Assessment - Mercedes Benz

Assessment - Mercedes Benz

Assessment - Mercedes Benz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

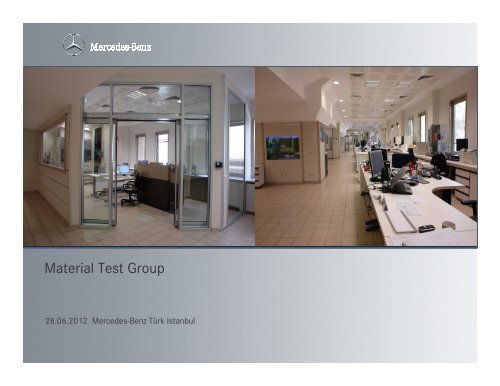

Material Test Group<br />

28.06.2012 <strong>Mercedes</strong>-<strong>Benz</strong> Türk Istanbul

Index<br />

1. Accredited test scopes<br />

2. Metal material tests<br />

3. Non-Metal material tests<br />

Folie 2

Accredited test scopes<br />

Folie 3

Accredited test scopes<br />

1.Chemical Analysis<br />

1.1 Spectrometric (OES) elemental<br />

analysis for low alloyed steel:<br />

%C,%Si,%Mn,%P,%S,%Cr,%Mo,%Ni,%Al,%Cu,<br />

%Pb,%V,%As.<br />

2. Physical Analysis<br />

2.1 Tensile strenght tests for plate steels.<br />

EN ISO 6892-1 thickness,1-15mm<br />

2.2 Microvickers hardness tests HV0.3- HV10<br />

EN ISO 6507-1<br />

2.3 Martindale abrasion tests for fabrics DIN EN<br />

ISO 12947-2<br />

2.4 horixontal / vertical burning behaviour tests<br />

95/28EC, ECE-R 118,FMVSS302, CMVSS302<br />

2. Physical Analysis<br />

2.5 Burning behaviour drop tests<br />

95/28EC, ECE-R 118<br />

2.6 Buring behaviour tests for electircal wires<br />

ECE-R 118<br />

2.7 Determine the capability of isolution materials<br />

to repel fuel or lubricant ECE-R 118<br />

2.8 Xenontest colorfastness and ageing test for<br />

non-metal materials.<br />

(DIN EN ISO 105-B06)<br />

Folie 4

1. Chemical Analysis<br />

1.1 Spectrometric analysis<br />

- Elemental analysis for low alloyed steel<br />

were performed with ARL 3460 optic emission<br />

spectrometer (OES). The results given in % units from<br />

the computer in less then 30sec.<br />

The inspected elements are<br />

%C,%Si,%Mn,%P,%S,%Cr,%Mo,<br />

%Ni,%Al,%Cu,%Pb,%V,%As,<br />

Folie 5

2. Physical Analysis<br />

2.1 Tensile strength tests according to<br />

DIN EN ISO 6892-1 with ZWICK Z600<br />

tensile test equipment<br />

•Material Steel plates:<br />

•Thickness,1-15mm<br />

•Max. capasity 600kN<br />

•working distance max.1940mm<br />

•Working width max. 740mm<br />

2.2 Micorvickers hardness tests<br />

according EN ISO 6507-1 with ZWICK ZHV 10 test<br />

equipment. HV 0.3 - HV10<br />

Folie 6

2. Fiziksel Testler<br />

2.3 This part of IS0 12947 is applicable<br />

to the determination of the inspection<br />

interval to breakdown of specimens<br />

covering all textile fabrics including<br />

nonwovens apart from fabrics where the<br />

specifier indicates the end performance<br />

as having a low abrasion wear life. In<br />

accordance to DIN EN ISO 12947-2<br />

2.4 According to 95/28EC, ECE-R118,<br />

FMVSS302, CMVSS302 regulations<br />

determining of the horizontal and vertical<br />

burning behaviour of non-metal materials<br />

Folie 7

2. Physical tests<br />

2.5 According to 95/28EC, ECE-R118, FMVSS302,<br />

CMVSS302 regulations determining of the melting<br />

burning behaviour of non-metal materials<br />

2.6 Electric cables shall undergo the resistance to flame<br />

propagation test described in ISO standard 6722,<br />

paragraph 12. Minimum of 50 mm insulation at the top of<br />

the test sample shall remain unburned.<br />

2.7 Determining the cabability to repel fuel or lubircant of<br />

insulation materials used in the engine compartment and<br />

any seperate heating compartments.<br />

Folie 8

2. Physical tests<br />

2.8 XENON TestSpecification of colour fastness (to light at high<br />

temperatures) and ageing (to light at high temperatures) to artificial light at<br />

