CIMdata cPDm Late-Breaking News

CIMdata cPDm Late-Breaking News

CIMdata cPDm Late-Breaking News

- TAGS

- cimdata

- cpdm

- news

- www.cimdata.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

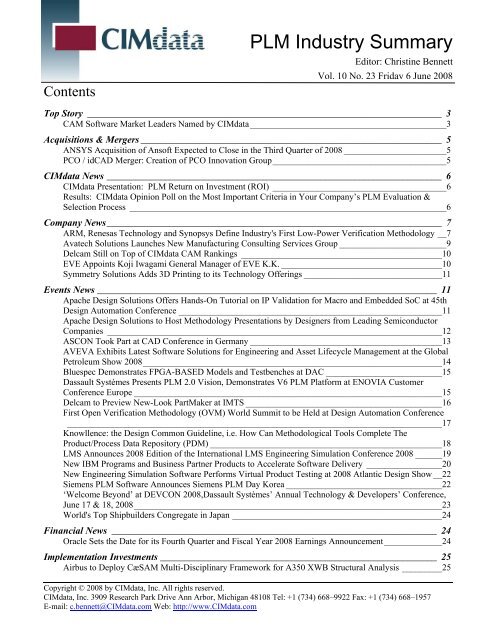

Contents<br />

PLM Industry Summary<br />

Editor: Christine Bennett<br />

Vol. 10 No. 23 Friday 6 June 2008<br />

Top Story _________________________________________________________________________ 3<br />

CAM Software Market Leaders Named by <strong>CIMdata</strong> ____________________________________________3<br />

Acquisitions & Mergers ______________________________________________________________ 5<br />

ANSYS Acquisition of Ansoft Expected to Close in the Third Quarter of 2008 _______________________5<br />

PCO / idCAD Merger: Creation of PCO Innovation Group _______________________________________5<br />

<strong>CIMdata</strong> <strong>News</strong> _____________________________________________________________________ 6<br />

<strong>CIMdata</strong> Presentation: PLM Return on Investment (ROI) _______________________________________6<br />

Results: <strong>CIMdata</strong> Opinion Poll on the Most Important Criteria in Your Company’s PLM Evaluation &<br />

Selection Process _______________________________________________________________________6<br />

Company <strong>News</strong> _____________________________________________________________________ 7<br />

ARM, Renesas Technology and Synopsys Define Industry's First Low-Power Verification Methodology __7<br />

Avatech Solutions Launches New Manufacturing Consulting Services Group ________________________9<br />

Delcam Still on Top of <strong>CIMdata</strong> CAM Rankings _____________________________________________ 10<br />

EVE Appoints Koji Iwagami General Manager of EVE K.K. ____________________________________ 10<br />

Symmetry Solutions Adds 3D Printing to its Technology Offerings _______________________________ 11<br />

Events <strong>News</strong> ______________________________________________________________________ 11<br />

Apache Design Solutions Offers Hands-On Tutorial on IP Validation for Macro and Embedded SoC at 45th<br />

Design Automation Conference ___________________________________________________________ 11<br />

Apache Design Solutions to Host Methodology Presentations by Designers from Leading Semiconductor<br />

Companies ___________________________________________________________________________ 12<br />

ASCON Took Part at CAD Conference in Germany ___________________________________________ 13<br />

AVEVA Exhibits <strong>Late</strong>st Software Solutions for Engineering and Asset Lifecycle Management at the Global<br />

Petroleum Show 2008 ___________________________________________________________________ 14<br />

Bluespec Demonstrates FPGA-BASED Models and Testbenches at DAC __________________________ 15<br />

Dassault Systèmes Presents PLM 2.0 Vision, Demonstrates V6 PLM Platform at ENOVIA Customer<br />

Conference Europe _____________________________________________________________________ 15<br />

Delcam to Preview New-Look PartMaker at IMTS ____________________________________________ 16<br />

First Open Verification Methodology (OVM) World Summit to be Held at Design Automation Conference<br />

____________________________________________________________________________________ 17<br />

Knowllence: the Design Common Guideline, i.e. How Can Methodological Tools Complete The<br />

Product/Process Data Repository (PDM) ____________________________________________________ 18<br />

LMS Announces 2008 Edition of the International LMS Engineering Simulation Conference 2008 ______ 19<br />

New IBM Programs and Business Partner Products to Accelerate Software Delivery _________________ 20<br />

New Engineering Simulation Software Performs Virtual Product Testing at 2008 Atlantic Design Show __ 22<br />

Siemens PLM Software Announces Siemens PLM Day Korea ___________________________________ 22<br />

‘Welcome Beyond’ at DEVCON 2008,Dassault Systèmes’ Annual Technology & Developers’ Conference,<br />

June 17 & 18, 2008 _____________________________________________________________________ 23<br />

World's Top Shipbuilders Congregate in Japan _______________________________________________ 24<br />

Financial <strong>News</strong> ___________________________________________________________________ 24<br />

Oracle Sets the Date for its Fourth Quarter and Fiscal Year 2008 Earnings Announcement _____________ 24<br />

Implementation Investments _________________________________________________________ 25<br />

Airbus to Deploy CæSAM Multi-Disciplinary Framework for A350 XWB Structural Analysis _________ 25<br />

Copyright © 2008 by <strong>CIMdata</strong>, Inc. All rights reserved.<br />

<strong>CIMdata</strong>, Inc. 3909 Research Park Drive Ann Arbor, Michigan 48108 Tel: +1 (734) 668–9922 Fax: +1 (734) 668–1957<br />

E-mail: c.bennett@<strong>CIMdata</strong>.com Web: http://www.<strong>CIMdata</strong>.com

<strong>CIMdata</strong> PLM Industry Summary<br />

Bronswerk Heat Transfer BV Promotes Flomerics’ EFD.Pro from R&D to Mainstream Engineering Design<br />

____________________________________________________________________________________ 26<br />

Cirrus Design Soars with PTC® Product Development System __________________________________ 27<br />

Delcam’s FeatureCAM Generates Hundreds of Programs Each Month ____________________________ 28<br />

Domain Systems Successfully Deploys Oracle’s Agile PLM at Mindspeed Technologies ______________ 29<br />

Hochland NATEC Decides to go SAP PLM with CIDEON _____________________________________ 29<br />

Hynix Adopts Apache’s Dynamic Power Integrity Solution for DRAM Designs _____________________ 30<br />

IFS Applications Selected by General Dynamics To Provide IT Backbone for Navy Logistics Contract ___ 30<br />

Intergraph® Announces Golden Valve Award Winners at Annual Users Conference _________________ 31<br />

Intergraph® SmartPlant® Enterprise Key to Development and Operation of One of the World’s Largest<br />

Coal-Fired Power Plants _________________________________________________________________ 32<br />

Jotun Expands Collaboration with IFS ______________________________________________________ 33<br />

Lahti Precision - Expertise that Weighs _____________________________________________________ 34<br />

MediaTek Achieves Faster Time-to-Tapeout Utilizing Smart Hierarchical Modeling in Synopsys IC<br />

Compilers ____________________________________________________________________________ 34<br />

Nalco Company Selects Open Text to Manage Business Content Across the Enterprise _______________ 35<br />

OCE Selects Invention Machine to Accelerate Product Delivery and Discover New Market Opportunities 36<br />

Oticon Tapes Out Innovative Hearing-Aid DSP Using Synopsys IC Compiler _______________________ 37<br />

Saudi Basic Industries Corp. (SABIC) Standardizes on Intergraph® SmartPlant® Enterprise ___________ 38<br />

Sequence Signs Chelsio, Sets Milestone: 100th PowerTheater Customer ___________________________ 39<br />

Tyco Thermal Controls Selects Intergraph® SmartPlant® Enterprise ______________________________ 40<br />

Urban Outfitters Looks to Reduce Cycle Times and Manage Rapid Growth With TradeStone’s Merchandise<br />

Lifecycle Management Suite _____________________________________________________________ 41<br />

Wisconsin Department of Transportation Selects Autodesk 3-D Design Tools for Road and Highway Design<br />

____________________________________________________________________________________ 42<br />

Product <strong>News</strong> _____________________________________________________________________ 43<br />

Adobe Launches Public Beta of Acrobat.com ________________________________________________ 43<br />

Adobe Unveils Acrobat 9 Software ________________________________________________________ 44<br />

Altair Expands Reach of HyperWorks With New Canadian Channel Partners _______________________ 45<br />

Aras Achieves Four Star Certification Rating for Complex Enterprise Product Configuration & Change<br />

Management __________________________________________________________________________ 46<br />

Capvidia Releases FlowVision HPC _______________________________________________________ 47<br />

Cimatron Expands Offering in China with GibbsCAM Machining Solutions ________________________ 48<br />

Corel and Right Hemisphere Partner to Bring Complete 3D Technical Illustration Solution to Market ____ 48<br />

Corel Announces Pre-Release Public Technology Preview of Corel DESIGNER® Technical Suite X4 ___ 49<br />

Dassault Systèmes Unveils ENOVIA Life Sciences Accelerator for Engineering Design ______________ 50<br />

Delcam’s FeatureCAM Certified for Autodesk Inventor 2009 ___________________________________ 51<br />

ESI Group Announces New Agent in Brazil _________________________________________________ 51<br />

Geometric’s DFMPro Awarded Solution Partner Status by SolidWorks __________________________ 52<br />

Gerber Technology Launches First of New Series of Cutting Solutions ____________________________ 52<br />

I-Cubed Launches Rights Management Practice Solutions for Rights Management Initiatives __________ 54<br />

IBM Extends Enterprise Content Management Software Portfolio With Business Content Services ______ 55<br />

IBM Tranforms How People Work Together To Deliver Software ________________________________ 56<br />

Intergraph® SmartPlant® Foundation 2008 Offers Unique Engineering Collaboration Platform _________ 58<br />

Maple 12 Language Editions Increase Global Reach and Coverage of Software _____________________ 60<br />

Mastercam X2 Now Certified for Autodesk Inventor 2009 ______________________________________ 61<br />

MSC.Software Announces Integrated Enterprise Simulation for PTC Product Development Solutions ____ 61<br />

New Summer ’08 Release Expands Core Arena PLM Functionality to Facilitate Better Designs, Decisions,<br />

and Products __________________________________________________________________________ 62<br />

PTC Announces Windchill® ProductPoint Its New SharePoint®-Based Solution for Product<br />

Page 2

<strong>CIMdata</strong> PLM Industry Summary<br />

Development __________________________________________________________________________ 64<br />

PTC Introduces ProductView Visual Collaboration Software, Represents New Generation of Unified,<br />

Scalable Visualization Platform ___________________________________________________________ 65<br />

Right Hemisphere's 3D Visualization Technology to Integrate With SAP PLM ______________________ 67<br />

SimManager R3 Delivers Breakthrough Productivity with Workgroup to Enterprise Scalability _________ 68<br />

SPT Group and CD-adapco Announce Initiative To Enhance Computational Flow Assurance __________ 69<br />

Synopsys Delivers Comprehensive Design Support for TSMC 40-Nanometer _______________________ 70<br />

Top Story<br />

CAM Software Market Leaders Named by <strong>CIMdata</strong><br />

2 June 2008<br />

In the recently-released Version 17 of the NC Software and Related Services Market Assessment<br />

Report, consulting and research firm <strong>CIMdata</strong> Inc. named the worldwide CAM software market leaders<br />

for 2007 and projected those expected to be market leaders in 2008. For 2007, Dassault Systèmes was<br />

the market leader on the basis of both vendor revenues received and end-user payments for CAM<br />

software and services, CNC Software was the leader on the basis of industrial seats shipped, and Planit<br />

Holdings was the leader on the basis of industrial seats installed. SolidCAM was named as the most<br />

rapidly-growing vendor.<br />

Mr. Alan Christman, <strong>CIMdata</strong> Chairman and primary author of the report noted that, “Even though there<br />

have been a number of recent mergers and acquisitions, the CAM software market continues to be<br />

highly-fragmented and competitive. There is no single vendor or small group of vendors that dominate<br />

the worldwide market. <strong>CIMdata</strong> tracks approximately 50 CAM software vendors and the rankings in the<br />

Report each list 20-30 vendors, depending upon the category.<br />

The 2007 leading vendors on the basis of CAM software and services revenue received were Dassault<br />

Systèmes, Siemens PLM Software, PTC, Delcam, Planit Holdings, NDES (formerly Hitachi Zosen<br />

Systems), Tebis, Missler Software, Cimatron, and CNC Software. Dassault Systèmes and Siemens PLM<br />

Software were the clear leaders with double digit market shares and a combined market share of 27.9%.<br />

The remaining eight vendors in the top ten had a combined market share of 38.4% and the remainder of<br />

the vendors below the top ten had a combined market share of 33.7%. This data is shown in the<br />

following chart.<br />

Page 3

<strong>CIMdata</strong> PLM Industry Summary<br />

2007 Market Share of the Largest NC Vendors at the Vendor Level<br />

The 2007 top five vendors on the basis of CAM industrial seats shipped were CNC Software, Planit<br />

Holdings, Dassault Systèmes, Delcam, and PTC. The seat count rankings are significantly different than<br />

the vendor revenue rankings. For example, CNC Software was listed as the leading vendor on the basis<br />

of industrial seats shipped, but only the tenth-largest on the basis of vendor revenue received.<br />

Conversely, Siemens PLM Software was the second-largest vendor on the basis of revenue received, but<br />

fell out of the top five on the basis of industrial seats shipped. The changes in rankings are primarily due<br />

to the differences in level and breadth of product and associated software pricing among the vendors.<br />

The worldwide five most rapidly-growing CAM software vendors on the basis of revenue received in<br />

2007, as compared to 2006, were SolidCAM, Cimatron, OPEN MIND, Missler Software, and Dassault<br />

Systèmes. SolidCAM, and Cimatron each achieved revenue growth in excess of 30% in 2007, as<br />

compared to 2006. Over the past five years, SolidCAM has been the consistent growth leader with<br />

annual growth rates in the 30% range. For 2008, <strong>CIMdata</strong> is projecting that the five most rapidlygrowing<br />

companies will be Cimatron, SolidCAM, Geometric Technologies, OPEN MIND, and Dassault<br />

Systèmes. The rapid growth of Cimatron in 2007 and 2008 is a combination of improved organic growth<br />

and the acquisitions of Microsystems in 2007 and Gibbs and Associates in 2008.<br />

<strong>CIMdata</strong> also did worldwide rankings based on brand name as well as by total vendor. In some cases,<br />

this made a significant difference as some vendors only offer products under one brand and some offer<br />

products under multiple brands. The multiple brands offered are typically the result of acquisitions and<br />

then maintaining the acquired product as a separate brand. For example, the five largest brands for<br />

industrial seats shipped in 2007 were CNC Software Mastercam, Dassault Systèmes CATIA, PTC<br />

Pro/ENGINEER, Siemens PLM Software NX, and Planit Holdings AlphaCAM. As such, CNC Software<br />

Mastercam was the leading brand on the basis of industrial seats shipped, whereas some vendors such as<br />

Planit Holdings and Delcam had their shipments spread over multiple brands.<br />

Other vendor rankings contained in Version 17 of the NC Market Assessment Report include those for<br />

the educational market, those based on revenue by geography and industry, those for verification and<br />

post-processing vendors, the total number of people in a company, product development, direct sales,<br />

and the number of resellers per company.<br />

Version 17 of the NC Software and Services Market Assessment Report is available for purchase by<br />

contacting <strong>CIMdata</strong> at +1 (734) 668-9922 or by emailing to info@cimdata.com.<br />

Page 4

Click here to return to Contents<br />

Acquisitions & Mergers<br />

<strong>CIMdata</strong> PLM Industry Summary<br />

ANSYS Acquisition of Ansoft Expected to Close in the Third Quarter of 2008<br />

4 June 2008<br />

ANSYS, Inc. announced that, as a result of the Securities and Exchange Commission's continuing<br />

review of the Registration Statement on Form S-4, it currently expects to close the acquisition of Ansoft<br />

Corporation in the third quarter of 2008. ANSYS had previously announced that it had expected to close<br />

the acquisition in the second quarter of 2008.<br />

As previously announced, ANSYS and Ansoft have entered into a definitive merger agreement in which<br />

ANSYS will acquire Ansoft for a purchase price of approximately $832 million in a mix of cash and<br />

ANSYS common stock. Consummation of the transaction remains subject to customary closing<br />

conditions, including the approval of the Ansoft stockholders.<br />

Click here to return to Contents<br />

PCO / idCAD Merger: Creation of PCO Innovation Group<br />

28 May 2008<br />

idCAD Consulting and PCO Technologies announced their merger resulting in the creation of PCO<br />

Innovation, a global consulting and services group specialized in the implementation of the PLM<br />

(Product Lifecycle Management) approach and in the optimization of innovation processes.<br />

The merger between the French company PCO Technologies, PLM pioneer founded in 1997, and the<br />

Canadian company idCAD Consulting, offering its global expertise since 2000, is welcomed by both<br />

entities’ customers. The strategic merger broadens and complements each company’s expertise and<br />

geographical reach in the PLM market. PCO Innovation, strong in its European and North-American<br />

cultures and know-how, brings an array of services and solutions.<br />

PCO Innovation’s expertise is especially well-known to tackle every step of the PLM Information<br />

System, whether at a functional level (methodology, support, etc.), or at the information technology<br />

level (customization, integration, maintenance, etc.). Further to offering a strong technology expertise,<br />

PCO Innovation proposes its know-how in Consulting, Change Management and Project Management,<br />

and has already established key partnerships with the major specialized software editors.<br />

Olivier Letard, founder and co-CEO, points out the company's key assets which will guarantee its<br />

successful development:<br />

> A unique position on the high-growth PLM segment;<br />

> A guarantee of legitimacy in consulting through PLM software editors’ independence;<br />

> A global action capacity combined with high reactivity;<br />

> A complete offer combining consulting, technological integration and change management;<br />

> A mission of customer service and commitment;<br />

> A wide range of customers of different sizes and from different industry sectors;<br />

Page 5

<strong>CIMdata</strong> PLM Industry Summary<br />

> A strong, specialized hiring team;<br />

> Well-managed teams adopting a friendly approach.<br />

PCO Innovation intends to become the world's leading independent supplier of consulting and services<br />

specialized in PLM. With a history of sustained growth, the group will exceed 500 employees in 2008<br />

and is expected to reach 1000 within the next 3 to 5 years.<br />

Click here to return to Contents<br />

<strong>CIMdata</strong> <strong>News</strong><br />

<strong>CIMdata</strong> Presentation: PLM Return on Investment (ROI)<br />

13 June 2008<br />

Who: Ken Amann, <strong>CIMdata</strong> Director of Research<br />

Event: 2008 Greater China PLM Executive Summit<br />

When: June 13, 2008<br />

Where: Kempinski Hotel in Dalian, China<br />

Topic: PLM Return on Investment (ROI)<br />

Click here to return to Contents<br />

Results: <strong>CIMdata</strong> Opinion Poll on the Most Important Criteria in Your Company’s PLM Evaluation<br />

& Selection Process<br />

6 June 2008<br />

In another sign that PLM is moving from the engineering department to the board room, more than 55%<br />

of the those responding to <strong>CIMdata</strong>’s latest opinion poll indicated that the most important criteria in<br />

their company’s PLM evaluation and selection process were the ability to address their process and<br />

business requirements. Coming in a second with approximately 18% were technology features and<br />

functions. In <strong>CIMdata</strong>’s experience this illustrates that more and more companies understand PLM’s<br />

business enabling characteristics and as a result fewer companies see these solutions as just an extension<br />

of a computer-aided design (CAD) system.<br />

Additionally, less than five percent (5%) indicated that the products and solution suppliers they currently<br />

work were an important criteria in their company’s new PLM evaluation and selection process. This<br />

would appear to indicate that an incumbent PLM solution supplier doesn’t have a significant edge in<br />

new competitive situations. This may reflect a willingness to change, dissatisfaction with the incumbent,<br />

or a potential underestimation of the effort/cost that could be required to migrate from a long-time<br />

established environment.<br />

Finally, it is important to note that just less than twelve percent (12%) indicated that the future vision<br />

and direction of the supplier played an important role. In <strong>CIMdata</strong>’s opinion this is somewhat<br />

disappointing and it may indicate that either today’s solution suppliers are doing a poor job<br />

communicating their vision and direction and its value to their customers or that industrial companies<br />

are too focused on today’s (short term) requirements – a situation that can have long term negative<br />

Page 6

consequences for a company.<br />

<strong>CIMdata</strong> PLM Industry Summary<br />

NOTE: The results of these polls are anecdotal, not scientific.<br />

If you have a suggestion for a poll you'd like to see contact us at info@cimdata.com<br />

Click here to return to Contents<br />

Company <strong>News</strong><br />

ARM, Renesas Technology and Synopsys Define Industry's First Low-Power Verification<br />

Methodology<br />

3 June 2008<br />

Synopsys, Inc. announced that it has collaborated with ARM and Renesas Technology to define the<br />

industry's first methodology to address the rapidly increasing complexity of low power verification. The<br />

companies are documenting the methodology in a new book titled "Verification Methodology Manual<br />

for Low Power Designs" (VMM-LP) that will enable rapid and broad deployment of industry best<br />

practices for comprehensive verification of low power designs. The new VMM-LP is based on the<br />

collective verification and IP experience of ARM, Renesas, and Synopsys, and builds on the<br />

methodology originally published in the proven "Verification Methodology Manual for SystemVerilog"<br />

book developed by ARM and Synopsys.<br />

The adoption of aggressive power management techniques has led to an increase in verification<br />

complexity, creating a need for a structured and reusable verification environment to achieve power<br />

goals and first-pass silicon success. The VMM-LP documents the common causes of low power bugs,<br />

provides rules and guidelines for low power verification, specifies a SystemVerilog base class library<br />

facilitating the setup of a reusable verification environment, and recommends assertions and coverage<br />

techniques to achieve comprehensive low power verification. The source code for the SystemVerilog<br />

base class library described in the VMM-LP book will be made available with VMM standard libraries<br />

and applications under the popular Apache 2.0 open source license.<br />

"In 2007, 2.9 billion ARM Powered® processors were shipped into the market. As a leading provider of<br />

low-power semiconductor IP, we recognize the need for a rigorous verification methodology for<br />

successful deployment and integration of that IP," said John Goodenough, worldwide director of design<br />

Page 7

<strong>CIMdata</strong> PLM Industry Summary<br />

technology for the office of the CTO at ARM. "The Verification Methodology Manual for Low-Power<br />

Design helps address this need by capturing the collective expertise and methodologies of industry lowpower<br />

leaders across multiple market segments."<br />

"Comprehensive functional verification of our aggressively power-managed SoCs -- especially PMPtargeted<br />

devices containing tens of power states -- is a major engineering challenge. We believe the<br />

VMM-LP book will be a powerful tool in the hands of the chip verification community in achieving<br />

predictable verification closure of LP designs," said Santhosh Madathil, VLSI Design & Verification<br />

Practice Group head at Wipro Technologies.<br />

Low-power design techniques are used across electronic product market segments ranging from<br />

handhelds to enterprise servers. In addition to voltage-aware static and dynamic verification tools, such<br />

as MVSIM with VCS® and MVRC, which are part of the Eclypse low power solution from<br />

Synopsys, designers require a rigorous methodology to set up testbenches, generate test cases, attain<br />

coverage closure and pinpoint bugs using assertions. The VMM-LP methodology addresses these needs<br />

with guidelines, rules, assertions, coverage, and base classes based on proven industry best practices.<br />

"Our goal is to achieve first-pass silicon success for all of our power-managed designs," said Narayana<br />

L. Pidugu, senior director of the Hyderabad Design Center at Cypress Semiconductor. "Given our highly<br />

compressed development cycle, there is immense pressure on functional verification schedules. The<br />

methodology described in the VMM-LP is easily implemented by the MVSIM and MVRC low-power<br />

verification tools, which have already helped achieve our product development goals by enabling us to<br />

successfully deploy sophisticated power-management verification techniques in a consistent and<br />

reusable manner."<br />

"Low-power design techniques add an extra verification dimension to getting the product right the first<br />

time," said Hitoshi Sugihara, department manager of the DFM and Digital EDA Technology<br />

Development Dept. at Renesas Technology Corp. "We have successfully implemented the verification<br />

methodology for low power described in the VMM-LP book through our use of Synopsys' products. The<br />

VMM-LP methodology systematically outlines the best practices for low-power verification and will<br />

serve as a basic verification reference guide for Renesas."<br />

"Tools alone are not enough to address the verification challenges of multi-voltage techniques used in<br />

low-power designs," said Manoj Gandhi, senior vice president and general manager of the Verification<br />

Group at Synopsys. "Lack of a verification methodology for low power has created a significant void.<br />

We have collaborated with some of the low-power leaders in the industry by combining the verification<br />

expertise at ARM and Renesas to define a leading-edge, reusable methodology."<br />

About the VMM for Low Power<br />

The lead authors of the VMM-LP book are David Flynn, ARM fellow and co-author of the "Low Power<br />

Methodology Manual" (LPMM) [Springer]; Yoshio Inoue, chief engineer, Design Technology Division,<br />

Renesas Technology Corp.; Janick Bergeron, Synopsys fellow and moderator of the Verification Guild<br />

web site; and Srikanth Jadcherla, group director of Research and Development at Synopsys and founder<br />

of ArchPro Design Automation, Inc., which was acquired by Synopsys in 2007.<br />

The VMM-LP book defines a robust and scalable verification architecture that can be used to quickly<br />

setup and complete verification of low-power designs. The methodology will address all aspects of<br />

functional verification of power management functions, including suggestions for static versus dynamic<br />

verification, design-for-verification techniques, and use of assertions and coverage metrics to achieve<br />

rapid verification closure.<br />

Page 8

<strong>CIMdata</strong> PLM Industry Summary<br />

Availability<br />

The VMM-LP book is currently scheduled for release in the fall of 2008. The source code for the<br />

SystemVerilog base class library described in the book will be available free-of-charge under the<br />

popular Apache 2.0 open source license on the VMM Central web site (http://www.vmmcentral.org/).<br />

To receive information about the availability of the VMM-LP book and source code, please register your<br />

interest at http://www.vmmcentral.org/vmmlp/. To learn more about the VMM-LP, register online at<br />

http://www.synopsys.com/dacvmm/ to attend the VMM User Forum lunch at the Anaheim Marriott on<br />

June 10, 2008 during the Design Automation Conference.<br />

Click here to return to Contents<br />

Avatech Solutions Launches New Manufacturing Consulting Services Group<br />

5 June 2008<br />

Avatech Solutions, Inc. announced the launch of the Avatech Consulting Services Group to meet the<br />

needs of the manufacturing sector.<br />

Trading on Avatech’s years of experience in engineering and design solutions, this new group will focus<br />

on providing process improvements that also impact client efficiencies outside of design and<br />

engineering. Benefits can extend enterprise-wide, affecting the shop floor, sales, purchasing, customer<br />

service, even suppliers—dramatically increasing profits.<br />

“New technology, in and of itself, is not enough,” said Scott Hale, vice president of the new consulting<br />

group for Avatech. “Improving and automating processes is often the key to achieving extraordinary<br />

productivity gains and lower costs. As technology evolves, however, many manufacturers find it hard to<br />

stay abreast of the best available advances and how to properly leverage them for the greatest time and<br />

cost savings across the entire company.”<br />

Hale continued, “Our consulting group will look beyond technology to create advantages for<br />

manufacturers that provide exponential time and efficiency gains. Our team thoroughly understands the<br />

key challenges regarding processes that manufacturers face. Team members have been pulled from a<br />

roster of Avatech experts who have a proven history of streamlining and automating processes that are<br />

nothing short of transformative. The new group will operate out of Avatech’s 18 existing offices across<br />

the country.”<br />

Avatech client SVI Trucks, a builder of fire, police, and multi-use emergency vehicles in Loveland,<br />

Colorado, wanted to speed delivery times and improve quality.<br />

“Avatech helped us integrate engineering, fabrication, and assembly processes, which allow us to build<br />

higher quality trucks in less time. The bottom line is that our customers receive better value and we are<br />

more efficient,” stated Dave Sargent, SVI’s engineering manager.<br />

“We have a long history of working with our clients to implement the latest design technology,” stated<br />

George Davis, president and CEO of Avatech Solutions. “With our new Consulting Services Group, we<br />

will be focusing sharply on clients’ business goals, while targeting processes in addition to technology.<br />

With global competition at a fever pitch, American manufacturers need these services more than ever to<br />

increase efficiency and control costs. All of us at Avatech see ourselves as partners with our customers<br />

in their innovation process, leading to increased market share and long-term corporate sustainability.<br />

“This initiative will directly support our stated objectives to leverage our deep talent pool and grow the<br />

Page 9

services component of our business,” concluded Davis.<br />

Click here to return to Contents<br />

<strong>CIMdata</strong> PLM Industry Summary<br />

Delcam Still on Top of <strong>CIMdata</strong> CAM Rankings<br />

5 June 2008<br />

Delcam continues to rank as the world’s leading specialist supplier of manufacturing software and<br />

services in the latest NC Software and Related Services Market Assessment from renowned US<br />

consulting and market research firm, <strong>CIMdata</strong>. The company increased its market share by achieving<br />

sales growth of 15% from 2006 to 2007, compared with an overall growth in vendor revenues of less<br />

than 8%. The report also confirmed that Delcam has the largest overall staff numbers devoted to CAM,<br />

including the largest CAM development team in the industry.<br />

Delcam’s Managing Director, Hugh Humphreys, was delighted with the results and claimed that they<br />

represented a clear validation of the company’s aggressive growth strategy. "For several years, we have<br />

aimed to build our company’s sales by diversifying outside our traditional market in the mould, tool and<br />

die sector and increasing our business in other areas, in particular in the automotive and aerospace<br />

sectors,” he commented. "We have achieved consistently above-average increases in sales through<br />

significant acquisitions, in particular, the FeatureCAM and PartMaker ranges of software, and through<br />

organic growth.”<br />

Mr. Humphreys also emphasised his company’s commitment to high levels of R & D investment as a<br />

key part of the company’s success. The <strong>CIMdata</strong> report states "over time one would expect the<br />

organization with the most resources to provide a greater breadth and depth of internally developed<br />

product” and Mr. Humphreys certainly supports this view.<br />

"Together, our complete set of CAM programs, PowerMILL, FeatureCAM, PartMaker and ArtCAM,<br />

comprises the world’s most comprehensive collection of machining software, giving us an unrivalled<br />

ability to provide solutions to all of a company’s programming needs,” he claimed. "This benefits larger<br />

companies, which can meet all of their CAM needs from a single supplier. At the same time, smaller<br />

companies can choose exactly the system they need for their particular combination of products and<br />

machine tools, rather than having to accept a compromise solution from a CAM supplier with a more<br />

limited range of software.”<br />

Mr. Humphreys is already confident of an even better showing in next year’s report. "We had our best<br />

quarter ever in the first three months of 2008,” he reported. "I am confident that this pattern will be<br />

repeated over the complete year.”<br />

Click here to return to Contents<br />

EVE Appoints Koji Iwagami General Manager of EVE K.K.<br />

2 June 2008<br />

EVE announced it has appointed Koji Iwagami to the position of general manager of EVE K.K., a<br />

wholly owned subsidiary based in Yokohama, Japan.<br />

Iwagami joins EVE from Mentor Graphics Japan, Co. Ltd, where he served as sales director for the<br />

electronic design automation (EDA) Solution Sales Division. Under his direction, Catapult-C synthesis<br />

became the number one high-level synthesis tool in Japan. Previously, he worked for Spinnaker Systems<br />

Page 10

<strong>CIMdata</strong> PLM Industry Summary<br />

Inc. as senior manager in the EDA sales and marketing department.<br />

"We are delighted to welcome Koji Iwagami to EVE," remarks Tsugumi Fujitani, vice president of<br />

Japan and Asia Sales. "His tenacity and sales skills have been recognized throughout his career. With his<br />

track record in selling implementation and verification tools, he is well positioned to make EVE the<br />

number one choice of emulation and hardware/software co-verification solutions by design teams in<br />

Japan."<br />

Iwagami holds an industrial engineering degree from Seijo University in Tokyo.<br />

Click here to return to Contents<br />

Symmetry Solutions Adds 3D Printing to its Technology Offerings<br />

2 June 2008<br />

Symmetry Solutions, a local value-added reseller (VAR) of SolidWorks® technology solutions,<br />

announced it has become an official vendor of Z Corporation® 3D printers and scanners.<br />

Z Corporation is a manufacturer of 3D high-definition printing and scanning hardware, which produce<br />

full color physical prototypes from digital data. Symmetry Solutions believes 3D printing technology is<br />

a new essential for clients seeking the best in design capabilities at an affordable price.<br />

“We picked up Z Corporation products to better serve our customers’ design engineering needs,”<br />

explains Symmetry Solutions vice president of sales, Paul Rudin. “These rapid prototyping tools are<br />

easy-to-use and relatively inexpensive. And you can make a physical prototype out of a SolidWorks 3D<br />

model very quickly, to easily test or validate design form, fit or function.”<br />

Rudin cites several reasons for choosing Z Corporation’s technology over other brands on the market: 1)<br />

it is the only 3D printing technology with full color capabilities; 2) the material used contains no<br />

hazardous materials, making them more appropriate for use in office or studio environments; and 3) the<br />

relatively inexpensive price point.<br />

“With their focus on and expertise with the entire product development process, we are extremely<br />

excited to have Symmetry Solutions on board as a VAR,” says Andy DeHart, vice president of sales<br />

from Z Corporation. “They bring a turn key solution that delivers a fast ROI and the highest level of<br />

value to Z Corporation customers.”<br />

Symmetry Solutions has also signed on as a reseller of GeoMagic 3D software, which is sold as a<br />

companion to Z Corporation 3D scanning technology. Rudin reports that Symmetry Solutions intends to<br />

incorporate these new products into the technical support and training programs for its Midwestern<br />

customer base.<br />

Click here to return to Contents<br />

Events <strong>News</strong><br />

Apache Design Solutions Offers Hands-On Tutorial on IP Validation for Macro and Embedded SoC<br />

at 45th Design Automation Conference<br />

4 June 2008<br />

Apache Design Solutions will host a hands-on tutorial at this years’ 45th Design Automation Conference<br />

Page 11

<strong>CIMdata</strong> PLM Industry Summary<br />

(DAC), titled “IP Validation for Macro and Embedded SoC”. The tutorial gives attendees first-hand<br />

experience in running Apache’s products for validating embedded macro, analyzing full-chip power<br />

including package, and generating portable power delivery network model for co-design.<br />

WHO: Apache Design Solutions<br />

WHAT: Hands-on-Tutorial titled "IP Validation for Macro and Embedded SoC"<br />

WHERE: Design Automation Conference<br />

Anaheim Convention Center<br />

Room 213D<br />

WHEN: 2:00 p.m. - 5:00 p.m., PDT<br />

Monday, June 9, 2008<br />

Specifically the tutorial will cover the following:<br />

• Block-level power analysis of a full-custom IP from Virage Logic using RedHawk-MMX<br />

• Package model extraction using PakSi-E<br />

• Full-chip power analysis including validated custom IP and package models using RedHawk-EV<br />

• Chip Power Model generation using RedHawk-CPM<br />

For more information please go to: http://www.dac.com/events/eventdetails.aspx?id=77-140<br />

Click here to return to Contents<br />

Apache Design Solutions to Host Methodology Presentations by Designers from Leading<br />

Semiconductor Companies<br />

4 June 2008<br />

Apache Design Solutions will host methodology presentations by designers from Broadcom, IBM,<br />

STMicroelectronics, Texas Instruments, Toshiba, and TSMC at this years’ 45th Design Automation<br />

Conference (DAC) in Anaheim, California. The designers will share their best practices on critical<br />

design challenges such as SoC power and noise sign-off, custom IP validation, and chip-package codesign.<br />

For presentation details and registration, go to http://www.apache-da.com/apacheda/Home/<strong>News</strong>andEvents/Seminars.html#Customer<br />

(Due to its length, this URL may need to be<br />

copied/pasted into your Internet browser’s address field. Remove the extra space if one exists.)<br />

WHAT: Methodology presentations by designers from Broadcom, IBM, STMicroelectronics, Texas<br />

Instruments, Toshiba, and TSMC<br />

WHERE: Apache Design Solutions, Booth #2311<br />

Design Automation Conference, Anaheim Convention Center, Anaheim, CA<br />

WHEN:<br />

Broadcom: Reducing jitter in DDR interface<br />

June 10, 2:00 pm<br />

June 11, 10:00 am<br />

Page 12

IBM: Power integrity and low power design analysis<br />

<strong>CIMdata</strong> PLM Industry Summary<br />

June 9, 12:00 am<br />

STMicroelectronics: Embedded memory validation<br />

June 10, 11:00 am<br />

Texas Instruments: EMI noise modeling and compliance<br />

June 9, 11:00 am<br />

Toshiba: Chip-package-system co-design for cost reduction<br />

June 11, 1:00 pm<br />

TSMC: Power integrity and signoff methodology<br />

June 9, 2:00 am<br />

The company will also be demonstrating their complete line of power, noise, and reliability platform<br />

solutions for SoC and package/PCB designs. Demonstrations and presentations will include:<br />

• SoC dynamic power analysis from early design to signoff<br />

• Low power verification including MTCMOS, VTCMOS, and LDO<br />

• Methodology for early stage analysis from prototype to design<br />

• Analog, mixed-signal power integrity<br />

• Chip-Package-System co-design<br />

• Package and PCB power and signal integrity<br />

• Hands-on-Tutorial on chip-package co-design methodology<br />

For more information and registration, go to http://www.apache-da.com/apacheda/Home/<strong>News</strong>andEvents/Seminars.html#Product<br />

(Due to its length, this URL may need to be<br />

copied/pasted into your Internet browser’s address field. Remove the extra space if one exists.)<br />

Click here to return to Contents<br />

ASCON Took Part at CAD Conference in Germany<br />

4 June 2008<br />

ASCON Group, developer of Mechanical CAD solution – KOMPAS-3D, participated at CAD<br />

Conference in Erfurt, Germany. Theme of the event was “More benefit from CAD!” to show which<br />

additional benefit could be brought from CAD solutions (for example with help of integration in all the<br />

process of production (CAM, CAP, PLM), through parametric CAD or through simulation or analysis<br />

etc.)<br />

This year CAD Conference for the first time in its history was with international participation – two<br />

representatives of ASCON hold their speeches among German-speaking members. Vladimir Zakharov,<br />

R&D Chief of ASCON, made speech “Compatibility and Integration of CAD/CAM/PLM Solutions”<br />

and Irina Voronkina, Chief of International Business Development, organized a presentation<br />

“KOMPAS-3D for professional Design and efficiency of production”. Both appearances were highly<br />

Page 13

<strong>CIMdata</strong> PLM Industry Summary<br />

regarded and came up for a spirited discussion at the conference, where representatives of mid-range and<br />

small business, educational institutions, students, engineers and industrial designers took part and<br />

presented their issues as well as results of research.<br />

All the visitors of CAD conference had the ability to familiarize, try in use, get all the additional<br />

information or Demo version of Mechanical Computer-Aided Design Solution – KOMPAS. ASCON<br />

was present with its own stand at a fair, which was organized in Congress Center of Erfurt.<br />

Click here to return to Contents<br />

AVEVA Exhibits <strong>Late</strong>st Software Solutions for Engineering and Asset Lifecycle Management at the<br />

Global Petroleum Show 2008<br />

2 June 2008<br />

AVEVA will exhibit its solutions for engineering and asset lifecycle management at the Global<br />

Petroleum Show (GPS) 2008, located at booth 4533 in the Technology Pavilion. GPS will be held from<br />

10 to 12 June, 2008 at Stampede Park in Calgary, Alberta.<br />

AVEVA products to be showcased include:<br />

AVEVA Plant portfolio which is a set of integrated design and engineering applications combined with<br />

open and flexible lifecycle management solutions. It provides a fast, productive and risk-free way to<br />

design, build and operate large complex plants, whilst offering maximum flexibility in the choice of<br />

authoring tools. AVEVA Plant supports the entire plant lifecycle from concept, through engineering,<br />

construction, maintenance and life extension to decommissioning. At the heart of the AVEVA Plant<br />

portfolio is AVEVA PDMS.<br />

AVEVA PDMS, a leading 3D offshore design solution, is a datacentric, multi-disciplinary design<br />

environment for the 3D modelling of offshore structures. It has modules for the design of equipment,<br />

piping, HVAC, structure and cable trays. Modelling is carried out using a customer-defined catalogue<br />

and specification, in a full 3D environment, with the support of tools that ensure a clash-free design. A<br />

full range of drawings and pipe isometrics can be produced automatically from the model.<br />

AVEVA NET is an application-neutral environment for all engineering, operational, maintenance and<br />

safety data, no matter which programs created it. AVEVA NET makes data available and useful to a<br />

wide range of applications, including ready-made lifecycle solutions from AVEVA, customised<br />

solutions created by AVEVA and applications from other vendors.<br />

AVEVA's plant and marine solutions have been used on more than 3,000 major global engineering<br />

projects by over 1,700 customers worldwide on projects costing over USD $600 billion. In the Oil &<br />

Gas sector, over 80% of the largest production facilities in the North Sea and the Gulf of Mexico were<br />

designed using AVEVA technology in the last ten years, and 85% of the world's top 20 shipbuilders use<br />

AVEVA technology.<br />

For more information On Global Petroleum Show 2008 please visit<br />

http://www.petroleumshow.com/globalpetroleum/<br />

Click here to return to Contents<br />

Page 14

<strong>CIMdata</strong> PLM Industry Summary<br />

Bluespec Demonstrates FPGA-BASED Models and Testbenches at DAC<br />

3 June 2008<br />

Bluespec Inc. will demonstrate a synthesizable model and testbench running at 35,000 times faster<br />

than event-based simulation and its new development workstation in Booth #2367 during the 45th<br />

Design Automation Conference (DAC). DAC runs June 8-13 at the Anaheim Convention Center in<br />

Anaheim, Calif.<br />

Bluespec is the developer of the only general purpose high-level synthesis solution for synthesizable<br />

models, testbenches,<br />

control and algorithmic IP and System-on-Chip (SoC) interconnect. Its hardware<br />

demo, freed from the constraints of synthesizable RTL subsets, will show an FPGA-based<br />

implementation including hardware transactors, a synthesizable testbench, high-level models and AXI®<br />

bus components.<br />

An additional highlight will be Bluespec’s new Development Workstation for the design, analysis and<br />

debug of high-level models, testbenches and implementations.<br />

Rishiyur Nikhil, Bluespec’s chief technical officer, will present “From Executable Specifications to<br />

High-quality Implementations Using Bluespec,”<br />

June 8th, from 9:00 a.m. - 9:20 a.m. at the workshop,<br />

“High-Level Synthesis: Back to the Future,” in room 208A. Professor Arvind, Bluespec co-founder and<br />

board member, will present “HLS as an Enabling Technology: Some Complex Examples” from 1:30<br />

p.m. – 1:50 p.m. at the same workshop.<br />

Rishiyur Nikhil will also be chairing session 23, "Architectural and Precision Optimization in High-<br />

Level Synthesis" on Wednesday, June 11th, from 9:00A-11:00A in room 210AB.<br />

Collocated at DAC, Professor Arvind and Rishiyur Nikhil will be giving a tutorial entitled<br />

“Hands-on<br />

Introduction to BSV (Bluespec SystemVerilog)” on Saturday, June 7, 2008, in room 303B of the<br />

Anaheim Convention Center in Anaheim, CA. Details and registration for the tutorial are provided on<br />

the MEMOCODE 2008 conference website at: http://svl1.cs.pdx.edu/mem ocode08/<br />

Contact Bluespec’s Vice President of Marketing George Harper to schedule a demonstration. He can be<br />

reached at (781) 250-2200 or via email at george.harper@bluespec.com.<br />

Click here to return to Contents<br />

Dassault Systèmes Presents PLM 2.0 Vision, Demonstrates V6 PLM Platform at ENOVIA Customer<br />

Conference Europe<br />

3 June 2008<br />

Dassault Systèmes (DS) announced that its ENOVIA Customer Conference Europe (ECC Europe) in<br />

Munich, Germany will open today with more than 600 of Europe’s leading executives expected to<br />

attend. Over the next two days the event will provide a showcase for customer success stories, industry<br />

best practices and Dassault Systèmes’ V6 strategy.<br />

Themed “An Executive Perspective on PLM Collaboration,” the event features recognized leaders in<br />

innovation, key industry C-level speakers and Dassault Systèmes’ executives sharing their perspectives<br />

on how PLM best business practices are helping many of the world’s leading companies address market<br />

trends and challenges.<br />

Attendees at ECC Europe will learn more about the vision of “PLM 2.0” and experience Dassault<br />

Page 15

<strong>CIMdata</strong> PLM Industry Summary<br />

Systèmes V6 PLM platform through education, training, demonstrations and customer presentations.<br />

The V6 platform delivers a single platform for all PLM business processes, available to anybody<br />

anywhere, spanning engineering/manufacturing groups, business and end-users. V6 also gives intelligent<br />

access to IP, regardless of its data source or location.<br />

“With last week’s announcement of V6 availability, ECC Europe provides an ideal opportunity for all of<br />

our customers, prospects and business partners to experience Dassault Systèmes’ vision for the<br />

future of<br />

PLM and the integral role that ENOVIA<br />

will play. The event also allows us to showcase our customer<br />

success stories in existing and new markets like apparel, high tech and life sciences and share best<br />

business practices,” said Joel Lemke, chief executive officer, ENOVIA, Dassault Systèmes.<br />

ECC Europe highlights<br />

include:<br />

• Keynote addresses from companies, including Microsoft, IBM and Roland Berger Strategy<br />

Consultants;<br />

• “ENOVIA in Production” Customer Panel on Tuesday, June 3rd, featuring ABB Power, MAN<br />

Nutzfahrzeuge, Procter & Gamble, Warnaco;<br />

• Seven industry-specific tracks featuring customers, such as Sun Microsystems in high-tech &<br />

semiconductor; Scania and Bosch in automotive & transportation; Procter & Gamble in consumer<br />

packaged goods;<br />

• In addition, the following companies will be actively participating in ECC Europe’s PLM dialogue:<br />

Schuler, Bticino, Carraro, Stadler Rail, Sony Ericsson, Walter Wilhelm Associates, Cambridge<br />

Solutions, Prostep AG, and Toyota Motorsport, and more.<br />

• In-depth presentations and breakout sessions on the new V6 PLM platform and how it helps customers<br />

achieve PLM 2.0.<br />

• Day Two will feature sessions with Dassault Systèmes’ key technology leaders focusing<br />

on a variety<br />

of topics, including business process collaboration, enterprise federation and openness,<br />

mid-market<br />

solutions, mastering the supply chain<br />

and PLM 2.0 innovation.<br />

For more information on PLM 2.0 and V6, please visit http://www.3ds.com/V6.<br />

Click here to return to Contents<br />

Delcam to Preview New-Look PartMaker at IMTS<br />

3 June 2008<br />

Delcam will preview the forthcoming release of its PartMaker CAM software for programming turn-mill<br />

centres and Swiss-type lathes on booth D-3005 at the IMTS exhibition to be held in Chicago from 8th to<br />

13th September. Major highlights of this new version of PartMaker, Version 9, include a revamped and<br />

more productive user-interface, improved capabilities for programming directly on solid models and<br />

improved machine simulation for the ever increasingly complex machine architectures of today’s multiaxis<br />

turn-mill centres and Swiss-type lathes. A host of other productivity, user-driven enhancements will<br />

also be featured in PartMaker Version 9.<br />

The 2008 exhibition will be the first IMTS where PartMaker will be exhibited in the Delcam booth. The<br />

software will demonstrated along side Delcam’s other manufacturing products including the<br />

PowerMILL, FeatureCAM, ArtCAM and PowerINSPECT. The Delcam booth will be the largest CAM<br />

Page 16

<strong>CIMdata</strong> PLM Industry Summary<br />

booth at the exhibition, and will feature the most comprehensive range of CAM products at the show.<br />

"PartMaker Version 9 is another big step forward in the life cycle of the PartMaker suite of CAM<br />

software,” says PartMaker Inc. President, Hanan Fishman. "PartMaker Version 9’s enhanced user<br />

interface and other new features will make PartMaker users even more productive in programming<br />

their<br />

CNC equipment, while offering new users and even easier to learn, more capable CNC programming<br />

platform.”<br />

PartMaker is a Knowledge Based Machining system, allowing it to provide a substantial gain in<br />

programming<br />

efficiency by remembering the tools, material and process information necessary to<br />

machine individual part features. It thus relieves the user from re-entering the same features information<br />

for subsequent parts. It also improves productivity by placing the emphasis on tool management<br />

functions.<br />

PartMaker pioneered the field of specialist CAM software for turn-mills and Swiss-type lathes with<br />

its<br />

patented Visual Programming Approach<br />

for programming multi-axis lathes with live tooling. The<br />

software makes extensive use of pictures to help the user describe tools, part features and machining<br />

data. Synchronization of tools working on multiple spindles is achieved by a few mouse clicks.<br />

Click here to return to Contents<br />

First Open Verification Methodology (OVM) World Summit to be Held at Design Automation<br />

Conference<br />

5 June 2008<br />

Cadence Design Systems, Inc. and Mentor Graphics Corp. announced that the inaugural Open<br />

Verification Methodology (OVM) World Summit<br />

will be held Thursday, June 12 aligned with the<br />

Design Automation Conference (DAC) in Anaheim, Calif. This event will provide OVM users an<br />

opportunity to interact, share their successful experiences, and learn about upcoming enhancements to<br />

the methodology and its supporting library.<br />

The summit agenda includes multiple user presentations reporting the results of using the OVM on<br />

industrial projects, an opportunity for audience members to pose questions to a panel of OVM users, and<br />

a presentation from Mentor and Cadence on enhancement plans. The event runs from 7:40 a.m. until 11<br />

a.m., including a complimentary breakfast.<br />

The OVM World Forum will be held at the Sheraton Park<br />

Hotel at the Anaheim Resort, adjacent to the Anaheim Convention Center. For more information and<br />

free registration, users can go to: http://www.ovmworld.org/ovm-summit-form.php<br />

Open Verification Methodology<br />

The Open Verification Methodology, based on IEEE Std. 1800-2005 SystemVerilog standard, is the<br />

first open, language-interoperable, SystemVerilog verification methodology in the industry. It provides a<br />

methodology and accompanying library that allow users to create modular, reusable verification<br />

environments in which components communicate with each other via standard transaction-level<br />

modeling interfaces. It also enables intra- and inter-company reuse through a common methodology and<br />

classes for virtual sequences and block-to-system reuse, and full integration with other languages<br />

commonly used in production flows.<br />

Click here to return to Contents<br />

Page 17

<strong>CIMdata</strong> PLM Industry Summary<br />

Knowllence: the Design Common Guideline, i.e. How Can Methodological Tools Complete The<br />

Product/Process Data Repository (PDM)<br />

14 May 2008<br />

Knowllence organized a conference dealing with: “from geometry to PLM 2.0, the design common<br />

guideline”, that welcomed 75 attendees. The aim was to introduce the methodological tools completing<br />

the usual technical data management systems and launch the collaborative platform for system<br />

engineering: TDC System.<br />

This conference started with the testimonies of Philippe Bergin and Philippe Raffoux from Schneider<br />

Electric (Innovation department - R&D Efficiency & Quality). Their mission is to define world class<br />

processes and roll out appropriate tools, so that the 7,000 designers know<br />

how to achieve their efficiency<br />

and design sturdiness goals. Within the Radar (Required Activities of Design* to Achieve Robustness)<br />

project, Schneider Electric successfully implements the TDC software in the fields of functional analysis<br />

(VoC - Voice of Customer) and risk mastering (FMEA), throughout the steps of the offer creation<br />

process, whilst remaining DFSS (Design for Six Sigma) compatible.<br />

Jean-François Prevéraud (chief-editor of GISI) then presented the evolution of the engineering and<br />

design departments’ needs and requirements. While the PLM lifecycle management progressively<br />

disseminates, it should nevertheless not be limited to 3D geometry. It is such a strategic decision to opt<br />

for PLM 2.0 and integrate customers into the heart of the design process.<br />

Thierry Beaujon,<br />

CEO, then introduced the Knowllence vision. Knowllence is a methodological solution<br />

integrator into PLM 2.0. In a changing and uncertain, multicultural and complex environment,<br />

supporting the product/process development process with proven methodologies is no longer an option.<br />

In complement to the existing PDMs, Knowllence launches TDC System (*), a system<br />

engineering<br />

platform:<br />

To model the processes and guide the designers<br />

through the use of appropriate software modules: need<br />

analysis, requirement management, risk analysis, TRIZ,<br />

systematic innovation, etc.<br />

To direct and connect the information from the capture<br />

tools (TDC Worksuite captures the relevant<br />

data…) and from the storage/protection tools.<br />

Page 18

To alert the project teams of any impacting change.<br />

<strong>CIMdata</strong> PLM Industry Summary<br />

To inform on schedules, products and processes.<br />

Read more: http://www.knowllence.com/en/products/tdc_system.php<br />

Knowllence will detail these elements during several meetings in June in Paris: requirements<br />

management, TDC System demos, etc<br />

*TDC System is one of the first achievements of the “CoDeKF” R&D programme, driven by TDC-<br />

Knowllence along with the UTBM (Université de Technologie de Belfort-Montbéliard, France). The<br />

project is hallmarked Vehicle of the future cluster.<br />

Click here to return to Contents<br />

LMS Announces 2008 Edition of the International LMS Engineering Simulation Conference 2008<br />

5 June 2008<br />

Worldwide simulation experts to meet in Paris to discuss real-life simulation for intelligent system<br />

engineering<br />

LMS has announced the dates for the International LMS Engineering Simulation Conference 2008 to be<br />

held at the Disneyland Resort in Paris, France on October 8th and 9th, 2008. In the past, top-level<br />

speakers from leading aerospace, automotive and advanced manufacturing companies have presented<br />

innovative viewpoints and personal<br />

insight in the latest product development and engineering trends.<br />

With its international scope, LMS is predicting the 2008 Simulation Conference to be a unique platform<br />

Page 19

<strong>CIMdata</strong> PLM Industry Summary<br />

to discuss the latest developments in 1D and 3D simulation, intelligent system engineering, process<br />

integration and optimization.<br />

During the 2-day conference, engineering executives, senior managers and technical experts will share<br />

strategies and present application cases that illustrate how real-life simulation have helped them<br />

optimize their product development processes. The conference is the ideal venue to discover the latest<br />

technology evolutions in engineering simulation and to exchange best practices in application domains<br />

such as structural analysis, multibody simulation, vibrations, acoustics, fatigue and durability, vehicle<br />

dynamics, fluid systems, hydraulics and pneumatics, thermal management, electromechanical systems,<br />

intelligent control systems, single and multi-attribute optimization, and optimization for six sigma<br />

criteria. LMS invites engineering experts using LMS simulation software from around the world to<br />

submit an application or research presentation related to any of these topics before August 31, 2008.<br />

For more information about the International LMS Engineering Simulation Conference 2008,<br />

including<br />

presentation submissions, the early bird<br />

registration discount and online registration, please visit the<br />

LMS Simulation Conference website at http://www.lmsintl.com/lmsconferences/europe.<br />

Click here to return to Contents<br />

New IBM Programs and Business Partner Products to Accelerate Software Delivery<br />

2 June 2008<br />

IBM announced software and programs to help clients more quickly and effectively deliver software in a<br />

global team environment.<br />

IBM is announcing Open Services for Lifecycle Collaboration, a proposed industry-wide initiative<br />

aimed at simplifying collaboration across the software delivery lifecycle. Through the initiative, IBM is<br />

inviting business partners, developers, ISVs and customers to collaborate on a common architecture,<br />

based on open Internet standards, to effectively integrate their software development processes.<br />

Currently, software development tools vendors work with private vocabularies, formats and data<br />

repositories, which act as barriers to openly sharing resources across the software lifecycle. With Open<br />

Services for Lifecycle Collaboration, IBM is proposing an open architecture to help ensure the<br />

interoperability of software development resources, such as project requirements and test plans, which<br />

would ultimately allow a customer to assemble their ideal software development platform using<br />

preferred tools and vendors. Interested participants can join the initiative at http://www.jazz.net/.<br />

IBM is also announcing new software being developed by IBM business partners Black Duck Software,<br />

CAST Software, CM-Logic, iRise, Mainsoft, QSM, Ravenflow, SourceIQ, Surgient, VMLogix and<br />

WebLayers to integrate with new IBM Rational Jazz-based products announced today at the IBM<br />

Rational Software Development Conference. The new offerings help customers deliver more reliable,<br />

higher-quality software to market while managing costs.<br />

Furthering its global software development strategy, IBM is also announcing the IBM Rational<br />

Ensemble, a free Jazz technology offering for IBM business partners, that provides independent<br />

software vendors (ISVs), resellers and systems integrators with education and services for IBM Jazzbased<br />

technology to accelerate customer awareness and adoption. The Rational Ensemble provides Web<br />

portal access with links into Jazz community pages and content, specialized sales and marketing<br />

resources for Jazz offerings, go-to-market training and materials, educational<br />

Webcasts and events, Jazz<br />

Web content syndication, and access to Jazz experts through special live and online events. Business<br />

Page 20

Partners can join the IBM Rational Ensemble at http://www.jazz.net.<br />

<strong>CIMdata</strong> PLM Industry Summary<br />

“Businesses are looking to maximize the value they get from their software development investments<br />

while balancing teams comprised of globally dispersed project stakeholders,” said Scott Hebner, vice<br />

president of marketing and strategy, IBM Rational Software. “We are teaming with our partners to help<br />

organizations adopt a global approach to their software development<br />

and transform the way they work<br />

together.”<br />

New IBM Rational Business Partner Offerings and Incentives<br />

While the IBM Rational business partner community continues to grow, more than 1,000 business<br />

partners re-sold and fulfilled IBM Rational software products last year. At the<br />

same time, more than 60<br />

ISV partners delivered more than 80 integrations of their products with the IBM Rational portfolio of<br />

offerings through the Ready for IBM Rational software validation program.<br />

To support the growing community, IBM is offering new Web-based tools and offerings that make it<br />

easier for business partners to grow their businesses with IBM software. IT decision makers rely heavily<br />

on search engines to locate products and services. IBM is now offering Internet Marketing and Web<br />

Content Syndication to deliver and share up-to-date IBM and business partner offerings and product<br />

information to assist in customer buying decisions. IBM is also providing Search Optimization Guidance<br />

to business partners looking to optimize their Web 2.0 technologies such as RSS, podcasts and blogs, as<br />

well as get tips for how to optimize Google and Yahoo searches for better results.<br />

IBM is also providing new sales and marketing tools to business partners looking to sell IBM Rational<br />

software into specialized customer environments. Grow Your Business with IBM Software is Webbased<br />

tool that automatically recommends IBM Rational cross-sell software scenarios that utilize<br />

business partners’ existing areas of expertise and available skills. Grow Your Business with IBM<br />

Software helps IBM Rational business partners plan for profitable growth with links to IBM-cross-brand<br />

marketing programs, product sales and marketing dashboards, and ROI analysis. For more information,<br />

business partners can visit: www.ibm.com/partnerworld/growyourbusiness.<br />

New IBM Rational Sales and Marketing Playbooks containing go-to-market content and demand<br />

generation information are now available to IBM Rational business partners.<br />

Playbooks including “Streamline and Optimize Portal Development,” “Prevent On-line Security<br />

Breaches of Web Applications,” and “Extend and Modernize Existing System i Applications” and many<br />

others are available at: http://www.ibm.com/software/rational/partners/. An IBM Rational Team Concert<br />

playbook will be made available later this year.<br />

IBM is announcing new enhancements to its Rational Software Comes to You offering. IBM provides<br />

what a business partner needs to create a tailored event for customers in their own market including all<br />

relevant content from the 2008 IBM Rational Software Development Conference. Business partners can<br />

now co-host and manage events with IBM, infused with specific partner value and offerings, to gain<br />

market recognition and drive new leads for software and services. For more information<br />

about Rational<br />

Software Comes to You, business partners can visit<br />

http://www.ibm.com/jct9002c/partnerworld/mem/mkt/mkt_play_rsc2u.html<br />

Also at the Conference<br />

In related Rational Software Development Conference news, IBM announced winners of the inaugural<br />

Rational Awards recognizing business partners for delivering outstanding value to clients and innovative<br />

approaches to solving business issues. This year’s recipients Ascendant Technology, BSD Group,<br />

Page 21

<strong>CIMdata</strong> PLM Industry Summary<br />

CROZ, and Rocket Gang will be honored throughout the conference at Business Partner Day and main<br />

tent event activities.<br />

IBM Rational business partners BigLever, Instantiations, Ivar Jacobson International, Protecode,<br />

Relativity, Stoneworks, Surgient, and WebLayers will also demonstrate their product integrations and<br />

validations with products across the IBM Rational product portfolio including Telelogic<br />

DOORS and<br />

IB M Rational BuildForge. For more information, please visithttp://www.ibm.com/isv.<br />

For more information on IBM PartnerWorld visit http://www.ibm.com/partnerworld<br />

Click here to return to Contents<br />

New Engineering Simulation Software Performs Virtual Product Testing at 2008 Atlantic Design<br />

Show<br />

2 June 2008<br />

Noran Engineering, Inc. (NEi), announced that it will demonstrate new analysis and simulation software<br />

at the Atlantic Design and Manufacturing Show, June 3-5, 2008 at the Jacob Javits Center in New York<br />

City. NEi is at Booth # 338. Digital prototyping technology developed by NEi enables product engineers<br />

to visualize the response of their designs to structural and thermal loads before investing in physical<br />

prototypes and test programs. This means changes and optimization can occur early in the development<br />

process saving time, money and improving the ability to meet regulatory requirements like FDA<br />

approval.<br />

Features of interest to product developers include new virtual testing tools like Automatic Impact<br />

Analysis and Drop Test (AIA), Design Optimization, Automatic Surface Contact Generation<br />

(ASCG), and Hyperelastic and Composite Material modeling. AIA is used in a variety of areas<br />

including military projectiles, product packaging and drop testing of consumer electronic products like<br />

cellphones and laptops. Design Optimization finds solutions for design problems that are complex<br />

because of competing<br />

parameters, for example, structures that must be both strong and light. ASCG<br />

provides real world fidelity in modeling<br />

assemblies. Hyperelastic capabilities allow modeling of rubber<br />

like materials.<br />

Click here to return to Contents<br />

Siemens PLM Software Announces Siemens PLM Day Korea<br />

2 June 2008<br />

Siemens PLM Software announced ‘Siemens PLM Day’ Korea, the annual user conference to be held<br />

June 10, at the Grand Intercontinental Hotel in Seoul, Korea.<br />

Siemens PLM Software will unveil the next big breakthrough in digital product development<br />

with<br />

synchronous technology, the PLM industry’s first-ever history-free, feature-based modeling technology<br />

that provides users with up to 100 times faster design experience than ever before.<br />

The company will also launch NX 6, the latest version of it digital product development<br />

software that<br />

provides features driven from synchronous technology and new versions of the complete Velocity<br />

Series portfolio, including Solid Edge software with synchronous technology.<br />

Velocity Series is the PLM industry’s first comprehensive, preconfigured portfolio of digital product<br />

Page 22

<strong>CIMdata</strong> PLM Industry Summary<br />

design, analysis, manufacturing and data management software for the mid-market. The portfolio, which<br />

includes Solid Edge, Femap®, Teamcenter Express, and NX CAM Express, was introduced two-and<br />

a-half years ago and since then has achieved consistent and strong growth for Siemens PLM Software.<br />

“Siemens PLM Software is proud to provide innovative products based on cutting<br />

edge new technology<br />

to the fast maturing Korean PLM industry,” said Kwon Kyung-Ryeol, vice president and managing<br />

director of Korea operations, Siemens PLM Software. “The new products will greatly enhance our<br />

technology’s ease of use and provide greater performance<br />

for our customers.<br />

“In addition to providing detailed information on synchronous technology, NX6 and<br />

Velocity Series<br />

portfolio, Siemens PLM Day will provide customers an opportunity to share best practices and meet<br />

with our partners to better<br />

leverage PLM investments.”<br />

Attendees will have the opportunity to participate in breakout sessions for Digital<br />

Manufacturing/Collaboration, CAE/Digital Simulation, Digital Product Development, SMB solutions<br />

and Velocity Series.<br />

Siemens PLM Software’s<br />

partners and channels including HP, Z Corp., Sun Microsystems, CITEK<br />

System, SPACE Solution, Cadians System, ISMS, KimiData, and Daoul system will provide insight into<br />

hot trends, strategies, PLM vision and<br />

their respective offerings for the PLM industry including custom<br />

tailored<br />

solutions.<br />

For more information about ‘Siemens PLM Day’ and to register please visit http://www.ugs.co.k r.<br />

Click here to return to Contents<br />

‘Welcome Beyond’ at DEVCON 2008,Dassault Systèmes’ Annual Technology & Developers’<br />

Conference, June 17 & 18, 2008<br />

5 June 2008<br />

Dassault Systèmes (DS) announced the dates of its eighth annual DEVCON Conference, where<br />

developers, managers and partners will meet, learn and exchange about the future of 3D and PLM.<br />

DEVCON will take place at Paris’ Palais des Congrès on June 17-18, 2008.<br />

The world of PLM is changing with the arrival of PLM 2.0 (‘PLM Online for All’) and Web 3D.<br />

DEVCON attendees will gain valuable information about these major breakthroughs through the PLM<br />

Technology Showcase, in-depth looks into Dassault Systèmes PLM 2.0 open and Web-based scalable<br />

platform, V6, as well as its first release just announced on May 29, V6R2009. Keynotes<br />

providing<br />