Download PDF - Piano Technicians Guild

Download PDF - Piano Technicians Guild

Download PDF - Piano Technicians Guild

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

An International Non-Profit Organization of Registered <strong>Piano</strong> <strong>Technicians</strong><br />

Taylor Mackinnon, RPT<br />

President<br />

520 SE 29th Ave., Hillsboro, OR 97123<br />

(503) 846-1501<br />

E-mail: pres@ptg.org<br />

Richard Bittner, RPT<br />

Vice President<br />

519 Melody Ct., Royal Oak, MI 48073<br />

(248) 398-8721<br />

E-mail: vp@ptg.org<br />

Paul Monroe, RPT<br />

Secretary-Treasurer<br />

5200 Irvine Blvd., Sp. 310, Irvine, CA 92620<br />

(714) 730-3469<br />

E-mail: sec@ptg.org<br />

David P. Durben, RPT<br />

Immediate Past President<br />

2310 E. Romneya Dr., Anaheim, CA 92806<br />

(714) 491-7392<br />

E-mail: ipp@ptg.org<br />

Ruth B. Phillips, RPT<br />

Northeast Regional Vice President<br />

3096 Bristol Rd., Warrington, PA 18976<br />

(215) 491-3045<br />

E-mail: nervp@ptg.org<br />

Robert L. Mishkin, RPT<br />

Southeast Regional Vice President<br />

1240 NE 153rd St., N. Miami Beach, FL 33162<br />

(305) 947-9030<br />

E-mail: servp@ptg.org<br />

Jack R. Wyatt Sr., RPT<br />

South Central Regional Vice President<br />

2027 15th St., Garland, TX 75041<br />

(972) 276-2243 (H)<br />

(972) 278-9312 (W)<br />

E-mail: scrvp@ptg.org<br />

Robert S. Bussell, RPT<br />

Central East Regional Vice President<br />

224 West Banta Rd., Indianapolis, IN 46217<br />

(317) 782-4320<br />

E-mail: cervp@ptg.org<br />

Richard E. West, RPT<br />

Central West Regional Vice President<br />

1427 A St., Lincoln, NE 68502<br />

(913) 631-8227<br />

E-mail: cwrvp@ptg.org<br />

Larry Joe Messerly, RPT<br />

Western Regional Vice President<br />

2222 W. Montebello Ave., Phoenix, AZ 85015<br />

(602) 433-9386<br />

E-mail: wrvp@ptg.org<br />

Keith Eugene Kopp, RPT<br />

Pacific NW Regional Vice President<br />

61283 Killowan Lane, Bend, OR 97702<br />

(541) 388-3741<br />

E-mail: pnwrvp@ptg.org<br />

2 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

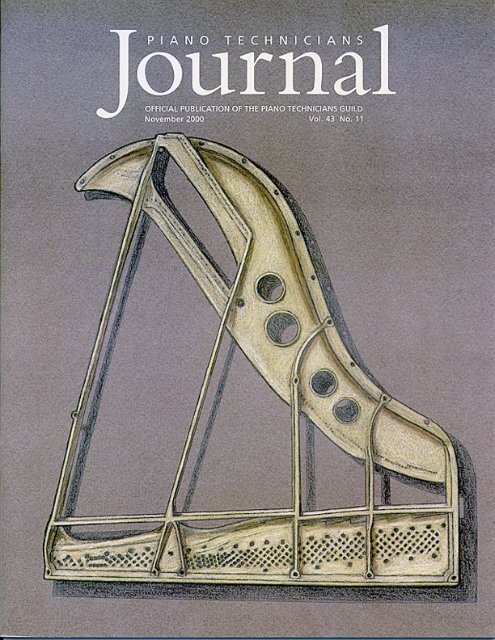

Plates in Focus<br />

Steve Brady, RPT<br />

Journal Editor<br />

You may notice a special emphasis on piano plates in this issue; it’s no<br />

accident. Some time ago the PTG Board of Directors approached me with a<br />

special request: a “theme” issue dealing with plates. We had hoped to cover<br />

plates from all angles, from raw materials, to design and manufacture, to<br />

breakage and repair techniques. Of greatest concern, however, was the matter<br />

of liability. When a plate breaks, whose fault is it?<br />

While an article on plate manufacture was not forthcoming, we’ve<br />

covered most of the other bases. Don Galt’s excellent article gives as much<br />

detail about the raw materials – not just for plates but for many other iron<br />

and steel piano parts as well – as most of us will ever need. Although Jim<br />

Ellis analyzes a specific plate that broke because of poor design, he also<br />

provides numerous insights into what constitutes a good plate design. From<br />

Wilford Young comes a welding repair method that has proven effective over<br />

many, many years and retired engineer Richard Oliver Snelson describes a<br />

hybrid restoration combining a mechanical repair with welded<br />

reinforcements. Finally, we’ve addressed liability by relating a tale that<br />

desperately needs to be told. As Marnie Squire’s story unfolds we see clearly<br />

that the technical authorities are unanimous: tuning a piano cannot possibly<br />

break a healthy plate.<br />

Indeed, a healthy plate can withstand unspeakable acts. In “The Tuner’s<br />

Life,” Carman Gentile tells of one such experience. I can recall many other<br />

instances myself. For example, a panicked piano owner called me after she<br />

discovered that her 11-year-old son had industriously removed all the plate<br />

rim lags from her small Chickering grand. The piano was horrendously out<br />

of tune. After replacing the lag screws, I found that the tuning had improved<br />

somewhat and was able to perform an uneventful tuning.<br />

In my shop, a concert-grand plate fell some four inches to a concrete<br />

floor when one of the hoist cables slipped. The plate didn’t break and,<br />

although this happened nearly 20 years ago, the piano is still humming along<br />

happily.<br />

The late Don Galt once related to me that he had seen a six-foot grand<br />

tumble end-over-end down a flight of 30 steps when a rope the movers were<br />

using suddenly broke as the piano approached the landing. Broken plate? No.<br />

“In fact,” Don said, “it was still pretty much in tune when we set it up<br />

afterward.” And that piano is still in service more than 25 years later.

Iron, Steel & <strong>Piano</strong>s<br />

By Don Galt, RPT<br />

(Reprinted from the <strong>Piano</strong> <strong>Technicians</strong> Journal, April, 1970.)<br />

Editor’s Introduction<br />

Don Galt served as Technical Editor of this publication from 1969 until 1977. One of the many special<br />

things that Don brought to his work as a piano technician and his work with the Journal was his extensive<br />

knowledge of iron and steel, gained over many years in his previous life as a re-bar engineer at<br />

Bethlehem Steel. I am reprinting this article in its entirety, and in a sidebar I’ve included a brief question<br />

and answer in which Don replies to a reader’s query on responsibility for plates broken while tuning.<br />

