23.1.03A AOAC Of fi cial Method 2003.04 Clopidol in Chicken Tis sues

23.1.03A AOAC Of fi cial Method 2003.04 Clopidol in Chicken Tis sues

23.1.03A AOAC Of fi cial Method 2003.04 Clopidol in Chicken Tis sues

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>23.1.03A</strong><br />

<strong>AOAC</strong> <strong>Of</strong> <strong>fi</strong> <strong>cial</strong> <strong>Method</strong> <strong>2003.04</strong><br />

<strong>Clopidol</strong> <strong>in</strong> <strong>Chicken</strong> <strong>Tis</strong> <strong>sues</strong><br />

Liq uid Chro ma tog ra phy<br />

First Ac tion 2003<br />

F<strong>in</strong>al Action 2006<br />

(Ap pli ca ble to the de ter mi na tion of res i dues of clopidol <strong>in</strong><br />

chicken mus cle at con cen tra tions �0.1 mg/kg.)<br />

See Ta bles <strong>2003.04</strong>A and <strong>2003.04</strong>B for the re sults of the<br />

<strong>in</strong>terlaboratory study sup port <strong>in</strong>g ac cep tance of the method.<br />

A. Pr<strong>in</strong> ci ple<br />

<strong>Clopidol</strong> is ex tracted from chicken mus cle with acetonitrile. The<br />

ex tracts are cleaned up on an alu m<strong>in</strong>a col umn and then on an an ion<br />

ex change col umn. <strong>Clopidol</strong> is sep a rated from co-ex tract ives by<br />

re versed-phase LC and quantitated at 270 nm.<br />

B. Re agents<br />

(a) <strong>Clopidol</strong> an a lyt i cal stan dard.—Pu rity >99.<br />

(b) Alu m<strong>in</strong>a.—Neu tral, 100–200 mesh (Merck KgaA, 64271<br />

Darmstadt, Ger many), or equiv a lent. Ac ti vate at 300�C for 4 h and then<br />

cool <strong>in</strong> des ic ca tor.<br />

(c) An ion ex change res<strong>in</strong>.—AG ® 1-X8 Res<strong>in</strong> 100–200 mesh,<br />

ac e tate form (Bio-Rad Lab o ra to ries, Her cu les, CA, USA), or<br />

equiv a lent. Im merse <strong>in</strong> meth a nol for 2 h be fore use.<br />

(d) Sol vents.—Acetonitrile and meth a nol, LC grade, and ace tic<br />

acid (gla <strong>cial</strong>), AR grade.<br />

(e) Meth a nol–am mo nia (sp.gr. 0.88) so lu tion.—98 + 2 (v/v).<br />

(f) So dium sul fate, an hy drous.—Heat at 650�C for 4 h. Cool <strong>in</strong><br />

des ic ca tor.<br />

(g) Mo bile phase.—Acetonitrile–deionized wa ter (20 + 80).<br />

Fil ter mo bile phase un der vac uum through 0.45 �m <strong>fi</strong>l ter be fore use.<br />

(h) Elut<strong>in</strong>g sol vent.—0.5% Ace tic acid (gla <strong>cial</strong>) <strong>in</strong> meth a nol.<br />

Mix 2.5 mL ace tic acid (gla <strong>cial</strong>) with 497.5 mL meth a nol.<br />

(i) Wa ter.—Deionized, �18.0 meg ohm-cm.<br />

(j) Fil ter mem brane.—Ny lon 66 mem brane, 0.45 �m � 47 mm<br />

(Supelco, Bellefonte, PA, USA; www.sigmaaldrich.com), or<br />

equiv a lent.<br />

(k) Glass wool.—Must be free of <strong>in</strong> ter fer ence with UV<br />

de tec tion. Store by im mers <strong>in</strong>g <strong>in</strong> meth a nol.<br />

C. Ap pa ra tus<br />

(a) Liq uid chromatograph.—LC sys tem con sist <strong>in</strong>g of sol vent<br />

de liv ery pump, uni ver sal LC <strong>in</strong> jec tor with 10 �L sy r<strong>in</strong>ge, UV<br />

de tec tor mon i tor <strong>in</strong>g 270 nm, and data out put de vice (re corder,<br />

