CARIZZMA by R-M - RM-Paint

CARIZZMA by R-M - RM-Paint

CARIZZMA by R-M - RM-Paint

- TAGS

- carizzma

- jp.rmpaint.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

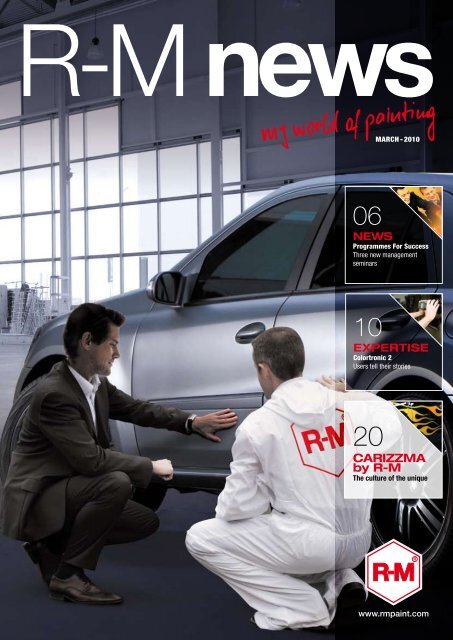

R-M news<br />

MARCH - 2010<br />

06<br />

NEWS<br />

Programmes For Success<br />

Three new management<br />

seminars<br />

10<br />

EXPERTISE<br />

Colortronic 2<br />

Users tell their stories<br />

20<br />

<strong>CARIZZMA</strong><br />

<strong>by</strong> R-M<br />

The culture of the unique<br />

www.rmpaint.com

02<br />

My world of painting<br />

CONTENTS<br />

04 05<br />

08<br />

12<br />

14<br />

20<br />

06<br />

07<br />

10<br />

16<br />

18<br />

22<br />

R-M News is a publication<br />

of the R-M division<br />

of BASF Coatings S.A.S.<br />

F-60676 Clermont Cedex<br />

www.rmpaint.com<br />

NEWS<br />

• Products<br />

A krofill and St o p Filler II: getting the foundation right first…<br />

profiller black: introducing the Grey Shade Concept<br />

• Colours<br />

Leading the way in preparing for the refinish colours of the future<br />

Colortronic 2 : the right colour’s just a click away<br />

• Services<br />

programmes For Success adds three new management seminars<br />

• Training<br />

paintshop Operations Management (Tp 23), a new training<br />

programme offered <strong>by</strong> R-M<br />

EXPERTISE<br />

• S upremetop CP<br />

The ultra scratch-resistant clearcoat<br />

• Colortronic 2<br />

Users tell their stories<br />

ZOOM<br />

• The professionals!<br />

The future’s bright, the future’s R-M<br />

WORLDWIDE<br />

• Export organisation strengthened<br />

• Austin’s panel & paint, “intelligent painting” with On y x HD<br />

• <strong>CARIZZMA</strong> out to conquer the Latvian market<br />

• Honda Body Service Tochigi goes “green” with On y x HD<br />

• Nascar 2009 season, R-M sponsors the Front Row Motorsport team<br />

• partnership with AXA in Spain<br />

• pribor Centar: new importer in Croatia<br />

<strong>CARIZZMA</strong><br />

• <strong>CARIZZMA</strong> <strong>by</strong> R-M: the culture of the unique<br />

• The making of “MTV pimp My Ride”<br />

• A “win-win” partnership<br />

Publication Manager:<br />

Gesine Arend-Heidbrinck<br />

Editor-in-chief: Laurence Rigaux<br />

Redaction: Marie-Laure Pierard<br />

Production: PointVirgule<br />

Photos: Didier Charre, Dingo, DR,<br />

Éric Roger - Point Carré, Christian Schryve,<br />

Fotolia, Régis Grman / MTV, F. Camuzat<br />

For further information please<br />

contact Jessica Morris<br />

tel: +00441244287744

Worked on this issue:<br />

Bird Jonathan, Blyenberg Gerry, Book Juergen, Borrega Rosalind,<br />

Brueggen David, Gaume Christopher, Golek Michael, Huet Philippe,<br />

Huon Frédéric, Itoh Takehito, Jaszowski Susan, Leclerc Thierry,<br />

Noda Yuuki, Parot Patrice, Peizuma Santa, Ricard Roland,<br />

Rogge Nadja, Romanillos Alberto, Schmitt Julia, Schoeps Si<strong>by</strong>lle,<br />

Sekta Velimir, Van Keulen Peter<br />

Product<br />

Offer<br />

My world of painting<br />

Colour<br />

Universe<br />

Programmes<br />

For Success<br />

EDITORIAL<br />

Ian Mooney<br />

R-M Brand Manager UK<br />

« My world of R-M » : <strong>Paint</strong>, Performance, People<br />

Training<br />

Programmes<br />

Ten years from now, R-M will be celebrating its 100th anniversary. But what will<br />

bodyshops look like in 2020? products, services, training and colour-search techniques<br />

are all evolving rapidly. From the moment it was founded, R-M has continually<br />

adapted to the changing needs of its customers. Now, as it was back then, our<br />

“world of painting” is unique in the marketplace. The secret behind it? Our ability to<br />

appreciate the complexity of the business and anticipate the trends to come… But<br />

it can also be traced back to the men and women who work for us, the real key to<br />

our performance. projects such as Supremetop Cp attest to our ability to introduce<br />

innovative developments, worldwide. Beyond the products themselves, we constantly<br />

support our customers in growing their business: <strong>by</strong> providing them with tools that<br />

make their lives easier, such as Colortronic 2, the spectrophotometer that identifies<br />

the right colour at the click of a button; <strong>by</strong> offering them training options (Tp 23) and<br />

new programmes For Success (management seminar) modules which enable them to<br />

keep up with the latest developments in their profession; <strong>by</strong> strengthening our export<br />

organisation, to support importers and our customers wherever they are in the world,<br />

including the emerging markets. Because in our “world of painting”, now more so than<br />

ever before, success can only be achieved through partnership.<br />

?<br />

Did you know?<br />

.... it all began with a duck!<br />

That’s right, a duck... well, OK, a decoy one...<br />

Built in 1896 in Detroit, the Mason Decoy factory became<br />

famous for its high-quality decoys, manufactured in sculpted<br />

wood and painted in a distinctive style.<br />

In 1919, Mason joined forces with Rinshed to form R-M,<br />

which quickly became the largest supplier of repair paints<br />

for the automotive industry….<br />

03

04<br />

News products<br />

ak ro f i l l and St o p filler ii<br />

Getting the foundation right first…<br />

Extreme weather conditions or vandalism can cause severe damage over the entire surface of a vehicle. R-M’s<br />

dual innovation provides a solid foundation upon which to perform repairs.<br />

The solution is R-M’s new two-stage repair system, adapted especially for large surfaces or even<br />

the complete repainting of vehicles. Two names, and two steps: Ak r o f i l l 2k sf primer, combined<br />

with St o p filler ii polyester spray filler.<br />

To start, Ak r o f i l l can be applied to any surface: aluminium, bare or<br />

galvanized steel, old but undamaged paint that is solvent resistant…<br />

for maximum adhesion with minimal surface preparation, it ensures<br />

an excellent base in just one coat. To complete the process, there’s<br />

St o p filler ii polyester filler, designed for convenient spray application.<br />

To further reduce the amount of time needed, Ak r o f i l l and St o p filler ii<br />

can be dried using infra red. The result: exceptional sanding performance.<br />

simplicity, effectiveness, a proven process and results that last and last… these are two products that<br />

will definitely not be forgotten in bodyshop cupboards!<br />

profiller b l a c k<br />

Introducing the Grey Shade Concept<br />

R-M is a company that’s always in tune with market trends and customer expectations and has therefore, expanded the<br />

Profiller range with the launch of Profiller black: the perfect primer filler for optimising the performance of topcoats.<br />

