Compact 32V - X-Flow

Compact 32V - X-Flow

Compact 32V - X-Flow

- TAGS

- compact

- x-flow.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

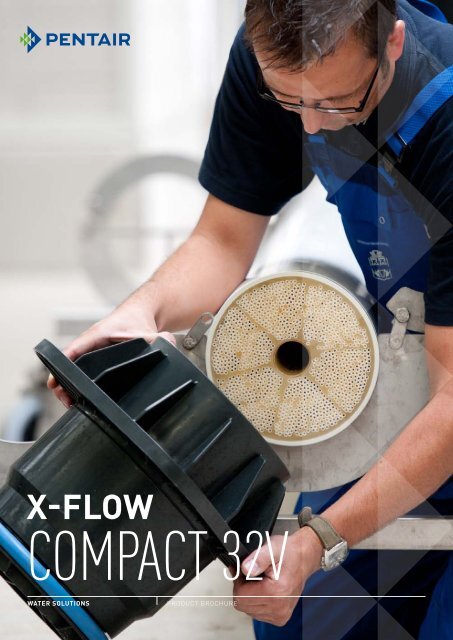

X-<strong>Flow</strong><br />

CompaCt <strong>32V</strong><br />

waTer soluTions product brochure

general inForMaTion Key FeaTures<br />

The <strong>Compact</strong> <strong>32V</strong> ultrafiltration (UF)<br />

membrane is the heart of Pentair X-<strong>Flow</strong>’s<br />

Airlift MBR Megablock technology – a<br />

compact wastewater treatment concept that<br />

enables municipal wastewater treatment<br />

plants to efficiently handle fluctuating<br />

amounts of water while complying with<br />

stringent regulatory requirements.<br />

This modular, energy-efficient and fully<br />

automated MBR system delivers highquality<br />

effluent that is suitable for discharge<br />

into the environment or into a reusable<br />

water source. At the same time, the Airlift<br />

MBR Megablock technology protects public<br />

health, operators and the environment.<br />

.<br />

pUre poWer in<br />

eVery inch<br />

Performance<br />

• High flux rates of 50 l/m²h and up<br />

• Removal of all suspended solids<br />

• Optimal flow distribution<br />

• No sludge carryover<br />

• High biomass concentration<br />

• Zero cleaning chemical waste discharge<br />

• Very good anti-fouling behavior<br />

Design<br />

• Small footprint<br />

• Minimized piping and connections<br />

• Modular design with 36 to 216 membrane<br />

modules<br />

• Easy extension for future capacity<br />

increase<br />

• Inside & outside placement possible<br />

operator-friendly<br />

• Simple & safe maintenance<br />

• Externally mounted membranes<br />

• High level of automation<br />

environment-friendly<br />

• Low energy consumption of 0.3 kWh/m³<br />

• Low chemical consumption<br />

reFerences<br />

Glanerbrug, Netherlands<br />

Capacity: 100-150 m 3 /h

sMall FooTPrinT<br />

& high eFFiciency easy consTrucTion & eXTension siMPle MainTenance & cleaning<br />

The design of the Airlift MBR Megablock<br />

contains several unique characteristics<br />

that lower the energy consumption and<br />

thereby lower the total costs of operation.<br />

The Airlift MBR Megablock offers flexible<br />

operation as it can handle fluctuating<br />

fluxes, which is ideal for WWTPs as<br />

they are constantly struggling with<br />

fluctuating fluxes due to daily cycles and/<br />

or weather conditions as unpredictable<br />

circumstances.<br />

Unlike other MBR systems, the Airlift<br />

MBR Megablock is able to switch off<br />

units that are not needed. This lowers the<br />

energy consumption by 25 to 50 percent<br />

when compared to submerged systems<br />

that need regular aeration to prevent the<br />

sludge from settling to the bottom of the<br />

tank if the aeration is switched off. The<br />

SED (specific energy demand in kWh/m³)<br />

of the Airlift MBR Megablock thus offers<br />

significant cost savings during low flows,<br />

which is a major step forward in the water<br />

reuse market.<br />

Within the Airlift MBR Megablock concept,<br />

the <strong>Compact</strong> <strong>32V</strong> membrane modules are<br />

not placed in a traditional skid, but into an<br />

innovative frame construction with a small<br />

physical footprint. The smart and robust<br />

plug-and-play system can be constructed<br />

quickly and easily onsite.<br />

Modular pre-fabricated segments provide<br />

simple and reliable mounting and easy<br />

connection on the plant. The simplified<br />

connections result in a faster total<br />

construction time and significantly reduce<br />

the time required for unit built-up and<br />

membrane loading.<br />

Each Megablock consists of 36<br />

ultrafiltration (UF) membrane modules with<br />

a nominal capacity of 75 m3 /h. The simple<br />

expandable style design makes it possible<br />

to easily extend the system to a maximum<br />

of six sections for a total of 216 membrane<br />

modules when extra capacity is required.<br />

A full Megablock with six segments is 18 m<br />

(59 feet) long and delivers up to 10 MLD<br />

(2.64 MGD) crystal-clear, bacteria-free<br />

water.<br />

The <strong>Compact</strong> <strong>32V</strong> modules are placed<br />

outside the bioreactor and all modules<br />

can be reached individually. Due to the<br />

externally mounted membrane system,<br />

the wastewater is on the inside rather than<br />

the outside of the tubular membranes<br />

providing a cleaner working environment<br />

for treatment plant staff. The operator is not<br />

in direct physical contact with the sludge,<br />

can work within controlled air conditions<br />

and does not have to work inside the sludge<br />

tanks.<br />

Moreover, the cleaning of the membranes<br />

is entirely automatic without operator<br />

intervention and even hair and lint are<br />

removed automatically by the DrainStep<br />

system. The Airlift MBR Megablock also<br />

offers a unique integrity detecting solution.<br />

In case of an incident, the integrity of the<br />

modules can be checked individually without<br />

dissembling the whole unit.

