICAL TURNING CENTERS (TO 1997); (2) 8 Position Turrets;<br />

Allen Bradley Control; Chip Conveyor; Coolant; Light Curtains; All With (2 or 3) 10, 20 or 30 HP Spindle<br />

Motors (3 Less Control Screen, 4 No Controls)<br />

1 – OLOFSSON CNC 2-SPINDLE VERTICAL TURNING CENTER; GE Fanuc OTT Control; Chip Conveyor<br />

3 – WERTH 6-12-VNC & (2) 8-8-12-VNC 2-SPINDLE CNC VERTICAL TURNING CENTERS; GE Fanuc<br />

15-TT Controls; Light Curtains; (2) Fanuc 6S Spindle Motors; Coolant Tank w/ Magnetic Chip Conveyor<br />

1 – WERTH 9-12-VNC CNC 3-SPINDLE VERTICAL TURNING CENTER; GE Fanuc 15-T Controls; Light<br />

Curtains; Chip Conveyor<br />

7 – SAGINAW MACHINE (4) AC300-2E/A & (3) AC200-2A 2-SPINDLE CNC VERTICAL TURNING CENTERS<br />

1 – KASPER VCNC-100 2-SPINDLE CNC VERTICAL TURNING CENTER; GE Fanuc O-T Control; Light<br />

Curtains; (2) Spindle Motors 12S; Coolant Tank w/ Magnetic Conveyor<br />

1 – KINGSBURy VTC-3 CNC VERTICAL TURRET LATHE<br />

4 – SAGINAW MACHINE AC 300 2 CNC 2-SPINDLE VERTICAL TURNING CENTERS; GE Fanuc Controls<br />

8 – SAGINAW MACHINE VO-300-3 3-SPINDLE VERTICAL TURNING CENTERS; (2) 20 HP Spindle Motors;<br />

Coolant<br />

2 – NEW BRITAIN 66 TWIN SPINDLE VERTICAL TURNING MACHINES; 10 HP Spindles; Rebuilt By Werth<br />

Engineering Inc.<br />

1 – OLOFSSON CHUCKER; Automatic Loader & Unloader<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

CnC HOrIzOntaL & vertICaL turnInG Centers • CnC CHuCkers<br />

(53) cnc verTical TurninG cenTers<br />

8 – HARDINGE (4) CONqUEST V200 & (4) VT200 CNC<br />

VERTICAL TURNING CENTERS; GE Fanuc 18-T Control;<br />

Light Curtains; 12-Position Turret; Spindle Motor 40P<br />

12 – HARDINGE VT 100 CNC VERTICAL TURNING CENTERS;<br />

GE Fanuc 18-T Control; Light Curtains; 12-Position Turret;<br />

Coolant Tank w/ Chip Conveyor (1 Missing Controls)<br />

8 – OLOFSSON SV5 & SV5-T8 CNC VERTICAL TURNING<br />

CENTERS; GE Fanuc O-T Control<br />

19 – OLOFSSON CNC VERTICAL TURNING CENTERS; Allen<br />

Bradley Series 9 Control; (13) 15 HP; (6) 20 HP (3 Missing<br />

Control Screen, 2 Missing Controls)<br />

6 – BULLARD 8-STATION VERTICAL TURNING MACHINES;<br />

(2) Spindles Per Station<br />

cnc hOriZOnTal BOrinG Machines<br />

1 – KASPER CNC 2-SPINDLE HORIZONTAL BORING MACHINE; S/N HBS 181895139; GE Fanuc Power Mate Control; Light<br />

Curtains; Spindles 3-HP; Samscomatic Electronic process Controller; Coolant Tank w/ Magnetic Chip Conveyor<br />

1 – ExCELLO 747 CNC 4-SPINDLE HORIZONTAL BORING MACHINE; Allen Bradley Series 9 Controls; Chip Conveyor<br />

(21) cnc chucKers<br />

5 – SUGA ST-200 2-AxIS CNC CHUCKERS; 14” Swing; 10 1/4” x 30” 2-Axis Tool Holder; (1) With 16” Swing; All With GE<br />

Fanuc O-T Controls; Magnetic Chip Conveyor<br />

4 – SUGA ST-200W 2-AxIS CNC CHUCKERS; Max Swing-16” with 8 Tool Capacity Turret Mounted on 10 1/4” x 30”<br />

T-Slotted 2-Axis Tool Holder; GE Fanuc Series O-T CNC Control; 1991<br />

6 – SAGINAW MACHINE 2-AxIS CNC CHUCKERS; (2) N50-1, 8-Position Turret; (4) N50-1A; (2) 16” Swing with Duplomatic<br />

8 Station; All With GE Fanuc O-T Control; Automatic Loader & Unloader; Chip Conveyor (1 Missing Control Panel)<br />

1 – WERTH 11-14-HNC 3-SPINDLE CNC CHUCKER; Allen Bradley Series 9 Controls; (9) Tool Holders; (3) 10 HP Spindle<br />

Motors; Automatic Load & Unload; Chip Conveyor<br />

5 – OLOFSSON 3-SPINDLE & 2-SPINDLE CHUCKERS<br />

cnc accessOries<br />

4 – BENCH TOP TOOL PRESETTERS; (2) with 7-Size Turret; Heidenhain Single Axis Digital Readout<br />

1 – MAPAL N/A BORING TOOL CARBIDE INSERT PRESETTER; 9” x 16” c.c. Capacity with Mapal NO ME2 2-axis Digital Readout<br />

1 – MAPAL-PRAZISIONSWERKZEUGE MN-399-6-H BORING TOOL HOLDER PRESETTER<br />

LARGE qUANTITy OF 40 TAPER & 50 TAPER TOOL HOLDERS<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 7