The right preparation is essential if a repair job is to be done<br />

right. Given the success of Profiller g r e y , the tinted primer<br />

filler launched in 2007, R-M has taken that success further<br />

with the launch of Profiller b l A c k , in November 2009.<br />

Easy to use, for enhanced productivity<br />

Just as with Profiller g r e y , the technical advantages are<br />

numerous: Profiller b l A c k is suitable for use in all kinds of<br />

repairs, from small to large areas and at virtually any ambient<br />

temperature. The product is very easy to apply - just two to<br />

three coats are all that are needed, and the flash off times<br />

between coats are just a few minutes until it is matt. Whether<br />

wet or dry, sanding is made easier and a great deal quicker.<br />

Profiller b l A c k is incredibly versatile, so it can be applied<br />

to all kinds of materials: old paint finishes that are resistant<br />

to solvents, bare or galvanized steel or aluminium. However,<br />

it is recommended that Eu r o f i l l is applied beforehand when<br />

repairing bare sheet metal surfaces measuring over 2 cm2 .<br />

The product dries very quickly: just 30 minutes at a<br />

temperature of 60°C or eight minutes when dried using short<br />

wave infrared. Two different hardeners can be used, depending<br />

on the type of repair to be completed: D70, which is suitable<br />

for application at low temperatures or when repairing minor<br />

damage, and D80, for high temperatures and particularly<br />

recommended for larger areas. The mixing ratio for the two<br />

products is the same: 100:25:25.<br />

Grey Shade Concept: all shades of grey, for optimum<br />

colour finishes<br />

The major innovation that comes with this new product,<br />

however, is the ‘Grey shade Concept’: when mixed with<br />

Profiller g r e y in varying proportions, Profiller b l A c k<br />

provides the painter with the ability to mix a wide range of<br />

primer filler shades, from black to<br />

light grey - an innovative solution<br />

that enables the user to get the<br />

most out of all R-M’s colour<br />

topcoats. The two pack primer has<br />

been tested with great success on<br />

the Italian market and, because it<br />

complies with VOC standards, it<br />

has everything needed to become<br />

the bodyshops’ favourite option!

Leading the way in preparing<br />

for the refinish colours of the future<br />

BASF Coatings AG’s colour designers already know<br />

what colours will be adorning tomorrow’s cars! And<br />

these key trends are being followed closely <strong>by</strong> R-M’s<br />

own colour specialists, who are now developing<br />

the corresponding repair solutions.<br />

Don’t despair: despite today’s widespread gloom, the future’s set<br />

to be full of colour! R-M News would like to introduce you to three<br />

major influences in future style, identified for the European market<br />

<strong>by</strong> colour designers Eva Höfli and Mark Gutjahr.<br />

“Patrons of the earth”<br />

Environmental subjects are gaining ground, with a new twist:<br />

no longer do luxury and elegance have to contradict people’s<br />

environmental attitudes. In the world of colour, this<br />

translates to a rise in importance of pastel tones,<br />

Eva Höfli and Mark Gutjahr - BASF Coatings AG’s colour designers<br />

With Colortronic 2,<br />

the right colour’s just a click away<br />

Recognised as a pioneer in the world of refinish<br />

paint colour technology, R-M introduced the portable<br />

spectrophotometer to the world of automotive repairs<br />

as long ago as 1995. A new, integrated version -<br />

Colortronic 2 - has just been launched, meeting<br />

the needs of every bodyshop.<br />

state-of-the-art technology applied to getting the colour absolutely<br />

right: with its software integrated into shop Master or Color<br />

Explorer 2, this tool, which comes with a user-friendly interface,<br />

makes it easier than ever to identify the right colour and select the<br />

right formula. All that’s left to do then is to mix the bases.<br />

Easy to handle, robust and highly portable, the tool is designed<br />

to serve all kinds of organisations and cope with the demands of<br />

every bodyshop. Intuitive and extremely simple to use, it enables<br />

the correct colour to be identified in an instant with<br />

News Colours<br />

from apricot to shades of grey and even beige, as well as<br />

warm, discreet greens and browns.<br />

“The pleasure of experimentation”<br />

Experimenting in the quest for pleasure and boldness will never<br />

go out of fashion. Daring colours such as garish yellows or<br />

combinations of pink and intense red; extraordinary chromatic<br />

changes; chameleon effects or glittering finishes taken to the<br />

extreme in ice blue and deep violet... the way technology is<br />

nowadays, practically anything goes.<br />

“Beyond silver”<br />

Black, white, anthracite… colour is the new material, with<br />

technical refinement giving way to sensual moments and the<br />

pleasure of touching. Warm whites, intense blacks, powerful<br />

changing effects and brilliant sparkles are the predominant<br />

notes of this universe.<br />

just the touch of a button, thanks to its triple-angle reading<br />

technology. The result: precise measurements on metallic<br />

and pearl finishes and complex special effects. The users are<br />

given guidance in selecting the right variant, no longer having to<br />

trust their own eyes or search for the colour code on the vehicle.<br />

Think of all the mistakes that eliminates!<br />

In the blink of an eye, Colortronic 2 provides access<br />

to its extensive and regularly updated colour<br />

database, informed <strong>by</strong> the latest findings<br />

from bodyshops which can be stored<br />

so as to serve as a reference. No<br />

more lost time or defects:<br />

how’s that for a way to<br />

boost profitability?<br />

05

06<br />

News Services<br />

Programmes For Success adds<br />

three new management seminars<br />

Anyone looking to manage their paint shop in a more efficient,<br />

profitable way will quickly discover that it’s not that easy.<br />

That’s reason enough for R-M to develop training modules<br />

designed for business owners, managers and bodyshop supervisors.<br />

Designed in conjunction with top sector<br />

specialists who share their experience<br />

and expertise, the programme consists<br />

of three, 2-day modules, each designed<br />

to improve participants’ understanding<br />

of the winning theories and practices in<br />

a friendly atmosphere that favours<br />

sharing R-M’s fundamental values. The<br />

programme focuses on three main areas:<br />

Module 1: “Improving operational<br />

performance”<br />

If you want to hold your own in a fiercely<br />

competitive market, it’s essential to have<br />

the right organisation. This module offers<br />

participants a global vision of how to get<br />

their bodyshops operating at optimal<br />

levels, <strong>by</strong> looking at the optimisation<br />

of paintwork processes, the application<br />

of key performance indicators, the<br />

analysis of costs and the profitability<br />

threshold. The human aspects also need<br />

to be considered, especially if you’re<br />

a manager. With this in mind, the seminar<br />

addresses issues such as assigning<br />

roles to each member of the team (from<br />

the receptionist to the technicians and<br />

supervisors) and motivational techniques.<br />

At the end of the seminar, participants will<br />

have a global vision of how to manage<br />

the painting process as well as the<br />

correct use of equipment and workflows,<br />

while not forgetting optimisation of the<br />

workspace, workforce and profitability.<br />

Module 2: “Key Performance<br />

Indicators”<br />

Though essential to achieving profitability<br />

in any business, key performance<br />

indicators (kPIs) are often underestimated<br />

in bodyshops.<br />

Experienced consultants have developed<br />

this module with a view to helping<br />

management better understand company<br />

mechanisms, to improve both efficiency<br />

and profitability.<br />

Theory and practical exercises follow<br />

on from each other as participants learn<br />

to develop and track kPIs. A case study<br />

subsequently serves as a prelude to<br />

a Q&A session, during which participants<br />

are invited to share their experiences.<br />

By the end of the course, those taking<br />

part will be better equipped to apply<br />

their knowledge and ultimately to boost<br />

profitability.<br />

Module 3: “Introduction to marketing<br />

techniques”<br />

Marketing is becoming increasingly<br />

important in the world of vehicle repairs.<br />

It is with this in mind that R-M’s marketing<br />

people developed this third module.<br />

It provides easy access to proven<br />

tools for effective market analysis and<br />

development of strategic marketing plans.<br />

The seminar introduces delegates to<br />

modern marketing and its key aspects:<br />

the “five Ps” (product, price, place,<br />

promotion and people), the marketing<br />

mix, communications and working<br />

successfully with agencies.<br />

It enables managers or anyone with<br />

management responsibility to analyse<br />

their positioning, catchment area and<br />

those of their competitors, and of course<br />

their customers’ activities, before moving<br />

on to develop an action plan. Using this<br />

knowledge, participants will be better<br />

equipped to attract new business and<br />

strengthen their image as professionals<br />

in the body repair business.<br />

“Having attended this seminar, I was able to reorganize my<br />

bodyshop <strong>by</strong> following key performance indicators and it enabled<br />

me to increase repair productivity <strong>by</strong> 30% !”<br />

Massimo Siena, the owner of R-M bodyshop “IL MAGO” - Italy.