<strong>in</strong> te gra tor, or data sys tem for mea sur <strong>in</strong>g peak heights). If LC is not<br />

equipped with de-gas mod ule, gently sparge mo bile phase with<br />

he lium for 5 m<strong>in</strong> im me di ately be fore use. Set flow rate of mo bile<br />

phase at 1.0 mL/m<strong>in</strong>; set de tec tor wave length at 270 nm with<br />

sen si tiv ity of 0.01 absorbance unit full scale. Peak res o lu tion should<br />

be as <strong>in</strong> di cated <strong>in</strong> Fig ure <strong>2003.04</strong>A.<br />

(b) LC col umn.—30 cm � 3.9 mm id of �Bondapak C18, 10 �m<br />

(Wa ters Corp., Milford, MA, USA; www.wa ters.com), or<br />

equiv a lent.<br />

(c) Blender.—Suitable for m<strong>in</strong>c<strong>in</strong>g chicken.<br />

(d) Ho mog e nizer.—Overhead probe high-performance<br />

dispenser for volumes from 1 to 2000 mL.<br />

(e) Cen tri fuge.—Capable of centrifug<strong>in</strong>g 80 mL capacity glass<br />

tubes with Teflon-l<strong>in</strong>ed screw caps at 1400 � g.<br />

(f) Ro tary evap o ra tor.—With water bath, tap water cooled<br />

condenser, and vacuum aspirator.<br />

(g) Alu m<strong>in</strong>a cleanup col umn.—Chro mato graphic tubes (400 �<br />

20 mm id), <strong>fi</strong>t ted with draw-off valve. Place small plug of glass wool<br />

at bot tom of col umn; <strong>fi</strong>ll with 40 mL meth a nol, pour <strong>in</strong> 15 g alu m<strong>in</strong>a,<br />

and tap on sides of col umn to pro duce even set tl<strong>in</strong>g of bed; dra<strong>in</strong><br />

sol vent. Prer<strong>in</strong>se col umn with 10 mL meth a nol to con di tion; dra<strong>in</strong><br />

sol vent to top of pack <strong>in</strong>g ma te rial.<br />

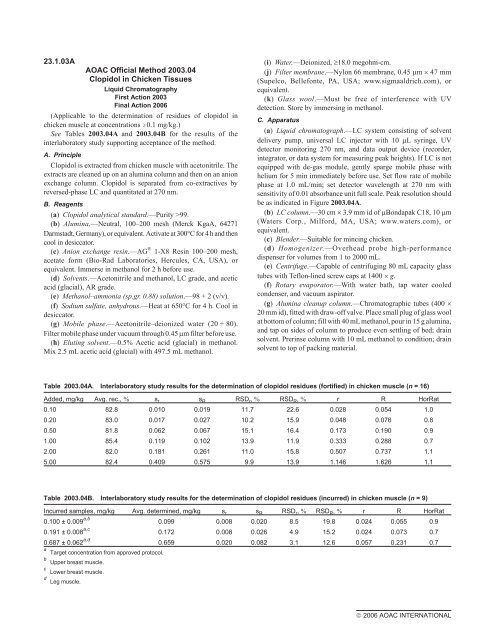

Ta ble <strong>2003.04</strong>A. Interlaboratory study re sults for the de ter mi na tion of clopidol res i dues (for ti <strong>fi</strong>ed) <strong>in</strong> chicken mus cle (n = 16)<br />

Added, mg/kg Avg. rec., % s r s R RSD r , % RSD R , % r R HorRat<br />

0.10 82.8 0.010 0.019 11.7 22.6 0.028 0.054 1.0<br />

0.20 83.0 0.017 0.027 10.2 15.9 0.048 0.076 0.8<br />

0.50 81.8 0.062 0.067 15.1 16.4 0.173 0.190 0.9<br />

1.00 85.4 0.119 0.102 13.9 11.9 0.333 0.288 0.7<br />

2.00 82.0 0.181 0.261 11.0 15.8 0.507 0.737 1.1<br />

5.00 82.4 0.409 0.575 9.9 13.9 1.146 1.626 1.1<br />

Ta ble <strong>2003.04</strong>B. Interlaboratory study re sults for the de ter mi na tion of clopidol res i dues (<strong>in</strong> curred) <strong>in</strong> chicken mus cle (n = 9)<br />