This item appeared in the November, 1970 issue of PTJ, p.10. – SB<br />

There is little in the appearance of a piano to<br />

reveal the massive forces that its members exert<br />

on one another, without respite, through many<br />

decades of time. It is only when the instrument<br />

absorbs the energy of the musician, translates it and throws it<br />

back as sound energy at small or great dynamic levels that<br />

the magnitude of these forces is hinted at.<br />

Even so, the dynamism of the pianist and the stolidity of<br />

the piano foster the illusion that the former, rather than the<br />

latter, is actually the source of the sound.<br />

So perhaps it is natural that piano users are ignorant of,<br />

and even piano technicians sometimes take for granted, the<br />

highly stressed metallic members to which the modern<br />

piano largely owes its dynamic compass.<br />

To gain a little sympathetic understanding of these<br />

members, this paper attempts a short description of the<br />

important iron products used in piano building: their<br />

manufacture, their physical properties, and their reactions to<br />

the loads they are asked to carry in the piano.<br />

For the reader’s convenience the article is divided into<br />

the following sections:<br />

General Considerations<br />

Pig Iron — The Blast Furnace<br />

Gray Cast Iron — The Cupola<br />

Steel — Making the Material<br />

Steel — The Rolling Mill<br />

Steel — Wire Drawing<br />

The Iron - Iron Carbide System<br />

Testing & Properties<br />

The first five sections of the article, down through<br />

“Steel — The Rolling Mill,” are fairly general, but with<br />

occasional references to our special interests.<br />

The section on “Steel – Wire Drawing” gives a very<br />

brief description of this procedure, leaving out more than it<br />

tells (as does every part of the article).<br />

The last two sections entitled “The Iron — Iron<br />

Carbide System” and “Testing & Properties,” will probably<br />

make the greatest demands on the reader’s attention. The<br />

author hopes that this attention will be rewarded with an<br />

enlarged understanding of how these materials do their<br />

work in the piano. If any reader gives up and jumps off<br />

during “The Iron-Iron Carbide System,” I hope he or she<br />

will climb back aboard for “Testing & Properties.”<br />

General Considerations<br />

Pure elemental metallic iron is a rare thing outside of the<br />

laboratory and we never encounter it in pianos. The steel<br />

music wire and the gray cast-iron plates of pianos, as well as<br />

other familiar iron products such as structural steel, wrought<br />

iron, white cast iron and so on, are mixtures of iron and<br />

carbon, iron being by far the predominant ingredient. They<br />

are not chemical compounds, so their proportions and<br />

hence their properties can and do vary widely. If the carbon<br />

content is less than about two percent by weight, the<br />

material is called steel. If the carbon is more than two<br />

percent it is called cast iron. This two percent figure is not<br />

arbitrary, but we will not explore its significance at the<br />

moment. These terms illustrate the sort of paradox that can<br />

grow up on a subject when the usage develops gradually.<br />

Steel is defined as a mixture or alloy of iron and carbon, and<br />

yet what is called cast iron contains more carbon than steel<br />

does.<br />

In practice, most steels have well less than two percent<br />

carbon, and most cast irons have well more than that<br />

amount. Gray cast iron, as used in piano plates, contains<br />

about 3.5 percent carbon, structural steel about 0.25<br />

percent, tool steels usually one percent or more, piano wire<br />

about 0.90 percent. The properties of the material depend a<br />

great deal on the percentage and form of the carbon<br />

present.<br />

Continued on Next Page<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 17

Iron, Steel & <strong>Piano</strong>s<br />

Continued from Previous Page<br />

All steels and cast irons also contain other elements and<br />

materials. Some of these, such as sulphur and phosphorus,<br />

are residual impurities which generally have been reduced<br />

in manufacture to the economic minimum. Others, such as<br />

silicon and manganese, may be purposely left in in controlled<br />

amounts, or be purposely added, to give the material<br />

special qualities. Examples are gray cast iron, containing<br />

considerable silicon, and the many alloy steels containing<br />

chromium, nickel, molybdenum and so on.<br />

The steel category includes a large spectrum of materials,<br />

classified by carbon content, as well as by the percentage<br />

ranges of other alloying elements. Music wire is generally<br />

made from carbon steel, as distinguished from alloy steel,<br />

which means that no deliberate alloy additions are used.<br />

(Except manganese. Almost all steels, either carbon or alloy,<br />

contain appreciable amounts of manganese.)<br />

Apart from the chemical distinction between steel and<br />

cast iron, one of the most important differences is that the<br />

various steels are generally ductile and malleable in varying<br />

degrees, while cast iron generally is not. (The amenability of<br />

a material to plastic deformation under stress without<br />

fracture is called ductility or malleability, according as the<br />

stress is tensile or compressive.)<br />

Wire could not be made from cast iron because the<br />

manufacturing process and most wire usages demand a<br />

ductile material. On the other hand, piano plates could be<br />

made of steel by forging, casting or welding, but among<br />

other disadvantages they would be costly far beyond any<br />

strength superiority they would have over plates of gray cast<br />

iron.<br />

We will return to some of the other properties and<br />

reactions of these materials after a short excursion into iron<br />

and steel making.<br />

The manufacture of steel divides rather naturally into<br />

two stages:<br />

1) making the material and 2) making the product from<br />

the material (product meaning bars, structural shapes, sheets,<br />

wire, etc.). With gray cast iron on the other hand, the<br />

material is generally turned out in product form, as we shall<br />

see.<br />

Pig Iron — The Blast Furnace<br />

The first step for either steel or cast iron is to recover iron in<br />

usable form from iron ore, which is iron oxide (rust) in<br />

varying mixtures with earth, sand and rock. This recovery is<br />

mostly a process of getting rid of the oxygen by heating the<br />

ore in the presence of carbon and limestone. This takes place<br />

in a blast furnace, which is a shaft, typically 25 feet or more<br />

in diameter by 75 feet or more in height, charged with<br />

18 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

layers of coke, ore and limestone, which form a descending<br />

column. Air is forced in at the bottom, and the coke burns<br />

partially to carbon monoxide, which in turn reduces the<br />

iron oxide ore. The limestone forms a molten, fluid slag,<br />

which, floating on the molten iron, accumulates and carries<br />

off much of the waste matter. The blast furnace operates<br />

continuously, with materials charged at the top and the slag<br />

and molten pig iron drawn off at the bottom. This is a hot<br />

process, with a temperature gradient in the furnace from a<br />

few hundred degrees at the top to about 2,750 degrees F. at<br />

the bottom.<br />

Pig iron, the blast furnace product, contains fairly large<br />

percentages (totaling seven percent or more) of impurities<br />

such as silicon, manganese, sulphur, phosphorus and an<br />

excess of carbon. “Impurities” is a relative term, as some of<br />

these inclusions are impurities only as they are in excess for<br />

the purpose at hand.<br />

Gray Cast Iron — The Cupola<br />

If the end product is to be gray cast iron, the pig iron from<br />

the blast furnace is refined in an oxidizing furnace known as<br />

a cupola. In foundry practice the cupola charge usually<br />

includes cast iron and steel scrap and ferro-silicon, as well as<br />

the pig iron. Coke for fuel and limestone for flux are also<br />

included. Because little or no chemical correction is possible<br />

in the cupola after melting, the charge must be carefully<br />

planned as to proportions of entering materials, based on<br />

the constitution of these materials and the desired constitution<br />

of the product. A typical melt for piano plates might<br />

contain 3.5 percent carbon and 2.4 percent silicon, about<br />

which more will be said later.<br />

The molten “cast iron” is drawn off and poured into<br />

molds, usually of sand, in which it takes the shapes of the<br />

patterns used in preparing the molds — piano plates, for<br />

example.<br />

Steel — Making the Material<br />

If the end material is to be steel, the pig iron from the blast<br />

furnace is refined in one of various types of oxidizing<br />

furnace permitting closer control than the cupola of the<br />

iron foundry. The reader will have heard of the Bessemer<br />

converter and the open-hearth furnace, both long used in<br />

steel making. The electric furnace, once limited to special<br />

steel manufacture, is now used extensively in the production<br />

of more common grades. Steel music wire may be made of<br />

either open hearth or electric furnace steel, never Bessemer.<br />

(The very fast Bessemer process is not deliberate enough to<br />

allow the analysis and chemical corrections necessary to the<br />

careful manufacture of high carbon steel.)

