View PDF - Professional Painter Magazine

View PDF - Professional Painter Magazine

View PDF - Professional Painter Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Painting doors ❯❯ Colour tinting ❯❯ Pro <strong>Painter</strong> Facebook<br />

WINTER 2011 VOLUME 8,<br />

NUMBER 4<br />

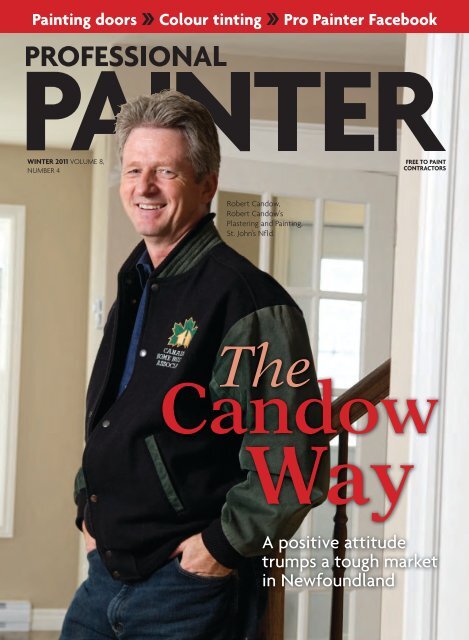

Robert Candow,<br />

Robert Candow's<br />

Plastering and Painting,<br />

St. John's Nfld.<br />

The<br />

FREE TO PAINT<br />

CONTRACTORS<br />

Candow<br />

Way<br />

A positive attitude<br />

trumps a tough market<br />

in Newfoundland

“<br />

KILZ PRO-X<br />

IS MY<br />

PAINT FOR<br />

LARGE AND<br />

SMALL<br />

PROJECTS.”<br />

Nathan Bavolek, Owner<br />

Nathan James & Company<br />

Design & Construction<br />

We asked you what you wanted in a paint.<br />

Durable finish. Fast application. Great feel.<br />

All at a great price.<br />

We heard you. Now after years of testing,<br />

it’s available. We call it KILZ PRO-X paint.<br />

Available in over 1,100 colours in flat,<br />

eggshell and semi-gloss sheens. Give<br />

KILZ PRO-X paint a try. We know you’ll<br />

be impressed. After all, you told us how<br />

to make it.<br />

Enter to<br />

WIN<br />

5 pails of<br />

KILZ PRO-X <br />

Paint<br />

KILZ PRO-X <br />

Paint<br />

kilzpro-x.com/casweeps<br />

<br />

8 weeks of winners!<br />

Closes 12/25/11<br />

Scan this QR<br />

code to enter<br />

sweepstakes

F e A t u R e s<br />

16<br />

the Candow "Can Do" attitude<br />

Robert Candow of Candow's Plastering and Painting<br />

keeps the sunny side up<br />

B R o A D s t R o K e s<br />

10<br />

12<br />

14<br />

Pro <strong>Painter</strong> Facebook<br />

<strong>Painter</strong>s talk on line about their businesses<br />

Guest Column<br />

understanding your leadership style<br />

tech Savvy<br />

tricky tinting<br />

A P P l I C A t I o N s<br />

22<br />

26<br />

tattoo Wall testimony<br />

How tattoo Wall makes money for painters<br />

Sanding for profit<br />

Perfect sanding involves three machines and four steps<br />

D e P A R t M e N t s<br />

5<br />

Prime Coat<br />

Getting with an association<br />

6 www.getpainting.com<br />

Wooster...silk Brush...Green tape...<br />

30<br />

Final Coat<br />

Jim Caruk on painting doors<br />

SaleS<br />

Dante Piccinin<br />

professionalpainter@rogers.com<br />

Phone: (905) 858-0281<br />

ContributorS<br />

Jim Caruk, Rob Koci, Bruce MacKinnon,<br />

Agnes von Mehren<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

22<br />

26<br />

30<br />

<strong>Professional</strong> <strong>Painter</strong> magazine is published by<br />

Dynamic Paint Products Inc., Mississauga, ont.<br />

Canadian publication mail agreement<br />

PM# 40070230. <strong>Professional</strong> <strong>Painter</strong> magazine<br />

and Dynamic Paint Products Inc. do not<br />

warrant or assume any legal liability or<br />

responsibility for the accuracy, completeness<br />

or usefulness of any information, apparatus,<br />

product, or process disclosed herein.<br />

inside<br />

Winter 2011<br />

VoluMe 8, NuMBeR 4<br />

3

Better Results with Every Roll<br />

People know us as The Wooster Brush Company, but we also make the top roller brands in the industry.<br />

Regardless if a painter is looking for faster application rates, smoother finishes, or a solution for rough and<br />

uneven surfaces—there’s a Wooster roller that’s right for the job.<br />

®<br />

super fab<br />

Contractors’ all-time favorite! Exclusive golden yellow<br />

fabric provides exceptional capacity with all flat to<br />

satin paints, stains, and waterproofing. Resists<br />

matting for complete coverage and smooth results.<br />

Available in 9½” length with 3/8”, 1/2”, 3/4”, 1” or<br />

1¼” naps.<br />

®<br />

pro doo-z<br />

Exclusive high-density white fabric with a golden<br />

pinstripe marks Pro/Doo-Z as the perfect roller sleeve<br />

for all paints, enamels, primers, urethanes, and<br />

epoxies. Interlocked fibers prevent shedding and resist<br />

matting for the smoothest professional finish. Available<br />

in 9½” length with 3/16”, 3/8”, 1/2”, or 3/4” naps.<br />

<br />

polar bear<br />

Different from the average bear. Exclusive white plush<br />

fabric for huge paint pickup and release with all flat,<br />

eggshell, or satin paints, stains, sealers, and primers.<br />

One universal pile height reaches into textures and<br />

uneven areas, provides a finish as smooth as ice.<br />

The Wooster Brush Company • 800-392-7246 • woosterbrush.com

join the<br />

I<br />

hate to admit this, but I painted for 28 years and<br />

not once did I look into joining a homebuilders’<br />

association. I assumed it was meaningless to me<br />

as a painter. After all, homebuilders are the developers<br />

who take advantage of us, right? Wrong!<br />

In this issue, I spoke with Bob Candow of Bob Candow’s<br />

Plastering and Painting in St. John’s Nfld. As a<br />

Bluenoser, I just know I’m gonna hear about this for the<br />

rest of my life, but I learned a lot from a Newfie, one of<br />

the nicest Newfies I ever had the pleasure of talking to I<br />

might add. That’s a pretty high bar.<br />

Bob opened my eyes to the importance of all trades—<br />

painters included—being involved in local home builders’<br />

associations. First off, as Candow said with surprising<br />

enthusiasm, painters (and all trades) earn their living<br />

from the building industry, so giving back to the industry<br />

to make it better for the generations who come after us,<br />

makes us better too.<br />

It is a simple fact: You earn all your money from the<br />

building industry. Everything the association decides,<br />

lobbies for, works to change, provides information for, all<br />

affects you in one way or another.<br />

And being part of a group of building industry professionals<br />

broadens your horizons. Candow jumped in with both<br />

feet and got involved in the national builders association as<br />

well, and that allowed him to travel the country and see how<br />

things are done elsewhere. He brought that knowledge back<br />

home to Newfoundland and used it to his advantage.<br />

Candow points out that when municipal, provincial or<br />

federal politicians are asked to legislate anything to do<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