8<br />

straIGHt sIde Presses & COIL Feed LInes<br />

(19) sTraiGhT siDe Presses & cOil FeeD lines<br />

(Equipment May be Offered Individually and as Lines)<br />

1 – VERSON TS2-1500-280-60 1500-TON STRAIGHT SIDE TRANSFER PRESS;<br />

Stroke 18”; SPM 15-30; LITTELL S200-36 (Reel) 626D – 5PD (Straightener)<br />

7 – 24 (Feed) Electronic Feed Line; 20,000 Lb. x 36”<br />

1 – DANLy S2-1000-84-72 1000-TON STRAIGHT SIDE DOUBLE CRANK PRESS; Stroke<br />

8”; SPM 15-30; PERFECTO 10-50 Coil Cradle-Straightener; 50,000 Lb. x 50” Wide;<br />

1 – VERSON T-SE2-800-181-48T 800-TON TRANSFER PRESS; Stroke 12”; SPM<br />

15-30; Transfer Stations 8; LITTELL S200-36 (Reel) 626 (Straightener) Coil Reel<br />

& Straightener; 20,000 lb. x 36”; Capacity 6”-24” x .200”-.156”<br />

1 – VERSON T-SE2-800-178-36 800-TON STRAIGHT SIDE DOUBLE CRANK<br />

TRANSFER PRESS; Stroke 12”; SPM 20-40; 12 Station Transfer; LITTELL<br />

90-30 (Reel) 614-75D (Straightener) Coil Reel & Straightener; 10,000 Lb. x 30”;<br />

Capacity 6” x .200<br />

1 – VERSON T-S2-800-178-36T PR 800-TON STRAIGHT SIDE DOUBLE CRANK<br />

TRANSFER PRESS; Stroke 12”; SPM 20-40; LITTELL 90-30 (Reel) 614 7PD<br />

(Straightener) Coil Reel & Straightener; 10,000 Lb. x 30”<br />

3 – VERSON T-S2-800-168-66T 800-TON STRAIGHT SIDE DOUBLE CRANK TRANSFER<br />

PRESSES; 8 Station Transfer; LITTELL S200-36 (Reel) 424 7PD (Straightener) Coil Reel<br />

& Straightener; 20,000 Lb. x 36”<br />

3 – VERSON SE2-800-108-42T 800-TON STRAIGHT SIDE DOUBLE CRANK<br />

PRESSES; Stroke (1) 10”; (2) 6”; SPM 20-60; LITTELL 90-30 (Reel) 614 7PD<br />

(Straightener) Coil Reel & Straightener; 10,000 Lb. x 30”<br />

1 – VERSON SE2-800-96-48T 800-TON SSDC PRESS; Stroke 10”; SPM 20-60; LITTELL<br />

S200-36 (Reel) 626D 5PD (Straightener) Electronic Feed Line; 20,000 lb. x 36”<br />

1 – VERSON T-S2-600-168-36 600-TON STRAIGHT SIDE DOUBLE CRANK<br />

TRANSFER PRESS; Stroke 12”; SPM 20-40; LITTELL 90-30 (Reel) 614<br />

(Straightener) 7-24 (Feeder) Electronic Feed Line; 10,000 Lb. x 30”<br />

2 – VERSON SE2-600-84-42T 600-TON STRAIGHT SIDE DOUBLE CRANK<br />

PRESS; Stroke 6”; SPM 20-60; (1) w/ PERFECTO RS-10-30-B (Reel) 38-18-7<br />

(Straightener) Coil Reel & Straightener; 10,000 Lb. x 30”; (1) w/ ROWE 12020-DS-<br />

J (Reel) C20-HD-CB (Straightener) Coil Reel & Straightener; 12,000 Lb. x 30”<br />

1 – VERSON SE2-600-84-42 600-TON STRAIGHT SIDE DOUBLE CRANK<br />

PRESS; Stroke 6”; SPM 20-80; BLISS 60-5H-18-48 Coil Cradle Straightener;<br />

6000 Lb. x 18” x .171”<br />

1 – VERSON T-S2-450-154-36T 450-TON STRAIGHT SIDE DOUBLE CRANK<br />

TRANSFER PRESS; Stroke 12”; SPM 25-35; LITTELL 90-30 (Reel) 614D<br />

(Straightener) Electronic Feed Line<br />

1 – VERSON HS2-300-72-36 300-TON STRAIGHT SIDE DOUBLE CRANK PRESS;<br />

Stroke 6”; 45 SPM; PERFECTO RS-15-24B (Reel) 22-7-18 (Straightener) Coil<br />

Reel & Straightener; Reel – 15,000 Lbs x 24” Capacity; ID 18” – 24”<br />

1 – VERSON HS2-250-72-36 250-TON STRAIGHT SIDE DOUBLE CRANK<br />

PRESS; S/N 11874, Stroke 6”<br />

1 – VERSON SS2-150-48-36T 150-TON STRAIGHT SIDE DOUBLE CRANK<br />

PRESS; 10” Stroke 10”; SPM 30-60<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

duaL raM transFer & FInebLankInG Presses & COIL Feed LInes<br />

(11) Dual raM TransFer Presses & cOil FeeD lines<br />

2 – VERSON TS4-1500-2500-144-144-48T 4000-TON DUAL RAM TRANSFER PRESSES; Left Side;<br />

Capacity 2500-Ton; Stroke 16”; SPM 15-25; Right Side Capacity 1500-Ton; Stroke 16”; SPM 15-25;<br />

6 Station Transfer<br />

1 – VERSON TS4-1000-2500-144-120-48T 3500-TON DUAL RAM TRANSFER PRESS; Left Side Capacity<br />

2500-Ton; Stroke 16”; SPM 15-25; Right Side 1000-Ton; Stroke 16”; SPM 15-25; 6 Station Transfer<br />

1 – VERSON 3500-TON DUAL RAM TRANSFER PRESS; Right Side Bed 144” x 48”; 6 Transfer<br />

Stations; Left Side Bed 120” x 48”; 5 Transfer Stations<br />

1 – VERSON T-S4-3000-120-96-48T 3000-TON DUAL RAM TRANSFER PRESS; LITTELL 7-24 (Feed)<br />

626D 5PD C210 (Cradle) Electronic Feed Line; 24” x .212” Zig Zag Electronic Feed 24”<br />

2 – VERSON TS4-2000-155-140-48 2000-TON DUAL RAM TRANSFER PRESSES; Left Side Capacity<br />

