Air Warrior Col. John W. Thompson - KMI Media Group

Air Warrior Col. John W. Thompson - KMI Media Group

Air Warrior Col. John W. Thompson - KMI Media Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

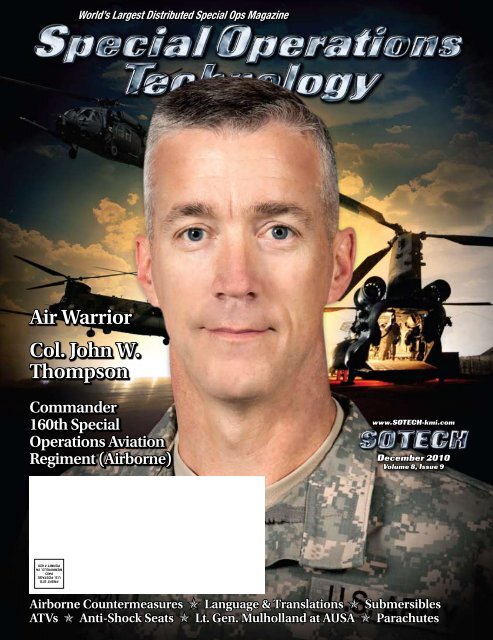

<strong>Air</strong> <strong>Warrior</strong><br />

<strong>Col</strong>. <strong>John</strong> W.<br />

<strong>Thompson</strong><br />

Commander<br />

160th Special<br />

Operations Aviation<br />

Regiment (<strong>Air</strong>borne)<br />

PRSRT STD<br />

U.S. POSTAGE<br />

PAID<br />

MERRIFIELD, VA<br />

PERMIT # 620<br />

World’s Largest Distributed Special Ops Magazine<br />

www.SOTECH-kmi.com<br />

December 2010<br />

Volume 8, Issue 9<br />

<strong>Air</strong>borne Countermeasures O Language & Translations O Submersibles<br />

ATVs O Anti-Shock Seats O Lt. Gen. Mulholland at AUSA O Parachutes

Small. Light. And incredibly fl exible. No wonder the L-3 GCS Hawkeye TM and Cheetah TM<br />

VSATs have been a staple of the U.S. Army’s data technology arsenal. Today, L-3 takes<br />

that technology to the next level with the even smaller and lighter HawkeyeTM III. Rapidly<br />

deployable and able to switch quickly between bands, this next-generation VSAT gives<br />

warfi ghters the data they need where they need it for informed, mission-critical decisions.<br />

Saving effort. Saving money. Saving lives now and in the future. For more information on<br />

HawkeyeTM III, visit L-3com.com/GCS.<br />

GCS<br />

PROUD TO DELIVER OUR 3,000 TH VSAT TO THE U.S. ARMY<br />

AND TO PRESENT THE NEW HAWKEYE TM III<br />

L-3com.com

Sp e c i a l Op e r at i O n S te c h n O l O g y<br />

De c e m b e r 2010<br />

VO l u m e 8 • iS S u e 9<br />

Fe at u r e S cO V e r / Q&a<br />

Special Sction: Countermeasures<br />

6<br />

11<br />

12<br />

16<br />

25<br />

28<br />

32<br />

Defeating Threats<br />

For aircraft carrying special operations teams, the defensive<br />

option remains increasingly sophisticated countermeasure<br />

systems—flares, decoys and other tactics—that ensure the<br />

aircraft will be protected against a missile attack.<br />

By Dennis McCafferty<br />

Mulholland Wish List<br />

What new systems do special operations forces require?<br />

Lt. Gen. <strong>John</strong> F. Mulholland Jr., commander of the U.S. Army<br />

Special Operations Command, outlines what he most wants<br />

contractors to provide.<br />

By Dave Ahearn<br />

Averting Personnel Injuries<br />

U.S. Navy special operations personnel and their watercraft can<br />

take quite a pounding, especially in severe sea states, often<br />

causing discomfort or even acute and chronic injuries. But<br />

systems with new technology can cushion the rough treatment.<br />

By Peter Buxbaum<br />

Unseen Underwater<br />

Submersibles, two-man undersea craft, provide a critical<br />

difference between special operations personnel arriving at a<br />

beachhead objective cold and exhausted with time running out,<br />

or arriving unseen at their destination, well-rested.<br />

By Dave Ahearn<br />

Being Let Down Gently<br />

For the first time in more than 50 years, the U.S. Army is<br />

fielding a new parachute—the T-11. The chute is catching<br />

up with reality: Warfighters today carry enormously heavier<br />

equipment loads than they once did, and the old chute couldn’t<br />

cushion the hard landing of all that weight.<br />

Little Vehicles, Big Capabilities<br />

A new type of war—with a fast-moving and elusive foe in the<br />

shadows—means U.S. military forces must fight in new ways<br />

with new tools, such as small, light all terrain vehicles.<br />

By Dave Ahearn<br />

Act Globally, Talk Locally<br />

The challenge of communicating globally has expanded<br />

traditional language instruction and led to rapid innovation.<br />

The Holy Grail of technology is a field device that can do<br />

two-way translation. That may be coming soon.<br />

By Henry Canaday<br />

w w w .SOtech-k m i .c O m<br />

21<br />

<strong>Col</strong>onel <strong>John</strong> W. <strong>Thompson</strong><br />

Commander<br />

160th Special Operations Aviation<br />

Regiment (<strong>Air</strong>borne)<br />

De pa r t m e n t S<br />

2<br />

3<br />

5<br />

18<br />

35<br />

Editor’s Perspective<br />

Whispers<br />

People<br />

Black Watch<br />

Calendar, Directory<br />

in D u S t r y in t e r V i e w<br />

36<br />

David Wilberding<br />

Vice President<br />

STIDD Systems Inc.

Sp e c i a l Op e r at i O n S<br />

te c h n O l O g y<br />

VO l u m e 8, iS S u e 9 De c e m b e r 2010<br />

World’s Largest Distributed<br />

Special Ops Magazine<br />

eDitOrial<br />

Editor<br />

Dave Ahearn davea@kmimediagroup.com<br />

Managing Editor<br />

Harrison Donnelly harrisond@kmimediagroup.com<br />

Senior Copy Editor<br />

Laura Davis laurad@kmimediagroup.com<br />

Correspondents<br />

Dennis McCafferty • Henry Canaday • Peter Buxbaum<br />

ar t & De S i g n<br />

Art Director<br />

Anna Druzcz anna@kmimediagroup.com<br />

Senior Graphic Designer<br />

Jittima Saiwongnuan jittimas@kmimediagroup.com<br />

Graphic Designers<br />

Scott Morris scottm@kmimediagroup.com<br />

Jennifer Owers jennifero@kmimediagroup.com<br />

Eden Papineau edenp@kmimediagroup.com<br />

Kailey Waring kaileyw@kmimediagroup.com<br />

aDVertiSing<br />

Account Executives<br />

James Eget jamese@kmimediagroup.com<br />

Laura Pawlowski laurap@kmimediagroup.com<br />

kmi me D i a gr O u p<br />

Publisher<br />

Kirk Brown kirkb@kmimediagroup.com<br />

Chief Executive Officer<br />

Jack Kerrigan jack@kmimediagroup.com<br />

Chief Financial Officer<br />

Constance Kerrigan connik@kmimediagroup.com<br />

Executive Vice President<br />

David Leaf davidl@kmimediagroup.com<br />

Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com<br />

Controller<br />

Gigi Castro gcastro@kmimediagroup.com<br />

CEO’s Assistant<br />

Carol Ann Barnes carolannb@kmimediagroup.com<br />

Op e r at i O n S , circulatiOn & pr O D u c t i O n<br />

Database Administrator<br />

Toye McLean toyem@kmimediagroup.com<br />

Call Center Coordinator<br />

Duane Ebanks duanee@kmimediagroup.com<br />

Data Specialists<br />

Wayne Brooks wayneb@kmimediagroup.com<br />

Stephine Green stephineg@kmimediagroup.com<br />

Sasha Scott sashas@kmimediagroup.com<br />

ma r k e t i n g & On l i n e<br />

Marketing & Online Director<br />

Amy Stark astark@kmimediagroup.com<br />

Trade Show Coordinator<br />

Holly Foster hollyf@kmimediagroup.com<br />

a pr O u D<br />

me m b e r O F :<br />

Special Operations Technology ISSN 1552-7891<br />

is published nine times a year by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong>.<br />