high temperatures in accordance with DIN EN ISO 105-B06:<br />

.Fastness to light at high temperatures<br />

End point determination: Exposure up to DE 4.3+/-0.4 of fastness type 6<br />

(irradiated/covered). Color measurement of the fastness type using a white reference<br />

tile as an underlay.<br />

<strong>Assessment</strong>: Comparison of irradiated specimen with original specimen with<br />

illuminant type D65. <strong>Assessment</strong> with blue scale (fastness types)<br />

Determination of ageing to light at high temperatures<br />

End point determination: as for fastness to light at high temperatures, but involving<br />

several, successive cycles.<br />

<strong>Assessment</strong>: Comparison of irradiated specimen with original<br />

specimen with illuminant type D65. <strong>Assessment</strong> with grey scale<br />

to DIN EN 20105-A02 Common applications include:<br />

• Automotive coatings, fabrics and plastics<br />

• Packaging, Paints, coatings and pigments, Plastics, Window<br />

profiles<br />

• Textiles including industrial and geotextiles<br />

Folie 9

Metaltests<br />

Folie 10

Index<br />

1 Chemical Analysis<br />

1.1 Carbon/Sulphur Determination<br />

1.2 Spectrometric analysis<br />

2 Physical Characteristics<br />

2.1 Tensile strength tests<br />

2.2 Bending and compression tests<br />

2.3 ERICHSEN cupping tests<br />

2.4 Welding control<br />

2.5 Welding and material defect<br />

control<br />

with penetrant liquid<br />

2.6 Spot welding control<br />

2.7 Hardness Tests<br />

3 Metallography<br />

3.1 Analysis with metallurgia microscope<br />

3.2 Analysis with stereo microscope<br />

4 Welding technique<br />

4.1 Welding training according to DIN EN<br />

287<br />

4.2 Welding control according to DIN EN<br />

5817<br />

4.3 Parameter adjustment of welding<br />

equipment<br />

4.3 Consultant services for suppliers<br />

5 Sample preparation<br />

5.1 For metallography and hardness tests<br />

5.2 for spectrometer and tensile stregth<br />

analysis<br />

Folie 11

1. Chemical Analysis<br />

1.1 Carbon / Sulphur determination in<br />

ferrous alloys<br />

•Analysis performed with LECO<br />

C-S 230<br />

•% C and % S amount is measured with<br />

0,00001 accuracy<br />

1.3 Spectrometric analysis<br />

- Ferrous Fe alloys<br />

- Aluminium Al alloys<br />

- Coopfer Cu alloys<br />

- Zinc Zn alloys<br />

Are conducted with ARL 3460 optic emission<br />

spectrometer. Analysis are performed in less than<br />

one minute and results are given by the computer.<br />

Folie 12

2. Physical Analysis<br />

2.1 Tensile, Bending and Compression tests<br />

Tests are performed according EN ISO6892<br />

with ZWICK Z600 tensile testing machine.<br />

For metallic materials<br />

Mills, pipes and metal plates<br />

•Max.600kN capasity<br />

•1940mm working distance<br />

•740mm max. Working width<br />

2.2 ERICHSEN Cupping Test<br />

Sheet Metal Test is with ERICHSEN 102 Deep Drawing Cup according to DIN50101.<br />

Folie 13

2. Physical Characteristics<br />

2.3 Welding Control<br />

•Destructive<br />

•Non-destructive (with penetrant liquids)<br />

•Welding and material defect control with penetrant liquid<br />

• Destructive<br />

• Ultrasonic detector<br />

2.4 Spot Welding Control<br />

Non-destructive<br />

Folie 14

2. Physical Characteristics<br />

2.5 Hardness Tests<br />

•Result units in Rockwell, Brinell and Vickers<br />

•Pressure force between 20-3000 kg<br />

•For all metallic material hardness tests<br />

Hardness of the samples prepared according to DIN Standarts<br />

is measured at Duravision300 hardness tester in accordance with<br />

the standarts given below:<br />

Brinell HB hardness: DIN 50 351<br />

Vickers HV hardness: DIN 50 133<br />

Rockwell HRC, HRB, HRA hardness: DIN 50 103<br />

Folie 15

3. Metallography<br />

Microstructure, welding and fracture<br />

analysis are conducted by the equipment<br />

given below.<br />

•Inverted Research Metallurgica<br />

microscope<br />

OLYMPUS PMG 3<br />

•Stereo Mikroscope OLYMPUS SZH 10<br />

•Visualizer WOLFVİSİON VZ-9<br />

Folie 16

4. Welding Technique<br />

At the Welding Training Center<br />

• MIG/MAG and TIG training in accordance with DIN EN 287 is conducted for welders<br />