sPeciFicaTions<br />

Membrane area [m²/ft²] 32 [344]<br />

Membrane Diameter [mm/mil] 0.3 [118]<br />

Pore size 30 nm<br />

Bacteria retention 99.9999%<br />

Virus retention 99.99%<br />

Silt Density Index < 3<br />

Turbidity < 0.1 nTu Feed Permeate<br />

scalabiliTy aT iTs besT<br />

With the Airlift MBR Megablock , Pentair<br />

X-<strong>Flow</strong> revolutionizes the construction<br />

and upgrading of municipal wastewater<br />

treatment plants.<br />

It is designed as a future-proof system<br />

as it enables water companies to invest<br />

only in what they need now and expand as<br />

circumstances demand. Modularly designed<br />

block units can easily be added at any time,<br />

which reduce up-front investments.<br />

X-<strong>Flow</strong> MoDule oVerView<br />

POTABLE<br />

WATER<br />

PROCESS<br />

WATER<br />

DESALINATION<br />

PRE-TREATMENT<br />

MUNICIPAL<br />

WASTEWATER<br />

INDUSTRIAL<br />

WASTEWATER<br />

XIGA 55 o o o o<br />

AqUAFLEX 55 o o o o<br />

SEAGUARD 55 o<br />

SEAFLEX 55 o<br />

COMPACT <strong>32V</strong> o<br />

COMPACT 33V<br />

(Airlift MBR)<br />

o o<br />

COMPACT 27 o<br />

COMPACT 33<br />

(Crossflow MBR)<br />

WATER<br />

MIRACLE<br />

o<br />

Number of segments 1 2 3 4 5 6<br />

Number of modules 36 72 108 144 180 216<br />

Typical flow (m 3 /h) 58 112 167 225 283 342<br />

Footprint (m x m) 3 x 3.2 6 x 3.2 9 x 3.2 12 x 3.2 15 x 3.2 18 x 3.2<br />

Footprint/capacity (m 3 /h/m 2 ) 6.0 5.8 5.8 5.9 5.9 5.9<br />

Nominal capacity (MLD) 1.4 2.7 4.0 5.4 6.8 8.2<br />

Maximum capacity (MLD) 1.7 3.5 5.1 7.0 8.7 10.4<br />

Power consumption (kWh/m 3 ) 0.3 0.3 0.3 0.3 0.3 0.3<br />

o<br />

WINE<br />

FILTRATION<br />

R-100 o<br />

HFS 60 SILICA o<br />

SILICA<br />

REMOVAL

Pioneers in<br />

membrane filtration<br />

abouT PenTair X-<strong>Flow</strong><br />

Pentair X-<strong>Flow</strong> has broad know-how and<br />

a proud history in the development and<br />

application of innovative membrane filtration<br />

technologies. The company develops<br />

and supplies membrane technology to<br />

global municipal and industrial markets.<br />

The product portfolio contains numerous<br />

standard membranes, modules and units<br />

for filtration and purification processes.<br />

Full circle MeMbrane Technology ParTner<br />

The success of any project, no matter how<br />

big or small, starts with the selection of the<br />

right membrane product, continues during<br />

the design and commissioning phase and is<br />

finally guaranteed by the right maintenance<br />

and timely service.<br />

Throughout the years, Pentair X-<strong>Flow</strong><br />

has especially gained expertise and<br />

experience in water purification, ranging<br />

from producing potable water to treating<br />

wastewater and the pre-treatment of<br />

seawater, but also in the food, beverage<br />

and pharmaceutical industries.<br />

With research, production, engineering,<br />

automation, project management and<br />

service in-house, Pentair X-<strong>Flow</strong> focuses<br />

on the development of durable and reliable<br />

products that can be tailored to the specific<br />

needs of our customers.<br />

Worldwide, Pentair X-<strong>Flow</strong> has an extensive<br />

network of professional sales offices, service<br />

centers, agents and distributors that work<br />

together to make Pentair X-<strong>Flow</strong> the partner<br />

of choice for world-class water purification<br />

solutions.<br />

As all of these aspects are equally<br />

important to us, Pentair X-<strong>Flow</strong> is able to<br />

support its customers from A-Z and achieve<br />

unique results together. The benefits of<br />

this full circle partnering approach are<br />

demonstrated by the many worldwide<br />

projects where Pentair X-<strong>Flow</strong>’s innovative<br />

membrane products are applied.

X-<strong>Flow</strong><br />

po. box 739, 7500 as enschede, netherlands WWW.x-floW.coM<br />

all pentair trademarks and logos are owned by pentair, Inc. all other brand or product names are trademarks or registered marks of their respective owners.<br />

because we are continuously improving our products and services, pentair reserves the right to change specifications without prior notice.<br />

pentair is an equal opportunity employer.<br />

compact-32 e-7/12 © 2012 pentair, Inc. all rights reserved.