1000-Ton; Stroke 20”; SPM 15-30; Right Side; Capacity 1000-Ton; Stroke 20”; SPM 15-30; 7 Station<br />

Transfer; LITTELL S200-36 (Reel) 626 (Straightener) Electronic Feed Line; 20,000 lb. x 36”<br />

1 – VERSON TS4-1000-1000-155-140-48T 2000-TON DUAL RAM TRANSFER PRESS; LITTELL<br />

S200-36 (Reel) 626D (Straightener) Electronic Feed Line; 20,000 lb. x 36” (Disassembled)<br />

1 – DANLy S2-1000-84-72 1000-TON STRAIGHT SIDE DOUBLE CRANK PRESS; Stroke 8”;<br />

SPM 15-30; PERFECTO 10-50 Space Saver Coil Cradle Straightener; 50,000 Lb. x 50”;<br />

2 – VERSON TS4-700-800-108-108-48 1500-TON DUAL RAM TRANSFER PRESSES; Left Side; Capacity<br />

800-Ton; Stroke 16”; SPM 15-30; Right Side Capacity 700-Ton; Stroke 16”; SPM 15-30; 6 Station<br />

Transfer; LITTELL S200-36 (Reel) 626D 5PD (Straightener) Electronic Feed Line; 20,000 Lb. x 36”<br />

FineBlanKinG Presses & cOil FeeD lines<br />

(Equipment May be Offered Individually and as Lines)<br />

4 – SCHMID HSR 630 (PRESS) HR-12 (CRADLE STRAIGHTENER)<br />

FINEBLANKING PRESSES W/ FEED LINE; Total Force 708-Ton<br />

(6300 KN); V-Ring Force 3000 KN; Counter Force 1400 KN; Bed 36”<br />

x 36”; DALLAS DJR-10,000x18 Coil Reel; 10,000 Lb. x 18”<br />

1 – SCHMID HSR 630 (PRESS) FINEBLANKING PRESS W/ FEED;<br />

Disassembled Press<br />

hiGh sPeeD sTraiGhT siDe<br />

DOuBle cranK Press<br />

1 – MINSTER P2-200-54 200-TON STRAIGHT SIDE PIECEMAKER<br />

HIGH SPEED PRESS; Stroke 3”; SPM 90 / 180; Crank Driven Feed<br />

& Scrap Chopper<br />

1 – BLISS 40-5M-12-48 COIL CRADLE STRAIGHTENER; 4000 lb. x 12”<br />

x .150”<br />

KnucKle JOinT Press<br />

1 – CLEVELAND NO 1 1/2-K KNUCKLE JOINT STRAIGHT-SIDE<br />

PRESS; S/N N/A; Single Geared; Bed Area 16” L – R; 18” F – B;<br />

Stroke – approx 3”. Air Actuated Mechanical Pin Clutch<br />

OPen BacK inclinaBle Presses<br />

2 – USI CLEARING 150 150-TON OPEN BACK INCLINABLE<br />

PRESSES; Stroke 6”; 45 SPM; Single Back Geared; Bed 33” x 50”;<br />

Slide 24” x 22”; Shut Height 22.5”<br />

SALE BEING HELD IN CONJUNCTION WITH<br />

Auctioneers • LiquidAtors • ApprAisers<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 9

CenterLess, dOubLe dIsC, & CyLIndrICaL GrInders<br />

(145) cenTerless GrinDers<br />

4 – MICRON MD-450-CNC CENTERLESS GRINDERS, S/N 53873-538 (2004), Fanuc 18i-TB Control,<br />

Fanuc Robotic Loader<br />

4 – GOLD CROWN GC 300 CNC CENTERLESS GRINDERS; S/Ns GC30094-02, GC30094-01,<br />

GC30096-01, GC30097-01 (1996-1998); Allen Bradley Series 9 Control; Wheel Dia. 24”;<br />

Wheel Width 12”; Spindle Speed 1400 RPM; Diamond Wheel Dresser; SBS Dynamic Balance<br />

System; Gaging<br />

2 – GOLD CROWN GC 500 CENTERLESS GRINDERS; S/Ns GC50095-07 (1997), GC50094-09<br />

(1995); Wheel Diameter 24”; Wheel Width 20”; Spindle Speed 1034 RPM; SBS Dynamic<br />

Balance System; Allen Bradley Panel View 1200; Feedall 1650 Thru Feed<br />

123 – CINCINNATI MILACRON 340-20 DE, 220-8, DR CINCO 15, EA NO.2 & MISC.<br />

CENTERLESS GRINDERS<br />

2 – LANDIS 14R CENTERLESS GRINDERS; 14” Dia. Wheel<br />

9 – CINCINNATI 340-20 DE, 325-12 DE & MISC. CENTERLESS GRINDERS<br />

1 – AGNEW CENTERLESS GRINDER<br />

(19) DOuBle Disc GrinDers<br />

7 – MATTISON 223N CNC DOUBLE END DISC GRINDERS; Allen Bradley Series 9 Control; CGI<br />

Model 3000 Gaging; (2) 20 HP Motors (1 With 1 Grinding Head)<br />

6 – GARDNER DOUBLE END DISC GRINDERS; (2) SDG3 30, 91) With With Allen Bradley Panel View<br />

Control; (2) 20 HP Motors; SDG3 23 With Allen Bradley Panel View Control, (2) 30 HP Motors; (2)<br />

SDG5-40 & N/A with (2) 40 HP Motors<br />

1 – GARDNER DOUBLE END OPPOSED DISC GRINDER; 40” Dia.; Rebuilt; (2) 75-HP motors;<br />

25 HP Hydraulic Pump; Allen Bradley Panel View CRT Control with Programmable Controller<br />

2 – GARDNER / C & B MACHINERy SDG-5-30 DOUBLE END OPPOSED 30” DISC<br />

GRINDERS; (2) 60 HP Motors; Allen Bradley “Panelview” CRT Control Panel with<br />

Programmable Controller<br />

1 – DOUBLE END OPPOSED DISC GRINDER; 30” Dia.Disks; (2) 60-HP Motors; Allen Bradley<br />