<strong>Paint</strong>shop<br />

Operations<br />

Management<br />

(TP 23),<br />

a new training<br />

programme<br />

offered <strong>by</strong> R-M<br />

How can you improve the performance<br />

and profitability of your paintshop?<br />

In today’s highly competitive market,<br />

that’s a legitimate question any<br />

manager in the auto repair business<br />

should be asking. To help you get a<br />

clearer picture, R-M has introduced a<br />

two-day training seminar dedicated<br />

specifically to this subject.<br />

Help team leaders and paintshop<br />

managers boost efficiency and<br />

performance, using the right tools:<br />

that’s what this new course sets out<br />

to do. To achieve this effectively,<br />

a specialist trainer addresses each of the<br />

paint business’s most essential points,<br />

like monitoring trends in the refinish<br />

paint market, evaluating the potential<br />

of the equipment used, analysing<br />

the paintshop’s performance levels,<br />

understanding the economic influence<br />

of repair and painting operations, as well<br />

as assessing service quality to increase<br />

customer satisfaction.<br />

As always in R-M training courses,<br />

participants are not expected to just sit<br />

back and listen passively to the trainer.<br />

Learning is supported <strong>by</strong> way<br />

of innovative educational methods,<br />

such as real-life role playing, practical<br />

exercises conducted either in groups<br />

or individually, in addition to - and above<br />

all - the sharing of experience.<br />

Gaining a clear operational view<br />

of painting processes<br />

At the end of the course, each<br />

participant will have been given sound<br />

advice and tools to apply in their<br />

garage, thus significantly improving<br />

business performance, materials and<br />

equipment management, as well as the<br />

management of human resources.<br />

Realistically, that means they will now<br />

be able to:<br />

- evaluate the potential of their<br />

equipment, with a view to making<br />

better use of it,<br />

News Training<br />

- put in place key performance indicators<br />

to measure and improve<br />

the performance of painting processes,<br />

- calculate the benefits of these<br />

processes and use the calculation<br />

as a tool to optimise the consumption<br />

of materials, for example and,<br />

- employ the right approaches in respect<br />

of quality and, working together with<br />

their staff, make the changes necessary<br />

to increase customer satisfaction.<br />

Naturally, this seminar is designed mainly<br />

for team leaders or paintshop managers,<br />

but managers from other departments,<br />

such as aftersales, are also welcome.<br />

The sessions are an excellent way<br />

to get a clear operational overview<br />

of your business’s painting activities.<br />

07

08<br />

Expertise<br />

Supremetop cp<br />

The ultra scratch-resistant clearcoat<br />

Developed in response to a request<br />

from Toyota, Supremetop CP is<br />

the result of an extraordinary joint<br />

development project conducted on an<br />

international scale <strong>by</strong> BASF employees<br />

in Japan, Germany, France and the<br />

United States.<br />

When it comes to finish quality, vehicle<br />

owners are becoming increasingly<br />

demanding. Unwilling to tolerate even<br />

minor damage caused <strong>by</strong> stone chips,<br />

automatic car wash brushes or road salt.<br />

Aware of this fact, a number of leading<br />

automotive manufacturers - including<br />

Toyota - now offer their vehicles with the<br />

option of “scratch-resistant clearcoat”.<br />

However, work still needed to be done<br />

to guarantee the same level of quality<br />

for repairs. To help remedy the situation,<br />

Toyota asked BAsf to develop a new<br />

clearcoat that would enable bodyshops<br />

to provide the same level of scratch<br />

resistance, even after a car has been<br />

repainted.<br />

Guaranteed, long-lasting durability<br />

“Toyota first asked us to work on this<br />

project two years ago”, explains si<strong>by</strong>lle<br />

schoeps, project manager at BAsf<br />

Coatings’ Advanced Technology laboratory<br />

in Münster. The bar was placed pretty high,<br />

with the customer demanding a clearcoat<br />

that would be extremely scratch-resistant,<br />

even after extensive exposure to the sun’s<br />

rays and to bad weather. We therefore<br />

had to put our samples through a series<br />

of accelerated ageing tests in the<br />

laboratory, before moving on to test<br />

their resistance to scratches”. This dual<br />

approach involved BAsf staff in Germany,<br />

france and Japan working together.<br />

Toyota needed to know that it had a global<br />

solution capable of meeting the needs of<br />

all markets, anywhere in the world. Our<br />

colleagues in the Us concentrated on<br />

developing the changes required to adapt<br />

the clearcoat to the specific constraints<br />

of Californian legislation.<br />

Extraordinary cooperation,<br />

for optimal results<br />

At BAsf Japan, Takehito Itoh, an expert<br />

working in the product laboratory, was

pivotal when it came to dealing with<br />

the client. “My role was to serve as an<br />

interface between the customer and<br />

the BAsf Coatings development team.<br />

This involved interpreting exactly what<br />

it was Toyota wanted, ensuring that the<br />

development team fully understood<br />

this, and then ‘translating’ the technical<br />

information so the people at Toyota had<br />

a clear grasp of the product we<br />

developed based on state-of-the-art<br />

technology.<br />

In this respect, my responsibilities<br />

included evaluating the various samples<br />

submitted for testing and determining<br />

to what degree they met the customer’s<br />

expectations”. The development,<br />

therefore, called for seamless<br />

cooperation between everyone involved<br />

in the project. “We really did work<br />

“hand in hand’ on this”, stresses si<strong>by</strong>lle<br />

schoeps, “in complete harmony, despite<br />

the differences in culture, language…<br />

and time zones”.<br />

Albeit rather challenging, the result was<br />

worth it. With su p r e m e t o p CP, R-M is<br />

now in a position to offer a clearcoat<br />

that fulfils Toyota’s specifications to the<br />

letter: a level of gloss comparable to<br />

that of a new vehicle, truly hardwearing,<br />

suitable for use on minor repairs and fully<br />

compliant with VOC legislation.<br />

Expertise<br />

Compatible with On y x HD,<br />

Supremetop CP is easy to<br />

apply with a spray gun (mixing<br />

ratio: 100g: 40g: 20g with<br />

the new H 802 hardener<br />

and a standard thinner).<br />

09<br />

Two coats should be applied with<br />

a flash off time of 3 minutes<br />

between applications. The product<br />

dries in 40 minutes at 60° or can be<br />

dried in just 10 minutes using infrared<br />

and has excellent polishing performance.

10<br />

Expertise<br />

Colortronic 2<br />

Users tell their stories<br />

Finding exactly the right colour,<br />

immediately, is now possible, thanks<br />

to Colortronic 2. The challenge of<br />

identifying the correct colour match<br />

- a problem faced <strong>by</strong> many<br />

bodyshops on a daily basis - will<br />

soon be no more than an unpleasant<br />

memory. Read on to discover how!<br />

Getting the colour right is the “be-all and<br />

end-all” of body repair customer satisfaction<br />

because it’s the first thing people notice.<br />

However, as any automotive refinisher will<br />

tell you, achieving the correct match for a<br />

vehicle’s original colour, when performing a<br />

repair is not always as simple as it sounds.<br />

Whether you opt to conduct a database<br />

search or make a visual assessment using<br />

colour cards, the result will often be… a<br />

waste of time and a negative impact on<br />

productivity. Not to mention the added<br />

potential of random mistakes anyone can<br />

make inadvertently, potentially reducing<br />

the profitability of the repair to zero.<br />

A tool optimised for paintshops<br />

It should come as no surprise therefore,<br />

to find that Colortronic 2 - our second -<br />

generation portable spectrophotometer<br />

- has been so enthusiastically received<br />

<strong>by</strong> users. “We originally introduced this<br />

technology among distributors in 1995”,<br />

explains Thierry Leclerc, Technical sales<br />

support Manager for france, “and<br />

they continue to use it to this day”. The<br />

second-generation device benefits from<br />

the accumulated experience of users and<br />

the enhancements introduced in terms of<br />

integration. The result? A compact, robust,<br />

user-friendly tool perfectly suited to the<br />

FABRICE GRAND - Bellevue Bodyshop - France<br />

needs of anyone working in a paint shop.<br />

Easy to carry around, the device enables<br />

users to take measurements any time,<br />

anywhere, under any lighting conditions.<br />

simply place the device on the vehicle and<br />

press the button. Back at the bodyshop,<br />

the device can be connected to a PC<br />

equipped with either shop Master or Color<br />

Explorer 2 software, which will then check<br />

the database to find the option that best<br />

matches the colour analysed. The database<br />

in question, which contains almost 200,000<br />

references, is updated three times a<br />

year. Users can also perform a search<br />

of jobs previously performed within the<br />

bodyshop. In cases where exactly the right<br />

colour cannot be identified, the program<br />

automatically adjusts the formula to match<br />

it. since it can be connected directly to the<br />

scale, the correct mix of tinters can then

... in the field<br />

In the Ukraine and Germany, painters are currently learning how to use the device and,<br />