prime coat<br />

By Bruce MacKinnon<br />

association nation<br />

Your local homebuilder association can do a lot for you<br />

“<strong>Painter</strong>s (and all trades) earn<br />

their living froM the Building<br />

industry, so giving BacK to the<br />

industry to MaKe it Better for<br />

the generations who coMe<br />

after us, MaKes us Better too.”<br />

with buildings, they seldom understand what the consequences<br />

are. They need an informed body to speak to and<br />

be informed by; that is one of the key roles of a homebuilders’<br />

association.<br />

Seeing the building process from the trades’ and the<br />

builder’s perspectives can help you see the big picture.<br />

You could even learn to appreciate what your builder has<br />

to go through to get the project completed.<br />

Bob Candow is the first painter I’ve heard of who is<br />

on such a board, and I hope there are more. Besides<br />

personal enrichment and learning, being involved presents<br />

another opportunity. <strong>Painter</strong>s sitting on association<br />

boards could have a greater say in getting the paint trade<br />

more respect (there is that word again). Candow is now<br />

in an enviable position to urge more professionalism<br />

among painters in his province and has been instrumental<br />

in introducing a program to acquaint youth with<br />

trades in general and encourage interest in the tradesman’s<br />

life.<br />

Wherever you find yourself, you also have the opportunity<br />

to change the paint industry for the up-and-coming<br />

generation of career painters. You have a chance to have<br />

a say in creating similar trade introductions.<br />

Association membership may also be one way to put<br />

pressure on governments to introduce Red Seal certification<br />

for the painting trade, with its standardized training<br />

and testing for painters. Such changes would benefit<br />

everyone in the building industry by getting rid of the<br />

fly-by-night guys and raising quality standards, customer<br />

satisfaction and probably prices for higher-end work.<br />

But it’s not just about prestige for guys who work hard<br />

every day doing work most people shudder to think about.<br />

Getting proper respect would help painters across Canada<br />

be much happier in their chosen profession, and everyone<br />

knows that someone doing something they love to do will<br />

always do great work.<br />

If nothing else, being part of local, provincial or<br />

national homebuilders’ associations would get the building<br />

industry to take painters more seriously. And your<br />

contractors and customers would take you more seriously,<br />

too. That’s a win-win.<br />

5

6<br />

www.getpainting.com<br />

Magikage Ninety 9½” frame<br />

This frame has a chrome-plated shank with<br />

a popular 90-degree bend. The right angle<br />

creates even surface pressure. Sturdy 5-wire<br />

cage and nylon endcaps fully support sleeves<br />

for smooth rolling. The comfortable poly<br />

propylene threaded grip is also Sherlock GT<br />

pole compatible.<br />

Silver Tip paintbrushes<br />

Silver Tip brushes are made with a blend of white<br />

and silver Wooster CT polyester that virtually<br />

eliminates brushmarks. Thin, soft, flexible ends<br />

provide exceptional leveling and smoothing.<br />

Perfect for latex paints, applying enamels to metal<br />

or polyurethanes on wood. Wooster Silver Tip<br />

brushes deliver a high-quality finish at a low price.<br />

Pro/Doo-Z covers<br />

When you need a roller that provides dense, high-capacity<br />

fabric with interlocked fibers to prevent shedding,<br />

Pro/Doo-Z covers is your choice. No other roller<br />

produces smoother results. You get flawless coverage<br />

with all paints, flat to gloss. Wooster Pro/Doo-Z<br />

delivers confidence with even the most demanding<br />

coatings: industrial enamels, epoxy floor finishes,<br />

and moisture-cure or catalyzed urethanes.<br />

For more information on the tools and suppliers seen here, go to www.getpainting.com<br />

or call 1-800-670-6021.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011

Ultra/Pro paintbrushes<br />

These brushes provide professional results in Extra-Firm,<br />

Firm, or Soft formulations. Made with NylonPlus filament,<br />

Extra-Firm offers superior stiffness and cut-in control.<br />

The nylon/polyester Firm blend has outstanding capacity<br />

and coverage, great for all-purpose painting. The 100 per<br />

cent nylon Soft blend produces mirror-like results and<br />

cleans easily.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

Chinex FTP paintbrushes<br />

Chinex brushes offer better cleanability and durability<br />

than any other brush. They outwear bristle seven to<br />

one. The FTP has more stiffness and a fuller, softer<br />

tip that is available exclusively from Wooster.<br />

With increased paint release and reduced drag for<br />

the smoothest finish, new Chinex FTP brushes are ideal<br />

for today’s paints.<br />

For more information on the tools and suppliers seen here, go to www.getpainting.com<br />

or call 1-800-670-6021.<br />

7

8<br />

www.getpainting.com<br />

Products<br />

Dynamic ProFessional Brushes<br />

dyna-Flo Polyester/Nylon<br />

Polyester/nylon filament blend provides<br />

premium performance and professional<br />

results in latex and oil-based paints. Full<br />

and firm brush head for greater control.<br />

solomon Polyester/Nylon<br />

Delivers outstanding value for a production<br />

applicator. excellent performance in all paints.<br />

commander Polyester<br />

Premium quality with professional featureschiseled<br />

brush head, square stainless ferrule,<br />

tapered round polyester filaments.<br />

silk Poly/Bristle<br />

This premium quality paint brush delivers<br />

professional results in both oil-based and<br />

water-based coatings. it’s professional<br />

features include a round, stainless steel<br />

ferrule and chiseled end.<br />

For more information on the tools seen here, go to www.getpainting.com or call 1-800-670-6021.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011

Products<br />

Dynamic EDgEwisE PaintEr’s taPEs<br />

Edgewise Premium 14-day tape<br />

when you need a clean release within 14 days, this is<br />

the tape you need. it is safe for most surfaces, provides<br />

sunlight/UV resistantance and sticks to rough and uneven<br />

surfaces. available in 24, 36, 48mm x 55mm sizes.<br />

Edgewise General Purpose tape<br />

this is a high tack, versatile tape suitable for production,<br />

commercial, residential, construction and industrial<br />

masking applications. it is made from semi-creped<br />

paper and a solvent based natural rubber adhesive.<br />

available in 24, 36, 48mm x 55mm sizes.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

Edgewise <strong>Professional</strong> 60-day tape<br />

this tape is a residue-free release tape safe for 60-plus days.<br />

it protects against bleeding and seepage and is sunlight/UV<br />

resistant. it is available in 24, 36, 48mm x 55mm sizes.<br />

Edgewise Premium 7-day tape<br />

with this tape, you have safe release within seven days.<br />

as with the other releases, it is sunlight/UV resistant and<br />

safe for most surfaces. available in 24, 36, 48mm x 55mm sizes.<br />

For more information on the tools seen here, go to www.getpainting.com or call 1-800-670-6021.<br />

9

facebook painters<br />

A FAceBook<br />

Conversation<br />

Pro <strong>Painter</strong> magazine’s Facebook page has attracted a small but loyal following in the<br />

last year. The conversation below is a small part of what our Facebook painters are<br />

talking about while they help each other learn and grow professionally.<br />

Editor RB MacKinnon starts off this conversation by asking members about painting decks<br />