Panel View CRT Control Panel with Programmable Controller<br />

1 – C & B MACHINERy SDG6 DOUBLE END OPPOSED DISK GRINDER; 40” Diameter, (2) 50 HP<br />

Motors; 20 HP Hydraulic Pump; Allen Bradley Panel View CRT Control with Programmable Controller<br />

1 – ExCELLO DOUBLE END 4-SPINDLE BORING MACHINE; Spindle Motors 3 HP Hydraulic<br />

Pump 3 HP; Light Curtains; Torit Dust Collector<br />

(24) cylinDrical GrinDers<br />

2 – DANOBAT DANEx & R1-A CNC ANGLE HEAD CyLINDRICAL<br />

GRINDERS (TO 2000)<br />

4 – WARNER & SWASEy ACC 14CKA & 14CHK ANGLE HEAD<br />

CyLINDRICAL GRINDERS; All With Allen Bradley Panelview 1200<br />

Control; Bala Dyne Balancing System; Control Gaging Model 760;<br />

Grinding Head 20 HP; Diamond Truing<br />

2 – WARNER & SWASEy / NORTON PLAIN CyLINDRICAL GRINDERS;<br />

10” x 56” Bed; (converted for different use) Allen Bradley Panelview CRT<br />

Control Panel and Programmable Controller; Baladyne Readout; Control<br />

Gaging Grinding Monitor<br />

2 – NORTON & WARNER & SWASEy / NORTON 10 x 48 CTU PLAIN<br />

CyLINDRICAL GRINDERS; (Converted for Special Part) Allen Bradley<br />

Panelview CRT Control Panel; Programmable Controller; Baladyne<br />

Digital Readout; Control Gaging Grinding Monitor; Coolant System<br />

1 – NORTON CTU 10” x 18” CyLINDRICAL GRINDER; CGI 760 Gaging;<br />

Baladyne III Balance System; Wheel Head 15 HP<br />

2 – CINCINNATI 14” x 36” & 6” x 30” CyLINDRICAL GRINDERS<br />

2 – NORTON LCV-4 14” x 36” & 10” x 36” ANGLE HEAD<br />

CyLINDRICAL GRINDERS; Allen Bradley Panel View Control;<br />

Baladyne Balancing System; CGI Monitor; Wheel Head 15 HP; Spindle<br />

792 RPM; Wheel Dresser; Coolant Tank w/ Magnetic Separator<br />

2 – NORTON 10” x 18” ANGLE HEAD CyLINDRICAL GRINDERS;<br />

Automatic Truing; Wheel Head 15 HP<br />

3 – NORTON #10x18CV4 CyLINDRICAL GRINDERS; (Converted for<br />

Special Use) Allen Bradley Panelview CRT Control Panel with Allen<br />

Bradley PLC-5/15 Programmable Controller; Baladyne Monitor; 2 HP<br />

Hydraulic Pumps; Coolant System<br />

4 – BROWN & SHARPE 1430U UNIVERSAL, NO 1, NO 13 & 1020U<br />

CyLINDRICAL GRINDERS<br />

PLEASE NOTE: Equipment Removal Restrictions Apply.<br />

Please Visit www.hilcoind.com for More Information.<br />

10 to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Id & surFaCe GrInders • autOMatIC sCreW MaCHInes • FInIsHInG<br />

cnc iD GrinDers<br />

1 – DANOBAT RCPI CNC I.D. GRINDER; S/N 21S1 (2000);<br />

GE Fanuc 210i-T Controls; SBS Model SB-4500 Balancing<br />

System; Light Curtains; Spindle Motor 30 kw<br />

1 – HEALD 2EF 700 G CNC I.D. GRINDER; Siemens Control<br />

2 – HEALD & BRyANT I.D. GRINDERS<br />

(33) surFace GrinDers<br />

4 – MATTISON ROTARy SURFACE GRINDERS; Dual Head; 4 Station; Rotary Feed Table<br />

Size 54” dia; Face Grinding Wheels size 24” dia each; (3) with Allen Bradley “Panelview”<br />

CRT Control Panel and Programmable Controller; Coolant System; (1) Standard<br />

Controls; Rebuilt by Hydro-matic)<br />

1 – MATTISON 24A2P 2-SPINDLE ROTARy SURFACE GRINDER<br />

3 – BLANCHARD 5-SPINDLE VERTICAL SPINDLE GRINDERS<br />

1 – BLANCHARD 18-36 36” ROTARy SURFACE GRINDER<br />

3 – CINCINNATI MILACRON / HEALD 261-16” & 161-6” ROTARy SURFACE GRINDERS;<br />

Tilting Table; Magnetic Chuck; Coolant System<br />

1 – SWISHER AUTO CyCLE ROTARy SURFACE GRINDER; 16” Dia. Magnetic Chuck<br />

1 – STOFFEL ABWOOD RT300 SURFACE GRINDER; 14” Dia. Electro-Magnetic Chuck; Coolant<br />

2 – MAGERLE BROTHERS TyPE FPA-10-S3 & -S4.2 SURFACE GRINDERS; 10” x 40”<br />

Electromagnetic Chuck; Coolant System; 4-Way Power Table Feed; Power Head Feed<br />

10 – BROWN & SHARPE MICROMASTER (3) 1024 10” x 24”, (5) 618 6” x 18” & (2) 824<br />

8” x 24” HyDRAULIC SURFACE GRINDERS<br />

3 – THOMPSON 6” x 18” SURFACE GRINDERS; 6” x 18” Magnetic Chuck<br />

3 – COVEL HyDRAULIC, DOALL & HARIG 6” x 18” SURFACE GRINDERS<br />

1 – TAFT PEIRCE 5” x 12” SURFACE GRINDER; 5” x 12” Electro-Magnetic Chuck<br />

4 – HEALD, STANDARD ELECTRICAL TOOL, ExCELLO & CINCINNATI FACE GRINDERS<br />

(Over 200) TOOlrOOM Machines<br />

2 – VIGEL V-1618-380 (1994) & N/A CNC DRILL MACHINES<br />

(12) Vertical & Horizontal Band Saws, (10) Engine Tracer & 2nd Operation<br />

Lathes, (3) Radial Arm, (3) Milling Machines, (95) Grinders, (7) Lappers, (6)<br />

