JOHN ZINK CARBON ADSORPTION VAPOR RECOVERY SYSTEM

JOHN ZINK CARBON ADSORPTION VAPOR RECOVERY SYSTEM

JOHN ZINK CARBON ADSORPTION VAPOR RECOVERY SYSTEM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CLEAN COMBUSTION. CLEAR SOLUTIONS. <br />

John Zink Carbon adsorption<br />

Vapor reCoVery system

JoHn Zink CompAny<br />

A GlobAl leAder in environmentAl systems<br />

John Zink Company, LLC is a global leader in developing next-generation<br />

products, technologies and solutions that preserve and improve air and water<br />

quality. With our worldwide manufacturing and service capabilities, John<br />

Zink provides petroleum and chemical terminals around the globe with a safe,<br />

effective method to reduce emissions.<br />

From state-of-the-art research and development through manufacturing<br />

and commissioning services, John Zink’s engineers develop customized<br />

solutions to help optimize your entire system to meet even the toughest<br />

environmental regulations.<br />

QuAlity mAnAGement<br />

• John Zink operations meet the requirements of the internationally<br />

recognized IsO 9001:2000 Quality Management system.<br />

sAfety And HeAltH mAnAGement<br />

• The company’s OHsAs 18001 certification underscores our<br />

commitment to providing a culture of safety that focuses<br />

on identifying and eliminating workplace hazards while<br />

maintaining health and safety compliance.<br />

• John Zink is a recipient of the Voluntary Protection Program<br />

(VPP) star certification, OsHA’s most prestigious designation,<br />

for outstanding safety and health performance.<br />

environmentAl mAnAGement<br />

• John Zink and its operations meet the requirements of<br />

the internationally recognized IsO 14001 Environmental<br />

Management system.<br />

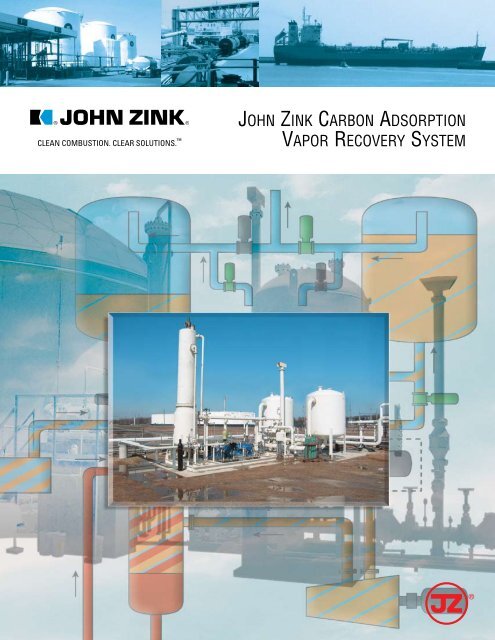

Pictured above, a John Zink marine vapor recovery unit located in Europe. John Zink’s VRUs are designed to meet worldwide standards such as<br />

ASME, ANSI, DIN, ATEX, EN, NEC, IEC, and CENELEC.