as these two testimonials confirm, they like it.<br />

be determined. Just imagine how many<br />

problems that eliminates! No longer do<br />

painters have to make decisions that could<br />

have serious consequences, based only<br />

on what their eyes tell them. The user is<br />

guided step <strong>by</strong> step through a process<br />

that - thanks to the intuitive, user-friendly<br />

interface - couldn’t be easier.<br />

“No more pain”<br />

Located in Condat-sur-Vienne, in central<br />

france, Carrosserie Bellevue assumed<br />

the role of pioneer when, in April 2009, it<br />

became the first garage in the country to<br />

use the Colortronic 2 spectrophotometer.<br />

since then, no one has been more satisfied<br />

than owner Rodolphe Pouvreau. “When<br />

you work on an average of 25 cars per<br />

week, cutting colour matching time <strong>by</strong><br />

as little as 15 minutes on each of them<br />

• Pavel Matskevich,<br />

paintshop manager<br />

for IP Matskevich in<br />

Simferopol, Ukraine:<br />

“The ability to identify colours accurately is<br />

something that vehicle painters are expected to<br />

do more and more. For that reason, we are very<br />

confident that we have made a good investment<br />

in Colortronic 2. The device’s interface has clearly<br />

been developed with painters in mind. What’s<br />

more, it’s extremely easy to use. That translates<br />

into time savings, because the device more or<br />

less instantly detects the exact match<br />

to the original colour, or that closest to it.”<br />

enables significant savings to be made in<br />

terms of overall manpower. What’s more,<br />

it’s highly reassuring to know that you<br />

no longer have to rely on “the painter’s<br />

eye”. Thanks to the use of electronic<br />

measurement, we are able to virtually<br />

eliminate colour matching errors. In my<br />

experience, the spectrophotometer has<br />

proven itself to be extremely easy to<br />

handle and use, a fact confirmed <strong>by</strong> our<br />

painters from the moment they picked it<br />

up.” An opinion echoed <strong>by</strong> fabrice Grand,<br />

one of the bodyshop’s four painters:<br />

“The device is so easy to use. Once the<br />

three green LEDs light up, you know the<br />

measurement has been taken. Before<br />

the days of Colortronic 2, we would have<br />

to take the vehicle out into the daylight,<br />

often working as a team of two to identify<br />

the colour using colour cards. As you can<br />

RODOLPHE POUVREAU<br />

Bellevue Bodyshop’s Manager - France<br />

Expertise<br />

• Albin Riemer,<br />

bodyshop worker in<br />

Duisburg, Germany<br />

“We’ve simply stopped worrying<br />

now that we use Colortronic 2<br />

and we use it whenever and<br />

wherever we can!”<br />

imagine, on days when it was raining or the<br />

light wasn’t good enough, that was a real<br />

pain. With Colortronic 2, that’s a pain we<br />

no longer have to endure. We can take the<br />

measurements either in the garage or the<br />

booth and be sure of the result.<br />

11

12<br />

Zoom<br />

Success Story<br />

The professionals!<br />

Bristol street Motors is a long<br />

established franchised main dealer<br />

network that continues to build an<br />

outstanding reputation for the highest<br />

level of service, particularly through its<br />

ten bodyshops, which provide national<br />

coverage from Dunfermline in scotland<br />

down to Gloucester in the south West.<br />

Now, thanks to the hard work put in <strong>by</strong><br />

Calum Thomson and the Bristol street<br />

Motors senior management, together<br />

with Mick Gilman and the R-M team,<br />

the entire network has been smoothly<br />

an successfully converted to R-M<br />

automotive refinish paint technology.<br />

for any bodyshop to convert from one<br />

established paint brand to another it<br />

can be a traumatic time, to complete<br />

the change over to a new paint brand<br />

for an entire network could cause some<br />

trepidation, so R-M News went to visit<br />

John Mills the Bodyshop Manager of<br />

Bristol street Motors in Banbury to see<br />

how the conversion was running.<br />

With more than 35 years industry<br />

experience, John Mills has been through<br />

a lot of paint changes in his career<br />

and knows, better than most of us, the<br />

potential problems that can occur, so we<br />

asked him how he thought the change<br />

over was managed.<br />

“I was extremely impressed with the<br />

smooth transition from the previous<br />

paint brand to R-M. Here at the Banbury<br />

branch Andy kidson and Lee Patman<br />

worked very hard with our painters, and<br />

the R-M distributor, Milton keynes <strong>Paint</strong><br />

and equipment has provided all the<br />

support we needed”.<br />

John Mills went on to say “I’m sure this<br />

decision will be very good for the ten<br />

bodyshops in the Bristol street Group,<br />

we have seen significant improvements<br />

in both paintshop performance and the<br />

painters are achieving consistently high<br />

standards of finish quality, though we<br />

have to admit that the new paint system<br />

has fitted in so well, it feels like we’ve<br />

had R-M here for ever”.<br />

R-M News asked the Technical Team<br />

Manager and National Head Trainer,<br />

Mick Gilman how he felt the installation<br />

programme had gone and he confirmed<br />

“I’ve had terrific feedback from all<br />

Mick Gilman<br />

Technical Team Manager<br />

and National Head Trainer<br />

Mick Gilman and his team complement the professionalism synonymous with<br />

Bristol Street Motors, converting the bodyshop network to R-M.<br />

the shops and I believe we have<br />

delivered the conversion programme,<br />

professionally, efficiently and bang on<br />

schedule. However, we mustn’t forget<br />

that to initiate a programme like this it<br />

relies on both parties working together<br />

and Calum Thomson and the Bristol<br />

street senior Management have been<br />

exemplary in their professionalism and<br />

a pleasure to work with”.