After various tests show that the desired constitution has<br />

been achieved in the furnace, the molten steel is poured<br />

into molds, where it cools and solidifies into ingots, oblong<br />

in form and varying in size from a ton or less to many tons.<br />

When the steel freezes in the ingot mold it has been in the<br />

molten state for the last time and the steel making might be<br />

said to be complete. The solid state processing which follows<br />

does not change the constitution of the material, that is, the<br />

proportions of its elemental ingredients.<br />

However, the various forming procedures and heat<br />

treatments do influence greatly the grain structure of the<br />

steel, and hence its physical properties such as strength and<br />

hardness. The special character of music wire depends as<br />

surely on the forming process as on the high temperature<br />

chemistry of the steel furnace. So now let us examine some<br />

of these forming processes in general and wire making in<br />

particular.<br />

Steel — The Rolling Mill<br />

The greatest tonnage of steel ingots goes next to the rolling<br />

mill (See Figure 1) in which a white-hot ingot is passed<br />

between rolls having appropriately shaped circumferencial<br />

grooves. The ingot is thus elongated and reduced in crosssection.<br />

Figure 1 — Rolling Mill<br />

Generally ingots are “broken down” into blooms, slabs<br />

or billets in the “blooming mill,” etc. (These industry terms<br />

identify the shape and size ranges of the products of the<br />

initial rolling operations.) The blooms, slabs and billets go<br />

on to smaller mills for rolling into various finished shapes.<br />

Larger shapes may be rolled directly from ingots.<br />

A sequence of many different roll passes is required to<br />

reduce an 18” square by 6’ long ingot, for instance, to more<br />

than 3/8 of a mile of 2” by 2” by 1/4” angles.<br />

The “hot working” of the steel by rolling, squeezes and<br />

elongates the grains or crystals, making the steel somewhat<br />

fibrous in structure, with considerably increased longitudinal<br />

strength and toughness. (Steel should not be thought of,<br />

however, as actually having fibers.) Flat rolled products, that<br />

is, sheets and wide plates, generally are cross-rolled early in<br />

the rolling sequence, not only to gain width but also so that<br />

the improvement in properties will not be limited to the<br />

longitudinal direction.<br />

Steel destined for piano wire making is rolled on a rod<br />

mill to a diameter of slightly over 1/4". It comes off of the<br />

mill in a continuous coil instead of being straightened and<br />

cut to length on the hot bed.<br />

Up to this point in steel music-wire making, all of the<br />

processing has been at high temperatures, beginning in the<br />

molten state in the blast furnace and the steel furnace where<br />

the temperatures approach 3,000 degrees F. The forming<br />

work on the rolling mill in the solid state requires temperatures<br />

of the order of 2,000 degrees or more.<br />

Steel — Wire Drawing<br />

If the hot work of rolling added strength and toughness by<br />

elongating the grain structure, the cold work of the drawing<br />

process which follows in wire manufacture has an even<br />

greater effect on the properties of the steel.<br />

After cleaning and coating, the rolled steel is drawn cold<br />

through a fixed hole, or die (See Figure 2), which results in<br />

elongation together with reduction of cross-section, and a<br />

great increase in hardness, tensile strength and yield strength.<br />

(This will be discussed in “Testing & Properties.”) As used<br />

here, “cold” does not necessarily mean cold to the touch.<br />

Work at any temperature below the recrystallization tem-<br />

perature (several hundred degrees) is “cold work.”<br />

Continued on Next Page<br />

Figure 2 — Wire Drawing<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 19

Iron, Steel & <strong>Piano</strong>s<br />

Continued from Previous Page<br />

A corollary result of the increase in<br />

hardness is a reduction in ductility; that is,<br />

some of the ductility is “used up.” The<br />

fairly high carbon content of music wire<br />

steel limits its ductility to a reduction in<br />

area of about 30 percent or less per draft.<br />

Obviously many drafts are required to<br />

reduce a 1/4” rod to the diameter of music<br />

wire and the ductility must be restored<br />

between drafts. This is done by patent<br />

annealing, which consists of reheating the<br />

wire to a selected temperature, perhaps<br />

1,500 degrees F., followed by slow cooling<br />

in air or in a medium maintained at a<br />

rather high temperature. The result is<br />

recrystallization into a ductile grain<br />

structure. The cycle of drawing and<br />

patenting must be repeated several times.<br />

The wire is finished on the final draft, with<br />

no further heat treatment, so its strength<br />

and hardness depends a great deal on the<br />

amount of reduction after the last anneal.<br />

The traction for pulling the wire<br />

through the die is supplied through the reel, or block, on<br />

which it is wound. Since the tension is quite high, the wire,<br />

which comes through the die straight, is strained or cold<br />

worked to the curvature of the block’s circumference. A<br />

technician struggling to untangle a small coil of recoiled<br />

piano wire that “got away” can readily estimate the diameter<br />

of the draw block, unless, of course, the wire was straightened<br />

before recoiling.<br />

At this point let us leave the solid-state processing of<br />

steel, and look at the constitution and micro-structure of the<br />

various iron-carbon mixtures.<br />

The Iron-Iron Carbide System<br />

The molten metal which comes from the cupola or the steel<br />

furnace is largely a solution of iron carbide in iron, or more<br />

properly, a mutual solution of the two in each other. As<br />

cooling proceeds, the metal undergoes a series of changes<br />

(reversible on reheating), of which freezing is merely the<br />

first. The nature of these changes, and the temperatures at<br />

which they occur, depend largely on the percentage of<br />

carbon in the metal.<br />

Figure 3, which is a simple version of the Iron-Iron<br />

Carbide Equilibrium Diagram, will help to visualize the<br />

state of different iron-carbon mixtures at various temperatures,<br />

and some of the changes that occur during solidification<br />

and cooling.<br />

20 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

Figure 3 – Iron-Iron Carbide Equilibrium diagram<br />

The horizontal scale represents the percentage of<br />

carbon by weight, and covers the range from pure iron (0<br />

percent carbon) to pure iron carbide (6.67 percent carbon).<br />

The vertical scale represents the temperature in degrees<br />

Fahrenheit. We will not concern ourselves with the intricacies<br />

in the extremely low carbon area at the left side of the<br />

diagram.<br />

The lightly cross-hatched area of Figure 3 represents a<br />

“mushy,” partly frozen state, bounded at the top by the line<br />

marked “liquidus” and at the bottom by the line marked<br />

“solidus.” Above the liquidus the material is completely<br />

molten. Below the solidus it is completely frozen or solidified.<br />

The mushy, partly frozen state between has an analogy<br />

in salt-water solutions, which are mushy through a considerable<br />

temperature range between the freezing point of pure<br />

water and the rather lower total freezing point of the<br />

solution. The reader will note that, for both pure iron and<br />

the eutectic cast iron (4.3 percent carbon) the liquidus and<br />

the solidus coincide — there is no mushy state, whereas at 2<br />

percent carbon the mushy state persists through a range of<br />

about 450 Farenheit degrees.<br />

Below the solidus, solid state changes occur during<br />

cooling, which, to simplify, consist of the separation of iron,<br />

carbon, and iron carbide in various forms as their mutual<br />

solubility changes with falling temperature. These separations<br />

are, of course, microscopic and result in changes in<br />

crystalline structure. Volumes could be written analyzing

these changes and their practical significance. We will limit<br />

ourselves to a few observations relevant to this article.<br />

To better understand Figure 3, one must realize that in<br />

the solid state iron exists (at different temperatures) in at<br />

least two allotropic forms. Below 1,333 degrees F. it is stable<br />

as alpha iron. Above 1,333 degrees it is stable as gamma iron.<br />

These forms have different crystalline structures and their<br />

interest to us is in the fact that the solubility of carbon in gamma<br />