Discussion Board Topic <strong>View</strong><br />

Topic: Painting decks<br />

Post #1<br />

Post #2<br />

Post #3<br />

Post #4<br />

Post #5<br />

Post #6<br />

RB MacKinnon wrote<br />

Who has a deck?<br />

Who has it varnished or painted?<br />

Who manages to keep it looking good?<br />

What do contractors do to maintain a deck?<br />

Paul Bisson wrote<br />

I have painted and stained decks over the years. I prep them good: always use a power washer, scrape by<br />

hand, then sand with power sander, dust really well, spot prime, then paint. I use a moisture meter to make<br />

sure moisture is low before applying the finish. I apply extra coats in high-traffic areas.<br />

RB MacKinnon wrote<br />

Thanks Paul for that. I really hate doing decks because no matter how I do them, they still peel after a few<br />

years. Is this common?<br />

Paul Bisson wrote<br />

It’s a common problem unless you are there with the carpenter when the deck is being built. What helps<br />

is proper dry lumber. I do not like pressure-treated and will not paint it. When the end cuts are sealed on<br />

regular lumber and primed all the way around, it sure helps. It doubles the life of the paint being sealed since<br />

moisture now has a hard time getting into the wood and lifting the coating. Rubber-backed rugs on decks<br />

are not good, as moisture builds up between the lumber and rubber back.<br />

Glen Rogers wrote<br />

Numerous deck products claim to last five - 10 years or even longer, but I have not found a single product<br />

that lives up to these claims. What I do find is many home owners disappointed with cracked, peeled and<br />

faded decks. In the B.C.’s Lower Mainland, problems tend occur as quickly as the first year. My suggestion to<br />

clients is to use a semi-transparent deck oil. That should avoid the nasty job of striping when the time comes<br />

to resurface.<br />

Paul Bisson wrote<br />

I agree. I believe in using a moisture meter, together with a little double-boiled linseed oil in the stain. Let it<br />

penetrate and stay wet a little longer to soak into the wood. Of course, saying that, you also must clean the<br />

wood well beforehand to remove dirt and other foreign matter likely to effect adhesion.<br />

10 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

Discussion Board Topic <strong>View</strong><br />

Topic: Pricing a job<br />

Post #1<br />

Post #2<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

Jason Windsor wrote<br />

broad strokes<br />

I hope you can help me. I am starting my own business and have not got my pricing down. My main concern<br />

is trim. I would like to know the base rate per linear foot or square foot. I have a huge opportunity but I need<br />

the right pricing. If you can help, that would be awesome.<br />

RB MacKinnon wrote<br />

I would not recommend taking on a large job if you don’t know your variables. At the very least, calculate<br />

how long per room it takes to do your trim, add that to your wall and ceiling square foot price and add time<br />

for preparation, plus a small amount for ongoing business expenses like insurances, materials, etc.<br />

That said, it would be unwise to do a large job on your own without experience. You may lose money, or<br />

worse, the customer suffers and the reputation of the painting industry suffers. The best advice would be to<br />

subcontract a good, experienced painter for the job and work alongside him, adding a wage for yourself. Observe,<br />

learn and find out what it really takes to do a proper paint job. Use it as an opportunity to learn from<br />

an expert. Don’t be greedy and expect to make a great score. That will save you years of bad experiences and<br />

accelerate your learning curve. I wish I had of done it this way to start. I would have learned a lot faster but<br />

like most people, I saw the dollars, not the sense.<br />

Picture Gallery<br />

The Pro <strong>Painter</strong> Facebook page has become a great place for painters to share their project pics.<br />

Paul Bisson recently painted a railway station.<br />

If you have a Facebook page and you would like to be a part of the conversation, just search “Pro <strong>Painter</strong><br />

magazine” in the search box of Facebook and the page will be one of the first to come up.<br />

11

oad strokes<br />

For effective leadership,<br />

understand your style<br />

In leading any organization, including a small painting company,<br />

leaders must understand this simple truth: style does matter.<br />

The distinctions of leadership styles could be endless; however,<br />

the following six styles are the most prominent.<br />

CharismatiC: This is leadership by infusion of energy<br />

often embodied in the personality of the leader. This leadership<br />

style may encompass a wide swath of personalities,<br />

but the common ingredient is that the energy ushered in<br />

by the leader is closely connected to the leader himself.<br />

Once Elvis leaves the building, so does some of that infectious<br />

energy!<br />

teChniCian: This is leadership by displaying both<br />

knowledge and skill. This style is highly valued in cultures<br />

where competence is high in economic value. It is leading<br />

by simply being the best producer of what your organization<br />

produces. This leadership style can influence their<br />

arena with an impeccable reputation, and sets the bar for<br />

the standard of work quality.<br />

strategiC: This is leadership by connecting the dots.<br />

This style is embodied in people who tend to be global and<br />

conceptual thinkers. They not only are able to see the end<br />

destination, but they know the path to get there must be<br />

identified and paved. Tragically, this style can be marred<br />

by the blues, because not only do strategic leaders see<br />

what could be, they see what is not.<br />

team Builder: Here, leadership is by roles and unity.<br />

This style recognizes that you can’t just assemble any group<br />

of people and claim you have a team. This leadership style<br />

is employed by people who look at people individually and<br />

find individual roles for them to fill. At the same time, they<br />

align these individuals into a cohesive whole.<br />

managerial: This is leadership by systems. This style<br />

focuses on doing things right. Processes and systems are<br />

designed and understood so that current operations function<br />

consistently. Though some would argue that managers<br />

are not leaders, you have to acknowledge that effective<br />

By glenn gutek<br />

managers have a profound influence on those that surround<br />

them. In fact, they have the capacity to lead a culture that<br />

prizes management, even at the expense of effectiveness.<br />

direCtive: Here we have leadership by control. This style<br />

was once enamored with the industrial revolution. In recent<br />

years, it has been stated that command and control are no<br />

longer cherished. However, any organization in crisis would<br />

love to have a directive leader step forward and bring order<br />

out of chaos. There is still a need for directive leaders.<br />

How to employ your understanding of<br />

leadership styles<br />

There are circumstances where certain styles flourish and<br />

others where they flounder. Your job is to find yourself<br />

in an environment where your style will flourish. As a<br />

leader, not only should you know your natural style, but<br />

you should also know the “shadow side” of that style: How<br />

does your winning formula undermine your effectiveness?<br />

Typically, a leader’s ineffectiveness will not be exposed,<br />

even if one of their weaknesses is revealed. Ineffectiveness<br />

will shine when your strength runs amuck. There is<br />

an old saying that if the only tool you have is a hammer<br />

the whole world looks like a nail. Some of the biggest<br />

mistakes in leadership are when you are using a hammer<br />

when sand paper is required.<br />

Effective leadership in today’s diverse culture will<br />

require a team approach, and teams require diverse leadership<br />

styles. By not only employing the best leadership<br />

style for you, but also knowing when to adapt to other<br />

styles, you can effectively lead your team to success.<br />

Glenn Gutek is a speaker and CEO of Awake Consulting<br />

& Coaching. For more information visit www.AwakeConsulting.com<br />

or contact Glenn at glenn@awakeconsulting.com<br />

or 407-901-4357.<br />

12 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

3 reasons why Bulls Eye 1-2-3 ®<br />

is the contractor’s choice<br />

GREAT HIDE<br />

GREAT ADHESION<br />

GREAT STAIN KILLER<br />

Preferred by professionals 2 to 1 over other water-base primers!<br />

It’s no wonder! Bulls Eye 1-2-3 dries fast, resists rust fl ashing and its mold and mildew<br />

resistant fi lm makes it ideal for high humidity areas. It seals porous surfaces and bites<br />

into oil-base enamels. And its proprietary resin system gives it exceptional fl exibility<br />

and durability, so it’s great for any painting project – inside and outside!<br />