In curred sam ples, mg/kg Avg. de ter m<strong>in</strong>ed, mg/kg sr sR RSDr , % RSDR , % r R HorRat<br />

0.100 ± 0.009 a,b<br />

0.099 0.008 0.020 8.5 19.8 0.024 0.055 0.9<br />

0.191 ± 0.008 a,c<br />

0.172 0.008 0.026 4.9 15.2 0.024 0.073 0.7<br />

0.687 ± 0.062 a,d<br />

0.659 0.020 0.082 3.1 12.6 0.057 0.231 0.7<br />

a<br />

Tar get con cen tra tion from ap proved pro to col.<br />

b Up per breast mus cle.<br />

c Lower breast mus cle.<br />

d Leg mus cle.<br />

� 2006 <strong>AOAC</strong> IN TER NA TIONAL

(h) An ion ex change col umn.—Chro mato graphic tubes (250 �<br />

10 mm id) with sc<strong>in</strong>tered glass disk, <strong>fi</strong>t ted with draw-off valve. Place<br />

small plug of glass wool at bot tom of col umn, and then <strong>fi</strong>ll col umn<br />

with 20 mL meth a nol. Add suf <strong>fi</strong> cient an ion ex change res<strong>in</strong> to<br />

col umn to form bed height of 2–3 cm af ter set tl<strong>in</strong>g by tap p<strong>in</strong>g gently<br />

on sides of col umn. Dra<strong>in</strong> meth a nol; prer<strong>in</strong>se col umn with 10 mL<br />

meth a nol to con di tion, dra<strong>in</strong> <strong>in</strong>g sol vent to top of col umn bed.<br />

(i) Vol u met ric flask.—Grade A, 100 mL, glass vol u met ric flask<br />

with stop per.<br />

(j) Pipets.—Grade A, glass pipets, 1, 2, 5, 10, and 15 mL.<br />

(k) Bal ance.—Elec tronic bal ance, ca pac ity 200 g, readability<br />

0.002 g.<br />

(l) Vor tex mixer.<br />

D. Prep a ra tion of Stan dard So lu tions<br />

(a) Stock stan dard so lu tion.—2.0 mg/mL. Dis solve 200.00 mg<br />

clopidol (cor rected for po tency) <strong>in</strong> meth a nol–am mo nia so lu tion <strong>in</strong><br />

100 mL vol u met ric flask, di lute to vol ume with meth a nol–am mo nia<br />

so lu tion, and mix.<br />

(b) In ter me di ate stan dard so lu tion.—0.020 mg/mL. Add 1.0 mL<br />

stock stan dard so lu tion, D(a), to 100 mL vol u met ric flask, di lute to<br />

vol ume with meth a nol, and mix.<br />

(c) Work <strong>in</strong>g stan dard so lu tions.—0.20, 0.40, 1.00, 2.00, and<br />

3.00 �g/mL. Add 1, 2, 5, 10, and 15 mL <strong>in</strong> ter me di ate stan dard<br />

so lu tion, D(b), to <strong>fi</strong>ve 100 mL vol u met ric flasks <strong>in</strong> proper or der,<br />

ap pro pri ately la beled. Di lute to vol ume with meth a nol, and mix.<br />

E. Prep a ra tion of Test Ex tracts<br />

Ac cu rately weigh 10.0 g rep re sen ta tive m<strong>in</strong>ced chicken mus cle<br />

<strong>in</strong>to 80 mL glass cen tri fuge tube. Add 20 g an hy drous so dium sul fate<br />

and 35 mL acetonitrile, and ho mog e nize for 1.5 m<strong>in</strong> at 15 000 rpm.<br />