and trainees at the production, as well as for the welders of suppliers<br />

• Parameter adjustments of welding machines in production are inspected<br />

• In case of problems consultant services to suppliers are offered<br />

Folie 17

5. Sample Preparation<br />

5.1 For metallography and hardness tests<br />

• Cutting<br />

• Precision cutting<br />

• Hot mounting<br />

• Polishing<br />

Folie 18

5. Sample Preparation<br />

5.2 For wet chemical analysis and<br />

spectrometer<br />

• Analytical balance for weight<br />

measurement of samples<br />

( 0.0001g accuracy)<br />

• Analytical balance for weight<br />

measurement of chemicals<br />

( 0. 01g accuracy)<br />

•Drilling machine<br />

Folie 19

5. Sample Preparation<br />

5.2 For wet chemical analysis and<br />

spectrometer<br />

• Grinding machine for<br />

spectrometer sample preparation<br />

• Furnace<br />

• Fine grinding machine for<br />

spectrometer sample preparation<br />

• Drying oven<br />

Folie 20

Non-Metaltests

Services Offered<br />

1. Chemical Analysis<br />

1.1 Gravimetric Analysis Determination of filler<br />

content<br />

1.2 Pyrolysis testing<br />

1.3 Determination of glasfiber amount<br />

2. Physical Tests<br />

2.1 Shore A / Shore D hardness measurement<br />

2.2 Ball indentation hardness test<br />

2.3 Compression set<br />

2.4 Tension set<br />

2.5 Tensile strength / Elongation at break<br />

2.6 Tear propagation resistance<br />

2.7 Peeling adhesion test<br />

2.8 Peening pressure<br />

2.9 Jib adhesion strength<br />

2. Physical Tests<br />

2.13 Resistance to friction<br />

2.14 Determination of impact properties<br />

2.15 Determination of Vicat softening temperature<br />

2.16 Density<br />

2.17 Mass per unit area<br />

2.18 Water content<br />

2.19 Refractive index<br />

2.20 Kinematic viscosity measurement - Ubbelohde<br />

method<br />

2.21 Flash and fire point<br />

� Cleveland Method<br />

� Abel-Pensky Method<br />

2.22 Boiling point<br />

3. Weathering Test<br />

2.10 Bending strength / bending at maximum bending 3.1 Wash-out discolouration<br />

force<br />

3.2 Ozone resistance<br />

2.11 Stitch pull strength<br />

2.12 Shearing strength<br />

3.3 Low/high temperature behaviour<br />

Folie 22

Services Offered<br />

3. Weathering Test<br />

3.4 Ageing tests<br />

� Hot air ageing<br />

� Testing in ASTM oils<br />

� Testing with coolants (antifreeze)<br />

� Testing in fuels<br />

� Ageing cycle<br />

� Water storage<br />

� Xenotest (DIN EN ISO 105-B06)<br />

4. Instrumental Analysis<br />

4.1 FTIR –Spektrophotometer analysis<br />

4.2 Gas chromatography analysis<br />

4.3 potansiometric titration analysis<br />

4.4 DSC analysis<br />

4.5 TGA analysis<br />

Folie 23

1. Chemical Analysis<br />

1.1 Gravimetric Analysis: Determination<br />

of filler content. The method according to<br />

the standarts DIN 53568 / DIN 53395 /<br />

DIN EN 60 is used for determining the<br />

residue on ignition produced by plastics,<br />

rubber and elastomers without pretreatment.<br />

1.2 Pyrolysis testing<br />

Determination of plastic materials with the<br />

pyrolysis technic and inspecton with FTIR<br />

1.3 Quantative determination of glassfiber in reinforced<br />

plastics according to DIN EN 60.<br />

Folie 24

2. Physical Tests<br />

2.1 Shore A/Shore D hardness<br />

•Plastics<br />

•Rubber<br />

is measured according to DIN 53 505 with Zwick<br />

7206 hardness tester.<br />

2.2 Ball indentation hardness test<br />

Measurements according to DIN EN ISO 2039-1 with<br />

Zwick 3106 hardness tester.<br />

2.3 Compression set<br />

•Rubbers<br />

•PU (Polyurethane materials)<br />

is determined according to DIN ISO 815 and Daimler-<br />

<strong>Benz</strong> specifications.<br />

Folie 25

2. Physical Tests<br />

2.4 Tension set<br />

Tension set of rubber is determined according<br />

to DIN ISO 2285 and Daimler-<strong>Benz</strong><br />

specifications.<br />

2.5 Tensile strength / Elongation at break<br />

•rubber<br />

•plastics<br />

•textile<br />

•1K-PUR adhesives<br />

•Floor covering<br />

•Leather and artifical leather<br />

•Sticky bands<br />

DIN EN ISO 527-1/2/3<br />

DIN EN ISO 1798<br />

DIN 53328<br />

DIN EN ISO 13934-1<br />

Folie 26

2. Physical Tests<br />

2.6 Tear propagation resistance<br />

•Rubber<br />

•Textile<br />

•Leather and artificial leather<br />

is determined with Zwick 1141.<br />

Tensile Testing Machine following VDA675210,<br />

VDA 675211B, DIN 53 356, DIN 57859-5<br />

and DIN EN ISO03377-1/2.<br />

2.7 Peeling adhesion test<br />

•Tissue reinforced elastomers<br />

•Textile reinforced hoses<br />

according to DIN 53 357 and DIN<br />

53 530 with ZWICK Z010 Tensile<br />

Testing Machine.<br />

Folie 27

2. Physical Tests<br />

2.8 Peening pressure<br />

Measurement of peening pressure of textile reinforced hoses<br />

according to DIN53758 with the specified apparatus.<br />

2.9 Jib adhesion strength<br />

Determination of adhesion strength of rubber containing jibs<br />

according to DIN ISO 6133 and Daimler-<strong>Benz</strong> specifications.<br />

2.10 Bending strength / bending at maximum bending force<br />

•Plastic<br />

•Plywood<br />

is determined according to DIN 53 452 and DIN EN 310 with ZWICK Z010.<br />

2.11 Stitch pull strength<br />

The stitch pull strength of leather, artificial leather and similar materials<br />