iron is fairly high, but in alpha iron it is extremely low.<br />

With these facts before us we are ready for definitions<br />

of some of the terms appearing in Figure 3.<br />

Austenite: A solid solution of carbon in gamma iron.<br />

The maximum carbon in austenite varies<br />

between 2 percent at 2,065 degrees F. and<br />

0.8 percent at 1,333 degrees F. (See A cm<br />

line.) Austenite does not exist below 1,333<br />

degrees F. because gamma iron changes to<br />

alpha below that temperature.<br />

Ferrite: Almost carbon-less alpha iron. (Limited to<br />

about 0.02 percent carbon, as carbon is<br />

virtually insoluble in alpha iron.)<br />

Cementite: Iron carbide (Fe 3 C). An extremely hard and<br />

brittle compound, hard enough to scratch<br />

glass. Contains 6.67 percent carbon by<br />

weight.<br />

Pearlite: A low-temperature (below 1,333 degrees<br />

F.), rather homogenous laminar mixture of<br />

ferrite and cementite, containing about 0.8<br />

percent carbon.<br />

Now, referring to Figure 3, let us follow a few ironcarbon<br />

materials from the molten to the cold state.<br />

Suppose we have molten steel of 0.8 percent carbon,<br />

which is permitted to cool slowly. Freezing commences at<br />

about 2,690 degrees F. and is complete at about 2,520<br />

degrees. The solid austenite then cools without change right<br />

down to the 1,333-degree line. At this point the gamma<br />

iron changes to alpha iron and the austenite transforms to<br />

pearlite as the carbon is cast out of solution in iron carbide<br />

laminae. This all-pearlite 0.8 percent carbon steel is said to<br />

have eutectoid composition.<br />

Pearlite actually retains its identity in non-eutectoid<br />

steels, but since its carbon content is uniform at 0.8 percent,<br />

these non-eutectoid steels are necessarily not pure pearlite.<br />

If the steel is hypo-eutectoid (less than 0.8 percent carbon)<br />

it consists of pearlite and ferrite grains mixed. If the steel is<br />

hypereutectoid (more than 0.8 percent carbon) it consists of<br />

pearlite and cementite grains mixed.<br />

The precipitated cementite in hyper-eutectoid steel<br />

forms at the pearlite grain boundaries, and this network of<br />

cementite increases the hardness and strength of the steel,<br />

compared with that of steel which is lower in carbon.<br />

It might be of interest to trace the cooling cycle of a<br />

hyper-eutectoid steel of, say 1.25 percent carbon. This steel<br />

starts to freeze at about 2,650 degrees F. and freezing is<br />

complete at about 2,350 degrees. It now remains solid<br />

austenite containing 1.25 percent carbon until it cools to<br />

the A cm line at about 1,675 degrees. At this point the solution<br />

is saturated with carbon and the excess carbon starts to<br />

precipitate in cementite. This precipitation of cementite<br />

continues on down to 1,333 degrees, at which point the<br />

remaining austenite, which has now reached eutectoid<br />

composition, transforms to pearlite, and we have a mixture<br />

of pearlite and Cementite grains as mentioned in the<br />

preceding two paragraphs, and a rather hard steel.<br />

Hypo-eutectoid steel (less than 0.8 percent carbon),<br />

after freezing, continues to cool as austenite down to the A 1<br />

line, at which point it begins to cast out ferrite crystals. This<br />

continues on down to 1,333 degrees F. at which point again<br />

the remaining austenite has reached eutectoid composition,<br />

and transforms to pearlite, resulting in pearlite grains in a<br />

ferrite matrix. Ferrite is similar in properties to pure iron.<br />

Hence steels low in carbon are relatively soft and of lower<br />

tensile strength than the high carbon steels.<br />

The temperature-related changes we have been discussing<br />

are also time-related. The equilibrium states represented<br />

by the various areas of Figure 3 assume that the cooling<br />

metal has the necessary “leisure” for the changes to take<br />

place. Sudden cooling may force non-equilibrium changes<br />

that alter the crystalline structure and the properties of the<br />

material.<br />

These facts are the basis of the heat treatment of steel,<br />

which consists of slowing or speeding the cooling rate<br />

through critical temperature ranges to facilitate or inhibit<br />

change. Thus, in the wire-drawing process, ductility was<br />

restored between drafts by reheating the wire above the A 3 -<br />

A cm lines to the all-austenite condition, then cooling it<br />

slowly to below the A 1 line. A rapid quench cooling on the<br />

other hand would have increased the hardness and reduced<br />

the ductility by forcing a non-equilibrium change into one<br />

of the harder forms, as, for instance, Martensite (not defined<br />

in this article).<br />

Steel for piano wire, having about 0.85 to 0.90 percent<br />

carbon, is near eutectoid composition and hence mostly<br />

pearlite. It affords an excellent compromise between high<br />

tensile strength and high ductility.<br />

Now let us look at the cast iron area of Figure 3. We see<br />

at once that a cast iron of 4.3 percent carbon has the<br />

minimum freezing point of all the iron-carbon mixtures<br />

Continued on Next Page<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 21

(2,065 degrees F.). We see also that it has no mushy stage,<br />

since the liquidus and solidus lines coincide at that carbon<br />

ratio. In foundry work this material would have the obvious<br />

advantage of remaining fully fluid at a relatively low temperature,<br />

flowing freely in intricate molds such as those<br />

required for piano plates. Also, with almost no temperature<br />

change during freezing, shrinkage during freezing would be<br />

minimal, resulting in sound castings free of shrinkage<br />

defects. While the carbon in gray cast iron rarely exceeds 3.5<br />

percent, the advantages named above are still partly retained<br />

at this percentage.<br />

In view of what we have said about the hardness of<br />

mixtures high in carbon (cementite), a 3.5 percent carbon<br />

cast iron might seem much too hard and brittle to be useful.<br />

Indeed it would be if all the carbon remained in combination<br />

as cementite. But the silicon present in the metal comes<br />

to the rescue. As freezing and subsequent cooling progresses,<br />

most of the carbon in excess of the eutectoid ratio (0.8<br />

A plea for advice about a distressing occurrence<br />

comes from New York State:<br />

“As a former member, retired, I am seeking some<br />

information. I pulled up an old piano 1/2 note to 440<br />

pitch, informing the man it was risky to raise the pitch. In<br />

doing so, after the pull-up, the plate [cracked] in the treble<br />

section.<br />

What I want to know is, who is responsible?<br />

This is the first time this has happened to me in 58<br />

years tuning.”<br />

Some [technicians] tune pianos for a lifetime<br />

without ever experiencing a broken plate. But it does<br />

occur once in a while. It is always sudden and unpredictable,<br />

the result of some unseen internal strain in<br />

the plate. It may be the result of metal fatigue in a<br />

plate that was never quite perfectly fitted to the heavy<br />

wooden frame of the piano, but was forced to conform<br />

to it by the many bolts and screws. It may be the<br />

result of slight and gradual changes in the wooden<br />

frame itself, to which the cast-iron plate is not able to<br />

accommodate itself. It may be the result of a hidden<br />

weakness in the casting, which finally “lets go.” It is, as<br />

I say, a rare thing, but it does occur. It has been known<br />

to occur when the piano was sitting idle by itself,<br />

22 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

percent) is precipitated as graphite flakes, interspersed with<br />

the ferrite and cementite crystals, so that little cement-ite is<br />

present except in pearlite form. This formation of graphite<br />

is essential to the character of gray cast iron, and the silicon<br />

is the chief agent in its formation. Hence the great importance<br />

of silicon in gray cast iron. (Figure 3 does not try to<br />

show this effect.)<br />

Testing & Properties<br />

Since the properties of a material determine its suitability<br />

for a particular purpose, the testing of these properties is<br />

very important.<br />

Some vital properties of engineering materials are<br />

toughness, hardness, and fatigue strength. Toughness is<br />

measured by the energy absorbed before fracture in a<br />

standardized impact test. Hardness is measured by the<br />

penetration of a standardized indenting die. Fatigue strength<br />

is measured as the maximum stress tolerable under indefi-<br />