Cen tri fuge for 3 m<strong>in</strong> at 1400 � g. Use holder to po si tion<br />

pre con di tioned alu m<strong>in</strong>a col umn, C(g), above pre con di tioned an ion<br />

ex change col umn, C(h), as shown <strong>in</strong> Fig ure <strong>2003.04</strong>B, while<br />

en sur <strong>in</strong>g that meth a nol lev els <strong>in</strong> col umns do not drop be low level of<br />

re spec tive pack <strong>in</strong>g ma te ri als. De cant clear tis sue ex tract <strong>in</strong>to<br />

alu m<strong>in</strong>a col umn and let it run through both col umns to waste at<br />

ap prox i mately 3 mL/m<strong>in</strong>, mak <strong>in</strong>g sure that tis sue ex tract lev els <strong>in</strong><br />

col umns do not drop be low level of re spec tive pack <strong>in</strong>g ma te ri als.<br />

Re-ex tract by add <strong>in</strong>g 35 mL acetonitrile to tis sue sed i ment plug, and<br />

mix on a Vor tex mixer to break up tis sue sed i ment. Dis rupt plug with<br />

a spat ula, if re quired. Recentrifuge and ap ply tis sue ex tracts to<br />

as sem bled col umns. R<strong>in</strong>se as sem bled col umns with 20 mL<br />

meth a nol. Re move alu m<strong>in</strong>a col umn and r<strong>in</strong>se sep a rately with<br />

ad di tional 20 mL meth a nol. Elute clopidol off an ion ex change<br />

col umn with 20 mL 0.5% ace tic acid–meth a nol mix ture <strong>in</strong>to 100 mL<br />

evap o rat <strong>in</strong>g flask. Evap o rate to dry ness on ro tary evap o ra tor at<br />

60�C. Dis solve res i due <strong>in</strong> proper vol ume of meth a nol for LC<br />

anal y sis (1.0 mL, or as ap pro pri ate for the ex pected con cen tra tion of<br />

analyte).<br />

F. Prep a ra tion of Cal i bra tion Curve<br />

Check sys tem suit abil ity be fore de ter mi na tion by <strong>in</strong> ject <strong>in</strong>g<br />

stan dard so lu tion (such as 1.00 �g/mL), then 10 �L of 0.20, 0.40,<br />

1.00, 2.00, and 3.00 �g/mL clopidol work <strong>in</strong>g stan dard so lu tion,<br />

D(c), <strong>in</strong> du pli cate un der LC con di tions. Pre pare 5-po<strong>in</strong>t stan dard<br />

curve (peak height re sponse, <strong>in</strong> mil li me ters, vs clopidol<br />

con cen tra tion, �g/mL), which should be l<strong>in</strong> ear be tween 0.20 and<br />

3.00 �g/mL. The r 2 should be �0.99.<br />

� 2006 <strong>AOAC</strong> IN TER NA TIONAL<br />

Fig ure <strong>2003.04</strong>A. Liq uid chromatograms for clopidol<br />

de ter mi na tion. (A) Con trol; (B) stan dard so lu tion<br />

(0.50 �g/mL); (C) for ti <strong>fi</strong> ca tion chicken mus cle<br />

(0.10 mg/kg).<br />

G. LC De ter mi na tion<br />

In ject <strong>in</strong> du pli cate 10 �L test ex tracts <strong>in</strong>to LC sys tem. Peak<br />

heights should agree with<strong>in</strong> 5% for du pli cate <strong>in</strong> jec tions. Cal cu late<br />

res i due of clopidol <strong>in</strong> orig i nal chicken test portion us <strong>in</strong>g the<br />

fol low <strong>in</strong>g for mula:<br />

<strong>Clopidol</strong>, mg/kg =<br />

P � b v<br />

�<br />

m w<br />

where P = peak height (mm) at clopidol re ten tion time of test<br />

ex tracts, b = <strong>in</strong> ter cept at or di nate, m = slope, from cor re spond <strong>in</strong>g<br />

l<strong>in</strong> ear re gres sion equa tion, v = <strong>fi</strong> nal ex tract vol ume of test por tion<br />

(mL), w = test por tion mass (g).

Fig ure <strong>2003.04</strong>B. Alu m<strong>in</strong>a and ion-ex change res<strong>in</strong><br />

as sem bled col umns.<br />

Reference: J. <strong>AOAC</strong> Int. 84, 685(2003).<br />

CAS 2971-90-6 (3,5-dichloro-2,6-dimethyl-4-pyrid<strong>in</strong>ol)<br />

� 2006 <strong>AOAC</strong> IN TER NA TIONAL