Blast Cabinets, Moore Jig Borer, (25) Drills, (14) Saws, (3) Hydraulic Hose<br />

Crimpers, Duplicator Punch, Keyseater, (16) Belt & Disc Sanders, Parts Washer,<br />

(2) Rotary Tables, Center Lap, Scales, Down Draft Table, (14) Hones. EDM, Etc.<br />

(100) auTOMaTic screW Machines<br />

24 – WICKMAN (16) 6-SPINDLE & (8) 8-SPINDLE 1” SCREW MACHINES,<br />

Bar Feed; Six Slides; Pickoff<br />

114 – ACME GRIDLEy RA6 1-1/4” & 1”, RAN6 1”, RA8 3/4”, RB8 1-1/4”,<br />

RB6 2-5/8” & RB6 6” AUTOMATIC SCREW MACHINES, With Bar Feed<br />

HUGE ASSORTMENT OF GEARS & SCREW MACHINE TOOLING<br />

BelT sanDers / FinishinG eQuiPMenT<br />

4 – TIMESAVERS 19” & AEM 36” WIDE BELT SANDERS<br />

4 – ACME 30” ROTARy INDEx & BRADLEy-THOME WIRE BRUSH<br />

DEBURRING MACHINES<br />

13 – ALMCO, SPIRATRON & ROTO-FINISH VIBRATORy BOWL FINISHERS;<br />

ALMCO PARTS DRyER, VIBRATORy SCREENER & (3) CONVEyORS<br />

5 – (2) IMPCO & (3) ACME POLISHERS, Automatic Loader & Unloader<br />

4 – PARTS LEVELERS<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 11

InsPeCtIOn • InduCtIOn Heat treat equIPMent • WeLdInG<br />

insPecTiOn<br />

4 – BROWN & SHARPE CHAMELEON 7107, VALIDATOR, xCEL 765 & MICRO VAL<br />

COORDINATE MEASURING MACHINES<br />

1 – MAUER KMZ 151010 & KM2-W151210 COORDINATE MEASURING MACHINE<br />

2 – ZEISS MC 8/12/6 & UPMC 850 COORDINATE MEASURING MACHINES<br />

1 – MITUTOyO B120 COORDINATE MEASURING MACHINE<br />

1 – M&M 3515 GEAR INSPECTION MACHINE, IBM PC<br />

2 – ITW HEARTLAND 4900 GEAR INSPECTION MACHINES<br />

2 – MITUTOyO CONTOUR TRACING & MEASURING MACHINES<br />

1 – MITUTOyO SURFTEST SV-600 SURFACE ROUGHNESS MEASURING<br />

INSTRUMENT<br />

1 – RAM OPTICAL INSTRUMENT OMIS II VISION MEASUREMENT SySTEM<br />

1 – RAMLOCK HyDRAULIC C-FRAME PRESS; Bed 12” x 15”; 5 HP<br />

10 – Z-MIKE 1201B & 1220S 2-1/2” CAPACITy & 1210G 1-3/4” CAPACITy LASER<br />

MICROMETERS (TO 2006)<br />

14 – OGP & JONES & LAMSON 30” & 14”, GAGEMASTER 12”, SCHERR TUMICO,<br />

APEx 10” & MICRO VU 7-1/2” OPTICAL COMPARATORS<br />

Hardness Testers; Roundness Gages; Granite Surface Plates To 48” x 96” x 12”; Large<br />

Collection of Micro-Hite and Manual Height Gauges; Micrometers; Calipers<br />

ParTs hOPPers/elevaTOrs<br />

1 – DIRECTIONAL REGULATED SySTEMS PARTS HOPPER W/ ELEVATOR<br />

CONVEyOR; 7 1/2” x 10’ Elevator Conveyor<br />

1 – PARTS HOPPER W/ ELEVATOR CONVEyOR; 7” x 6’ Elevator Conveyor<br />

1 – W/A SySTEMS HOPPER FEEDER<br />

laser WelDinG cells<br />

7 – UTILASE LASER WELDING CELLS; (4) USI 7SLWTM (1996); (3) 12SLWTM<br />

w/ (2) Welding Heads; All With Allen Bradley PanelView 1200 Control; Rofin-Sinar #860<br />

HF Laser; Torit Dust Collector; Alpha Chiller<br />

2 – LASER WELDING SySTEMS<br />

1 – FERRANTI SCIAKy LS6K-5BD1 LASER WELDER; 3-Stations<br />

heaT TreaT<br />

1 – ELECTRIC FURNACE CO. BELT FURNACE; (4) Zones; Preheat 1800<br />

Deg.; H1 2100 Deg.<br />

6 – EFC 60 SP-GR R.F. GENERATORS; 1,000 BTU; (2) Honeywell Temperature Controls<br />