Broken Plate! Who Is Responsible?<br />

with no tuner within miles!<br />

It is safe to assert that a “healthy” plate, properly<br />

designed, properly fitted and secured in the piano,<br />

will not break under the ordinary stresses of the<br />

tuning process, even when the string tension is being<br />

raised back to standard after long neglect. It is designed<br />

to stand much higher stresses than those set up<br />

by strings tuned to standard pitch.<br />

There is even some question whether such a<br />

plate could be broken by deliberately over pulling the<br />

strings or whether the strings would not break first.<br />

But since the tuner does not do this, the question is<br />

academic.<br />

So there is no basis for considering the tuner to<br />

be responsible for plate breakage that occurs during<br />

or after tuning. This fact is easier for customers to<br />

accept if they are forewarned that there is risk involved<br />

in raising the pitch of a piano. That this risk is<br />

extremely small is shown by the fact that our inquirer<br />

tuned for 58 years, including, I am sure, hundreds of<br />

pitch raises as drastic as this one, without ever experiencing<br />

a broken plate.<br />

— Don Galt

nitely repeated cyclic loads.<br />

The properties of steel most important to us in connection<br />

with piano wire are those called tensile properties.<br />

Because there are some striking similarities between wire<br />

drawing and the tensile testing of steel, we will examine the<br />

latter in some detail.<br />

The tensile test consists of stretching a specimen of<br />

known cross sectional area to failure in a testing machine.<br />

The maximum tensile stress endured by the specimen<br />

before failure, divided by the original cross-sectional area,<br />

gives the ultimate tensile strength per unit of area, usually<br />

called simply the tensile strength. In countries using the<br />

English system, the tensile strength and the other tensile<br />

properties, such as elastic limit and yield strength, are given<br />

in pounds per square inch. It is usual to use a specimen<br />

accurately machined to a diameter of 0.505". This has a<br />

cross-section of 0.2 square inch, which is a convenient<br />

divisor for converting the measured load on the specimen<br />

into the stress per square inch.<br />

While the tensile strength is easily determined with<br />

proper equipment, it is not the most important tensile<br />

property of steel. More important is the amount of stress it can<br />

stand without permanent deformation. The specimen elongates<br />

as it undergoes constantly increasing loads in the testing<br />

machine. At first this elongation is elastic; that is, if the<br />

tension is removed the original length will be recovered. As<br />

the load is further increased an elastic limit is reached, and<br />

plastic, or permanent deformation begins. The precise elastic<br />

limit is seldom determined in practice, as the process is<br />

cumbersome. It requires the alternate application and release<br />

of increasing loads, with measurement of the gauge length<br />

each time to determine if the behavior is still elastic.<br />

The tensile property usually obtained instead of the<br />

elastic limit is the yield point, which, in steel, is only slightly<br />

above the elastic limit. This is the unit tensile stress at which<br />

the specimen continues to elongate for a period without<br />

any increase in load. The term “yield” is quite descriptive of<br />

what takes place. At and above the yield point permanent<br />

slips occur along planes in the crystals, until they are arrested<br />

by crystal boundaries and broken grains. At first, yielding is<br />

distributed throughout the length of the specimen, but as<br />

the load rises a “neck” starts to develop in the specimen and<br />

further elongation is concentrated at this neck. After<br />

necking starts, elongation continues under decreasing loads,<br />

because the effective cross-section is decreasing, and this<br />

continues until fracture occurs at the neck.<br />

The cold work of stretching actually hardens and<br />

strengthens the stretched steel, so that the true unit stress on the<br />

material at fracture (the load divided by the instantaneous<br />

cross-section of the neck) is considerably greater than the tensile<br />

strength (the maximum load achieved, divided by the<br />

original cross-section). If one thinks of wire drawing as a<br />

sort of controlled tensile test, in which a “continuous neck”<br />

of uniform cross-section is formed, it is not hard to see how<br />

the drawn wire develops strength and hardness superior to<br />

those of the hot rolled rod from which it is drawn. The<br />

drawn wire exhibits a new elastic limit and yield point,<br />

higher than those of the steel in as-rolled condition, and is<br />

capable of elastic behavior within these limits.<br />

It is imperative that the cold work of drawing not be<br />

overdone, lest the wire become too brittle.<br />

(The tensile test and the drawing process are not perfectly<br />

analogous. In drawing, the lateral compression of the metal by the<br />

die is an effect similar to cold forging—an effect absent from the<br />

tensile test.)<br />

What we have discussed is the testing of rolled steel.<br />

Wire can be tested similarly, though it is customary to quote<br />

the breaking strength of wire rather than the tensile<br />

strength. Tensile strength is a property of the material<br />

independent of size, whereas breaking strength is a property<br />

of the specimen, depending on both tensile strength and<br />

sectional area.<br />

Generally, smaller sizes of piano wire have higher tensile<br />

properties than larger sizes because of the additional drafting<br />

or cold work. Also, wire used for bass string cores generally<br />

is made with lower properties, in order to preserve enough<br />

malleability so that the wire can be swedged, or flattened at<br />

the start and finish of the winding. Moreover, some manufacturers<br />

make more than one grade of wire, for example,<br />

two grades of bass and two grades of treble wire. For the<br />

most part these different grades and sizes come from the<br />

same steel and owe the difference in their properties to the<br />

amount of drafting and the spacing of annealings in the<br />

manufacturing sequence.<br />

The yield strength of the wire, which cannot be exceeded<br />

in piano stringing and tuning without serious<br />

damage, is determined by a rather arbitrary process known<br />

as the 0.2 percent offset method. It is generally found to be<br />

about 70 percent of the breaking strength. I do not mean to<br />

pass lightly over the elastic limit and yield strength. The<br />

non-determination of elastic limit, and the use of an<br />

arbitrary method for yield strength, are dictated by practical<br />

considerations, not by any lack of importance of these<br />

properties. Long and careful practice has shown that this<br />

testing method for yield strength gives a valid measure of<br />

the two properties in piano wire.<br />

In common with many other materials, steel under high<br />

Continued on Next Page<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 23

Iron, Steel & <strong>Piano</strong>s<br />

Continued from Previous Page<br />

tensile stress continues to elongate slightly for an indefinite<br />

time. This elongation is called creep. In most steel uses creep<br />

is considered negligible if the temperature is less than 40<br />

percent of the melting point on the absolute scale, i.e., less<br />

than about 700 degrees F. With piano strings, whose pitch is<br />

so sensitive to a very small change in tension, creep at<br />

ordinary temperatures is probably a factor in both the quick<br />

loss of pitch in newly strung pianos (so-called primary<br />

creep), and in the long-term loss of<br />

pitch (secondary creep).<br />

Fatigue in metal has been mentioned<br />

briefly, fatigue strength being the<br />

tolerance of indefinitely repeated cyclic<br />

loads. The high frequency reverse<br />

bending that occurs constantly in a<br />

highly tensioned vibrating string,<br />

particularly at the ends where the<br />

transverse waves are reflected, is surely<br />

high stress cyclic loading, and many<br />

string breaks in playing must be regarded<br />

as fatigue failures.<br />

Whenever a string is placed in a<br />

piano, it is necessarily cold worked at<br />

several points, such as the bridge pins,<br />

the agraffe, etc. Every non-elastic bend<br />

that is put into the wire tends to harden<br />

the wire by effectively cold working the<br />

steel at that point. The fibers on the<br />

convex side of any plastic bend have<br />