For more information, please visit www.rustoleum.ca or call 1-800-387-3625<br />

for a dealer near you!

oad strokes | Tech Savvy<br />

14 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

Colour Matching 101<br />

E<br />

very paint has a unique set of characteristics and<br />

ingredients—sheen level, elasticity, opaqueness,<br />

tint quality, base quality, the nature of the fillers<br />

and VOC levels. If the paint is more than five<br />

years old, it is possible that even the formulation<br />

has changed; Witness the drastic changes in the last two<br />

years due to changing VOC regulations. There are a host<br />

of variables that need to be taken into account. Add to<br />

that the fact that, as we all know, not all paint is created<br />

equally, and where some are hard to match no matter<br />

what you do, others seem made for matching.<br />

Matching over time<br />

Even if you find a paint that matches the sheen level of the<br />

existing wall, new and old paint have different sheens and<br />

will fade differently. Older high-VOC paints break down<br />

much faster, and so even if the sheen matches after you<br />

touch it up with a mini-roller, a few months later the spots<br />

stand out. If you think the wall is situated where variable<br />

sheen will show, matching may not be the best way to go.<br />

Computer matching<br />

The most common way to match paint colours today is<br />

with the use of a computer matching system. With an<br />

accuracy of about 90 per cent, computer-based matching<br />

is nearly perfect for the untrained eye. For that next ten<br />

per cent, it takes the matching ability of the computer<br />

plus the experience of a good colour-matching technician<br />

who can adjust the computer-derived colour with small<br />

amounts of tint to get it just right.<br />

How the computer does it<br />

Computer matching uses a spectrophotometer that scans<br />

the paint sample using a tungsten bulb to simulate daylight.<br />

The bulb produces pure white light since white light<br />

is made up of all the colours of the visible light spectrum.<br />

Newer machines use light emitting diodes (LEDs) that are<br />

even more accurate and use less power.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

Constantly changing paint formulations have made accurate,<br />

invisible touchups almost, but not completely, impossible<br />

By Bruce MacKinnon<br />

The paint sample to be matched is held in front of the<br />

light box and flooded with white light that reflects off<br />

the sample onto a small wheel at the back of the light<br />

chamber. The rotating wheel is a highly-efficient analyzer,<br />

made up of as many as 31 interference filters. Each filter<br />

is designed to allow only a specific wavelength (ten nanometres<br />

worth) of light to pass through it, while all the<br />

other colours are reflected away.<br />

Fiber optic cables then transmit the colour information<br />

collected to a photo diode that digitizes the information<br />

for the computer software to read and create the<br />

perfect recipe of tints in a specific paint base to match<br />

the paint sample.<br />

Base and paint line effect<br />

The paint base and the paint line are critical. Only topline<br />

paints should be used when tinting because they<br />

hold colour longer. Also, flatter paint will return a more<br />

accurate tint-matching combination, as glossier paint<br />

makes the processing of the chip more unreliable. A<br />

glossy colour sample will cause glare and reflect light off<br />

the sample.<br />

The latest spectrophotometers come equipped with<br />

LED lights that create a laser-like beam of light that can<br />

reflect off an object and reject ambient light in the room.<br />

This means painted samples like rad covers or metal can<br />

be brought in to be read and don’t have to be clamped to<br />

the light box in front of the machine.<br />

When you are done matching<br />

Once a sample has been matched and a small amount<br />

of paint is mixed up, the new paint should be rolled on<br />

using a mini-roller to more accurately create the roller<br />

texture and stippled effect of the paint. The tighter the<br />

nap of the roller at the time of application the glossier the<br />

finish, so matching the paint texture on the wall is just as<br />

important.<br />

15

Kevan Dick,<br />

Lantzville Painting<br />

Nanaimo, B.C.<br />

Photo: Ned Pratt/KlixPix cover story | Robert Candow’s Plastering and Painting<br />