All Rights Reserved. Reproduction without permission is<br />

strictly forbidden. © Copyright 2010.<br />

Special Operations Technology is free to members of the<br />

U.S. military, employees of the U.S. government and<br />

non-U.S. foreign service based in the U.S.<br />

All others: $65 per year.<br />

Foreign: $149 per year.<br />

Corporate Offices<br />

<strong>KMI</strong> <strong>Media</strong> <strong>Group</strong><br />

15800 Crabbs Branch Way, Suite 300<br />

Rockville, MD 20855-2604 USA<br />

Telephone: (301) 670-5700<br />

Fax: (301) 670-5701<br />

Web: www.SOTECH-kmi.com<br />

The Department of Defense is in the rare position where fiscal 2012 agency<br />

budgets likely will be cut amidst a hot war and many rising threats. While<br />

Secretary of Defense Robert Gates wishes to see the cuts he is proposing in the<br />

defense budget go to create savings that can be funneled into other military<br />

programs he deems essential, some deficit-cutting advisers are urging that the<br />

savings from defense program cuts be used instead to lessen budget deficits and<br />

government borrowing. We are betting on the latter, rather than the former,<br />

outcome.<br />

Congress next year will decide just how large those cuts in existing programs<br />

will be, but it is clear that the proposed administration budget released in<br />

February will call for substantial reductions in many areas, perhaps offset by<br />

some increases elsewhere or spending on new initiatives such as personnel or veterans’ needs. Though the department<br />

has seen, and survived, major spending cuts before, they typically came in peacetime. For example, the “peace<br />

dividend” defense spending cuts came as the <strong>Col</strong>d War ended decades ago, and the threat of a nuclear exchange<br />

receded. Too, at the end of World War II, defense spending plunged as victorious troops returned home to be hailed<br />

as heroes.<br />

This time, however, there is no treaty signing on the deck of a huge ship, no hated wall being demolished. Rather,<br />

hostilities continue. Though sometimes in disarray, terrorists still plot ways to bring devastation to American shores,<br />

and to the streets of magnificent cities such as London and Paris. Terrorist leaders are being picked off steadily in<br />

U.S. strike missions, but their organizations still persist in launching further attacks with rifles, belt bombs, truck<br />

bombs and more. And the enemy is diabolically inventive, eventually countering each U.S. move to defeat improvised<br />

explosive devices, bombings and the like. Let us also not forget the rise of near-peer competitors.<br />

What all this means is that U.S. commanders cannot say they will do less because their agencies are funded<br />

less, especially because allies won’t pick up any slack (their defense budgets are being<br />

cut as well). Rather, American forces will have to do more with less, whether it is<br />

devising better IED detection devices, improved handheld translators, or other vital<br />

improvements. My bet is that both the U.S. military and contractors will rise to the<br />

challenge, increasing protections for the nation, its allies, civilians and others. We’ve<br />

done it before, and we’ll do it again.<br />

Ot h e r kmi me D i a gr O u p ma g a z i n e S a n D we b S i t e S<br />

Military Medical/<br />

CBRN Technology<br />

www.MMT-kmi.com<br />

U.S. Coast Guard<br />

Forum<br />

www.CGF-kmi.com<br />

Geospatial<br />

Intelligence Forum<br />

Official Publication of the United States Geospatial Intelligence Foundation<br />

Brig. Gen.<br />

Jeffrey<br />

C. Horne<br />

Deputy Director<br />

for Mission Support<br />

National<br />

Reconnaissance<br />

Office<br />

Tactical GEOINT ���International Satellites ���Geospatial Standards ���UAV Imagery<br />