8 – HOLCROFT HEAT TREAT SySTEMS; Carbonitriding Furnace; Quench<br />

Station; Washer; Draw Furnace; Cooling Station<br />

2 – SURFACE COMBUSTION DRAW FURNACES; 1,000,000 BTU;<br />

Temperature 1400-1750 Deg.; Chamber Size 60” x 32” x 36”; Quenching<br />

2 – HOLCROFT DRAW FURNACES; Chamber Size 60” x 36”x 36”; Pnuematic Door<br />

2 – EFC BELT FURNACES; Belt Width 26”; (4) Zones; Length 25’<br />

Pangborn Rotary Blasting Machine; Smoke Eater; Washer; Holcroft Transfer<br />

Car (2006); Tumbling Machines<br />

inDucTiOn heaT TreaT eQuiPMenT<br />

24 – CHI, MICROPULSE; (7) WELDUCTION; (5) IPE CHESTON; (8) TOCCO<br />

(2) INDUCTOHEAT INDUCTION HEAT TREAT SySTEMS<br />

1 – INDUCTION HEAT TREAT SySTEM; Consisting of: Induction Heater Unit;<br />

Sundstrand 6” x 16” c.c. Bench Center; Magneforce HS2500R; Coolant<br />

System; Trion Air Cleaner<br />

1 – TOCCO / OHIO CRANKSHAFT 1RS2-1 INDUCTION HEATING UNITS<br />

1 – ROBOTRON 2 STATION CONVEyORIZED INDUCTION HARDENER<br />

WelDinG eQuiPMenT<br />

5 – LINCOLN WIRE, TIG & ARC WELDERS<br />

1 – PEER 50 KVA ROCKER ARM SPOT WELDER<br />

1 – MILLER LMSW-52T 2.5 KVA SPOT WELDER<br />

1 – AIR qUALITy ENGINEERING SMOKE EATER<br />

neeDle BearinG inserTiOn sysTeMs<br />

6 – LETNAN NEEDLE BEARING INJECTOR SySTEMS (TO 2006); All With<br />

Vibratory Bowl Feeders<br />

FaBricaTinG Machinery<br />

(2) BUFFALO Ironworkers; RICHARDS Multiform Bender; EUROMAC<br />

Hydraulic Notcher; (2) D&K 4’ x 12 Ga. Manual Finger Brakes; PECK, STOW &<br />

WILCOx 22 Ga. x 36” Bending Roll; (4) LOCKFORMER Lockformers; Whitney<br />

4” Hand Alligator Shear; Delta 8” Jointer<br />

12 to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

asseMbLy LInes • rOtary Index dIaL MaCHInes<br />

DrillinG sTaTiOns<br />

2 – KINGSBURy 8-STATION DRILLING STATIONS; (2) Sleave Press Machine<br />

With Allen Bradley PanelView 1200 Control<br />

2 – WRIGHT 4-STATION HORIZONTAL DRILLS; GE Fanuc Power Mate Control<br />

asseMBly lines<br />

1 – JOHANN A. KRAUSE 22-STATION ASSEMBLy CELL (2004); (23) Siemens<br />

Simatic Touch Screens; (7) Thyssenkrupp EGM Measuring Computers; (5)<br />

Beckhoff Panel PC’s; (2) Leak Testers; (2) Scales; (3) Vision Cameras; (21) Light<br />

Curtains; (2) Pick-N-Place Stations; (34) Aluminum Part Shuttles; 250’ Shuttle Track<br />

1 – VALVE BODy TEST STAND (2004); Siemens Simatic Multi Panel Touch<br />

Screen; Hydraulic Pump 18.5 kw<br />

2 – JOHANN A. KRAUSE ASSEMBLy MACHINES (To 2004); Siemens Simatic<br />

Multi Panel Touch Screen; PC; Etc.<br />

7 – JOHANN A. KRAUSE 6 TO 20-STATION ASSEMBLy CELLS; Up to (21) Siemens<br />

Touch Screens; Up to (38) Aluminum Part Shuttles & 250’ Shuttle Track; Etc.<br />

2 – 6 & 16-STATION ASSEMBLy CELLS; Touch Screens; PC’s; Light Curtains; Etc.<br />

1 – WILSON MACHINE ASSEMBLy MACHINE<br />

Balancers<br />

3 – ITW BALANCE ENGINEERING BALANCERS (To 1999); Allen Bradley<br />

PanelView 1200 Control; CBI 2000 Control; Pump Motor 15 HP; Automatic<br />

Loader & Unloader Parts Elevator, Parts Handling System<br />

2 – SCHENCK AUTOMATIC BALANCERS W/ PIERCING (2004, 2006);<br />

Siemens Controls w/ Model MP270B Touch Screen; 3-Stations;<br />

Measure,Correct & Audit; Magnetic Chip Conveyor; Hydraulic Pump 10 HP<br />

2 – SCHENCK TURNER CNC VERTICAL & HORIZONTAL BALANCING<br />

MACHINES (2000); Schenck CAB 642 Control<br />

14 – BALANCE ENGINEERING BALANCERS; Allen Bradley PanelView 1200 &<br />

CBI 2000 Control<br />

1 – BALANCE ENGINEERING, HINES & BALANCE TECHNOLOGIES BALANCERS<br />

auTOMaTeD ParT MarKinG Machines<br />

1 – ENSHU AUTOMATED PART MARKING MACHINE; Programmable Controller;<br />

Enclosure; Light Curtain; Touch Screen Operator Panel<br />

slanT Mills<br />

3 – STANDARD DETROIT SLANT MILLS; (3) Spindles; Stroke 24”<br />

rOTary inDeX Dial Machines<br />

1 – STANDARD #4T80E-VALVE BODy 4-STATION 60” DIA. ROTARy INDEx DIAL<br />

MACHINE<br />

1 – ExCELLO 4-STATION ROTARy INDEx DIAL MACHINE<br />

13 – KINGSBURy ROTARy INDEx DIAL MACHINES TO 14-STATION<br />

7 – R&B, ANN ARBOR L&L 7 & 8-STATION & (4) OLOFSSON 5-STATION DIAL<br />

MACHINES<br />

2 – STANDARD #4T80E INPUT SHAFT DIAL MACHINES<br />

2 – KINGSBURy 34 & 40-STATION TRANSFER LINES; TCP Smart Screen Control;<br />

Gould Diagnostic Networking Base; Indramat Trans 01 Drive Contrrol;<br />

2 – KINGSBURy 3-STATION INDEx & TRANSFER MACHINES<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 13

asseMbLy • sLOtters • transFer LInes • CHIP PrOCessInG<br />

hyDraulic BushinG &<br />

hyDraulic PiercinG Presses<br />

5 – ROCK TOOL HyDRAULIC BUSHING PRESSES (TO 1996);<br />

Allen Bradley Panelview Control;<br />

1 – LINCOLN PARK ENG. 2-STATION BUSHING PRESS; Allen Bradley<br />

Panelview Control<br />

1 – STEV-FRAN ENGINEERING SLEEVE & BUSHING PRESS;<br />

Allen Bradley Panel View Control<br />

1 – NOVI PRECISION HyDRAULIC PIERCING PRESS; Allen Bradley<br />

PanelView 1200 Control<br />

2 – TELEDyNE RING PRESSES; Campbell Parts Hopper w/ Elevator conveyor<br />

1 – HyDRAULIC BUSHING PRESS; (2) Parts Hoppers; Automatic Load & Unload<br />

18 – AGNEW, AMERICAN BROACH, GLOBAL ENGINEERING, RAMLOCK,<br />

COLONIAL, ROCK TOOL, ROBERTS & MORE HyDRAULIC C-FRAME PRESSES<br />

3 – HyDRAULIC HORIZONTAL BUSHING PRESSES<br />

2 – KOPPy HyDRAULIC PIERCING MACHINES<br />

slOTTers<br />

17 – KOPPy HyDRAULIC SLOTTERS<br />

2 – NAGEL POLISHING MACHINES (TO 1996)<br />

Chip Reclamation Systems; Chip Dumpers<br />

asseMBly Machines<br />

1 – WILSON MACHINE ASSEMBLy MACHINE; Indexing Part Loader; 3-Station Transfer<br />