probably been stretched beyond the<br />

yield strength. This point will then be<br />

slightly more brittle than other parts of<br />

the string, and a likely candidate for<br />

ultimate fracture. One such point is the<br />

agraffe. Another is the point of tangency<br />

where the string starts to wind around<br />

the tuning pin. Repeated small tuning<br />

changes subject a short section of the<br />

string to alternate bending and straightening,<br />

which, even though slight, tend<br />

to work-harden the steel. This is<br />

probably why so many “old age” string<br />

breaks occur at the tuning pin.<br />

It should be obvious that piano<br />

strings are hard-working elements of<br />

the musical structure of the piano and<br />

we should be careful not to do anything<br />

to make their lot harder. Specifically, we<br />

should avoid subjecting them to<br />

unnecessary plastic bends by kinking or<br />

24 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

any other means, and to excessively high tension. Remember<br />

that any tension approaching 70 percent of the breaking strength is<br />

dangerously close to the yield strength.<br />

A few more words are in order about the properties of<br />

gray cast iron, which is a more prosaic cousin of piano wire.<br />

Its eminent suitability from the standpoint of manufacturing<br />

convenience in piano plate work has been mentioned.<br />

Its low freezing point (compared with other iron-carbon

material), and the proximity to each other of its liquidus and<br />

solidus temperatures combine to make for sound, uniform<br />

castings.<br />

Gray cast iron also has about the same coefficient of<br />

thermal expansion as steel music wire, which is a factor<br />

favoring tuning stability. Lighter metals sometimes used for<br />

piano plates have somewhat higher coefficients of thermal<br />

expansion.<br />

Gray cast iron has good machinability, as anyone who has<br />

drilled a piano plate has observed. This characteristic is<br />

enhanced by the presence of the carbon in graphite flake<br />

form.<br />

Gray cast iron has low tensile and compressive strength<br />

compared with steel, its ultimate tensile strength being about<br />

25,000/30,000 pounds per square inch. Structural steel has a<br />

tensile strength about three times as high, and cold drawn<br />

piano wire about ten times as high. In piano plates this relative<br />

low strength is not a particular disadvantage. The plate needs<br />

to be heavy enough to afford a solid platform for the strings<br />

to stand on while they are shaking the soundboard. Furthermore,<br />

the parts of the plate must be large enough so that there<br />

will be little deflection under load. These two requirements<br />

WIRE DRAWING A.D. 1540<br />

Pure Sound<br />

Top quality Stainless<br />

Steel <strong>Piano</strong> Wire<br />

from 1600 N/mm 2 - mid 19th century<br />

to 2200 N/mm 2 - modern pianos (short scaling)<br />

Most versatile high tech piano wire based on latest<br />

developments in stainless steel processing.<br />

Tuning stability better than average.<br />

Lower inharmonicity. Lovely sound!<br />

Prices in Euros: approx. 95¢ to the Euro at June 2000<br />

500 g - 15.00 250 g - 8.50 - 125 g - 5.50 (0.700 mm - 1.50 mm)<br />

500 g - 21.00 250 g - 11.00 - 125 g - 7.00 (0.500 mm - 0.675 mm)<br />

Complete list of breaking strengths, yield points<br />

and other data available.<br />

Pure Sound<br />

Juan & Mary Más Cabré<br />

Eline Verestraat 46 • 1183 KZ AMSTELVEEN, Netherland<br />

Phone: +31.20.6418099 Fax: +31.20.6407621<br />

E-mail: info@puresound-wire.com<br />

permit use of a material of relatively low unit strength.<br />

One of the properties of gray cast iron, which makes it<br />

particularly suitable for machinery bases, is also to its advantage<br />

in piano plates. This is its tendency toward internal selfdamping<br />

of vibrations. This property, largely due to the<br />

honeycombing with graphite carbon, means that plates of<br />

gray cast iron are not apt to show objectionable resonance.<br />

They do not “ring.” Happily, the words “bell metal,” which we<br />

all have seen cast into some piano plates, are simply not true.<br />

The graphite carbon of gray cast iron makes it very<br />

difficult to weld. Many piano technicians have had successful<br />

experiences in repairing broken plates by welding. It must be<br />

said, however, that the weldability of gray cast iron is poor, and<br />

that these successful repairs are in spite of, not because of, the<br />

properties of the metal. After welding, the homogeneity of the<br />

casting is gone, and there is sure to be a zone of weakness<br />

somewhere. Fortunately the plate is usually over-designed as<br />

far as structural strength is concerned and the weakness of the<br />

weld repair is not necessarily fatal. Sometimes there is no<br />

alternative to attempting repair by welding and it is not the<br />

author’s intent to write against it. But due to the microstructure<br />

of the material, welding cannot be thought of as a<br />

reliable means of making broken gray<br />

cast iron “as good as new.”<br />

Of course, there are other iron<br />

materials to be found in pianos in<br />

smaller quantities. Tuning pins are made<br />

of cold-drawn steel wire, not so hard,<br />

considerably larger in diameter than<br />

piano wire. The many steel screws are<br />

made of steel that is made brittle by the<br />

presence of sulphur, so that it will thread<br />

easily and cleanly. The leg plates of<br />

grand pianos are made of a tougher cast<br />

iron than the gray cast iron of the string<br />

plates. They are lower in carbon, much<br />

lower in silicon and higher in manganese,<br />

and their carbon is not in graphite<br />

flake form. They exhibit a fair degree of<br />

malleability and less likelihood of<br />

fracture under shock than gray cast iron.<br />

But these two cousins in the iron<br />

family, steel music wire and gray cast<br />

iron plates, are the real backbone of the<br />

modern piano. Without them it would<br />

be, as it once was, a very different<br />

instrument.<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 25

<strong>Piano</strong> Plate Breakage: A Case Stud<br />

By Steve Brady, RPT<br />

Journal Editor<br />

The story I relate here is about an event, or series<br />

of events, in the life of Marnie Squire, an<br />

Associate member of the Cincinnati, OH,<br />

chapter of PTG. She has been kind enough to<br />

provide the documentation from her case for use in this<br />

issue of the Journal. “If it can help save someone else from<br />

the kind of nightmare I went through,” she says, “I’m happy<br />

to share my story.”<br />

At about 10:30 a.m. on Friday, July 2, 1993, Marnie<br />

Squire arrived to tune a small Fischer grand piano at a home<br />

in Middletown, OH. The piano, an Aeolian product, had not<br />

been tuned in 13 years. Squire played the piano briefly to<br />

evaluate its condition and found several keys not playing as<br />

well as some damper problems. The piano was 37 cents flat.<br />

After bringing the piano back to a condition of rough<br />

playability, Squire began the process of raising pitch. Using a<br />

Sanderson Accu-Tuner, she completed a “normal” first pass<br />

and had nearly completed a second pass. Then, “I was about to<br />

tune the second or third string from the bottom of the bass<br />

section. I played the keys and a huge ‘bang!’ happened. I had<br />

no idea what had happened and was very shaken.” Looking<br />

over the piano she saw a crack in the second plate strut from<br />

the top and another crack in the tuning pin area at the bass/<br />

tenor break. Mortified, she called the owner of the piano, who<br />

was at work and explained what had happened.<br />

The piano owner filed a lawsuit over the broken plate.<br />

The owner enlisted the aid of another piano technician in the<br />

area as an “expert” witness and this technician (whose name is<br />

omitted here) told the piano owner that Squire had brought<br />

the pitch up too fast, that she didn’t know what she was doing,<br />

and that she had actually broken the plate!<br />

In September of 1993, Marnie Squire retained an attorney<br />

to defend herself in the lawsuit and the long process of<br />

gathering evidence began. Several PTG members sprang to<br />

Squire’s aid by examining the piano and writing opinions,<br />

some even performing sophisticated analyses based on the<br />

physical evidence. From over two dozen written opinions<br />

placed at my disposal by Marnie Squire, I have excerpted a<br />

number of relevant quotations.<br />

Willard Sims, piano service manager at Baldwin from 1946 to<br />

1984, wrote on September 17, 1993:<br />