tHe world’s most AdvAnCed vApor reCovery teCHnoloGy<br />

from JoHn Zink CompAny<br />

John Zink’s Carbon Adsorption Vapor Recovery Units (VRUs)<br />

safely prevent harmful volatile organic compounds (VOCs) from<br />

being released into the atmosphere during operations that involve<br />

the transfer of evaporative hydrocarbons.<br />

Because John Zink’s VRUs are highly adaptable for a variety of<br />

applications, our engineers can customize an emission control solution<br />

that optimizes your specific system. Our VRU systems are available<br />

with Adsorption-Absorption (ADAB) and Adsorption-Condensation<br />

(ADCON) configurations, as well as varying vacuum technologies<br />

to best suit specific facility needs.<br />

potentiAl AppliCAtions for use of tHis system<br />

Are As follows:<br />

• storage tank vents • Truck loading racks<br />

• Railcar loading facilities • Marine terminals<br />

• Process vents<br />

The u.s. Environmental Protection Agency has recognized John Zink’s<br />

VRu technology as being both the Best demonstrated Technology (BdT)<br />

and Maximum Achievable control Technology (MAcT).<br />

CHemiCAls suitAble for vApor reCovery<br />

AppliCAtions (pArtiAl list):<br />

• Benzene • Butane<br />

• carbon Tetrachloride • chlorobenzene<br />

• chloroethane • chloroform<br />

• crude Oil • cyclohexane<br />

• dichloroethane • diesel Fuels<br />

• distillate Fuels • Ethanol<br />

• Ethylbenzene • Ethyl Tert-Butyl Ether<br />

• Gasoline • Hexane<br />

• Hexene • Isobutane<br />

• Jet Fuels • Methanol<br />

• Methylene chloride • Methyl Tert-Butyl Ether<br />

• naphtha • Pentane<br />

• Pentene • Perchloroethylene<br />

• Propane • Toluene<br />

• Trichloroethane • Trichloroethylene<br />

• Xylene<br />

www.johnzink.com

superior performAnCe<br />

John Zink’s VRUs are designed to meet the most stringent emissions<br />

requirements worldwide. In typical installations such as truck, rail, tank<br />

and marine loading, our VRUs achieve emission control efficiencies of 99%<br />

or better. Most systems are designed to meet 1 – 10 milligrams of VOC<br />

Recovered Product (in liters per 1000 liters loaded)<br />

Estimated Power consumption (kW)<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Recovered Product for Various Loading Operations*<br />

Truck/Rail Vapor<br />

Balanced Loading<br />

Truck/Rail Non-Vapor<br />

Balanced Loading<br />

Barge<br />

Loading<br />

Loading Operation Type<br />

Power consumption vs. daily Loading<br />

for a Typical Gasoline Truck Loading Application*<br />

0<br />

0 4,000,000 8,000,000 12,000,000 16,000,000<br />

daily Product Loaded (Liters)<br />

Ship<br />

Loading<br />

Gasoline Ethanol Benzene Stabilized Light North Sea Crude<br />

* Typical power consumption for Truck/Rail Vapor Balanced Loading may be found in the plot below.<br />

* Values are typical for systems designed for 10 g/nm3 Liquid Ring Vacuum Pump - ADAB Dry Vacuum Pump - ADAB<br />

(10 mg/l). John Zink will optimize each system<br />

based on the individual application. Power consumption may vary.<br />

released per liter of product loaded, or 1 – 10 grams per cubic meter of vapor<br />

vented. John Zink has designed VRUs that meet stricter emissions standards<br />

including the TA Luft standard of 150 milligrams of VOC released per normal<br />

cubic meter of vapor vented (approximately equal to 0.15 mg/l).

JoHn Zink’s vApor reCovery differenCe<br />

John Zink has a proven track record of success with vapor recovery<br />

technology; there are more than 2,000 John Zink ® brand vapor control<br />

systems in service in more than 40 countries.<br />

Our Research, Development and<br />

Test Center, located in Tulsa, Okla.,<br />

is the launch pad for low-emission<br />

systems that address our customers’<br />

needs while preserving and protecting<br />

the environment.<br />

Our service organization is the largest in the industry. With our 24-hour<br />

service hotline, you can depend on the kind of service that keeps your operations<br />