16 – KOPPy ASSEMBLy MACHINES<br />

BlasT cleaninG sysTeMs<br />

3 – ENGINEERED ABRASIVES INDEx 60 & 48 INDEx INDExING BLAST CABINETS<br />

DeBurrinG & BurnishinG Machines<br />

4 – HAMMOND 2 & 3 STATION DEBURRING MACHINES; Allen Bradley<br />

PanelView 550 Control; Automatic Load & Unload<br />

12 – JAMES ENGINEERING, SURFTRAN & SUPFINA DEBURRING MACHINES<br />

(TO 1996); Allen Bradley Panel View 550 Control; Automatic Load & Unload<br />

1 – UNITED INDUSTRIAL ENGINEERING 2-SPINDLE VERTICAL DEBURRING MACHINE<br />

5 – ACME & JAMES DEBURRING MACHINES; Single & 3-Spindle<br />

2 – R&B MACHINE BURNISHERS; (2 & 3) Vertical Spindle Heads; 10-Station Transfer<br />

lOaD TesTinG Machines<br />

3 – FUTURE TECHNOLOGIES AxIAL LOAD TESTERS; Allen Bradley PanelView Control<br />

1 – ALPHA CCASH-25-460 CHILLER<br />

ParTs hanDlinG eQuiPMenT<br />

(2) Parts Hoppers w/ Elevator Conveyor; (25) Parts Handling Systems; (8) Parts Elevators<br />

TransFer lines<br />

8 – HUELLER HILLE 20, 30 & 37-STATION, CROSS & TRECKER 11 & 15-STATION<br />

& (3) INGERSOLL TRANSFER LINES<br />

leaK TesT eQuiPMenT<br />

2 – ATW LEAK TESTER w/ SHUTTLE SySTEMS; Siemens MP270B Touch Screen;<br />

Beckhoff Panel PC; ATC Leak Test Instrument<br />

4 – LUCAS ASSEMBLy & TEST LEAK TESTERS; Allen Bradley PanelView Control<br />

4 – KLC, WILSON & FTI LEAK TESTERS<br />

vane seTTers / TaB rOllers<br />

8 – UTICA VANE SETTERS; Panel Mate Control; Light Curtains<br />

8 – SPEN TECH TAB ROLLERS (1998); 3-Pos. Rotary Index Table; Automatic Unloader<br />

chiP PrOcessinG sysTeMs<br />

1 – FILTRA SySTEMS ALUMINUM CHIP HANDLING SySTEM; (3) Drag Conveyors;<br />

Super Clean Filter; (2) Pumps 15 HP; (11) Pumps 100 HP<br />

1 – PERCOR ALUMINUM CHIP PROCESSOR; Scrap Conveyor 36” Wide; Chip<br />

Crusher; Screw Conveyor; Chip Wringer; Pneumatic Transporter; Filter System; Job<br />

# P.7424; Reg. # 48-7<br />

1 – ENGINEERED SySTEMS CHIP HANDLING SySTEM<br />

14 to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Parts WasHers • FOrkLIFts • Cranes • sHOP & FaCtOry<br />

(55) DusT & MisT cOllecTOrs<br />

19 – MONROE ENVIRONMENTAL 3-STAGE MIST COLLECTORS (TO 1995);<br />

22 – MONROE ENVIRONMENTAL MIST COLLECTORS<br />

2 – MONROE ENVIRONMENTAL AIR SCRUBBERS<br />

12 – TORIT, AAF, ARRESTALL, BENNETT, ENGINEERED ABRASIVES DUST<br />

COLLECTORS<br />

(156) ParTs Washers & BelT Washers<br />

7 – ROCK TOOL, REIS ELAN & BELCO HIGH PRESSURE DEBURR AND<br />

WASHING MACHINES<br />

1 – PROCECO SW 3-S-72-30-24 DUAL CHAMBER PARTS WASHER<br />

6 – MIDBROOK INC HURRICANE 2-STAGE PARTS CLEANING SySTEMS<br />

(2004-2006)<br />

1 – INTERCONT SJW-4 FRONT LOAD PARTS WASHER<br />

133 – GERREF, BELCO, RANSOHOFF, INTERNATIONAL, ACME, LAMB, GRAPAR,<br />

qUIN, DURR, ASE, CENTRI SPRAy, HURRICANE, Etc. Single & 2-Stage Stage<br />

Belt and Rotary Parts Washers, Most With Blow Off (To 2003)<br />

1 – BOWDEN CCRB-3-U-D-530 “LIqUID TURBO CHARGER” CONVEyORIZED<br />

PARTS WASHER (2001)<br />

1 – STEAM HEATED CONVEyORIZED PARTS WASH SySTEM<br />

6 – MISC. PARTS WASHERS<br />

Fire TrucKs<br />

2 – TACKMASTER PLANT FIRE TRUCKS<br />

(17) FOrK liFTs<br />

2 – HOIST 40,000 LB. & 25,000-LB. LIFT TRUCKS (Both 2002); Lift 110”;<br />

Cushion Tires; Dual Front Tires; 60” Forks; Gasoline Engine<br />

2 – HySTER 15,500 LB. Gasoline & 10,000 LB LPG LIFT TRUCKS; 3-Stage Mast;<br />

Automatic Transmission<br />

1 – CATERPILLAR GC40K 8,000 LB LIFT TRUCK; Lift 209”; 3-Stage Mast; LP Type<br />