National <strong>Air</strong> & Space Intelligence Center<br />

www.GIF-kmi.com<br />

www.GIF-kmi.com<br />

ww .GIF -kmi.co<br />

May/June M /J 2009<br />

Volume 7, Issue 3<br />

Military Information<br />

Technology<br />

Military Logistics<br />

Forum<br />

www.MLF-kmi.com<br />

Military Training<br />

Technology<br />

Dave Ahearn<br />

301-670-5700 Ext. 140<br />

Ground Combat<br />

Technology<br />

www.GCT-kmi.com<br />

Military Advanced<br />

Education<br />

www.MIT-kmi.com www.MT2-kmi.com<br />

www.MAE-kmi.com

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

Boeing delivered the 40,000th Combat<br />

Survivor Evader Locator (CSEL)<br />

combat search and rescue communications<br />

system to U.S. joint services,<br />

expanding their ability to reach and<br />

rescue isolated pilots or combat personnel.<br />

“CSEL provides U.S. forces with<br />

a tactical advantage by serving as a<br />

Boeing Delivers 40,000th CSAR Comms<br />

SureFire Wins Two<br />

USSOCOM Contracts<br />

SureFire LLC won two contracts from USSO-<br />

COM for weapon lights. One pact will provide<br />

forces with the VBL-H (Visible Bright Light-<br />

Heavy) fire control device for the crew-served<br />

weapon systems used by U.S. special operations<br />

forces. The $16.6 million contract procures an<br />

indefinite quantity of SureFire HellFighter heavygun<br />

WeaponLights. In the second deal, USSOCOM<br />

will obtain the Visible Bright Light III (VBL-III)<br />

in support of the USSOCOM weapons accessories<br />

program, under a $14.9 million indefinite quantity<br />

agreement.<br />

HellFighter has been used in combat operations<br />

in both Iraq and Afghanistan and has proved<br />

to be an effective target illuminator and searchlight,<br />

as well as a non-lethal escalation-of-force<br />

preventer, the company stated. In addition to<br />

mounting to the .50 caliber M2HB, M134 Mini-<br />

Gun, and M240-variant machine guns, Hell-<br />

Fighter can also be hand carried as a searchlight<br />

or mounted to a vehicle or watercraft.<br />

In the other contract, the company will supply<br />

new “V-Series” LED WeaponLights—the M620V<br />

Scout Light and M720V RAID light—both of which<br />

feature high-output white-light and infrared illumination<br />

from the same sealed unit. Unlike incandescent<br />

weapon-mounted lights, which require an<br />

infrared filter to produce enough infrared illumination<br />

for use with night vision devices, V-Series<br />

LED lights require no IR filter. To convert from<br />

white to IR light (or vice versa), the user need<br />

only twist the light’s self-locking selector ring.<br />

Work on the contracts will be performed by Sure-<br />

Fire at their Southern California facilities and is<br />

expected to be completed by September of 2015.<br />

The contracts were awarded by the Naval Surface<br />

Warfare Center, Crane Division, in Crane, Ind.<br />

global emergency-call system for downed<br />

personnel,” said Michael Bates, Boeing<br />

CSEL program manager. “Rescue forces<br />

can quickly locate, authenticate and<br />

communicate with isolated personnel for<br />

urgent recovery operations.”<br />

The CSEL system uses a flexible,<br />

modular communications architecture<br />

over multiple satellite links for dependable,<br />

secure communications. “This<br />

network-centric system combines everything<br />

downed pilots and combat forces<br />

need in one easy-to-use, multifunction<br />

radio,” Bates added. “Boeing is currently<br />

working with the U.S. <strong>Air</strong> Force on nextgeneration<br />

system improvements.”<br />

Remington Upgrades<br />

M24 Sniper Weapon<br />

The Army awarded Remington Arms Co. Inc. a five-year<br />

contract worth up to $28.2 million to upgrade as many<br />

as 3,600 M24 sniper weapon systems. That system, now<br />

called the M24E1, will be improved by Remington under<br />

the firm fixed-price, indefinite delivery/indefinite quantity<br />

contract. The improvement will center on converting from<br />

the 7.62 mm NATO caliber, which is the .308 Winchester,<br />

to the .300 Winchester Magnum, enhancing both precision<br />

and range. Further, the upgrade will involve a new chassis<br />

(or stock) assembly, and a folding buttstock for easier<br />

transport and greater concealment.<br />

Further, the improved weapon will boast a 6.5-20x50<br />

variable power Leupold riflescope with a reticle within the<br />

first focal plane, and a .300 Winchester Magnum bulletdrop<br />

compensator. Other advancements include a quick<br />

attach/detach Advanced Armament Corp. suppressor with<br />

muzzle brake, a five-round detachable box magazine and<br />

advanced corrosion-resistant coatings.<br />

Jason Schauble, Remington Defense Division vice<br />

president, explained the goal in the program. “Remington<br />

has made significant investments in manufacturing modernization,<br />

end-user driven research and development, and<br />

complementary technologies to provide a wide range of<br />

reliable, durable and maintainable small arms solutions,”<br />

he said.<br />

Winning in a competition this year that lasted nine<br />

months, Winchester received the award from the Army<br />

Joint Munitions and Lethality Contracting Center. Executing<br />

the program will be the Project Manager Soldier Weapons<br />

at Picatinny Arsenal, N.J., and its Product Manager<br />

Individual Weapons unit. Remington thus far has produced<br />

almost 15,000 M24 sniper weapon systems over 22 years.<br />

The payoff for combat troops is that the upgraded weapon<br />

will be able to chamber a longer and more powerful round,<br />

giving soldiers an edge in operations in Southwest Asia.<br />

jason.schauble@remington.com<br />

www.SOTECH-kmi.com SOTECH 8.9 | 3

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

EOD Small<br />

Unmanned Vehicles<br />

The <strong>Air</strong> Force gave Boeing and iRobot Corp. an initial<br />

contract to provide small unmanned ground vehicles (SUGV)<br />

to its Explosive Ordnance Disposal team. The contract calls<br />

for up to 70 model 310 SUGV robots, with an initial value<br />

of $3.84 million. The indefinite delivery/indefinite quantity<br />

contract will run through September 2012. Boeing, the prime<br />

contractor, and iRobot developed the SUGV family of vehicles<br />

under a strategic alliance that began in 2007.<br />

The unmanned vehicle is designed to give warfighters<br />

real-time awareness of critical situations and allow them<br />

to complete missions from safe standoff distances. Boeing<br />

provides program management, contracts and qualitycontrol<br />

support from offices in Huntsville, Ala. IRobot is<br />

responsible for engineering, manufacturing, training and<br />

logistics services, with the majority of work conducted in<br />

Bedford, Mass.<br />

Saving Lives: THULS System Lets<br />

Medics Record Battlefield Care<br />

The THULS medical<br />

care card permits medics<br />

to record information<br />

on pre-hospital care<br />

given to troops on the<br />

battlefield. That card<br />

currently is used at<br />

the Special Operations<br />

Combat Medic Course<br />

at Fort Bragg, N.C., and<br />

with several operational<br />

units, according to MIR<br />

Inc., which partnered<br />

with Combat Medical<br />

Systems on the card. The<br />

Tactical Combat Casualty<br />

Care Card is being offered to SOF.<br />

A THULS DA Form 7656, the<br />

card can be written on with an<br />

Ultra-fine Sharpie or Staedler<br />

Permanent Map Pen and erased<br />

with >90 percent rubbing alcohol.<br />

Using a pencil, it can be written on<br />

and erased in all weather conditions,<br />

including underwater and<br />

through both human blood and<br />

moulage. Warfighters are able to<br />

4 | SOTECH 8.9<br />

pre-fill their personal information<br />

with a permanent pen and keep<br />

their cards in their IFAK or breast/<br />

sleeve pockets. Because the cards<br />

are re-writable, operators/medics<br />

can train with the cards to build<br />

the muscle memory necessary for<br />

use during the chaos of combat—<br />

enabling units to have a much<br />

higher success rate in documenting<br />

pre-hospital care.<br />

Recon Scout Provides<br />

Remote Eyes for Intel<br />

The Recon Scout can be fitted<br />

with a new SearchStick pole that permits<br />

a camera to see over a 12-foot wall<br />

or into a second-story window, maker<br />

ReconRobotics Inc. said. Jaws on the<br />

pole grasp the two-wheeled, 1.2-pound<br />

Recon Scout robotic vehicle, and the<br />

pole can extend from a retracted 20.5inch<br />

length to six feet. As cameras on<br />

the SearchStick pole gather visual intel,<br />

the robot transmits live video to a handheld<br />

operator control unit, providing<br />

operators with vital situational awareness<br />

that protects the lives of soldiers<br />

during high-risk operations, according<br />

to the company.<br />

The SearchStick also can be used<br />

to quietly place a robot into an elevated or confined space, where it can<br />

search the environment for adversaries, IEDs or other threats. Once the<br />

inspection is complete, the operator can use the jaws on the SearchStick<br />

to retrieve the robot. Zistos Corp., a world leader in pole camera technology,<br />

will manufacture the SearchStick for ReconRobotics.<br />

“We have nearly 1,200 Recon Scout micro-robots deployed around<br />

the world, and this new product dramatically expands their utility and<br />

versatility,” said Alan Bignall, president and CEO of ReconRobotics. “No<br />

other robot in the world can be used as a pole camera, and no other<br />

pole camera can instantly deploy its optical system as a mobile microrobot.<br />

When used together, our Recon Scout robot and SearchStick pole<br />

give soldiers and tactical operators a uniquely powerful reconnaissance<br />

system that can safely reveal hidden threats, limit collateral damage and<br />

resolve dangerous situations.”<br />

The Recon Scout SearchStick and robot system is particularly useful<br />

for gaining visual access into walled compounds, rooftops, attics, ventilation<br />

systems, tunnels and crawl spaces. And because most Recon Scout<br />

robots are equipped with infrared optical systems, this visual reconnaissance<br />

can be conducted in complete darkness. Recon Scout robots may<br />

be specified in any of three transmitting frequencies, allowing police<br />

and military personnel to operate up to three robots in the same environment<br />