since leaving school, Ian Mooney<br />

has worked in the automotive refinish<br />

industry, starting his career as an<br />

Apprentice <strong>Paint</strong>er and working his<br />

way up through a number of key roles<br />

to become one of the most successful<br />

Regional sales Managers in the Uk.<br />

Ian’s knowledge and experience at<br />

many levels from the practical aspects<br />

of running a bodyshop through<br />

distribution and the paint manufacturing<br />

industry, together with his extraordinary<br />

enthusiasm and passion for this industry,<br />

makes him perfectly qualified to manage<br />

R-M Automotive Refinish in the Uk.<br />

R-M News met up with Ian Mooney, soon<br />

after his appointment and asked him<br />

what plans he had for R-M in the Uk.<br />

After getting off to a great start <strong>by</strong><br />

winning some important group and PDI<br />

business, together with fantastic support<br />

through dynamic and forward looking<br />

distribution, Ian will continue<br />

to grow the R-M business <strong>by</strong> talking<br />

to and listening carefully, to R-M<br />

distributors, end users and key industry<br />

Ian Mooney<br />

UK Brand Manager<br />

The future’s bright,<br />

the future’s r-m<br />

R-M’s recently appointed UK Brand Manager Ian Mooney<br />

gets straight to the heart of the matter…<br />

decision makers, so we can continue to<br />

improve on R-M’s offer in the Uk, with<br />

products, services and technical support<br />

that meets or even exceeds the needs of<br />

all our customers.<br />

The best team in the industry<br />

I consider myself very fortunate to<br />

work with a well established, highly<br />

committed, enthusiastic and professional<br />

team at R-M, which I truly believe to be<br />

the best in the industry. This has been<br />

reflected in the continual growth of the<br />

R-M brand as our customers recognise<br />

not only the leading edge product<br />

technology that is synonymous with the<br />

brand, but also the level of service and<br />

professionalism we have to offer.<br />

Our customers value distribution…<br />

R-M Distribution is acknowledged<br />

amongst the best in the industry and<br />

I know that our customers value their<br />

services, not simply due the fact that<br />

they support the brand, but also in<br />

the way they work together with our<br />

customers to help them to remain<br />

profitable. The high levels of service and<br />

support provided <strong>by</strong> R-M’s Uk distributors<br />

Zoom<br />

is playing a vital role in the Uk market<br />

and I will be working closely with them to<br />

help ensure that between us we provide<br />

our customers with the very best value for<br />

money.<br />

Maintaining profitability<br />

We want our customers to be profitable,<br />

that’s why we offer a complete range of<br />

services together with our distribution<br />

partners to assist our customers in<br />

maintaining the best possible profit<br />

margins.<br />

Working with approvals<br />

Although R-M has a significant number<br />

of excellent OEM and work provision<br />

approvals, my aim is to enhance these in<br />

the Uk with new opportunities as well as<br />

increasing R-M’s market share through<br />

the current portfolio.<br />

13

14<br />

Worldwide<br />

Rosalind Borrega was recently<br />

appointed to the position of Commercial<br />

sales support Manager for export to<br />

southern and Eastern Europe, as well<br />

as Russia, North-West Europe and<br />

Northern Africa. At the same time,<br />

Peter Van keulen was asked to head<br />

up Business Development in the Middle<br />

East. Peter and Rosalind possess indepth<br />

knowledge of the countries which<br />

will be their responsibility as well as<br />

the entire R-M product range, having<br />

both been picked from the “Global<br />

Trainer” team. “The challenge is a big<br />

one”, says Rosalind Borrega, “given<br />

that I will be dealing with 30 countries,<br />

each of which has its own culture,<br />

legislation and customs. Our task will<br />

be to support importers in adapting<br />

what we offer to the specific needs<br />

of their markets, while also providing<br />

them with the tools and materials they<br />

need. Our strategic goal will be to<br />

support our customer service in these<br />

countries, which promise enormous<br />

Export<br />

Export organisation strengthened<br />

Always looking to support its customers wherever they are in the world, while developing its business<br />

in countries with strong growth potential, R-M is enhancing its export organisation significantly.<br />

Rosalind Borrega - Commercial Sales Support Manager - Export Peter Van Keulen - R-M Business Development Middle East<br />

potential for the future and to achieve<br />

that, I will be organising working<br />

groups in each of them. The emphasis<br />

will be on reinforcing their knowledge<br />

of the market, helping them build a<br />

strategy that takes into account future<br />

developments, and implementing viable<br />

action plans. Beyond that, our role<br />

will involve providing feedback to the<br />

Product Managers and acting as the<br />

“voice of exports”, a voice that needs<br />

to be heard from the moment new<br />

products are being developed.”<br />

Working hand in hand<br />

with local experts<br />

After years of working in the field, Peter<br />

Van keulen has now settled in Dubai.<br />

Equipped with both technical and sales<br />

skills, he knows how to talk to the<br />

users and even, when necessary, to<br />

roll up his sleeves and handle a spray<br />

gun. “I’m going to be working closely<br />

with the region’s importers to grow the<br />

business and attract new customers”,<br />

he explains. “Our local partners are the<br />

people who will be able to open new<br />

doors for us. Our product portfolio is<br />

fully approved <strong>by</strong> practically all the<br />

major vehicle manufacturers, throughout<br />

the world. That means that, in theory at<br />

least, we can approach any importer we<br />

want to and from a technical point of<br />

view, there are no longer any barriers”.<br />

In developing R-M’s business in the<br />

Middle East, Peter Van keulen will be<br />

placing a lot of faith in the On y x HD<br />

range of paints, which has already<br />

received a warm welcome in the region,<br />

proving its quality even amid conditions<br />

of extreme heat and humidity. But just<br />

having the right product is not enough<br />

- it’s also important to know that you<br />

have the support of a local organisation<br />

capable of telling people about them<br />

and teaching people how to use them.<br />

“My prime objective will be to build a<br />

regional team of trainers”, says Peter.<br />

“A strong local organisation is what<br />

will enable us to make our mark”.

South Africa<br />

Austin’s Panel<br />

& <strong>Paint</strong>:<br />

“intelligent<br />

painting”,<br />

with On y x HD<br />

The story of a successful<br />

partnership with Toyota,<br />

Africa’s biggest vehicle<br />

manufacturer… based on optimized<br />

productivity and complete<br />

respect for the environment,<br />

thanks to R-M’s On y x HD<br />

Don Austin and Gavin Austin - Austin’s Panel & <strong>Paint</strong><br />

Don Austin can say with some<br />

justification that he leads a colourful<br />

life - more than 25 years have passed<br />

since he arrived in south Africa from<br />

Zimbabwe and he has managed to<br />

overcome pretty much all the challenges<br />

one can expect to be faced with in the<br />

world of automotive paint…<br />

The challenge of express repairs<br />

Don acquired his belief that standards<br />

in terms of cleanliness and the<br />

environment should be strictly observed<br />

while working in the custom paintshop,<br />

Colour Creations. At no time has he ever<br />

grown tired of picking up a spray gun<br />

and practising what might be termed<br />

“intelligent painting”. Constantly aware<br />

of the need to respect the environment<br />

in its activities, his company - Austin’s<br />

Panel & <strong>Paint</strong> - is currently taking on<br />

the challenge of providing express<br />

repairs, in association with the Toyota<br />

factory in Prospecton, in the suburbs of<br />

Durban. His new express repair centre<br />

subcontracts for the new paintshop<br />

set up <strong>by</strong> Toyota in 2007, allowing for<br />

complete independence in conducting<br />

minor body paint repairs.<br />

Respect for the environment and<br />

precision in colour: On y x HD has it all<br />

Over the past two years, his garage<br />

has converted to use R-M’s On y x HD<br />

waterborne paint. “As far as I know”,<br />

says Don, “we were the first people in<br />

south Africa to use On y x HD waterbased<br />

paint. And since we began, we have<br />

really appreciated the technical support<br />

provided <strong>by</strong> the people at R-M”. Working<br />

in an environment that complies fully with<br />

the strict standards in place as regards<br />

cleanliness, his garage has succeeded<br />

in obtaining IsO 14001 environmental<br />

certification. “We are extremely proud<br />

to have been awarded this certification,<br />

which also enables us to maintain an<br />

excellent working relationship with<br />

Toyota”. But that’s not the only benefit<br />

Worldwide<br />

that comes from using On y x HD,<br />

if Gavin Austin - Don’s son -<br />

is to be believed. According to him,<br />

On y x HD is the most colour accurate<br />

paint he has ever worked with. “The<br />

matches between On y x HD colours and<br />

those formulated for Toyota models are<br />

almost always perfect”, says Gavin.<br />

A mobile unit for last-minute repairs<br />

With a view to speeding up operations,<br />

the company has invested in an M204<br />

short-wave infrared paint curing arch,<br />

as well as a new, fully equipped paint<br />

booth. The garage repairs an average<br />

of over ten vehicles per day, at a rate<br />

of two-and-a-half hours for each, from<br />

preparation right through to finishing.<br />

To increase satisfaction levels at<br />

Toyota, Austin has also developed a<br />

mobile repair unit capable of operating<br />

autonomously. Constantly parked on<br />

the docks in Durban, the unit makes it<br />

possible to quickly perform small repairs<br />

on cars destined for export.<br />

A terrific success story, especially when<br />

one considers that Toyota is the largest<br />

automobile manufacturer on the African<br />

continent and south Africa’s leading<br />

exporter!<br />

15

16<br />

Latvian<br />

<strong>CARIZZMA</strong> out<br />

to conquer the<br />

Latvian market<br />

After the success of the “Carizzmatic”<br />

Audi TTs at the 2009 Automechanics<br />

exhibition, R-M and <strong>CARIZZMA</strong><br />

are gradually making progress<br />

in the Latvian market.<br />

following appearances in Paris,<br />

London, Dubai and Essen, two of the<br />

four AUDI TTs painted with <strong>CARIZZMA</strong><br />

made a stopover in Riga in the spring<br />

of 2009, during their tour of the world’s<br />

automotive exhibitions. The very least<br />

that can be said is that their brilliant<br />

colours left no visitor indifferent.<br />

Attendance on the stand of RG Grupa,<br />

the R-M importer, reached record levels<br />

as the two stars were exhibited during<br />

the four days of the show.<br />

Inspired <strong>by</strong> subjects dear to fans of<br />

tuning, the “Hot Rod” and “Nascar”<br />

models were the ones displayed at this<br />

exhibition, to demonstrate the infinite<br />

possibilities that <strong>CARIZZMA</strong> <strong>by</strong> R-M<br />

colours offer. “The duo was definitely<br />

the major attraction at the show, and<br />

many of the visitors told us that they<br />

IN BRIEF<br />

Worldwide<br />

had never before seen cars so tastefully<br />

painted” said an enthusiastic santa<br />

Peizuma, director of RG Grupa. This was<br />

the first time that R-M had appeared<br />

at this exhibition, which is held every<br />

four years in Riga, Latvia: an event that<br />

attracts around 35,000 visitors, including<br />

automotive professionals, tuning<br />

specialists and the general public.<br />

Fruitful contacts<br />

following this success, RG Grupa is<br />

to work on the launch of <strong>CARIZZMA</strong> in<br />

the Latvian market, supported <strong>by</strong> R-M.<br />

Amidst a difficult economic climate, the<br />

importer is introducing initiatives which<br />

may bear fruit in the spring and summer<br />

of 2010. “The customization market is<br />

highly active in Latvia”, explains santa<br />

Peizuma. “The show enabled us to make<br />

European deal with the Fiat group<br />

(Fiat, Alfa Romeo, Lancia and Fiat Professional)<br />

BAsf Coatings is already an OEM<br />

paint supplier for the fiat Group and<br />

is now being recommended, on a<br />

European level, as the group’s supplier<br />

of refinishing paints. The agreement<br />

builds on similar ones signed in Italy at<br />

the beginning of 2009. The deal will see<br />

BAsf Coatings named as the official<br />

supplier of refinish paint for the fiat<br />

group’s aftersales network in Europe,<br />

useful contacts. We have now begun<br />

collaborating with a specialist who works<br />

for Brabus, the specialist manufacturer<br />

of custom Mercedes. He was invited to<br />

Clermont in france for a “VIP” visit and<br />

is currently using <strong>CARIZZMA</strong> to paint<br />

a handsome collector’s Mercedes.<br />

Projects 2010<br />

Elsewhere, we are looking to form<br />

partnerships with constructors, as R-M<br />

has done in france with the distributor<br />

Peugeot Martin. We are in contact with<br />

Inchcape Motors, a major importer<br />

working with ford, Mazda, BMW, etc.<br />

Lastly, we are now negotiating with the<br />

Latvian TV, which is planning to launch<br />

a programme like “Pimp My Ride”. for<br />

us, that could serve as an outstanding<br />

marketing tool.”<br />

which includes the fiat, Alfa Romeo,<br />

Lancia and fiat Professional brands.<br />

In addition to products, R-M will be<br />

offering all the fiat network’s painting<br />

specialists a complete range of<br />

services (technical and sales training,<br />

management consultancy, how to<br />

develop their bodywork painting<br />

business), as well as its new<br />

Colortronic 2 spectrophotometer.

Japan<br />

Honda Body<br />

Service Tochigi<br />

goes “green”<br />

with On y x HD<br />

For the first time ever in Japan - and in<br />

just one month - Honda Body Service<br />

Tochigi has abandoned all use<br />

of solvent-borne paints in its<br />

workshops, replacing them with<br />

waterbased On y x HD.<br />

IN BRIEF<br />

Honda Body service Tochigi is the first<br />

body shop in Japan to have completely<br />

switched over to waterborne paint. While<br />

it may have been a rather quick switch,<br />

everything went smoothly thanks to the<br />

close partnership the Honda body repair<br />

shop, located in Tochigi, to the north of<br />

Tokyo, maintains with BAsf Coatings<br />

Japan. This truly exemplary collaborative<br />

effort has led to unprecedented success<br />

and will, in the future, serve as a model<br />

for setting-up new partnerships along<br />

the same lines.<br />

Renowned for its incredible durability<br />

and perfect finish, while at the same<br />

time being as easy to apply and dry<br />

as a solvent-based paint, On y x HD<br />

boasts an additional benefit that helped<br />

convince Honda - full compliance with<br />

the VOC standards designed to limit the<br />

Global cooperation agreement with Kia Motors<br />

BAsf Coatings and kia Motors have<br />

signed a global cooperation agreement<br />

on training. This agreement makes BAsf<br />

Coatings an official partner to kia Motors’<br />

aftersales network for automotive repairs,<br />

throughout the world. The R-M paint<br />

brand in particular, will be providing a full<br />

range of services tailored to the needs of<br />

the kia network. Among these, training is<br />

deemed to be of particular importance.<br />

Progressive modules developed<br />

especially for kia Motors will enable all the<br />

company’s aftersales staff, painters and<br />

managers to receive training in the latest<br />

repair and administration techniques. kia<br />

Motors Corporation is one of the fastestgrowing<br />

vehicle manufacturers in the<br />

world. Each year, the company produces<br />

over 1.3 million vehicles in a total of<br />

nine countries, all of which are sold and<br />

Worldwide<br />

emissions of volatile organic compounds<br />

(VOC). Protecting the environment is a<br />

top priority for BAsf Coatings Japan.<br />

The company already promotes the<br />

use of “eco-friendly” paints among the<br />

country’s bodywork repairers and hopes<br />

to quickly convert them all into users of<br />

waterborne paints. Another priority is<br />

raising awareness among the general<br />

public. Honda and BAsf have organized<br />

a customer event for local citizens to<br />

introduce what they have achieved and<br />

why VOC reduction is necessary working<br />

together with the city of Utsunomiya,<br />

where officials are accutely aware of the<br />

problems caused <strong>by</strong> VOC emissions.<br />

The collaboration between local<br />

government, paint supplier and paint<br />

user increases the public’s awareness<br />

of the environmental protection efforts<br />

being made <strong>by</strong> the local bodyshops.<br />

maintained <strong>by</strong> a network of distributors<br />

and dealers in 165 countries.<br />

stephen Oh (kia Motors), David Lee (kia Motors),<br />

kenneth Marshall (BAsf) and Masataka Ishikawa (BAsf)<br />

17

18<br />

Worldwide<br />

The season has just come to an end and<br />

R-M is very proud to have been associated<br />

with this competition which is extremely<br />

popular in the United states. Every weekend<br />

between the months of february and<br />

November, thousands of fans watch these<br />

BAsf and AXA, both of them leading<br />

companies in their sectors, share<br />

a common goal: to provide their clients<br />

with the best possible service. so it’s<br />

hardly surprising that the two chose to<br />

collaborate on a joint project, involving<br />

close coordination between the R-M<br />

distribution network and the managers<br />

of body repair workshops in the AXA<br />

network.<br />

On september 17th 2009, in the city<br />

of Madrid, AXA held an “Accident Day”<br />

at its offices - an event that took place<br />

simultaneously in twelve European<br />

countries with the participation of<br />

over 3,500 employees. The aim of the<br />

initiative was to raise the awareness<br />

of AXA staff as to what customers<br />

are looking for in terms of accident<br />

thrilling stock car races. This year it was car<br />

number 34 from the front Row Motorsport<br />

team, based in Denver and headed up <strong>by</strong><br />

entrepreneur Bob Jenkins, which enjoyed<br />

the privilege of being painted <strong>by</strong> R-M.<br />

This car took to the grid of the sprint Cup<br />

management and the employees<br />

involved in handling it. R-M took part<br />

in the events organised during the day,<br />

in its capacity as a “preferred supplier”,<br />

via a demonstration stand: a vehicle<br />

shell was used to show the remarkable<br />

quality of repairs performed using<br />

R-M paints.<br />

The stand was visited <strong>by</strong> AXA’s board<br />

of directors as well as representatives<br />

of the insurance trade press. The stand<br />

United States<br />

NASCAR 2009 season,<br />

R-M sponsors the Front<br />

Row Motorsport team<br />

races, the top category in the competition,<br />

with John Andretti behind the wheel. The<br />

team also entrusted its vehicle to the expert<br />

hands of driver Tony Raines, who was<br />

contesting the Nationwide series, the other<br />

important category in NAsCAR racing.<br />

Spain<br />

Partnership with AXA in Spain<br />

R-M has been working in partnership with the AXA insurance company in Poland since 2007.<br />