THE CA<br />

APPRO<br />

Robert Candow is a “can do”<br />

painting markets in Canada.<br />

16 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

NDOW<br />

ACH<br />

painter in one of the toughest<br />

By Bruce MacKinnon<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

The man behind Robert Candow’s Plastering<br />

and Painting keeps 12 to 15 men hopping<br />

on two plastering crews and three painting<br />

crews, doing mostly subdivision and custombuilt<br />

homes in and around St. John’s Nfld.<br />

Candow was 14 when he learned his first life lesson. He<br />

was hired to paint the outside of his girlfriend’s house and<br />

discovered how suited he was to being a painter. It took a<br />

few years for that lesson to stick, but it was the beginning<br />

of a lifetime of lessons that have made this student of the<br />

craft the success he is today.<br />

Lesson Two<br />

While still in high school, Candow took a job working in<br />

a hospital kitchen in the meat room, the kind of job any<br />

union person would drool over. It was a secure government<br />

job he could have kept comfortably for 30 years, but<br />

Candow decided early on that he didn’t like to see people<br />

given promotions based on seniority instead of on merit.<br />

“I watched my truck-driving dad and stay-at-home mother<br />

work very hard for what they had,” Candow says. “As a<br />

kid I decided that whatever I did for a living I would do<br />

for myself.”<br />

His opportunity to paint came at age 17 when two local<br />

painters promised him a full-time job. He went out and<br />

bought his long-dreamt-of van and then got laid off two<br />

weeks later. Not to be deterred, and fancying himself artistic,<br />

Candow started making decorative plaster casts to sell.<br />

As well, he played the club circuit with the rock band he<br />

started after dropping out of university.<br />

17

cover story | Robert Candow’s Plastering and Painting<br />

Lesson Three<br />

The next turning point came when Candow got his first<br />

unemployment cheque. Thinking back to his first career<br />

decision, he decided on the spot that he wasn’t going to<br />

accept money he didn’t work for. He never took another<br />

EI payment again.<br />

A year later Candow went to a local paint store to<br />

negotiate a credit account to get started on his own and<br />

the owner almost laughed him out of the store. He got his<br />

credit though, and not long after, while playing music in a<br />

bar one night, the man who laid him off had a new offer,<br />

this time to become his partner. Candow had the van and<br />

the credit while his new partner provided the experience<br />

and the ability to sell. “Grey hair makes all the difference<br />

in the painting business,” Candow says. “People assume<br />

that you don’t know what you are doing if you are young.”<br />

The two started a ten-year partnership and did well painting<br />

subdivision homes and custom-built units.<br />

After ten years, the partnership broke up suddenly<br />

when Candow’s partner walked away, unhappy about<br />

Candow’s refusal to “put all the company’s eggs in one<br />

basket.” They had an opportunity to work exclusively for<br />

one higher-paying builder, but Candow refused. His partner<br />

went with the contractor and Candow went his own<br />

way. The “exclusive,” high-paying contractor went under<br />

eighteen months after the split.<br />

Lesson Four<br />

During the early years, Candow learned to do all the<br />

ugly work others refused to do and picked up all the<br />

customers his competition didn’t like. “It made me a<br />

better painter and a more patient person,” Candow says.<br />

“I didn’t think anyone owed me anything, and I felt that<br />

since I was young, I had to earn my stripes.”<br />

Two of Candow’s four brothers became union presidents<br />

and it made for some interesting dinner conversations.<br />

“But I have an expert consultant in my corner: my<br />

82-year-old grandmother, who always told me to not just<br />

work hard, but smart,” Candow says.<br />

Lesson Five<br />

Candow’s route to success was to read books about<br />

wealthy and successful people to learn tidbits he could<br />

put into practice. His life-changing book was The Wealthy<br />

Barber. “I got so excited; I bought six more of the books<br />

for my friends. I love to help people succeed,” Candow<br />

says. “I have one friend who has just retired and he keeps<br />

thanking me for giving him the book. He learned to put<br />

18 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

money away in RRSPs before it became fashionable. It<br />

was about the magic of compound interest.”<br />

Giving back<br />

The game-changer for Candow was meeting builder<br />

Geoff Clark of Fairview investments right after his<br />

partnership split. Clark introduced Candow to the Eastern<br />

Newfoundland Home Builders’ Association(ENHBA)<br />

where he had his eyes opened to the larger picture of the<br />

building industry.<br />

“Geoff said the association supports the trades, how<br />

about I support the builder’s association,” Candow says.<br />

“I didn’t think I had anything to offer builders, but as I<br />

got involved in the nuts and bolts of the association, and<br />

also in the Canadian Home Builders’ Association, I was<br />

exposed to all aspects of building and got a whole new<br />

appreciation for what builders have to do to create safe<br />

homes.”<br />

Candow’s attitude towards the industry was at odds<br />

with the opinions of his brothers, the union heads, who<br />

felt the industry owed them something. “I made my entire<br />

living from the building industry, so every decision the<br />

associations made, everything they lobbied for, and what<br />

they worked for affected me directly or indirectly. It was<br />

only right to give back some of my time and effort to<br />

support it.”<br />

Making a difference<br />

At every level of government—municipal, provincial and<br />

federal— laws are passed by politicians who don’t always<br />

understand or see how their decisions affect the building<br />

industry. “The decision-makers need an informed body to<br />

speak to and to be educated by,” Candow says. “Sitting<br />

around the table I got to see lots of different points of<br />

view and added my opinions when and where it seemed<br />

right to do so. From bankers and suppliers to tradespeople,<br />

each component of the construction process has<br />

unique challenges.”<br />

Band of brothers<br />

Meeting contractors from across the country showed<br />

Candow was not alone in the challenges he faced. “I<br />

discovered we all have trouble with employees, like<br />

absenteeism and quality of work,” Candow says. “Before<br />

joining, I thought it was just me who had employee problems<br />

and I just couldn’t get my men to work right. But I<br />

saw good and bad bosses and trades wherever I went. It’s<br />

human nature more than any system. The broad view I<br />

experienced is what changed me.”<br />

Candow has settled with a core of a dozen men who<br />

enjoy painting and plastering as much as he does. Some<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