at the same time. The robot allows tactical teams to quickly<br />

and safely clear large multi-level structures before personnel enter<br />

these environments.<br />

Several branches of the U.S. military and international friendly forces<br />

have deployed Recon Scout robots around the world to assist warfighters<br />

in route clearing operations, remote reconnaissance and IED inspection.<br />

In addition, nearly 200 police and security agencies use Recon Scout<br />

robots for tactical reconnaissance, including the many police tactical<br />

teams as well as the FBI, U.S. Marshals, Border Patrol, DEA and the<br />

Bureau of Alcohol, Tobacco, Firearms and Explosives.<br />

www.SOTECH-kmi.com

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

people<br />

Marine Corps Lieutenant<br />

General Thomas D.<br />

Waldhauser has been<br />

named commanding general<br />

of I Marine Expeditionary<br />

Force, and commander of<br />

the Marine Corps Forces<br />

Central Command in Camp<br />

Pendleton, Calif. He also has<br />

been tapped for re-appointment<br />

to the rank of lieutenant<br />

general. Waldhauser—<br />

currently the deputy<br />

commandant for plans,<br />

policies, and operations in<br />

Washington, D.C.—replaces<br />

Marine Corps Lieutenant<br />

General Joseph F. Dunford<br />

Jr. Dunford is advancing to<br />

assistant commandant of the<br />

Marine Corps, and will be<br />

promoted to the rank<br />

of general.<br />

Brendan O’Connell has<br />

been named president of<br />

the Department of Defense<br />

business unit at Harris RF<br />

Communications. Harris RF<br />

Communications, maker<br />

of comms for vehicles and<br />

dismounted troops that<br />

can be used in theater, was<br />

formerly headed by Stephen<br />

Marschilok, who was named<br />

president of the Harris public<br />

Oshkosh Gains $797 Million Army Truck Order<br />

The Army provided Oshkosh Defense with<br />

a $797 million truck and trailer order. The<br />

company will supply more than 4,700 family<br />

of medium tactical vehicle (FMTV) trucks and<br />

trailers under the order from the Army TACOM<br />

Life Cycle Management Command.<br />

The FMTV supports Army and National<br />

Guard units at home and abroad in combat<br />

operations, relief efforts, unit resupply missions<br />

and other functions. “We are eager to fill this<br />

new order and continue to drive Oshkosh FMTVs<br />

off the production lines and into the field,” said<br />

Mike Ivy, vice president and general manager of<br />

Army programs for Oshkosh Defense.<br />

This order is part of a five-year FMTV<br />

contract awarded to Oshkosh Defense for the<br />

safety and professional<br />

communications unit.<br />

O’Connell spent the last<br />

five years as vice president<br />

of DoD sales. Prior to that,<br />

he held management positions<br />

of increasing responsibility,<br />

including director of<br />

European and Central Asia<br />

sales and director of Asia<br />

Pacific sales, Middle East sales<br />

and government programs.<br />

Jason Kovatch<br />

Jason Kovatch joined the<br />

engineering team at AR<br />

Modular RF. Kovatch will<br />

become a development engineer,<br />

creating and supporting<br />

all automated test systems<br />

and amplifier product development<br />

and testing. He previously<br />

has been employed<br />

at the Agilent Technologies<br />

signal analysis division and<br />

Hewlett Packard. He also has<br />

worked in NASA programs,<br />

serving as an associate at the<br />

Jet Propulsion Laboratory in<br />

Pasadena, Calif., to advance<br />

a microgravity containerless<br />

program and the Deep<br />

Space Network.<br />

Paul Osenar was named<br />

president and CEO of<br />

Protonex Technology Corp.<br />

A co-founder of the firm,<br />

Osenar was chief technology<br />

officer since 2004 and a<br />

member of the board of directors<br />

since the company’s<br />

founding. Osenar succeeds<br />

Scott Pearson in the CEO<br />

post, which Pearson held for<br />

the last six years. Pearson<br />

will become board chairman<br />

and remain with the company<br />

in a non-executive capacity.<br />

Harry Fitzgibbons, Protonex<br />

chairman since May 2006,<br />

remains on the board as a<br />

non-executive director.<br />

Michael Strianese, L-3<br />

chairman, president and<br />

chief executive officer, was<br />

presented with the <strong>John</strong><br />

W. Dixon Award at the<br />

Association of the United<br />

States Army (AUSA) 2010<br />

annual meeting and<br />

production of the Army’s medium vehicle fleet,<br />

as well as support services and training, through<br />

fiscal 2013. The order brings total FMTV orders<br />

to date to more than 14,000 trucks and trailers.<br />

The Army’s delivery order includes more than<br />

4,150 trucks and 590 trailers. Deliveries are<br />

scheduled to begin in September 2011 and<br />

finish in August 2012.<br />

exposition in Washington,<br />

D.C. Strianese received the<br />

award for the company’s<br />

ongoing contributions to<br />

the armed forces and the<br />

defense industry.<br />

Warren Sitzinski<br />

Army Veteran Warren<br />

Sizinski joins 50d Tactical<br />

to deliver next-generation<br />

thermal control products to<br />

the armed forces. “I’m very<br />

excited about joining this<br />

team,” Sizinski said. “The<br />

efficient cooling provided by<br />

50d Tactical products is doing<br />

everything from improving<br />

soldier alertness in the field to<br />

extending talk time of mobile<br />

communications gear.” 50d<br />

Tactical is part of HTFx ,<br />

which among other things<br />

makes thermal gear that can<br />

help to keep soldiers cool even<br />

in very hot climates.<br />

www.SOTECH-kmi.com SOTECH 8.9 | 5

Special Sction: Countermeasures<br />

Defeating<br />

Threats<br />

6 | SOTECH 8.9<br />

www.SOTECH-kmi.com

www.SOTECH-kmi.com<br />

Co u n t e r m e a s u r e s s a v e a i r C r a f t, C r e w s.<br />

By De n n i s mCCaf f e r t y<br />

soteCH Co r r e s p o n D e n t<br />

m C C a f f e r t y D@km i m e D i a g r o u p.Co m<br />

As in sports, much of the attention in military-combat assets<br />

is focused on the offense, meaning systems that attack. But it’s<br />

often the defense that wins the game.<br />

For aircraft carrying special operations teams, the defensive<br />

option remains increasingly sophisticated countermeasure sys-<br />

tems—flares, decoys and other tactics—that ensure the aircraft<br />

will be protected against a missile attack.<br />

SOTECH 8.9 | 7

Special Sction: Countermeasures<br />

That protection is critical, literally<br />

a matter of life and death<br />

for crew members on SOF<br />

and other U.S. military aircraft.<br />

Consider, for example,<br />

an incident involving<br />

an MV-22 Osprey flown by a<br />

Marine Corps pilot in Iraq,<br />

where enemies mounted<br />

an intense missile attack<br />

directed at the aircraft.<br />

Bill Kasting, ATK vice<br />

president and general manager<br />

for defense electronic<br />

systems, explained how, a<br />

few months ago, that Marine Corps pilot<br />

spoke to ATK employees who work on the<br />

AAR-47 sensor system that is mounted on<br />

aircraft such as the Marine pilot’s Osprey<br />

to detect incoming missiles. The Marine<br />

pilot described how his Osprey was fired<br />

upon by multiple missiles.<br />

Fortunately, the pilot’s MV-22 was<br />

equipped with the ATK AAR-47 sensor<br />

system, which immediately detected the<br />

incoming missiles. “The AAR-47 actually<br />

alerted them to the situation, and they<br />

were allowed to perform their evasive<br />

maneuvers and deploy the countermeasures,<br />

and they really felt that the [AAR-<br />

]47 was the primary reason they were able<br />

to survive that engagement,” Kasting said<br />

in an interview with SOTECH.<br />

ATK makes the sensor that swiftly<br />

detects incoming threats, while others<br />

make the system that deploys countermeasures<br />

to confuse an incoming missile,<br />

neutralizing the enemy weapon. The<br />

AAR-47 sensor is designed to work with<br />

the ALE-47 chaff dispenser provided by<br />

Symetrics Industries.<br />

AAR-47 sensor units, which are small<br />

and light so they don’t hog aircraft space<br />

and payload capacity, utilize dual sensor<br />

capabilities. “One is the UV sensor,”<br />

Kasting explained. “It’s non-imaging UV,<br />

which is the primary sensor to detect<br />

a missile firing. And then there’s also a<br />

laser warning sensor integrated into that<br />

[system unit] as well, that detects laser<br />

threats. [The AAR-47] is actually the only<br />

system out there today that integrates<br />

laser warning and missile warning into a<br />

single sensor.”<br />

The AAR-47 system currently is<br />

mounted on Navy and Marine Corps rotary<br />

wing aircraft including “the UH-60s, the<br />

8 | SOTECH 8.9<br />

Bill Kasting<br />

CH-53s, the UH-1 and the MV-22,” Kasting<br />

said. “It’s also deployed<br />

on several fixed wing aircraft:<br />

the C-17, the C-130s<br />

and also some of the<br />

smaller aircraft.” The Navy<br />

recently awarded ATK a $67<br />

million indefinite delivery/<br />

indefinite quantity contract<br />

to produce AAR-47s.<br />

Improvements in the<br />

AAR-47 include enhanced<br />

capabilities to pick out and<br />

identify incoming enemy<br />

missiles, even when they<br />

are flying in airspace cluttered with a<br />

confusion of other traffic, Kasting said.<br />

ATK also is working on improvements<br />

to the AAR-47 so it will tell the ALE-47<br />

countermeasures dispenser the direction<br />

from which the enemy missile is arriving,<br />

allowing countermeasures to be dispensed<br />

just in that direction.<br />

ATK is now working on the nextgeneration<br />

sensor system, which would<br />

so precisely track the exact location of an<br />

incoming enemy missile that the sensor<br />

could guide a different type of countermeasures<br />

system, such as a directional<br />

infrared countermeasures system that<br />

can defeat the heat-seeking infrared homing<br />

guidance systems on man-portable<br />

air defense missiles, Kasting said.<br />

Another advancement will be sensors<br />

identifying smaller, but still potentially<br />

lethal, threats short of enemy missiles,<br />

such as small-arms fire up to unguided<br />

rocket propelled grenades, Kasting said.<br />

These are major advancements from<br />

the primitive countermeasures systems<br />

of years ago.<br />

In the not-so-distant past, these systems<br />

were analog-based designs. Today,<br />

everything is a micro-processor based<br />

digital solution. Hardware is still important,<br />

but more off-the-shelf hardware is<br />

being used to take advantage of the high<br />

level of processing available in today’s<br />

commercial marketplace, such as multicore<br />