is determined according to DIN EN ISO 13936-2<br />

with ZWICK Z010 Tensile Testing Machine.<br />

Folie 28

2. Physical Tests<br />

2.12 Shearing strength<br />

•Labels<br />

•Sticky bands<br />

is determined according to DIN 53 278 and DIN 50 017.<br />

2.13 Resistance to friction<br />

•Textile<br />

•Leather and artifical leather<br />

•Floor coverings<br />

according to DIN 54 021 with Crockmeter.<br />

2.14 Darbe Test cihazı<br />

This part of ISO 179/180 specifies a method for determining the<br />

Charpy/Isod/Dynstat impact strength of plastics under defined<br />

conditions. A number of different types of specimen and test<br />

configurations are defined. Different test parameters are specified<br />

according to the type of material, the type of test specimen and the<br />

type of notch.<br />

Folie 29

2. Physical Tests<br />

2.15 This international standart En ISO 306 specifies 4 methods for<br />

the determination of the Vicat softening temperature ( VST) of<br />

thermoplastic materilias.<br />

-- Method A50 using a force of 10 N and a heating rate of 50°C/h<br />

-- Method B50 using a force of 50 N and a heating rate of 50°C/h<br />

-- Method A120 using a force of 10 N and a heating rate of 120°C/h<br />

-- Method B120 using a force of 50 N and a heating rate of 120°C/h<br />

The methods specified are applicable only to thermo-<br />

Plastics, for which they give a messure of the temperature<br />

at which the thermoplastics starts to soften rapidly.<br />

The temperature at which a standart indenting tip with a<br />

Flat point penetrates 1mm into the surface of a plastic<br />

Test specimen is determined.<br />

Folie 30

2. Physical Tests<br />

2.16 Density<br />

•Density of solids is determined according<br />

to DIN EN ISO 1183 and DIN 53 420.<br />

•Density of liquids is determined according to DIN 51 757<br />

with PAAR Density meter.<br />

2.17 Mass per unit area<br />

•Textile<br />

•Leather and artifical leather<br />

Determined according to DIN EN 12127,DIN 53 352,<br />

DIN ISO 536 and DIN ISO 2420.<br />

2.18 Water content<br />

•Plastic<br />

•Wood and plywood<br />

Determined according to DIN 50 011, DIN 53 304, DIN 52 183<br />

and DIN 52375.<br />

Folie 31

2. Physical Tests<br />

2.19 Refractive index<br />

Refractive index is determined according to DIN 51<br />

423 with Atago refractometer.<br />

2.20 Kinematic viscosity measurement –<br />

(Ubbelohde method Measurement) of kinematic<br />

viskosity of automotive oils according to DIN 51<br />

562 with Schott AVS - 440<br />

capillary viscosimeter.<br />

Folie 32

2. Physical Tests<br />

2.21 Flash/fire point<br />

of automotive oils is determined according to<br />

a) Cleveland Method DIN EN ISO 2592<br />

b) Abel - Pensky Method DIN 51 755<br />

of solids is determined according to DIN 53 479<br />

and DIN 53 420<br />