Photo: Ned Pratt/KlixPix<br />

Home Builders’<br />

Associations<br />

RoBeRt CAndoW HAs BeCome an integral part of the<br />

Eastern Newfoundland Home Builders’ Association, a<br />

branch of the Canadian Home Builders’ Association.<br />

He has served on and has been chairman of provincial<br />

and national organizing committees, including local<br />

home shows and conferences. He has also served as<br />

president of the provincial chapter. In 2005 Candow<br />

won the award for Member of the Year, in the “Non-<br />

Builder” category.<br />

Wanting to give back to the industry that provided<br />

his living over his 20-plus-year career was what got<br />

Candow into the association ten years ago, but the<br />

education he receives more than outweighs the few<br />

hours he continues to put in each week. He is proof<br />

that home builders’ associations aren’t just for and<br />

about builders.<br />

Building sub-trades are crucial to the completion a<br />

project, so input is needed from a representative from<br />

each trade and sub-trade, especially in these days of<br />

specialization. “Builders asked me for a painter’s-eye<br />

view of the building process and, as a result, they<br />

learned how to improve their homes by understanding<br />

19

20<br />

cover story | Robert Candow’s Plastering and Painting<br />

our needs better. If we can do a better job as a result<br />

of their co-operation, the job, the trade and the builder<br />

all look better,” Candow says. “If you care about your<br />

trade, you have to get involved. Every painter in your<br />

region will benefit from your input.<br />

“Seeing what the other trades need in the process<br />

helps you better prepare for those trades and helps you<br />

become more tolerant of delays ahead of you.” More<br />

importantly, Candow saw the same disparity between<br />

trades as he saw at home. All across Canada, there<br />

were good, bad and indifferent painters, carpenters<br />

and electricians. Individual ethics and backgrounds<br />

dictated the work ethic of the trades, not the province<br />

you worked in.<br />

Candow’s best example of an expanded viewpoint<br />

came from a trip to Calgary where he and fellow St.<br />

John’s contractor Elmo Russell looked at high-end<br />

townhouses. A contractor back home wanted to build<br />

a set of high-end townhouses but was being blocked by<br />

City Hall and the neighbours. It was typical NIMBYism,<br />

the “Not in my backyard” attitude Candow says.<br />

Townhouses had a reputation of being low quality,<br />

poorly built, unsightly and for low-income residents.<br />

“It looked like we were going to lose a lot of highend<br />

work, until we came back from our trip and spoke<br />

in City Hall, explaining that some people didn’t want<br />

big yards with lawns or pools or large garages,” Candow<br />

says. “Instead they wanted high-end upgrades<br />

like hardwood floors, oak handrails and marble in the<br />

kitchens and bathrooms.”<br />

What was nearly a lost building project became<br />

a prized high-end townhouse development, which<br />

launched several others like it on the island. “Projects<br />

like this are a vision of the future, where higherdensity<br />

housing done right decreases our footprint<br />

on the environment while providing more homes for<br />

more people,” Candow says. “David Suzuki would be<br />

proud.”<br />

Also as a result of Candow’s travels, rounded metal<br />

wall corners are the standard in higher-end homes<br />

now. He saw them in the same kind of new construction<br />

projects he was doing and brought the idea back<br />

to Newfoundland.<br />

But Candow is proudest of having been instrumental<br />

in forming the “Try the Trades” program for high<br />

school students and recent graduates. Candow does<br />

some in-classroom orientation for the budding tradespeople,<br />

and then they get four paid weeks (funded by<br />

provincial and federal dollars) of hands-on experience<br />

in each of the building subtrades. —BM<br />

of his crew are young people who went through a program<br />

Candow helped set up through the ENHBA, called<br />

“Try the Trades.”<br />

Since construction has become so specialized, this<br />

program gives youth a month of paid work to try out<br />

all the trades on a jobsite, to let them see what sticks. “I<br />

have nothing against college or university if that works<br />

for you, but there is nothing wrong with doing physical<br />

work and coming home dirty,” Candow says. “The key is<br />

being lucky enough to work at something you love, and I<br />

love what I do.”<br />

Mike Lee, a retired builder who still works with the<br />

ENHBA, helped Candow set up the Try the Trades program.<br />

“Rob is always looking for painters to keep up<br />

with the demand. After 30 years his reputation speaks for<br />

itself,” Lee says. “Now kids of people who had Rob paint<br />

their house are demanding he paint their new homes.<br />

There’s no better reference than that.”<br />

The Candow way<br />

Candow’s pet peeve is training guys to be proficient painters,<br />

only to see them take off to Alberta for the big bucks<br />

or set up shop in the same city as he is in. Another is his<br />

guys changing his system that works for something they<br />

like better without telling him.<br />

“I had one guy so determined to do things his way, I<br />

challenged him to paint doors and frames with me,” Candow<br />

says. “His way took a few minutes longer than my<br />

way. Then I told him to multiply those few minutes for<br />

all the doors and windows in the house and it came up to<br />

more than an hour. He wasn’t keen on the idea of staying<br />

an extra hour after quitting time to finish his work doing<br />

it his way.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011

“I don’t need employees who drag morale down or<br />

fight you all the time. Some guys are never happy. I have<br />

a system that works, and as long as it’s my business and<br />

my money, they do things my way. I also learned employee<br />

strategies by talking with other contractors and reading<br />

books. If I could get my employees on my side they<br />

will always do good work for me. But if they are ticked<br />

off at me, even if I’m right, then I lose in the long run.”<br />

The fun lesson<br />

Elmo Russell, of ERCO Homes, is a builder Candow met<br />

through the ENHBA and has travelled the country with.<br />

He taught Candow to loosen up a bit and put some fun<br />

back into his life. On various conference trips, Russell<br />

has dragged Candow off to learn how to ski, play golf and<br />

even ride motorcycles. “It’s cost me a pile of money ever<br />

since and it hasn’t changed my business ethic, but he did<br />

help me to loosen up a lot,” Candow says.<br />

“I just came along at the right time of his life,” says<br />

Russell. “I like to have fun no matter where I am or what<br />

I’m doing. Robert, though too serious at first, was always<br />

up to try anything. We had a lot of fun but got a lot of<br />

work done too.”<br />

Association partners<br />

But it isn’t all fun and games for Candow and Russell.<br />

They have worked tirelessly on the ENHBA and the Cana-<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

dian Home Builder’s Association together.“Robert is one<br />

of the very few Newfoundland contractors who is a nonbuilder<br />

who became president of the ENHBA,” Russell<br />

says. “He was the face and voice of our association and he<br />

could (and still does) speak about any issue with anyone.<br />

He is very highly respected in the association.”<br />

The biggest lessons of all<br />

Through watching his parents raise five kids, reading<br />

books and running a business, Candow has learned to live<br />

below his means. “People assume things will always be<br />

good and so get in way over their heads in debt,” Candow<br />

says. “I treat my own life the same as my business: don’t<br />

waste material, effort or work. Buy what you need and<br />

don’t waste money. It’s not about what you want to do; it’s<br />

about what you need to do to survive.”<br />

He also knows that the secret of success in painting has<br />

always been, and will always be, preparation. The majority<br />

of companies out there do 95 per cent of things right, but<br />

it is the rough wood in a closet or an unpainted edge under<br />

something that the customers see that annoys them the most.<br />

“I do the last five per cent as well,” Candow says. “If<br />

the customer catches their sweater on a rough piece<br />

of wood inside the closet or sees sloppy plastering or<br />

painting inside a cabinet or under a sink, it gets back to<br />

the builder, who remembers next time. I don’t leave the<br />

imperfections for the next guy to have to fix.”<br />

21

OUR WALLS<br />

CAN TALK<br />

Learning the real stuff from the best applicators<br />

This is a copy of Adam and Eve by art deco painter<br />

Lempicka, done as a Tattoowall by husband and<br />

wife team Maxime and Johanne Jacquel.<br />

By Agnes von Mehren<br />

Masters Academy president Agnes<br />

von Mehren interviews contractors<br />

and decorators who have taken the<br />

Tattoowall installers course for their<br />

ideas and comments.<br />

In the ever-changing world of painting and decorating,<br />

it is very important to stay open to learning<br />

new tricks and techniques that are the ticket<br />

to greater profits. At the Masters Academy of<br />

Decorative Arts, I run into a variety of students from<br />

different walks of life—painters, architects, contractors,<br />

decorators, sculptors, part-time artists, designers—all<br />

with one thing in common: They want to learn something<br />

new and they want to make a profit.<br />

Three of the students who have taken the classes for the<br />

certified applicator course of the Tattoowall—a contractor,<br />

a decorative artist0 and a contractor engaged in painting<br />

and in decorative art—gave me some application tips:<br />

Brian Snow, a contractor working in the Windsor<br />

area and the U.S., didn’t think the class was for him<br />

at first. “When I heard of a certified Tattoowall class I<br />

didn’t pay too much attention, as I was convinced this<br />

was something for the artsy folks. I was talked into<br />

attending by one of my associates who has taken the<br />

class,” says Snow.<br />

“What I learned in the day-and-a-half certification class<br />

speaks volumes and will add much more interest and<br />

profit to my business. I see this as a viable addition to my<br />

business and I have started to talk to my customers about<br />

22 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

it. Usually when customers want a faux finish or a mural on<br />

a wall, site scheduling and interaction with various trades is<br />

a concern. Tattoowall alleviates a lot of those problems due<br />

to the speed of installation. A typical mural can tie up a wall<br />

for several weeks, whereas Tattoowall can be installed from<br />

start to finish in about two days. For restaurants or jobs<br />

that require a repeating theme, using Tattoowall guaranties<br />

you will always get the theme you want and they are all the<br />

same. There is no other method that can guarantee that.<br />

"I’ve worked on major projects in the U.S., “Spiderman”<br />

being one of them, and I think this has great possibilities<br />

for movie and theatre sets. The versatility of the product<br />

is remarkable, especially on rough concrete as there is<br />

absolutely no distortion of the image. It’s also a clean<br />

application and pretty fast. I have a lot of experience in<br />

hanging wallpaper, which is a plus, but the Tattoowall is<br />

slightly different. I believe that anything is possible with<br />

Tattoo wall and with the interest in wallpaper today, I see<br />

big opportunities for this product.”<br />

Brian is also certified by Combo Master, The International<br />

Union of <strong>Painter</strong>s and Allied Trades and the International<br />

Alliance of Theatrical Stage Employees (IAATSE).<br />

Ralph Piesche is from Vancouver, B.C. and he was our<br />

first Doubting Thomas when he contacted us at the Academy.<br />

He wasn’t quite sure what to expect. His paint dealer<br />

is Martin Prus from Abbotsford, B.C. and when Martin<br />

was at the Dynamic PIP trade show, he was fascinated<br />

with the Tattoowall so much that he came to the Academy<br />

to see exactly what it was all about. Martin’s store is<br />

approximately 4,000 sq. ft and has some lovely furniture<br />

and designer products as well as paints and paintware<br />

products. He works with Ralph and thought he would<br />

enjoy learning about Tattoo Wall. It was perfect timing,<br />

since Ralph was facing a dilemma in his business.<br />

“As a decorative painter and plasterer, I have often been<br />

approached by clients inquiring if I do murals,” says Ralph.<br />

“I consider myself to be a small “A” artist, and in the past<br />

I have attempted to do some paintings but I soon learned<br />

that my natural talents had their limitations. What was<br />

most frustrating was the time it took to render a respectable<br />

mural. The Tattoowall is a great solution for this dilemma. I<br />

can now happily accept requests for murals and, along with<br />

my knowledge of plasters, glazes and faux techniques, it<br />

brings an excellent new addition to my portfolio.<br />

I was particularly impressed with the use of distressed<br />

plaster substrates and in the use of canvass with decorative<br />

borders. It renders the mural portable and provides a<br />

new and exciting way to market the product and my skills.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