processors and graphical processing<br />

units, said Michael Maas, technology<br />

director of survivability and protection<br />

solutions for BAE Systems, a global<br />

defense, security and aerospace company.<br />

“Just like your home personal computer,<br />

the capabilities and function of future<br />

solutions will be determined as much<br />

by the software as by the hardware,” he<br />

says. “Our military customers are looking<br />

for product solutions that reduce the<br />

overall weight of the self protection suite<br />

and have higher reliability, resulting in<br />

lower life cycle cost and higher mission<br />

availability.”<br />

BAE has recently unveiled the Boldstroke,<br />

an integrated aircraft survivability<br />

system for the U.S. Army’s Common<br />

Infrared Countermeasures program. The<br />

Boldstroke is a modular, lightweight and<br />

directable infrared countermeasure suite<br />

designed to protect the Army’s helicopter<br />

fleet from current and evolving threats,<br />

as well as multiple, simultaneous ones.<br />

It features a pointer-tracker system to<br />

support direct or fiber-coupled lasers,<br />

and a single rigid optical bench for easy<br />

assembly, alignment and stability in a<br />

flight environment. BAE Systems has<br />

more than 15,000 infrared and electronic<br />

countermeasures systems fielded<br />

worldwide on both fixed and rotary wing<br />

aircraft. The company’s AN/AAR-57 Common<br />

Missile Warning System (CMWS)<br />

has logged more than 1.4 million combat<br />

flight hours in protecting aircrews, for<br />

example, providing missile warning for<br />

rotary and fixed wing aircraft with a low<br />

false-alarm rate and the ability to detect<br />

and declare prior to missile burnout. It<br />

also features stabilized imagery during<br />

high-speed maneuvers to permit rapid<br />

threat detection and notification, ensuring<br />

the highest probability of successful<br />

threat countermeasures. The CMWS is<br />

compatible with existing chaff/flare/RF<br />

decoy dispensers and directional IR countermeasure<br />

systems.<br />

The current challenge for the vendor,<br />

Maas said, is to develop and field<br />

systems faster so that they’re not one or<br />

two generations behind the commercial<br />

market, which doubles capability every 18<br />

months, as the popular Moore’s Law has<br />

proven out. They need to work in extreme<br />

temperatures, with state-of-the-art processors<br />

that have high-power densities<br />

so they can “run hot.” Getting that kind<br />

of heat performance when “operating<br />

in the high ambient temperatures seen<br />

in the desert during the summertime is<br />

very challenging,” Maas said. “It’s hard<br />

to believe, but available packaging volume<br />

and its associated thermal cooling<br />

limitation is one of most difficult factors<br />

www.SOTECH-kmi.com

and in many ways can<br />

limit overall performance<br />

and reliability.”<br />

There’s also a need<br />

to develop system-level<br />

architectures that can<br />

accept updated processing<br />

elements without<br />

having to do a total<br />

redesign of the hardware<br />

and software. As<br />

in the commercial market,<br />

military customers<br />

want a system in which<br />

they can unplug a video<br />

card from a personal<br />

computer and replace it<br />

with a newer and more<br />

powerful card by simply<br />

loading new “software<br />

drivers” with no need to change the<br />

operational software. “Also, I believe that,<br />

just like your home computer’s ability<br />

to run multiple simultaneous programs,<br />

these future systems will support multifunctional<br />

capabilities through multicore<br />

parallel processing,” Maas added.<br />

The market for these products is not<br />

huge—just $10 million to $15 million<br />

annually per contract—but it’s a healthy,<br />

steady demand, said Mike Shoemaker,<br />

vice president of sales and marketing for<br />

Alloy Surfaces Company Inc., a Chester<br />

Township, Pa.-based subsidiary of<br />

the Chemring <strong>Group</strong> that manufactures<br />

infrared air countermeasures and is said<br />

to be the only manufacturer of special<br />

material decoys (SMDs). Its MJU-49/B, a<br />

special material decoy pyrophoric infrared<br />

(IR) countermeasure has been developed<br />

and manufactured for the U.S. Navy,<br />

designed to defend helicopters and jet<br />

aircraft from missile threats worldwide.<br />

It emits IR energy in the same band as<br />

an aircraft, and can be employed using<br />

the ALE-39 series or any countermeasure<br />

dispensing system capable of employing<br />

a round 36 mm flare. It contains<br />

no pyrotechnics other than a CCU-136<br />

squib, required to expel the SMD from<br />

the flare casing. Once expelled, the SMD<br />

reacts with oxygen to rapidly oxidize<br />

and generate an IR signature. However,<br />

the temperature is less than half the<br />

temperature of conventional materials,<br />

and SMD is considered extremely safe<br />

to handle.<br />

An AC-130U gunship jettisons flares over an area near Hurlburt Field, Fla. The flares are a countermeasure for heat-seeking missiles that may be fired at the aircraft<br />

during real world missions. The aircraft is from the 4th Special Operations Squadron. [Photo courtesy of U.S. <strong>Air</strong> Force]<br />

A formation of C-130 Hercules aircraft fire off chaff and flare countermeasures over the Nevada Test and Training Range during a<br />

mobility exercise. [Photo courtesy of U.S. <strong>Air</strong> Force]<br />

Another product, the company’s MJU-<br />

52/B, was developed with the United<br />

States Naval Surfaces Warfare Center<br />

to offer preemptive protection to fast<br />

jet fighters and fighter bombers. The<br />

MJU-52/B utilizes special material, Alloy<br />

Surfaces’ proprietary patented technology<br />

to emit IR energy to decoy missiles.<br />

It is manufactured in plastic trays and is<br />

deployed upon command with an electrical<br />

impulse to initiate a mechanical dispenser.<br />

The MJU-52/B can be ejected from<br />

any Bol Dispenser Series. It requires no<br />

pyrotechnics to expel this special material<br />

and is virtually unobservable to the<br />

naked eye.<br />

The technologies for these systems<br />

have evolved as the missiles that the aircraft<br />

are seeking to avoid have evolved,<br />

Shoemaker said. The relatively simple<br />

Vietnam-era of magnesium Teflon countermeasure<br />

systems has given way to a<br />

material mix that emits energy in two<br />

regions of the infrared spectrum as an<br />

evasive tactic. There are many different<br />

combinations now used in materials<br />

and composition, although most of this<br />

information is proprietary. “We’ll call this<br />

a cocktail,” he said. “You’ll have two or<br />

three different flares in the airplane and<br />

put them out in a different sequence—<br />

just like you do with a cocktail, mixing<br />

www.SOTECH-kmi.com SOTECH 8.9 | 9

Special Sction: Countermeasures<br />

a little bit of this and a little bit of that.<br />

Some systems are more covert, but that<br />

really doesn’t matter if you’re flying in<br />

the daytime and can be seen anyway. The<br />

main thing is giving the military customer<br />

a product that works in the heat<br />

of battle.”<br />

White Plains, N.Y.-based ITT Electronic<br />

Systems provides its ALQ-211 family<br />

of systems to military customers,<br />

equipping aircrews with multi-spectral<br />

(RF, IR and laser) situational awareness to<br />

allow for effective threat warning, sensor<br />

fusion and countermeasure capabilities.<br />

The systems are used by crews serving<br />

on the AH-64D Apache Longbow, CV-22<br />

Osprey, F-16 and other top defense aircraft.<br />

Before flights, crews can download<br />

local order-of-battle threat information<br />

and match this with other on-board,<br />

real-time links to intelligence systems<br />

on board. When a threat emission is<br />

encountered, the systems allow for analysis<br />

of the threat ID, lethality, mode of<br />

PSC�M<br />

NSN 6530�01�581�9724<br />

PSC�E<br />

NSN 6530�01�588�8059<br />

10 | SOTECH 8.9<br />

operation and changing angle of arrival<br />

to the aircraft. It provides protection by<br />

breaking missile lock through RF countermeasures<br />

and cues the use of chaff<br />

and flares.<br />

In designing these systems, it’s essential<br />

to stay on top of constant advancements<br />

on the part of the enemy’s<br />

technology capability, especially with<br />

respect to powerful processing tools. Yet,<br />

at the same time, the military customer<br />

is asking for greater streamlining in the<br />

ease-of-operation of these systems.<br />

“The evolutions in the threat systems<br />

drive the evolutions in the countermeasures<br />

systems,” said Chris Carlson,<br />

director of business development for ITT<br />

Electronic Systems’ Integrated Electronic<br />

Warfare Systems. “There aren’t a bunch of<br />

dumb guys on the other side coming up<br />

with these missiles. So we need to keep<br />

improving the countermeasure products<br />

to keep coming up with ways to get away<br />

from what they send out there.”<br />

As a result, systems are getting<br />

smaller and smaller, but with increased<br />

processing power and digital circuitry.<br />

And all needed data is centralized to help<br />

the user/operator on the aircraft.<br />

“The military customer doesn’t want<br />

the air crew looking at multiple displays<br />

and a barrage of information,” Carlson<br />

said. “We seek to give them a consolidated<br />

picture, to integrate all sensors on<br />

the system so they don’t need to go to a<br />

lot of different displays on different pages.<br />

You want to give them one clear story in<br />

an efficient way. The military customer is<br />

sending a consistent message these days:<br />

Don’t give us new boxes. Take the boxes<br />

you have and give them new functions.<br />

Give us more functionality in less space<br />

and weight.” O<br />

For more information, contact SOTECH Editor Dave Ahearn at<br />

davea@kmimediagroup.com or search our online archives for<br />

related stories at www.SOTECH-kmi.com.<br />

WHEN�DISASTER�STRIKES<br />

Patient�Transport�selected�by�militaries�across�the�globe.�<br />

Take�battleground�tested,�tough,�durable�RRP�Litter�Carriers�<br />

on�your�next�rescue�mission.<br />

5717�Sellger Drive,�Norfolk�VA�23502��USA<br />

Toll Free:�866.493.8726��Info 757.461.1122���Fax: 757.461.0383<br />

www.RapidRescueProducts.com<br />

EVERY�SECOND�COUNTS<br />

TAMPA,�FL�•�Dec�13�15,�2010<br />

Visit�us�at�T41�for�a�demo.<br />

VRC�14<br />

GS�07F�9263S<br />

VRC�20<br />

BP<br />

www.SOTECH-kmi.com

Mulholland Wish List<br />

Co m m a n D e r eyes t r a n s l a t i o n g e a r, Better isr, H a n D H e l D ieD DeteCtors.<br />