of liquids is determined according to DIN 51 757<br />

with PAAR Density meter<br />

2.22 Destillation<br />

Distillation range of petroleum products is measured<br />

according to DIN 51 751 with Petrotest distillation<br />

apparatus.<br />

Folie 33

3. Weathering Test<br />

3.1 Wash-out discolouration<br />

Wash-out discolouration of rubber is determined<br />

according to VDA 675 242.<br />

3.2 Ozone resistance<br />

Ozone resistance of rubber is determined<br />

According to VDA 675 311 at Hampden<br />

Ozone Testing Cabinet.<br />

3.3 Low / High temperature behaviour<br />

Hot storage behaviour and<br />

the change ofDimensions is<br />

determined according to<br />

DIN 53 497 and DIN 53 377.<br />

Folie 34

3. Weathering Test<br />

3.4 Ageing tests<br />

•Hot air ageing<br />

of rubber and adhesives according to DIN 53 508, VDA 675 310<br />

and Daimler-<strong>Benz</strong> specifications<br />

•Testing in ASTM mineral oils<br />

of rubber according to DIN 53 521<br />

•Testing with coolants (antifreeze)<br />

of rubber according to VDA 52 103<br />

•Testing with test fuels<br />

of rubber according to DIN 51 604 and VDA 675 302<br />

•Ageing cycle<br />

of adhesives in alternating ageing environments e.g. at<br />

room temperature, in hot and cold environment at<br />

humidity cabinet.<br />

•Water storage<br />

of plywood and adhesives according to Daimler-<strong>Benz</strong><br />

specifications.<br />

•Xenotest (DIN EN ISO 105-B06)<br />

Folie 35

4. Instrumental Analysis<br />

4.1 FTIR Spectrophotometer Analysis<br />

•Qualitative/quantitative analysis of rubber, plastics, textile, adhesives<br />

and oil are conducted by Perkin-Elmer FTIR Spectrum One instrument.<br />

•Direct analysis of small-sized materials without pretreatment is<br />

conducted with Split-Pea measurement unit.<br />

4.2 Gas chromatography Analysis<br />

Qualitative/quantitative analysis of volatile organic materials<br />

(particularly solvents) is conducted with Perkin-Elmer Autosystem GC.<br />

4.3 Potansiometric titration analysis<br />

•Conducted by Mettler DL 70 Potansiometric titration instrument<br />

•In automotive oils, determination of total base number according to<br />

DIN ISO 3771<br />

•Total acid number according to ASTM D 664<br />

•Determination of water content in engine oil and solvents according to<br />

Karl-Fischer method DIN ISO 3733<br />

Folie 36

4. Instrumental Analysis<br />

4.4 DSC Analysis<br />

DSC Analysis performaned with Netzsch DSC 204.<br />

Determination of polymetric materials with regard to:<br />

•Glass transition temperature<br />

•melting range<br />

•degree of crystallinity<br />

•heat capacity<br />

•oxidation and thermal stability<br />

4.5 TGA analysis<br />

•Materials are broken down into their constituents by heat<br />

•Qualitative/quantitative analysis are conducted with Netzsch TG<br />

209.<br />

Folie 37