Maxim and Johanne Jacquel<br />

applications<br />

The addition of embellishment intrigued me, as I am very<br />

familiar with Venetian plasters and glazes, and adding foils<br />

to the embellishment with Swarovski crystals creates a different<br />

kind of masterpiece. This is one product that has<br />

been a long time in coming to the marketplace and is quite<br />

different from the regular digital prints.”<br />

Our most recent graduates from the class are a husband<br />

and wife team, Maxim and Johanne Jacquel. Maxim is from<br />

France and Johanne is French-Canadian. Maxim comes from<br />

the manufacturing world of paint and knows everything<br />

about how paint is made and mixed. Needless to say, he is<br />

the “hands-on” guy of this team. Johanne is the decorator, a<br />

charming gal with a French accent who is a whiz with colour<br />

and design. A few passes with her hands and she can transform<br />

ordinary into extraordinary. They live in Newmarket,<br />

Ont., but most of their business is done in North York.<br />

“The course provides you not only with the skills and<br />

information needed to properly apply Tattoowall murals<br />

on any substrate, it is hands-on as well, from a small<br />

sample to a very large-scale sample,” Maxim says. “This<br />

allowed us to actually see how much space would be<br />

required to do the job as well as what equipment and<br />

manpower would be needed. The teachers and experts<br />

right there with us in small groups allowed us to identify<br />

and solve challenges as they presented themselves. It<br />

also allowed us to ask the questions galore that popped<br />

into our minds as we were learning and to have them<br />

answered immediately.”<br />

“As we worked at applying the Tattoowall to canvases<br />

on a table and on a wall, we could easily visualize its many<br />

possibilities for the varied clients in both our decorating<br />

and renovating businesses," Johanne added. "In fact,<br />

23

applications<br />

Brian Snow<br />

we’re already scheduled to apply a Tattoowall mural in<br />

a couple’s household gym. We’ve got a school principal<br />

who’s looking into putting up a very large mural on the<br />

block wall of the new school’s gym.<br />

“We have a close friend who noted how beautiful some<br />

of the children’s images from the school would look in their<br />

child’s bedroom. We purchased an Adam and Eve Tattoowall<br />

for our gym at home and we are thrilled with the result. One<br />

of the interesting things about this product is how it covered<br />

For Your<br />

Eyes Only<br />

a light switch (see photo, right)<br />

and it was so easy to apply. Imagine<br />

being able to do a mural in a<br />

day, when normally a large mural<br />

can take several weeks.”<br />

“As a contractor and a paint<br />

guy, I haven’t seen anything like<br />

this,” says Maxim. “Usually we<br />

are concerned as contractors<br />

in getting the job done quickly,<br />

clean up, and get out. The tools<br />

are also very simple: special tape,<br />

adhesive, brush, a spatula and<br />

that’s it. I also found that it’s almost mistake-proof as the<br />

images come with print registration lines that make it easy<br />

to line them up. Both of us found this is the most important<br />

part of the application, to make sure you line up those<br />

registration lines correctly. In our opinion, the Tattoowall is<br />

simply the ultimate decorator ‘pièce de résistance.’”<br />

All of these everyday people with different goals and<br />

types of business seem to agree that taking a class and<br />

Most customers won’t see the secret agent stealthily working under<br />

their topcoat. All they’ll know is that their old, cracked and alligatored<br />

surfaces have a classy new look that beats evil surfaces into submission.<br />

But you’ll know that it was XIM’s Peel Bond ® .<br />

Peel Bond seals surfaces, bridges cracks and bonds with old paint<br />

on a molecular level—leaving a smoother surface for all eyes to see.<br />

What’s Under<br />

Your Topcoat?<br />

www.peelbond.com<br />

Visit our blog and share your success.<br />

Rough Surface Peel Bond Latex Topcoat<br />

24 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

adding Tattoo Wall to<br />

their arsenal has made<br />

a big difference in their<br />

professional life and<br />

return-on-investment<br />

prospects. The common<br />

theme is the ease<br />

of the application and<br />

the different decorative<br />

techniques that can be<br />

used with the product.<br />

The ideas for application<br />

were many, and<br />

ranged from theatres,<br />

movie sets, wrapping<br />

Ralph Piesche<br />

buildings, floors, gymnasiums,<br />

elevator doors and many more. Most of our<br />

students are also interested in the speed and ease of application<br />

and how you don’t need to be an artist to produce a<br />

fabulous mural.<br />

Venetian plaster is applied to the substrate first, which<br />

We’ve<br />

kicked<br />

it up a<br />

notch!<br />

New formulations and new bold<br />

packaging make it easy to find<br />

exactly the right Elmer’s for the job.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

can be smooth or rough to provide texture. This way the<br />

finished result is a fresco and you cannot tell the difference.<br />

The Tattoowall is applied on top of the Venetian<br />

plaster, after which you can embellish it further with<br />

glazes and foils. This can also be applied to canvas using<br />

the same method (the canvas has to be stretched and<br />

primed first before anything is added to it.)<br />

Walls can really talk with the Tattoowall. You can actually<br />

create a 3D effect with this product by embellishing<br />

it with Venetian plasters and using stencils. You can even<br />

create the Tattoowall on top of wallcovering using the<br />

wallcovering as a frame and the Tattoowall inside the<br />

frame. We are looking for innovative ideas on using the<br />

Tattoowall and would like to hear from you.<br />

We are preparing a special Master Class in Toronto soon<br />

and you will be able to check the dates on our website. This<br />

is an opportunity to see European masters in action and to<br />

show spectacular applications of Tattoowall Wall.<br />

For more information please contact www.mada-masters.com<br />

or www.getpainting.com<br />

25

SURFACE PREPARATION:<br />

the easy Way<br />

to sand<br />

Sanding for a perfect finish<br />

By steve Maxwell<br />

26 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

I<br />

’ve been sanding wood as a cabinetmaker and<br />

carpenter for 25 years, and I can tell you all kinds<br />

of ways to waste your time sanding trim, cabinets<br />

and architectural millwork. I can also show you<br />

one particular approach to sanding that works every time,<br />

and it doesn’t even take that long.<br />

Three sands<br />

When you’re dealing with flat surfaces, the process involves<br />

three machines and four steps: begin with a belt sander;<br />

refine the surface using a half-sheet vibrating pad sander;<br />

create an ultra smooth surface using a quarter-sheet palm<br />

sander; and complete the job by slightly rounding corners<br />

and edges with a piece of hand-held sand paper. Don’t make<br />

the mistake of thinking that all these steps take a long time;<br />

they don’t. In fact, using these three different machines in<br />

the right order actually speeds the process considerably.<br />

The first thing to understand is that no piece of wood<br />

is smooth enough for stain and urethane as it comes from<br />

the lumberyard, no matter how well planed it seems to be.<br />

That’s because the planing process always leaves behind<br />

subtle (and sometimes not so subtle) undulations in the<br />

surface of the lumber. These can be hard to see until a<br />

finish goes on, bringing these flaws into clear focus. The<br />

results of no sanding (or bad sanding) are especially ugly<br />

after staining wood a dark colour.<br />

Belt sanding<br />

All this is why I begin sanding every flat surface with a belt<br />

sander spinning a 100-grit belt. My favorite machine for most<br />

jobs is a 3” x 21” model—light enough to use all day, but powerful<br />

enough to be productive. If I have a lot of sanding to do<br />

on large surfaces, I prefer a 4” x 24” belt sander.<br />

The thing about any belt sander is that it’s aggressive.<br />

This machine removes a lot of wood quickly, which is<br />

great in some ways though it also means introducing two<br />

particular hazards. The first is gouging.<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011<br />

surface preparation<br />

Keeping a belt sander flat and level with the surface<br />

of the wood is key. If you’re not paying attention as you<br />

work and you let the tool tilt left or right, one edge of the<br />

belt will grind a groove in the wood that’s hard to remove.<br />

Light pressure while maintaining an even keel is essential.<br />

A belt sander must also be used parallel to the grain,<br />

at least before moving on to the half-sheet vibrating pad<br />

sander that comes next. That said, it’s legitimate to use a<br />

belt sander cross grain for a while if you’ve got slightly<br />

mismatched edge-glued boards to level up, or if you’ve<br />

got solid wood edging to even out on a veneered plywood<br />

shelf. Cross-grain sanding is fastest, and that’s why it’s<br />

so useful for leveling, though the practice also leaves<br />

behind nasty scratches. That’s no problem, as long as you<br />

eliminate them completely by sanding parallel to the grain<br />

before setting the belt sander aside. Just be sure your<br />

sander really is completely parallel to the grain for these<br />

final steps. It’s easy to angle off a little bit.<br />

You know you’re finished with a belt sander when a<br />

spotlight shining off the wood at a shallow angle shows<br />

an even surface with no remaining mill marks or blemishes.<br />

You’ll get the longest belt life if you clean off sawdust<br />

and resin using a crepe rubber block held against<br />

the spinning belt.<br />

Finishing sander<br />

The half-sheet finishing sander must’ve been designed<br />

with painting contractors in mind. It’s my tool of choice<br />

for the second sanding stage because it’s fast yet fine.<br />

I typically use it with 120-grit sandpaper. If you’ve left<br />

behind any small flaws caused by the belt sander, the<br />

half-sheet machine makes quick work of removing them.<br />

The final stage of power sanding works best with<br />

a quarter-sheet finishing sander loaded with 220-grit<br />

paper. Go over all surfaces with a light hand, keeping the<br />

machine level.<br />

27

surface preparation<br />

One reason for using three different sanders like this<br />

is that it saves you time putting on and taking off different<br />

grits of paper. Just grab the machine you need, use it,<br />

then put it down and pick up another for the next stage.<br />

Each machine is also ideally suited to the particular stage<br />

I use them.<br />

Sanding for easy profit<br />

Creating ultra smooth sanded surfaces on wooden<br />

Random orbit sanders<br />

are great, but . . .<br />

Random oRbit sandeRs are often used as the one<br />

and only prep machine before finishing, but that can<br />

cause problems because it’s so easy for them to leave<br />

behind a pattern of irregular swirls that don’t become<br />

apparent until after a finish<br />

has been applied. This<br />

is irrelevant if you’re sanding<br />

decks and outdoor surfaces,<br />

but it’s definitely not<br />

what you want on wainscoting,<br />

hardwood paneling<br />

or a dark oak bar installation.<br />

Five-inch diameter random<br />

orbit sanders are good<br />

for light- duty applications,<br />

but I use one of my more<br />

powerful, six-inch models<br />

for most random orbit jobs.<br />

My favorite is the Porter<br />

Cable 7336. It also happens<br />

to be one of the simplest<br />

and cheapest. Fancier models<br />

include the ability to<br />

switch from a small oscillation<br />

pattern for fine work to<br />

a coarser pattern for removing<br />

wood more quickly. Variable speed is useful for<br />

throttling back any random orbit sander when scuffing<br />

up an existing exterior wood finish that needs recoating .<br />

If you have your heart set on the speed and simplicity<br />

of using a random orbit sander for final smoothing,<br />

then you’ll get the best results using sanding discs with<br />

micro-holes. These pick up dust and stray abrasive particles<br />

more effectively than the coarse pattern of larger<br />

holes found on stock sanders and discs. And more effec-<br />

architectural details can be a powerful competitive<br />

advantage when it comes to winning jobs and bidding<br />

up prices. I know from experience that it pays to make<br />

up finished wood samples to show clients what you’re<br />

capable of. Excellent results don’t require any particular<br />

genius and you don’t have to be a workaholic. But<br />

since it’s always good to look like a genius workaholic,<br />

just keep quiet about how easy it really is to make wood<br />

smooth.<br />

tive pick-up means fewer stray particles rolling around<br />

underneath the sander causing swirls. Very light hand<br />

pressure on the machine helps, too. —SM<br />

28 <strong>Professional</strong> <strong>Painter</strong> • Winter 2011

30<br />

final coat<br />

By Jim Caruk<br />

PAINTING<br />

THE COMPLETE DOOR<br />

Just because the tops and bottoms of doors are rarely seen,<br />

you still need to paint them with extreme care<br />

T<br />

he difference between a professional painter<br />

and a jack-of-all-trades is in details and<br />

in the prep. It’s all about the care you take.<br />

For example, how many painters, honestly,<br />

take the time to always, without exception,<br />

paint the tops and bottoms of all doors – interior and exterior?<br />

I recently had this issue with a painter who did a job for<br />

me about four years ago. My client had about 30 interior<br />

doors, and they called me in to take a look at them. They<br />

sheen had come off the paint. They looked flat, as if the<br />

paint was just primer. It was a weird one. Repainting only<br />

temporarily solved the problem. We couldn’t figure out<br />

why this was happening. We even called the manufacturer<br />

of the doors.<br />

Eventually, we took one of the doors off of its hinges<br />

and realized that my painter – as good as he was – had<br />

not bothered to paint the top and bottoms. They were raw<br />

wood. Nobody was looking at these surfaces, he might<br />

have thought, who cares if they were left unpainted. But<br />

wooden doors will absorb moisture if they aren’t sealed<br />

on every surface. Most professional painters know this.<br />

You probably know this. But in a rush, it can be tempting<br />

to neglect this all-important detail.<br />

The effects of that moisture absorption can lead to<br />

warping, which is why so many door manufacturers won’t<br />

warranty a door’s performance if the unit is not sealed<br />

properly. But in some cases, the paint finish on the door<br />

can degrade, too, as I found out.<br />

The top and bottom (and, of course, edges) of wooden<br />

doors need to be sealed with a primer coat and at least<br />

two coats of paint, preferably oil (and preferably an oilbased<br />

primer).<br />

Now the next question you may have is, does this apply<br />

to MDF doors as well, or only to solid wooden doors? It<br />

probably is true that solid wooden doors are more likely<br />

to absorb moisture and deform from unpainted edges<br />

but, to get in the habit of purely professional painting at<br />

all times, why would you have an A game and a B game?<br />

Why not paint like a top professional at all times? Paint<br />

all the surfaces of your doors, whether they show or not.<br />

And that applies to the top of door trim! <strong>Painter</strong>s will<br />

leave the top of trim unpainted, too. I know, you wouldn’t<br />

do this. But some of your fellow painters will do it. Not<br />

the ones I want to work on my high-end work, and not<br />

the ones you’d want to work on your own home. <strong>Professional</strong><br />

painting is all about the details and the prep. And<br />

enjoying the feeling that comes from knowing you take<br />

meticulous care in your work, all the time.<br />

Jim Caruk, well-known TV and real life contractor,<br />

is the founder of Build It Yourself Learning Centers<br />

(www.biyworkshops.com).<br />

<strong>Professional</strong> <strong>Painter</strong> • Winter 2011