Now it’s Spain’s turn to set up a project linking it with AXA, a group that ranks as the country’s<br />

second-largest provider of “non-life” insurance, with four million customers and a total of 6.6 million contracts.<br />

Pablo Moriche<br />

AXA Bodyshop network<br />

in charge of the<br />

AXA-BASF project<br />

was warmly received and widely praised<br />

<strong>by</strong> AXA managers specialising in the<br />

“Accident” sector. The Axa Calidad<br />

garage network comprises 1,300 repair<br />

centres, with 300 garages currently<br />

using our paints.<br />

The event served to open up a wide<br />

range of opportunities for R-M and its<br />

distribution network in spain to attract<br />

new members to its network.<br />

Juan Manuel Trigo<br />

BASF Refinish Market<br />

Development (KAM) -<br />

Responsible for<br />

AXA’s account

Croatia<br />

Pribor Centar:<br />

new importer in<br />

Croatia<br />

Based in Split, Pribor Centar d.o.o.<br />

(plc) was founded at the beginning<br />

of 2009. The company has two<br />

warehouses, in Split and Karlovac,<br />

and a training centre in Split.<br />

It employs five people, of whom<br />

two are technicians and three<br />

are sales representatives.<br />

“With over 10 years worth of experience<br />

in the area of automotive repairs, we<br />

were looking for the best partner from<br />

among the leading manufacturers”,<br />

explains Velimir setka, Director of Pribor<br />

Centar. R-M’s launch of waterborne<br />

paints has met with great success in<br />

countries close to ours and across the<br />

world. 2008 was a year of transition in<br />

Croatia for these products, which comply<br />

with the VOC standards, we therefore<br />

contacted Martina fischer, Export<br />

Manager for the sector, and reached<br />

an agreement to work together with R-M.<br />

for its part, R-M selected us on the basis<br />

of our experience and we are sure that<br />

this collaboration will be beneficial for<br />

both sides!”<br />

A collaboration<br />

that’s off to a great start<br />

At the beginning of 2009, the Croatian<br />

team went to Clermont in france<br />

for a “hands-on” training session.<br />

“We were delighted with the warm<br />

welcome reserved for us <strong>by</strong> the R-M<br />

staff”, says Velimir, “and highly impressed<br />

<strong>by</strong> the quality of the training and the<br />

patience of the export trainer, Michel<br />

Bohlinger. Access to information is fast,<br />

and if there’s a problem, it’s quickly<br />

solved. To date, all of my employees are<br />

very happy to be working with R-M”.<br />

A cautious strategy<br />

for a market in crisis<br />

“Taking into account the legislation<br />

on VOC in Croatia, we import only<br />

On y x HD and Un o 420 D paints and<br />

other products that comply with the<br />

standards. Nevertheless, given the lack<br />

of checks and the complexity of the<br />

conditions of application of the law,<br />

Worldwide<br />

Pribor Centar’s team in training session in Clermont with Michel Bohlinger<br />

most repair shops are still working with<br />

older, solvent-based products. Only the<br />

vehicle importers have moved on to<br />

water-based paint”, stresses Velimir.<br />

Croatia has 4.5 million inhabitants and<br />

a GDP of 70 billion dollars. In 2008,<br />

some 90,000 new vehicles were sold<br />

here - a figure which dropped <strong>by</strong> 50% in<br />

2009 due to the recession. The country<br />

is currently grappling with a difficult<br />

economic situation and the short-term<br />

forecasts are fairly pessimistic, with<br />

many bankruptcies expected to occur<br />

during 2010.<br />

“Our aim is to launch On y x HD nationally<br />

across Croatia, a country in which R-M<br />

is not yet very well known, and to gain<br />

new customers. To start with, we will<br />

be concentrating on the independents<br />

and the biggest bodyshops. At the<br />

beginning of 2010 we will start to<br />

negotiate with the brand networks”,<br />

says Velimir.<br />

19

20<br />

CarizzMa<br />

<strong>CARIZZMA</strong> <strong>by</strong> R-M<br />

The culture of the unique<br />

It’s a trend that continues to gather<br />

pace this year among vehicle owners:<br />

the desire to stand out, to be unique.<br />

The <strong>CARIZZMA</strong> concept enables<br />

their demands to be met easily -<br />

a demand that’s not confined to<br />

devotees of tuning, but a much wider<br />

clientele as well. The ability to offer a<br />

customer a paint job that sets them<br />

apart, means being able to offer<br />

them a vehicle that matches their<br />

personality and taste, perfectly.<br />

The <strong>CARIZZMA</strong> <strong>by</strong> R-M concept promotes<br />

a change of perspective and a change<br />

of habits in today’s bodyshops. With<br />

<strong>CARIZZMA</strong>, R-M is developing its own<br />

niche market - a market that offers the<br />

promise of growth and is enabling R-M to<br />

maintain its position of leadership in terms<br />

of innovation: <strong>CARIZZMA</strong> <strong>by</strong> R-M is the only<br />