2 – HySTER 7200-LB. DIESEL yARD LIFT TRUCKS; 2-Stage; Dual Front Tires;<br />

Fork Rotation; Enclosed Cab<br />

10 – HySTER 7000-LB., 6000-LB. & 4000-LB. LPG & ELECTRIC LIFT TRUCKS<br />

scissOr liFTs<br />

4 – GENIE, MEC & JLG SCISSOR LIFTS (To 2004)<br />

PuMPOuT TrucK<br />

1 – UNITED TRACTOR ELECTRIC PUMPOUT TRUCK (1995); Load 6000 Lbs; Tank 250<br />

Gallon<br />

MaTerial hanDlinG eQuiPMenT<br />

1 – AMERICAN MATERIAL HANDLING 32521-SSR 42” x 15’ MOTORIZED ROLLER<br />

CONVEyOR<br />

25 – 150-LB. SINGLE GIRDER TO 20-TON DOUBLE GIRDER BRIDGE CRANES<br />

24 – 350 LB. TO 1-TON JIB CRANES<br />

LARGE qUANTITy OF CHAIN FALLS & CHAIN HOISTS<br />

(Over 90) Presto, Herkules, Knight, Etc. Pneumatic Scissor Lifts and Tilt & Lift Tables;<br />

Portable Roller Conveyor; 25”w x 25 Ft.; (19) Southworth Hanaoka Sharyo (To 2006) &<br />

(1) T&S Portable Scissor Lift Tables; Electric Tug; Electric Flatbed Carts; Conveyor<br />

Lines & Shuttles (To 2005); (9) Dunnage Handling Systems<br />

shOP & FacTOry eQuiPMenT<br />

62 – FILTRA SySTEMS, HENRy, HyDROMATION & SUPERIOR COOLANT FILTER<br />

SySTEMS<br />

7 – BLISS, SPx, DAKE, OTC, ETC. 20-TON TO 100-TON HyDRAULIC SHOP<br />

PRESSES<br />

1 – MAGNAFLUx DEMAGNETIZER<br />

20 – GREENERD, FAMCO, AIR GAGE, DAKE & DAyTON ARBOR PRESSES<br />

(3) Advance Electric Floor Scrubbers; Battery Wash & Storage Systems; (5) Kaeser<br />

(2004-2006) & Ingersoll Rand Rotary Screw Air Compressors; (6) Horizontal Boring<br />

Machines; (2) Automatic Drill Machines; Centrifugal Disc Finisher; (3) Chip Dumper;<br />

Cooling Tower; Hydraulic Bearing Press; Hydraulic C-Frame Straighteneing Press;<br />

Hydraulic Paper Shear; (2) Abrasive Chop Saws; (2) Pin Presses; (2) Pneumatic C-<br />

Frame Presses; Shrink Wrap Machine; Stone Finisher; Torque Tester; Deburrer; Vertical<br />

Reamer; (3) Vision System (To 2003); HP Laser Jet Printer; 40 Taper & 50 Taper Tool<br />

Holders; Modular Offices; Huge Quantities of New & Used Parts: Motors; Pumps;<br />

Electrical Components; Allen Bradley & Fanuc Parts; Hand Tools; Rolling Staircases;<br />

Shop Fans; Shop Carts; Portable Pump Units; Material Carts; Vidmar Multi-Drawer<br />

Cabinets; Cafeteria; Hospital & Office Equipment<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 15

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX)<br />

Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • Phoenix • San Francisco • Toronto • Villahermosa (MX)<br />

hilco <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Forwarding Service Requested<br />

HILCO IndustrIaL, LLC<br />

& Maynards IndustrIes<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters, 5 revere drive, ste. 206 • northbrook, IL 60062 • all rights reserved<br />

Printed in usa • MOtO • IL License #444.000215 • Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

4-<strong>day</strong> <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong><br />

Final auction Sale at thiS Facility<br />

WillOW run TransMissiOn #3<br />

enTire FaciliTy<br />

Over 2,000 Machines<br />

• Over 200 Gear Machines<br />

• Over 250 cnc Machines<br />

• Over 40 Press Lines<br />

• Over 225 Grinders<br />

• Over 100 autOMatics<br />

terms of Sale<br />

a buyer’s premium of 16% for all webcast sales & 13.5%<br />

for all onsite sales will be in effect. everything will be sold<br />

to the highest bidder for cash, in accordance with the<br />

auctioneer’s customary “terms of sale”, copies of which<br />

will be posted on the premises of the sale and subject to<br />

additional terms announced the <strong>day</strong> of sale. all items will<br />

be sold “as is, where-is” without any warranties, express<br />

or implied. although obtained from sources deemed<br />

reliable, the auctioneer makes no warranty or guarantee<br />

to the accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the items<br />

on which they intend to bid prior to sale. absolutely no<br />

items will be removed until the <strong>day</strong> after the conclusion of<br />

the sale and payment is made in full. subject to additions,<br />

deletions and prior sale.<br />

Payment: aLL Purchases Must Be Paid in FuLL On<br />

the daY OF the auctiOn. if you intend to pay by wire<br />

transfer, we will accept payment the <strong>day</strong> after the sale<br />

OnLY iF a deposit of 25% of total purchases is made on<br />

the <strong>day</strong> of the sale. contact our office for wire transfer<br />

instructions. Only cash, wire transfer or certified check,<br />

payable to Maynards industries will be accepted.<br />

company checks payable to Maynards industries will be<br />

accepted only if accompanied by a bank letter of<br />

guarantee, (see sample letter below). all sales are subject<br />

to sales tax. Purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the auctioneer of their<br />

entitlement to claim such exemptions.<br />

Sample Bank letter<br />

(Bank name) unconditionally guarantees payment to<br />

Maynards industries from (company name). this<br />

guarantee will be valid for purchases made at the<br />

auction of racer trust on May 17 thru 20, 2011.<br />

Follow<br />

Us on: