Stone-Wash Treatment for Denim Garments

Stone-Wash Treatment for Denim Garments

Stone-Wash Treatment for Denim Garments

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LIPARI PUMICE AND THE HISTORY OF JEANS<br />

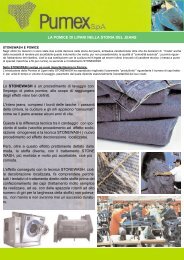

STONE WASH AND PUMICE<br />

In the last three decades there have been two decisive events in the history of jeans, both of which were not only driven by the influence of fashion,<br />

but also by the need to make denim garments more com<strong>for</strong>table and hence widely acceptable, <strong>for</strong> though denim was renowned <strong>for</strong> being<br />

extremely com<strong>for</strong>table, they were in reality not so. The first event regarded the abandoning of rivets, with the substitution of stitching, a problem<br />

which was solved with the help of great technical ef<strong>for</strong>ts (and special sewing machines), the second was STONE WASH.<br />

Pumice plays an important role in STONE WASHING. The introduction of Lipari Pumice in the STONE WASH process has above all improved<br />

productivity, i.e. the number of garments processed in a given time and wash volume, the parameters of which essentially determine the acceptability<br />

of the cost.<br />

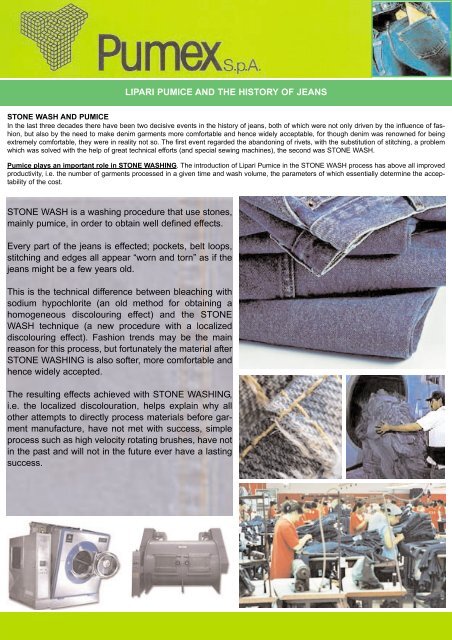

STONE WASH is a washing procedure that use stones,<br />

mainly pumice, in order to obtain well defined effects.<br />

Every part of the jeans is effected; pockets, belt loops,<br />

stitching and edges all appear “worn and torn” as if the<br />

jeans might be a few years old.<br />

This is the technical difference between bleaching with<br />

sodium hypochlorite (an old method <strong>for</strong> obtaining a<br />

homogeneous discolouring effect) and the STONE<br />

WASH technique (a new procedure with a localized<br />

discolouring effect). Fashion trends may be the main<br />

reason <strong>for</strong> this process, but <strong>for</strong>tunately the material after<br />

STONE WASHING is also softer, more com<strong>for</strong>table and<br />

hence widely accepted.<br />

The resulting effects achieved with STONE WASHING,<br />

i.e. the localized discolouration, helps explain why all<br />

other attempts to directly process materials be<strong>for</strong>e garment<br />

manufacture, have not met with success, simple<br />

process such as high velocity rotating brushes, have not<br />

in the past and will not in the future ever have a lasting<br />

success.

THE ROLE OF LIPARI PUMICE IN STONE<br />

WASH<br />

As already anticipated, the success of Lipari<br />

Pumice in STONE WASH is essentially due to<br />

the increase in productivity. By using Lipari<br />

Pumice, one can process simultaneously a<br />

large quantity of garments, with an increase in<br />

productivity in the region of 20% to 30% with<br />

respect to pumice from alternative origins,<br />

which are almost always less dense and more<br />

brittle, but also frequently contain a high content<br />

of impurities that end up damaging a certain<br />

number of garments during the washing<br />

process. Hence Lipari Pumice helps decrease<br />

the total cost due to increased productivity,<br />

with less rejects and less rework.<br />

It is however difficult to calculate the<br />

effective consumption of pumice <strong>for</strong> jeans<br />

(kg / per garment), since one needs to<br />

account not only <strong>for</strong> the different garment<br />

size, but one must also take into account<br />

other factors:<br />

- The apparent density, porosity and buoyancy<br />

(or not) of the pumice<br />

- The type of washing machine<br />

- The ratio pumice to material<br />

- Percentage of water used in the machine<br />

washing (the lower the value, the<br />

higher the pumice consumption, and the<br />

faster the process cycle time).<br />

However taking into account the data and<br />

experience of STONE WASH customers,<br />

who find that it is possible to complete 4<br />

to 5 wash cycles with Lipari Pumice,<br />

given the average ratio of pumice to garment<br />

material as 2,5 : 1, and with the<br />

average pair of jeans weighing between<br />

700 gr to 900 gr., it is possible to calculate<br />

an average consumption of 350 gr. of<br />

Lipari Pumice per pair of jeans.