“The tuning of a piano by an experienced technician<br />

will not cause the string plate to fail.” In another letter dated<br />

April 10, 1994, Sims reiterated this stance: “I repeat my statement<br />

that the tuning of a piano will not cause plate failure. If<br />

a rebuilder refurbished and perhaps rescaled the piano, re-<br />

26 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

moving and resetting the plate, then that action may result in<br />

plate failure.”<br />

Sandy West, a later piano service manager for Baldwin, elaborated:<br />

“It is my considered opinion that a broken plate cannot<br />

be blamed or attributed to a typical tuning/service call. My<br />

experience is that strings will break before the plate will. A<br />

broken plate is usually the result of some major trauma, such<br />

as the piano being dropped or the result of a defect in the<br />

manufacture of the plate. In both such instances the actual<br />

crack or break may not show up for quite some time. It will<br />

develop over time as an eventual result of the continued pressure<br />

on the fault by all the strings. Simply tuning the piano<br />

would not cause such damage.”<br />

Dr. Albert Sanderson pointed out that Marnie Squire’s pitchraising<br />

method had been entirely appropriate, then added:<br />

“It has been my observation that plates that break under<br />

normal tuning stress have a flaw in the casting that can be<br />

seen when the break is examined. A flaw could be a bubble<br />

in the casting or a crack that has been growing gradually over<br />

the years owing to metal fatigue.”<br />

Noted piano rebuilder Tony Geers reiterated the now-familiar<br />

theme:<br />

“Based on the information we have at hand, most notably<br />

the fact that the piano plate broke in both the tuning pin<br />

area and treble bar, it would be our conclusion that faulty<br />

installation of the plate during the manufacturing process is<br />

the most likely cause for the breakage. It is impossible for a<br />

tuner to break a plate by tuning alone. There must be other<br />

circumstances present, i.e., faulty manufacturing, flaw in the<br />

cast iron, piano dropped, etc. Tuning works against the strength<br />

of the cast-iron plate. Over-tuning would cause string breakage<br />

long before any possible damage to the plate could occur.<br />

“If the plate was improperly installed at the factory, plate<br />

breakage is a very real possibility. Improper installation could<br />

be the bending of the plate over the pinblock or securing<br />

bolts or screws. When tension is added by tuning, extreme<br />

stress is focused on the bent portion of the plate; such as in<br />

the area of the tuning pins and treble bars.”<br />

A letter from prominent piano technician and educator Jim<br />

Geiger stated:<br />

“The conclusion is that a normal piano plate, designed<br />

to withstand 40 tons of pressure would not be broken by the<br />

tension from the piano strings regardless of the applied tension,<br />

how fast the tension is applied and at what point of the

ase Study<br />

scale the tension is applied. In the piano factories the tension<br />

is applied as fast as the tuner can bring the strings up to pitch.<br />

Indeed, it should not be possible to break a normal piano<br />

plate with string tension alone, because the strings would<br />

break first. There is just not enough margin between the actual<br />

string tension and the tension at which failure will occur<br />

for the piano wire to be able to produce the force necessary<br />

to cause a good piano plate to fracture.”<br />

University technician Rolf von Walthausen added some background<br />

on the material, then pointed out that some piano models<br />

frequently suffer cracked plates. In this particular case, it turned out<br />

that many Aeolian grands had suffered the same fate. von Walthausen<br />

wrote:<br />

“<strong>Piano</strong> plates are made of cast iron, which is a material<br />

that is extremely hard, but also brittle. Properly cast and installed,<br />

it is capable of withstanding tremendous pressure from<br />

the strings, which are fastened to and held in tension by the<br />

plate. Improperly cast or installed, a cast-iron plate could easily<br />

break or crack. Even if piano wire, which is a steel alloy<br />

with great tensile strength, is stretched quickly beyond a certain<br />

stiffness, the wire will break far, far before exerting a<br />

force on the piano plate that would cause breakage or any<br />

type of damage to the plate.<br />

“Some brands of pianos have frequent occurrence of plate<br />

breakage or cracking. It is rare to find an old Bechstein grand<br />

piano, for example, without a crack in the plate. Opinions<br />

from experts differ as to why this is so (poor casting, design or<br />

installation), but one thing is never disputed: tuning or pitch<br />

raising was never the cause.”<br />

Nevin Essex, another highly regarded technician from the<br />

Cincinnati area, wrote:<br />

“I have been teaching piano tuning and technology<br />

through the <strong>Guild</strong>, at universities and on my own since 1982.<br />

I have researched teaching methods and developed my own.<br />

Nowhere have I ever seen or heard any scientific evidence<br />

that suggests that a piano tuner can break a plate. My understanding<br />

is that plates are designed to withstand much more<br />

tension than exists in any piano. I have never heard any credible<br />

account of a piano tuner breaking a plate. I was never<br />

taught nor do I teach any technique or method designed to<br />

prevent a plate from breaking while tuning. Tuning methods<br />

that emphasize raising pitch evenly do so for the purpose of<br />

achieving a good tuning, not for preventing the plate from<br />

breaking.<br />

The author of The <strong>Piano</strong> Book, Larry Fine, weighed in with<br />

an opinion that even contributed a touch of humor to the situation:<br />

“There are only two ways I know of that a tuner can<br />

break a piano plate that is not defective while servicing a<br />

piano in the home. One way is to excessively tighten the<br />

nose bolt that supports the plate in the center area of the<br />

piano. This is an adjustment not normally made outside of a<br />

piano rebuilding shop. The other way is to take a sledge hammer<br />

to it. In other words, it is virtually impossible for a piano<br />

tuner to break a plate during the normal tuning and pitchraising<br />

of a piano unless the plate is already defective and<br />

ready to break, in which case any tuner, regardless of skill or<br />

method of tuning, will be the unwitting agent of such breakage<br />

by fate alone. Even in a worst-case scenario, in which a<br />

tuner sought to sabotage a piano by stretching all the strings<br />

far above standard pitch, chances are that the strings would<br />

break long before the plate would. Tuners are sometimes<br />

blamed for plate breakage by understandably distraught piano<br />

owners, but in every such case the blame is misguided<br />

and completely unjustified.”<br />

In expectation that the lawsuit would come to trial,<br />

Marnie Squire asked Jim Ellis to look at the piano and to<br />

render an opinion from his background as an engineer. After<br />

examining the piano, Ellis wrote a formal analysis (included in<br />

this issue of PTJ) proving that the plate was poorly designed.<br />

“What I couldn’t understand,” he said, “is why the plate hadn’t<br />

broken when the piano was first strung in the factory.”<br />

Enter Paul Monachino, who had worked for the now-defunct<br />

Aeolian Corporation during the years when the subject piano was<br />

manufactured. Delivering the death-blow to the plaintiff’’s case,<br />

Monachino wrote:<br />

“This problem is nothing new in this style piano. I have<br />

seen this particular plate cracked in the same place many, many<br />

times. The fault lies in the construction of the plate and not in<br />

the tuning of the piano.” (Monachino’s emphases —SB)<br />

The night before the case was scheduled for trial, the<br />

piano owner’s “expert” witness backed out, leaving the<br />

prosecution with no case at all. The shame of the whole story<br />

is that Marnie Squire had been placed in such a position to<br />

begin with. Besides having to spend hundreds of dollars in<br />

attorney’s fees, she was “a nervous wreck” for the year that<br />

passed before resolution. The silver lining to this cloud is that,<br />

because of what she went through, and the unanimous<br />

opinions provided by the real experts, this kind of nightmare<br />

— a lawsuit obviously without basis in fact — should not<br />

have to be suffered by any piano technician again.<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 27