By Da v e aH e a r n, soteCH eD i t o r<br />

D a v e a@k m i m e D i a g r o u p.C o m<br />

Special operations forces could use<br />

advanced language translation gear,<br />

smaller and lighter intelligence, surveillance<br />

and reconnaissance systems, and<br />

handheld IED detectors, according to<br />

Lieutenant General <strong>John</strong> F. Mulholland<br />

Jr., commander of the Special Operations<br />

Command.<br />

Mulholland made his comments in<br />

responding to a question from Special<br />

Operations Technology as he led a panel<br />

discussion focused on SOF during the<br />

recent Association of the United States<br />

Army annual meeting in Washington,<br />

D.C.<br />

He added that he wishes to make any<br />

systems acquired be non-specific to special<br />

operations troops, saying he wishes<br />

as much as possible to acquire items that<br />

can be shared across the Army. Further, he<br />

would like technology that can be shared<br />

with international partners.<br />

Language translators that can permit<br />

American troops to communicate with<br />

those speaking another language are a critical<br />

asset, Mulholland said, noting that when<br />

U.S. forces first arrived in Afghanistan after<br />

the September 11 bombings, there were<br />

no linguists with them speaking Arabic<br />

or Farsi.<br />

Mulholland said he wants to see longlasting,<br />

high powered battery systems,<br />

wishing for “the most powerful, longlasting<br />

Energizer Bunny” to power soldiers’<br />

gear.<br />

Another important need is a means<br />

of reducing the weight of all the batteries<br />

that soldiers now must carry to power<br />

their gear, added Command Sergeant<br />

Major Jeffrey J. Mellinger, of the Army<br />

Materiel Command. While an individual<br />

battery may not seem to weigh all that<br />

much, when there are a dozen different<br />

kinds of batteries carried simultaneously,<br />

it can impose a heavy strain on troops,<br />

he said.<br />

“When you talk about putting it on<br />

your back, traipsing up and down mountains,”<br />

the burden can be difficult, he said.<br />

He urged contractors to consider how to<br />

improve commonality in battery-powered<br />

systems, how to reduce power consumption<br />

by soldier-portable hardware, and<br />

how batteries can be recharged “when<br />

you’re on the side of a mountain.” Solar<br />

arrays, which aren’t mobile, may not be<br />

the answer here, he said. And anything<br />

using fuel, which can weigh six pounds per<br />

gallon, may not be the answer either.<br />

Mulholland said he doesn’t want<br />

the typical troop to be forced to carry<br />

15 batteries.<br />

Similarly, Mellinger too is concerned<br />

that every time a new capability is added,<br />

the capability may be contained in a new,<br />

additional device that each soldier must<br />

carry. He cited the addition of devices<br />

being mounted on the M4 carbine, noting<br />

that sooner or later the Army will run out<br />

of rail on the weapon that can be used to<br />

mount extra systems.<br />

What may be another special operations<br />

need is at a higher level: in the air.<br />

“There isn’t enough aviation” capacity<br />

for special operations personnel, said<br />

Brigadier General Kevin W. Mangum,<br />

commanding general of the Army Special<br />

Operations Aviation Division. That<br />

often leaves SOF missions dependent on<br />

non-SOF air, he added. O<br />

For more information, contact SOTECH Editor Dave Ahearn at<br />

davea@kmimediagroup.com or search our online archives for<br />

related stories at www.SOTECH-kmi.com.<br />

www.SOTECH-kmi.com SOTECH 8.9 | 11

By peter Bu x B a u m<br />

soteCH Co r r e s p o n D e n t<br />

B u x B a u m p@k m i m e D i a g r o u p.C o m<br />

seats—a n D tHen B o a t H u l l s—to C u s H i o n,<br />

C u r B i n j u r y-C a u s i n g s H o C k s.<br />

United States Navy special operations<br />

personnel perform many of their missions<br />

on smaller water craft. These vessels—and<br />

the personnel inside them—can take quite a<br />

pounding, especially in severe sea states.<br />

Repeated exposure to wave shocks and<br />

to the forces of the ocean can impair performance,<br />

produce discomfort, and cause acute<br />

and chronic injuries. That is why the Naval<br />

Special Warfare Command tests smaller boats<br />

for their ability to absorb shocks and protect<br />

the crew.<br />

In the past, naval personnel often preferred<br />

standing to sitting while operating their<br />

vessels, believing that they could use their<br />

legs from a standing position to absorb<br />

impacts. While there is some truth to that<br />

belief, special operations personnel are often<br />

exposed to forces that cannot be handled<br />

12 | SOTECH 8.9<br />

merely by standing or bending the legs.<br />

Much of the activity surrounding shock mitigation<br />

involves equipping combatant craft<br />

with seats that cushion the blows to which<br />

crews are subjected.<br />

In one case, the seats in an entire fleet<br />

of small boats were replaced with seats<br />

equipped with shock mitigation technologies.<br />

These special seats contain their own suspension<br />

systems, in the form of shock absorbers<br />

that smooth the ride for naval special warfighters.<br />

The command keeps on eye on such<br />

technologies that can improve the safety of<br />

crew members.<br />

“Combatant craft crewmen work in an<br />

environment dictated by the mission, not<br />

at the convenience of sea-state conditions,”<br />

said Bruce Holmes, a science and technology<br />

adviser at Naval Special Warfare Command.<br />

“Boat-related musculoskeletal injuries occur<br />

as a result of the environment in which<br />

the crew and passengers are required to<br />

operate. The purpose of the seat is to shield<br />

the operator from the high shock environment<br />

generated by the sea-state and<br />

craft speed.”<br />

Techno-Sciences Inc. (TSI), in collaboration<br />

with Lord Corp., has developed what<br />

the companies term a reliable, revolutionary<br />

shock absorber system using magnetorheological<br />

(MR) fluid technology for seated<br />

occupants aboard high-speed watercraft, in<br />

a cost-effective package providing optimal<br />

shock and vibration protection.<br />

Traditional seats using passive shock<br />

absorbers in these vessels provide limited<br />

benefit to the warfighter because they<br />

can only be optimized for one occupant<br />

www.SOTECH-kmi.com

Averting Personnel<br />

Injuries<br />

weight (typically the 50th percentile male)<br />

and a single shock condition. Outside<br />

these ideal conditions, they provide subpar<br />

protection.<br />

But in maritime operations, especially<br />

onboard special operations craft, ideal conditions<br />

do not exist. Conditions such as high<br />

sea states, boat speed, course relative to<br />

wind direction, and boat payload/weights are<br />

highly variable—leading to erratic shock and<br />

vibration conditions.<br />

In addition, MR devices provide advantages<br />

over competing active damping technologies<br />

due to their simplicity, company<br />

officials explained. MR fluid shock absorber<br />

systems are enabled by versatile MR fluid technology,<br />

which allows the system to respond<br />

instantly and controllably to varying levels<br />

of vibration, shock or motion with simple,<br />

robust designs.<br />

This novel seat suspension by TSI and<br />

Lord automatically varies the damping and<br />

energy attenuating capabilities, providing<br />

protection for all warfighters, regardless of<br />

their size and weight<br />

and the operational conditions.<br />

This system leverages decades<br />

of Lord production experience of various<br />

MR devices.<br />

In particular, the Lord Motion Master<br />

Ride Management System has provided vibration<br />

and shock isolation in over 75,000 commercial<br />

truck seats since initial production in<br />

1998. While this system has been developed<br />

and tested with the U.S. Navy’s RHIBs and<br />

Mark V SOC in mind, the system can easily be<br />

adapted into seats for all armed services and<br />

any high speed watercraft.<br />

“The biggest problem with smaller craft is<br />

wave shock,” said Doug Taylor, CEO of Taylor<br />

Devices in North Tonawanda, N.Y. “It can<br />

cause damage to equipment and to people. A<br />

severe wave shock can knock someone out.<br />

The most important thing about any armed<br />

vessel is to optimize the blending of man<br />

and machine.”<br />

Naval Special Warfare has pursued existing<br />

and future technologies in pursuit of<br />

mitigating musculoskeletal, boat-related<br />

injuries. After it came to light that operators<br />

on the Mark V Special Operations Craft were<br />

subjected to a litany of debilitating injuries,<br />

NSW performed a market survey in 2004 of<br />

available systems and directed minor design<br />

changes of existing shock mitigating seat<br />

technologies. As a result, the standard rigid<br />

STIDD V-4 seats in the Mark V were replaced<br />