range of custom paint to comply fully with<br />

the VOC legislation in place in Europe.<br />

Technical aspects have often put a brake on<br />

the ability to fulfil the wishes of customers<br />

with wild imaginations. This is no longer the<br />

case, as the R-M brand’s slogan testifies:<br />

“Perfection made simple”. Today, with<br />

<strong>CARIZZMA</strong> <strong>by</strong> R-M paint, it’s possible<br />

to create unique designs on virtually any<br />

surface. Given how strong the demand<br />

for customizing is, this is an excellent<br />

opportunity for bodyshops to grow their<br />

business and fully apply their expertise. To<br />

start using <strong>CARIZZMA</strong> <strong>by</strong> R-M doesn’t call<br />

for a big investment in materials because<br />

the system is based on the full On y x HD<br />

range, to which all that was needed was to<br />

add a few new products. Easy to apply, with<br />

great coverage, it’s truly quick-drying and<br />

environmentally friendly: the range multiplies<br />

the benefits, at the same time giving great<br />

results and making your bodyshop more<br />

productive.<br />

CARRIZZMA, how does it work?<br />

In practice, <strong>CARIZZMA</strong> consists of the<br />

full range of On y x HD waterbased refinish<br />

paint, together with its base colours -<br />

Cry S tA l BA S e - to which have been added:<br />

seven CANDIZZ (dyes) for seven essential<br />

colours (black, violet, blue, green, yellow,<br />

orange and red) and four special effect<br />

powders (special flakes). Combining<br />

them enables the painter to create unique<br />

effects, subtle or completely new colours.<br />

And when it comes to the result, the<br />

options are almost unlimited!<br />

A mixing clear, HB 009, has been<br />

developed especially for diluting the<br />

colours, all of which can be combined<br />

with the others. Extremely simple to use,<br />

simply mix the paint and then apply that

mix onto the matt base, or mix it directly<br />

with a colour. Packaged in 50g bottles,<br />

the powders enable you to create almost<br />

any metallic, sparkle or metal flake effect<br />

you like, with an exceptional result. The<br />

principle behind CANDIZZ is exactly the<br />

same: all that’s required is to disperse the<br />

powder in the HB 100 basic mix and the<br />

work can begin. Between one and five per<br />

cent of CANDIZZ or special effect powder<br />

is enough to ensure an exceptional custom<br />

paint job.<br />

The most recent addition to the<br />

<strong>CARIZZMA</strong> range can now come into play<br />

- new Cu S t o m c l e A r CP clearcoat, which<br />

ensures long-lasting UV protection for the<br />

paint. Easy to polish, the clearcoat ensures<br />

a brilliant gloss and excellent durability.<br />

It is mixed to the usual mixing ratio with<br />

the standard hardener, H420, and sC 850<br />

thinner, and just like the rest of the range,<br />

it complies with the VOC legislation.<br />

Let’s get “<strong>CARIZZMA</strong>tic”!<br />

Because it isn’t always easy to establish<br />

yourself in a new business, R-M supports<br />

apprentice “<strong>CARIZZMA</strong>tic” painters with<br />

a color book as finding module and three<br />

training modules: “initiation”, to discover<br />

custom paints; the “advanced” module<br />

for perfecting complex detail techniques<br />

and; the “expert” module, in which artistic<br />

creativity is taught <strong>by</strong> masters in vehicle<br />

customizing.<br />

Another tool that shouldn’t be overlooked<br />

in order to ensure things get off to a great<br />

start is the website www.carizzma.com.<br />

Everything you need is there, including<br />

the colour guide, etc. The “find out more”<br />

section enables the public at large to find<br />

the contact details of “<strong>CARIZZMA</strong>tic”<br />

bodyshops via the R-M distributor<br />

network. As for the technical sheets,<br />

they can still be found on the<br />

Growing sales<br />

with <strong>CARIZZMA</strong><br />

CarizzMa<br />

www.rmpaint.com website.<br />

R-M works together with professionals<br />

to discover everything they need to know<br />

about latest trends in the sector and meet<br />

the needs of body repairers so they can in<br />

turn increase customer satisfaction.<br />

R-M markets “Premium” products and<br />

service with unrivalled performance,<br />

specially designed for bodyshops.<br />

A project to develop a network of<br />

“Carizzmatic” garages is being<br />

considered, to encourage the sharing<br />

of skills between the different people<br />

involved, says Gesine Arend-Heidbrinck -<br />

Communications Manager, R-M.<br />

Take the example of Groupe Martin<br />

By keeping a close eye on trends, Groupe Martin,<br />

a Peugeot dealership in Denain and Anzin, france,<br />

succeeded in giving its sales a fresh boost thanks to a<br />

bold concept. Their staff came up with the idea of customizing<br />

three new vehicles with special-effect paints from the <strong>CARIZZMA</strong><br />

range. The result: the cars sold like wildfire in the days that followed!<br />

for the customer, it provides an opportunity to own a completely unique<br />

vehicle, one that reflects their personality, at a price lower than the extra<br />

charge they’d pay for a metallic paint job or other option on a standard<br />

production model. An experiment that is sure to have many followers<br />

- both at dealerships and among sellers of second-hand cars.<br />

21

22<br />

CarizzMa<br />

The making of “MTV Pimp My Ride”<br />

In Europe - and in particular, France, Belgium and Switzerland - fans of car makeovers have been passionately following<br />

the initial episodes of “Pimp My Ride”, broadcast for the first time in French on MTV. For this version of the cult show,<br />

which was born in the USA, the team of pimpers was provided <strong>by</strong> ProRider, under the artistic direction of Gerry Blyenberg,<br />

with <strong>CARIZZMA</strong> <strong>by</strong> R-M as the exclusive supplier of paint… Here, we take a behind-the-scenes look at the programme<br />

with Gerry, interviewed in mid-September after having pimped five of the planned ten cars.<br />

Gerry Blyenberg<br />

On screen, everything occurs as if <strong>by</strong><br />

magic... in front of his house, Adrien -<br />

a budding DJ - shows us an old Mondeo<br />

estate well past its best. In the garage,<br />

the team of pimpers gets down to its job.<br />

All the work is performed at breakneck<br />

speed, to music, amid an atmosphere<br />

marked heavily <strong>by</strong> rap and punctuated <strong>by</strong><br />

the clowning around of presenter Ramzy<br />

Bedia… Before long, it’s a euphoric Adrien<br />

who we see driving away at the wheel<br />

of an unrecognisable car, one given a<br />

complete makeover <strong>by</strong> Gerry and his<br />

team. With the help of the <strong>CARIZZMA</strong> <strong>by</strong><br />

R-M, the range of custom paints from R-M<br />

Automotive Refinish and unique in Europe<br />

as the first to fully comply with VOC<br />

legislation. But despite this apparent ease,<br />

a lot of work has been going on behind<br />

the scenes!<br />

From selection to design<br />

Each car symbolises a<br />

character - a personality<br />

just waiting to be<br />

discovered… The<br />

first five models<br />

selected were an<br />

old Dodge pick-up,<br />

a ford Mondeo, a<br />

Chevrolet Astro van, a VW Beetle and a<br />

Mini. Once the cars had been selected,<br />

Gerry sketched out a design project for<br />

each of them on paper and reviewed it<br />

with MTV, sometimes making changes to<br />

details or to the colour. Highly distinctive<br />

designs, adapted to the models, to the<br />

personality of the owner… and to the<br />

sensitivity of the designer.<br />

A customised paint job, the visual<br />

element par excellence<br />

Preparation, they say, is key if the right<br />

result is to be achieved: two weeks all in<br />

all, including one week of filming, during<br />

which it’s not really possible to do any<br />

work… After filming at the candidate’s<br />

home, the programme moves to the<br />

garage, where the set is permanently<br />

installed. Just a few seconds to film a<br />

spectacular, express strip down, “although<br />

we really spent half a day stripping the<br />

car down off camera…” One week left,<br />

nights included, to work around the clock<br />

and transform an old banger into a king<br />

of the road. The<br />

team starts <strong>by</strong><br />

changing the<br />

wheels, fixing up any dented bodywork,<br />

repairing the upholstery, changing and<br />

adding accessories… followed most<br />

importantly <strong>by</strong> giving the car a new paint<br />

job! Customised paint, the visual element<br />

par excellence, is essential to this style of<br />

doing up cars in a highly media-friendly<br />

way. “At times, we had to find another<br />

colour really quickly, one that would be<br />

better suited to the style of the car.”<br />

A challenge for him, and for the people<br />

at R-M too. Gerry says:<br />

“Shooting for a production such as MTV<br />

and its “Pimp My Ride” programme<br />

calls for extraordinary dynamism. We<br />

had to be highly responsive throughout<br />

the shoot. The R-M team demonstrated<br />

outstanding professionalism, giving<br />

us what we needed from the company’s<br />

<strong>CARIZZMA</strong> range of custom paints.<br />

Indeed, MTV chose R-M brand because<br />

it’s the ideal partner: responsive and<br />

dynamic”.<br />

Copyright photos : Regis Grman / MTV

The two companies first teamed up<br />

one year ago. Combining their highly<br />

complementary talents, they have already<br />

succeeded in reinventing colours through<br />

the creation of a matt chocolate finish<br />

for a very special Mini, matt white for<br />

a Lamborghini LP560 and an anthracite<br />

grey, much commented upon at the<br />

Geneva Motor show, using<br />

a Mercedes ML500 as the base.<br />

A “win-win”<br />

partnership<br />

Driven <strong>by</strong> the same passion, R-M and Patrice Parot, founder of Parotech<br />

and a respected designer in the world of car customising, are working<br />

together on some major projects.<br />

The attention Patrice Parot pays to the<br />

curves, materials and colours, always<br />

with sensational results on exceptional<br />

vehicles, can only fuel admiration and<br />

make others want to follow him in his<br />

experiments in striking the perfect<br />

balance. Patrice Parot doesn’t hide<br />

the pleasure he gets from working with<br />

R-M, which is supporting him in his<br />

international development <strong>by</strong> providing<br />

him with technical<br />

assistance. “The R-M<br />

brand has innovation<br />

and customizing in its<br />

genes... the <strong>CARIZZMA</strong><br />

range offers many<br />

advantages: it’s<br />

CarizzMa<br />

simple to use and extremely high quality,<br />

while at the same time being kind to the<br />

environment”.<br />

Two exceptional projects serve to illustrate<br />

what is an exemplary partnership: on the<br />

one hand, the preparation of an ML 4x4<br />

in the purest of Parotech styles, finished<br />

in anthracite grey. On the other hand, the<br />