An Analysis of a Broken Plate<br />

By Jim Ellis, RPT<br />

Knoxville, TN Chapter<br />

Background<br />

When Steve Brady called and asked me if I would<br />

contribute an article about broken piano plates<br />

(to replace an article promised by someone else,<br />

but which had never actually materialized), his deadline was<br />

just five days away and I was leaving on a trip in three days.<br />

When I returned it would be too late. Because of the time<br />

constraint Steve and I decided that I should just use an<br />

analysis that I did back in May, 1994 for the Journal article.<br />

The piano was a 1973 J&C Fischer that had been<br />

neglected for several years and allowed to go 37 cents flat.<br />

The scale design had only three major divisions, no agraffes,<br />

and the forward termination for the strings was a long<br />

curved capo bar that ran all the way from #1 in the bass to<br />

#88 in the treble. The middle section spanned 32 triplestring<br />

unisons without any additional support and the<br />

bearing angle of the strings against the bar was excessive.<br />

The dimensional cross section of the bar was minimal, and<br />

there were no shoulder (nose) bolts to secure the plate struts<br />

to any beams underneath. Immediately after the tunertechnician<br />

brought the piano up to standard pitch and<br />

began to check the tuning, the middle section of the capo<br />

bar broke.<br />

Another technician claimed that the plate broke<br />

because the tuner brought the piano back up to standard<br />

pitch in one tuning rather than in several small increments<br />

spread out over a period of days, weeks or months. The<br />

owner filed a lawsuit against the tuner for an amount that, in<br />

my opinion, was far in excess of the actual worth of the<br />

piano. I was asked to be an “expert witness” for the tuner.<br />

Although the piano was located in the Cincinnati area some<br />

260 miles from where I live, I agreed to do it for net<br />

expenses only. The intentions of the piano owner may have<br />

been perfectly honest, but his/her decision to sue was based<br />

upon an erroneous conclusion by another technician and<br />

the result could have set a precedent that would have been<br />

absolutely wrong!<br />

After taking a good look at this particular piano I was<br />

28 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

surprised that that section of the capo bar had not broken<br />

when the piano was first chipped at the factory. I was later<br />

told that some of them did.<br />

The following is the analysis that I presented to the<br />

tuner-technician’s attorney and I was well aware that I<br />

might be called upon to present it in court later on. Fortunately<br />

for everyone the suit was withdrawn the day before<br />

the hearing. This was such a no-winner! The design of the<br />

piano was, in my opinion, just asking for trouble.<br />

The original analysis included four figures, which are<br />

included here, and eight photographs — primarily for the<br />

education of the attorney — that do not appear here<br />

because they are no longer available.<br />

Tuning Procedure Used by Mrs. Squire<br />

Mrs. Squire and I discussed the procedure she had used to<br />

tune the piano just before the plate broke. The piano had<br />

been neglected and not tuned for more than a decade. Mrs.<br />

Squire measured its pitch and found it to be about 37 cents<br />

flat. In tonal nomenclature, a “cent” is 1/100 part of a<br />

semitone; a “semitone” is 1/12 part of an octave; and an<br />

octave represents a ratio of 2:1 in frequency, or pitch. In<br />

going up the musical scale, each of the 12 semitones in an<br />

octave increases by the 12th root of 2, or 1.059463094<br />

above the one below it. Therefore, being “37 cents flat”<br />

means that the frequency (pitch) of the notes on the piano<br />

was about 98 percent of what it should have been at standard<br />

pitch (A=440Hz).<br />

When a piano is flat (low in pitch) by this much,<br />

current procedure calls for raising the pitch of each string<br />

very, very slightly above its normal frequency so that when<br />

it settles after tuning it will be at, or very near, the desired<br />

pitch. It is well within the limits of good tuning practice to<br />

raise the pitch of a piano by 37 cents at one time. Obviously,<br />

the tuner then repeats the tuning in order to obtain a finer<br />

tuning, since the piano will always settle back some. This<br />

procedure is accepted and recommended throughout the

industry. It is my understanding that Mrs. Squire had<br />

actually finished the tuning, and was playing chords to<br />

evaluate the job, when the plate finally broke.<br />

Mrs. Squire was following a tuning procedure that was,<br />

and is, appropriate for the occasion. I can find no fault at all<br />

with what she did.<br />

The Actual Cause of the Plate’s Failure<br />

In order to describe clearly what happened, and what<br />

caused this plate to break in this piano, I must first outline<br />

the most basic principles of cast-iron plates in grand pianos.<br />

Basic Construction of a <strong>Piano</strong> Plate<br />

The plate of a piano is the structure that provides a very<br />

strong, rigid and stable framework inside which all the<br />

strings are strung. It is what makes the modern piano<br />

capable of staying in tune for weeks and months at a time.<br />

<strong>Piano</strong> plates are made of gray cast iron, and not “bell metal,”<br />

as some people believe.<br />

Cast iron is chosen because it is economical, mechanically<br />

stable and has a low coefficient of thermal expansion.<br />

It is very strong under compression, but weak under tension,<br />

Figure 1<br />

and brittle. Its properties depend upon the amount of<br />

carbon and other impurities that it contains, and these can<br />

vary widely. For these reasons, a quality grand piano is<br />

designed so that the areas of high stress concentration in the<br />

plate are those that are under compression, not tension. For<br />

maximum stability and strength, piano plates are almost<br />

always cast in one piece. They are usually finished with a<br />

bronze-lacquer-base paint.<br />

For purposes of illustration, Photo 1 is a photograph of<br />

the tuning-pin area of a high-quality grand piano, not the<br />

piano with the broken plate. [EDITOR’S NOTE: Remember<br />

none of the photos referenced in this article are available for<br />

publication. — SB] The photo shows the reinforcing bars<br />

that are a part of the plate structure, tuning pins, agraffes,<br />

capo bar and strings. The bars that run parallel to the strings<br />

and carry the load of the tension of all the strings lie mostly<br />

above the strings. The total tension can be anything from<br />

30,000 to 50,000 pounds, depending upon the size and<br />

scaling of the piano. Because the strings are all pulling<br />

inward on these bars in a plane that lies below their<br />

centerlines, the bars have a tendency to arch upward in the<br />

middle (See Figure 1).<br />

Continued on Next Page<br />

November 2000 / <strong>Piano</strong> <strong>Technicians</strong> Journal 29

An Analysis of a Broken Plate<br />

Continued from Previous Page<br />

When a bar is bent, the material in the inner part of the<br />

bend is compressed, but that of the outer part of the curve is<br />

under tension and is elongated. Cast iron will not withstand<br />

great bending forces because of its low tensile strength.<br />

The tendency of a piano plate to bow upward in the<br />

middle is normally restrained by anchoring it to massive<br />

wooden beams under the soundboard using shoulder bolts<br />

that extend through the soundboard. There are other<br />

shoulder bolts in this piano, but they are not visible in the<br />

photo. The outer perimeter of the plate is bolted to a very<br />

rigid rim made of laminated hardwood to hold the plate<br />

perfectly flat, and not allow it to bend under the tension of<br />

all the strings. By anchoring the plate in this way, the only<br />

major forces acting on it are compressive, not tensile.<br />

The plate flange at the front of the piano, the bar that<br />

extends across the width of the piano, and the bars that<br />

connect A-B and C-D together, all form a very rigid<br />

structure. Another part of the casting extends downward<br />

from point X and attaches to a massive “cross-beam” that<br />

traverses across the width of the piano below the<br />

soundboard. The point where several of the plate bars<br />

converge, is one of the regions of highest stress concentration<br />

in a grand piano. The part of the casting that ties this<br />

part of the plate to the cross-beam (sometimes referred to as<br />

the “horn” because of its shape), greatly improves the<br />

strength and stability of the plate by securing it (out in the<br />

span across the piano) to the massive structure under the<br />

piano.<br />

Photo 2 is a close-up of the tuning-pin area of the<br />

piano shown in Photo 1. It clearly shows how the strings in<br />

a grand piano extend through the agraffes, which form the<br />

forward termination of the speaking lengths of the strings.<br />

Agraffes are made of machined brass, with threaded studs at<br />

the bottom, which are screwed into threaded holes in the<br />

plate. In this division of the piano, they have three eyelets,<br />

one for each of the three strings in each unison (note).<br />

Making and installing agraffes is time-consuming and costly<br />

because it is detailed work. Nevertheless, this is the preferred<br />

way to terminate the strings of a grand piano, except for the<br />

high treble divisions, where a capo bar is usually used.<br />

Construction of the Plate That Failed<br />

Photo 3 is a picture of the inside of the Fischer piano with<br />

the broken plate. The bar (H-J) in the foreground is broken<br />

at point J, and protrudes upward and slightly to the rear of<br />

the piano.<br />

Photo 4 is a closer view of the broken bar (H—J). A<br />

total of 30 three-string unisons can be seen in this division<br />

of the piano.<br />

30 <strong>Piano</strong> <strong>Technicians</strong> Journal / November 2000<br />

Photos 5 and 6, taken at slightly different angles, are<br />

close-ups of the break at the right-hand end of the bar.<br />

Photo 7 shows the cracked plate at the left-hand end of<br />

the bar.<br />

Photos 5-6-7 clearly show that no agraffes are present.<br />

Instead, the treble capo bar has been extended all the way<br />

through the piano to act as a common forward termination<br />

Pinblock<br />

Figure 2<br />

for all the strings. This appears to have been a cost-cutting<br />

measure by the manufacturer. Photos 5 and 6 show that the<br />

bar jumped upward and toward the rear of the piano when<br />

it broke. Judging from my first-hand observation of the<br />

piano on May 2, 1994, and from the photographs I made,<br />

the angle of rise of the strings as they came forward from<br />

under the bar must have been at least 30 to 35 degrees<br />

before the bar broke. I consider this much bearing angle to<br />

be excessive. An angle of 16 to 18 degrees would have been<br />

more appropriate (See Figure 2).<br />

Photo 8 is a view looking inside the action compartment<br />

of the piano, with the keys and action removed. The<br />

sostenuto rod is in the lower foreground, and the damper<br />

flanges and wires are behind it. The bottoms of the dampers<br />

can be seen above the wires. The “belly rail” (to which the<br />

front edge of the soundboard is glued) lies behind the<br />

damper wires. The cross-beam is just under the belly rail.<br />

The open space between the damper wires (middle of the<br />

photo) under the cross-over between the bass and tenor<br />

strings is where the “horn” (described earlier) would be, if<br />

there were one, but there is not. Neither are there any<br />

shoulder bolts to secure the plate bars or string plate to a<br />

massive under-structure.<br />

The pinblock is the laminated hardwood plank that<br />