with STIDD-Taylor V-5.3 seats equipped with<br />

passive shock absorbers. All 21 operator seats<br />

were replaced on all 20 Mark Vs.<br />

“The STIDD-Taylor Shock Mitigating Seat<br />

has received wide acclaim for reducing injuries<br />

during severe sea-state conditions,” said<br />

Doug Taylor. “The seat was ergonomically<br />

designed by STIDD to restrain the operator<br />

so that he is not working his muscles to hold<br />

himself into the seat.”<br />

The shock absorbing device used in this<br />

seat developed by Taylor Devices involves a<br />

spring and damper combination that has the<br />

ability to sense the incoming force so that it<br />

can change its output accordingly.<br />

STIDD comes to the design and production<br />

of shock mitigating seats with a<br />

background in orthopedic and sports medicine<br />

research. “Our seats are compliant with<br />

medical guidelines as well as military specifications,”<br />

said Walter Gezari, CEO of STIDD<br />

Systems Inc., in Greenport, N.Y. “Before we<br />

get to the designing stage of a seat, we study<br />

where the force is going and how to dissipate<br />

it. We also figure out how to position and<br />

stabilize the user and place him in the proper<br />

orientation to accept the highest amount<br />

of load with the least amount of damage.<br />

The STIDD-Taylor seat solved the problem on<br />

the Mark V.”<br />

But Holmes views passive shock absorbing<br />

as a less-than-optimal solution. “The<br />

problem with a passive system is that the<br />

www.SOTECH-kmi.com SOTECH 8.9 | 13

craft must operate in both heavy and light sea-state and craft speed<br />

environments,” he explained. “What might work well to protect the<br />

operator during a high shock environment may not be ideal for a low<br />

shock environment and vice versa.”<br />

Seaspension Technologies in Largo, Fla., produces shock mitigating<br />

seating equipped with a patented damper and coil system that<br />

automatically reacts to the force being exerted on it. “We basically had<br />

a global damper manufacturer tweak an existing shock absorber with<br />

our input,” said company President Peter Burer.<br />

Seaspension, which started in the recreational boating market,<br />

first supplied shock mitigating seats to the Canadian Coast Guard<br />

around eight years ago. “We’ve had no failures with these shocks,”<br />

said Burer.<br />

More recently, Seaspension delivered custom shock mitigating<br />

seating for use in 35 U.S. Coast Guard specialized emergency rescue<br />

airboats, known as Iceboats. The tripod-mounted seat is designed to<br />

protect the crew from jolts experienced when the boat transitions<br />

from land to ice and water, and during operation in rugged conditions.<br />

Seaspension also has supplied seating to Edgewater Power<br />

Boats of Edgewater, Fla., for vessels that were delivered to the Trinidad<br />

Coast Guard.<br />

Active Shock LLC of Manchester, N.H., which concentrates on<br />

shock absorbers in the automotive space, developed a device for the<br />

U.S. Special Operations Command designed to be incorporated in a<br />

rigid inflatable boat (RIB). That project, developed under a SBIR grant<br />

in 2008, has not been acquired by the U.S. military.<br />

“What makes our shock absorbers unique is that they are controlled<br />

by computer,” said Scott Martineau, the company’s director<br />

of business development. “We use sophisticated algorithms that take<br />

information from a suite of sensors contained in the shock absorbers<br />

themselves to determine the optimum damping rate. In high sea<br />

states, the sensor can detect when the boat goes airborne and prevents<br />

the seat from bottoming out and transmitting the shock to the crew.”<br />

Seaspension, meanwhile, will soon be introducing a shock mitigating<br />

seat for use as either a bulkhead seat or as a replacement for<br />

the Marine Corps’s 11-meter RIB. “The damper system will allow anywhere<br />

from the fifth percentile female by weight to the 95th percentile<br />

male in the Marine Corps to be seated and protected from shocks<br />

without the use of tools or any kind of adjustment,” said Burer.<br />

That would cover women as light as 100 pounds to men as heavy as<br />

250 pounds.<br />

“The mechanism in the damper responds directly to forces,” said<br />

Burer. “The Navy is looking for a seat that can accommodate different<br />

sizes of personnel on a variety of missions subjected to different sea<br />

states without having to adjust the damping mechanism.”<br />

Seaspension’s new device uses a dual-damper system in order to<br />

accomplish that task. “We found it better to incorporate two independent<br />

shock absorbers to regulate those weights,” said Burer. “The seat<br />

is designed to be able to slip right into existing craft in the inventory<br />

of U.S. special operations and foreign militaries as well.”<br />

The principles central to shock mitigation are applicable not<br />

only to seating and the protection of crewmembers, but also to the<br />

protection of equipment mounted on vessels. “We are working on<br />

several new applications for our pedestals to be used as weapons and<br />

equipment platforms,” said Burer. “We recently bid our heavy duty<br />

pedestal as a mount for a .50 caliber gun on a 100-boat contract. We<br />

expect shock mitigation to be used much more in this application in<br />

the future and are actively testing and designing products to meet<br />

this demand.”<br />

14 | SOTECH 8.9<br />

Taylor Devices makes shock mitigation products that have been<br />

used on Navy warships for shock isolation on missiles and missile<br />

systems, radars, electronics consoles, boat davits, and for recoil isolation<br />

on heavy machine gun mounts. These “soft mounts,” which are a<br />

combination coil spring and hydraulic shock absorber, reduce the firing<br />

recoil from the .50 caliber heavy machine gun from 4,400 pounds<br />

to 500 pounds, according to Taylor. This allows the .50 caliber guns to<br />

be used on smaller combatant craft.<br />

The application of shock mitigation technologies can have the<br />

unintended side effect of allowing crews to push a vessel to the limits<br />

of its performance, a phenomenon which has both positive and<br />

negative implications. As crews become more comfortable, they push<br />

the boats harder, and as they push the boats harder, the more they<br />

are likely to be subject to additional wear and tear. That is especially<br />

the case when shock mitigation has been retrofitted onto a<br />

legacy platform.<br />

“As operators feel secure in the seat and comfortable at higher and<br />

higher speeds they have been driving the boats faster,” said Gezari,<br />

referring to the Mark V. “This allows them to run their missions faster<br />

and more successfully. But the boats have also experienced structural<br />

issues as a result.”<br />

For Holmes, special operations crews will best benefit when vessels<br />

are properly designed and evaluated for their shock absorbing<br />

properties from the beginning. The Special Operations Craft Riverine,<br />

he pointed out, does not have the same history of musculoskeletal,<br />

boat-related injuries as the Mark V or the Naval Special Warfare Rigid<br />

Inflatable Boat (NSW-RIB).<br />

“Health monitoring of the shock environment in manned areas<br />

of combatant craft needs to be implemented on all combatant craft,”<br />

said Holmes. “Monitoring of the shock environment will provide data<br />

that will be used to assist future research and measure how effective<br />

proposed systems are against mitigating shock.”<br />

Research is yielding a set of emerging standards that will likely<br />

find eventual widespread adoption and which will help in the measurement<br />

of the shock conveyed to the human body through vessels. The<br />

International Organization for Standardization, a Switzerland-based<br />

group, has released ISO 2631-5, a standard to measure vibration on the<br />

human body over time. Another emerging industry standard relating<br />

specifically to shock mitigating seats is known as SED-8 and is based<br />

on another ISO standard.<br />

“SED-8 measures the amplitude and frequency of incoming<br />

impacts and then measures the outgoing response” of the seat,<br />

explained Burer. “Different seat manufactures employ different kinds<br />

of tests to measure the shock absorbing capacity of their systems.<br />

With this standard, we can measure the effectiveness of the<br />

damper system.”<br />

At some point in the not too distant future, Burer predicted, a<br />

certification program for shock mitigating seats under SED-8 will be<br />

established.<br />

Meanwhile, NSW will be assessing all future combatant craft<br />

for operator exposure to shock levels that could cause musculoskeletal,<br />

boat-related injuries, said Holmes. The current combatant<br />

craft, medium requirements document contains a maximum<br />

spine stress dose shock exposure level, as defined by SED-8 and<br />

ISO standards. O<br />

For more information, contact SOTECH Editor Dave Ahearn at davea@kmimediagroup.com<br />

or search our online archives for related stories at www.SOTECH-kmi.com.<br />

www.SOTECH-kmi.com

LORD MR Suspension Systems are active damping systems, comprised of LORD MR technology devices and<br />

controllers, that respond controllably to varying levels of vibration, shock or motion. This enables improved levels of<br />

performance and mobility.<br />

With 70+ years of experience in vibration control for military applications and the world’s largest MR Fluid patent<br />

portfolio, we are the leader in Magneto-Rheological Systems. More than 500,000 MR Fluid technology devices have<br />

been sold for use on commercial vehicles. At LORD, we have the knowledge, resources and commitment to work<br />

with you for a successful launch of your application … Ask Us How.<br />

©2010 LORD Corporation. SA6032

16 | SOTECH 8.9 www.SOTECH-kmi.com

sp e C i a l o p s p e r s o n n e l a r r i v e resteD, s H a r p a t oBjeCtive u s i n g s u B m e r s i B l e s.<br />

By Da v e aH e a r n, soteCH eD i t o r<br />

D a v e a@k m i m e D i a g r o u p.C o m<br />

Here are two scenarios:<br />

In Scenario one, Navy SEALs arrive at<br />

their objective silently, slipping in at night,<br />

but the SEALs are cold and exhausted from<br />

a long swim in frigid waters, having used<br />

vast amounts of oxygen in tanks, not what<br />

you want in starting a mission. They have<br />

little time to perform their duties ashore<br />

before they must begin the long swim back<br />

to their ship.<br />

In Scenario two, the SEALs arrive at<br />

their objective rested, sharp and at the top<br />

of their game. They have ample time to<br />

complete their mission, rather than being<br />

rushed and tired.<br />

The difference between those two scenarios<br />

lies in submersible craft that can<br />

carry personnel to shore underwater and<br />

unseen, swiftly and without major exertion.<br />

STIDD Systems Inc. offers submersibles<br />

that can whisk SEALs smoothly and silently<br />

beneath the waves to enemy beaches. That<br />

means the SEALs are sharp, in shape and<br />

enjoying the best possible chance of success<br />

in operations at their objective.<br />

By using submersibles, insertion of<br />

SOF personnel into a hostile area can be<br />

accomplished with their ship well offshore<br />

to escape enemy notice. The STIDD submersible,<br />

which can be of varying sizes,<br />

swiftly transports the personnel to shore.<br />

According to STIDD, its Diver Propulsion<br />

Device (DPD) “is the most widely used<br />

two man underwater mobility platform in<br />

the world.” Further, “the Multi-Role Combat<br />

Craft (MRCC) is the only craft of its<br />

kind that operates on the surface and while<br />

submerged,” according to STIDD.<br />

“The DPD and MRCC, used either<br />

separately or together as a modular submersible<br />

platform, offer the unique combination<br />

of both surface and underwater<br />

capabilities, providing maritime forces<br />

unprecedented options for mission planning<br />

and execution.”<br />

STIDD submersibles provide greatly<br />

enhanced capabilities to SOF and marine<br />

units, the company stated. With far greater<br />

speed than the personnel could attain by<br />

swimming on their own, using a submersible<br />

confers several benefits:<br />

•<br />

•<br />

•<br />

The faster the movement to shore<br />

before the operation, and the faster<br />

the extraction from the hostile<br />

area after the mission is accomplished,<br />

the less chance there is for<br />

special operations to be detected by<br />

the enemy.<br />

While SEALs are highly powerful<br />

swimmers, a long swim from ship<br />

to objective can be exhausting. A<br />

STIDD submersible obviates the<br />

need for that exertion.<br />

<strong>Col</strong>d water can be numbing. But<br />

with a submersible, the time spent<br />

•<br />

in possibly frigid water is slashed,<br />

so that personnel are in peak shape<br />

when they begin operations.<br />

The faster personnel arrive at the<br />

littoral area, the longer they can<br />

spend there.<br />

Submersibles also aid personnel in carrying<br />

possibly weighty ordnance, such as in<br />

a mission to sink enemy ships in harbor. Or<br />

they might be headed into an enemy harbor<br />

to disable defensive systems such as mines<br />

or sonar systems. Another point is that submersibles<br />

permit personnel on intelligence<br />

and reconnaissance missions to cover more<br />

territory as they scout underwater in nearshore<br />

areas.<br />

The one area where there could be<br />

a further advance beyond submersibles<br />

would be a mini-submarine that could<br />

transport special ops personnel from ship<br />

most of the way to shore, in a warm and<br />

dry environment. However, a Northrop<br />

Grumman attempt to create an Advanced<br />

Seal Delivery System—a tiny submarine<br />

carried atop a nuclear submarine—ended,<br />

with cost overruns and a ruinous fire on<br />

an ASDS. O<br />

For more information, contact SOTECH Editor Dave Ahearn at<br />

davea@kmimediagroup.com or search our online archives for<br />

related stories at www.SOTECH-kmi.com.<br />

www.SOTECH-kmi.com SOTECH 8.9 | 17

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

Clean Water,<br />

Sanitation<br />

Systems<br />

Avert Sickness,<br />

Death Among<br />

Troops<br />

When you consider that 18.5 percent<br />

of U.S. military personnel deaths in<br />

Vietnam were caused by disease, not by<br />

enemy fire, it becomes clear that clean,<br />

safe drinking water is a vital necessity, not<br />

a luxury. While enemy fire killed 47,424<br />

personnel, disease killed another 10,785.<br />

Often, the cause of death was in drinking<br />

polluted water. But that doesn’t have to<br />

happen again. Several contractors are<br />

offering systems to provide potable water<br />

to troops, helping to keep them healthy<br />

even in combat zones filled with impurities<br />

and polluted streams. Now, troops<br />

heading out to clear an area can carry<br />

ample drinking water with them.<br />

For example, CamelBak makes a<br />

backpack that can carry 70 ounces, and<br />

another backpack carrying 100 ounces<br />

of pre-treated sterile water, complete<br />

with a hose that the soldier may drink<br />

from in the field. Blackhawk also offers<br />

a 100-ounce water storage backpack<br />

with hose to ensure proper hydration<br />

for troops.<br />

Those systems take on water that<br />

already has been purified. But Worldwater<br />

& Solar Technologies Inc. makes a much<br />

larger system that stores potable water,<br />

and also purifies polluted or saline water.<br />

It cranks out up to 30,000 gallons a<br />

day, enough to fill an enormous number<br />

of backpacks. Mounted on a trailer,<br />

the system uses solar energy charging<br />

batteries to power a mini-water treatment<br />

plant that uses various systems to treat<br />

water, including ultraviolet rays. Thanks<br />

to the solar power and batteries, the<br />

system works 24 hours a day, is silent and<br />

doesn’t pollute the environment.<br />

18 | SOTECH 8.9<br />

L-3 VideoScout-MXR Gives Troops<br />

Situational Awareness<br />

L-3 has created the VideoScout-MXR that<br />

can provide command center-level intelligence<br />

from multiple sources, including full-screen<br />

video, to dismounted personnel in theater. The<br />

unit, much like a laptop, can pull in intel data<br />

from multiple sources including manned and<br />

unmanned aircraft. That could mean gaining<br />

full motion video from a tiny unmanned aerial<br />

vehicle, providing a panoramic view of terrorist<br />

insurgents as they move. VideoScout runs<br />

Microsoft Windows, and comes with analog/<br />

digital radios.<br />

“Our new VideoScout-MXR provides<br />

warfighters with a compact, easy-to-use<br />

tool, allowing them to exploit their<br />

video anytime, anywhere,” said Larry<br />

Vernec, senior director of marketing<br />

and strategic business development<br />

at L-3 IEC. “Users can better<br />

leverage captured imagery, as well<br />

as their own applications, to create<br />

actionable video for on-the-move<br />

mission execution, planning and<br />

post-mission analysis.”<br />

A new type of Kevlar helmet<br />