Download PDF - Piano Technicians Guild

Download PDF - Piano Technicians Guild

Download PDF - Piano Technicians Guild

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

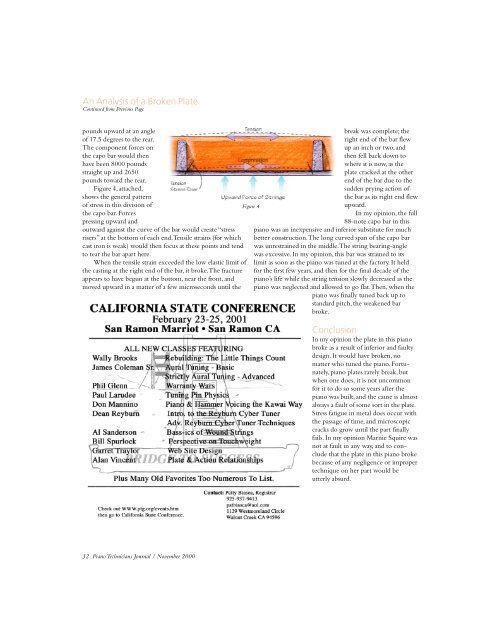

An Analysis of a Broken Plate<br />

Continued from Previous Page<br />

pounds upward at an angle<br />

of 17.5 degrees to the rear.<br />

The component forces on<br />

the capo bar would then<br />

have been 8000 pounds<br />

straight up and 2650<br />

pounds toward the rear.<br />

Figure 4, attached,<br />

shows the general pattern<br />

of stress in this division of<br />

the capo bar. Forces<br />

pressing upward and<br />

outward against the curve of the bar would create “stress<br />

risers” at the bottom of each end. Tensile strains (for which<br />

cast iron is weak) would then focus at these points and tend<br />

to tear the bar apart here.<br />

When the tensile strain exceeded the low elastic limit of<br />

the casting at the right end of the bar, it broke. The fracture<br />

appears to have begun at the bottom, near the front, and<br />

moved upward in a matter of a few microseconds until the<br />

32 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

Figure 4<br />

break was complete; the<br />

right end of the bar flew<br />

up an inch or two, and<br />

then fell back down to<br />

where it is now, as the<br />

plate cracked at the other<br />

end of the bar due to the<br />

sudden prying action of<br />

the bar as its right end flew<br />

upward.<br />

In my opinion, the full<br />

88-note capo bar in this<br />

piano was an inexpensive and inferior substitute for much<br />

better construction. The long curved span of the capo bar<br />

was unrestrained in the middle. The string bearing-angle<br />

was excessive. In my opinion, this bar was strained to its<br />

limit as soon as the piano was tuned at the factory. It held<br />

for the first few years, and then for the final decade of the<br />

piano’s life while the string tension slowly decreased as the<br />

piano was neglected and allowed to go flat. Then, when the<br />

piano was finally tuned back up to<br />

standard pitch, the weakened bar<br />

broke.<br />

Conclusion<br />

In my opinion the plate in this piano<br />

broke as a result of inferior and faulty<br />

design. It would have broken, no<br />

matter who tuned the piano. Fortunately,<br />

piano plates rarely break, but<br />

when one does, it is not uncommon<br />

for it to do so some years after the<br />

piano was built, and the cause is almost<br />

always a fault of some sort in the plate.<br />

Stress fatigue in metal does occur with<br />

the passage of time, and microscopic<br />

cracks do grow until the part finally<br />

fails. In my opinion Marnie Squire was<br />

not at fault in any way, and to conclude<br />

that the plate in this piano broke<br />

because of any negligence or improper<br />

technique on her part would be<br />

utterly absurd.