running strong – around the clock, around the world.<br />

Put our expertise to work on your vapor recovery systems and get to<br />

know John Zink’s vapor recovery difference.<br />

As CompAred to<br />

vApor Combustion teCHnoloGies:<br />

• can be installed in a hazardous area<br />

• no flame to serve as an ignition source<br />

• Positive rate of return on investment due to value of<br />

recovered product<br />

• Marine loading requires no vapor conditioning<br />

• no trade-off pollutants<br />

• no supplemental fuel requirements<br />

As CompAred to<br />

otHer vApor reCovery teCHnoloGies:<br />

• Worldwide acceptance as standard for<br />

evaporative hydrocarbon vapor control<br />

• near ambient pressure and<br />

temperature operation, no vapor<br />

holder, no refrigeration<br />

• Proven reliability<br />

• Easy to operate and maintain<br />

• Highest emission control efficiency<br />

• Low capital and operating costs<br />

• Electricity is only required utility<br />

www.johnzink.com

CArbon Adsorption-Absorption proCess witH dry vACuum pump<br />

John Zink’s ADAB vapor recovery design is suitable for a wide variety<br />

of applications. It is most commonly used to control hydrocarbon vapor<br />

emissions at terminals handling petroleum fuel products. John Zink’s VRUs<br />

combine physical adsorption with absorption to recover hydrocarbon vapors<br />

and return the recovered product to storage.<br />

tHe use of dry vACuum pump (dvp) teCHnoloGy<br />

offers siGnifiCAnt AdvAntAGes over otHer vACuum<br />

teCHnoloGies:<br />

• Reduced power consumption<br />

• Ethylene glycol and associated equipment are eliminated<br />

from system<br />

• decreased maintenance costs<br />

• no product contamination<br />

• Greater flexibility with products that can be loaded<br />

into the VRu<br />

1<br />

2<br />

The VRU is equipped with<br />

two identical adsorber<br />

vessels filled with activated<br />

carbon. One adsorber is on<br />

stream receiving vapors in<br />

the adsorption mode while<br />

the other adsorber is off<br />

stream in the regeneration<br />

mode. Switching valves are<br />

provided to automatically<br />

alternate the adsorbers<br />

between adsorption and<br />

regeneration, which<br />

assures uninterrupted<br />

vapor processing capability.<br />

The VRU will automatically<br />

start when a loading<br />

operation is ongoing and<br />

shutdown in a standby<br />

mode when the operation is<br />

complete.<br />

During adsorption, the<br />

inlet hydrocarbon vapor-air<br />

mixture to be processed<br />

flows up through the on<br />

stream adsorber vessel.<br />

In the adsorber, the<br />

activated carbon adsorbs<br />

the hydrocarbon vapor<br />

and allows clean air to<br />

vent from the bed with<br />

only minimal hydrocarbon<br />

content.<br />

PRODUCT<br />

LOADING RACK<br />

PRODUCT<br />

LOADING<br />

PUMP<br />

CONDENSATE<br />

COLLECTION<br />

STORAGE TANK<br />

LEAN ABSORB

6<br />

ADSORBER<br />

(REGENERATION MODE)<br />

1<br />

3<br />

ENT SUPPLY PUMP<br />

ABSORBER<br />

5<br />

6<br />

RICH<br />

ABSORBENT<br />

RETURN PUMP<br />

AIR VENT TO<br />

ATMOSPHERE<br />

PURGE AIR<br />

VACUUM<br />

BOOSTER<br />

BLOWER<br />

ABSORBENT &<br />

RECOVERED PRODUCT<br />

HYDRO<strong>CARBON</strong> <strong>VAPOR</strong><br />

AIR<br />

VALVE OPEN<br />

VALVE CLOSED<br />

4<br />

ADSORBER<br />

(<strong>ADSORPTION</strong> MODE)<br />

1<br />

2<br />

AS<br />

REQUIRED<br />

DRY VACUUM<br />

PUMP<br />

3<br />

4<br />

5<br />

6<br />

During regeneration, previously adsorbed hydrocarbon vapor is<br />

removed from the carbon and the carbon’s ability to adsorb<br />

vapor is restored. Carbon bed regeneration is accomplished with<br />

a combination of high levels of vacuum and purge air stripping.<br />

At the end of the regeneration cycle, the adsorber vessel is<br />

re-pressurized and then is placed back on stream.<br />

A dry vacuum pump (DVP) is the source of vacuum for carbon<br />

regeneration. The DVP extracts concentrated hydrocarbon vapor<br />

from the carbon bed, and discharges directly into the recovery<br />

device, a vertically packed absorption<br />

column. To limit the vapor temperature<br />

inside the DVP, absorbent is circulated<br />

through the outside jacket and is injected<br />

directly into the vacuum pump.<br />

In the absorber vessel, the hydrocarbon vapor from the DVP<br />

flows up through packing, while a hydrocarbon liquid flows<br />

down through packing. Inside the absorber, the vapor is<br />

liquefied, and the recovered hydrocarbon is returned back to<br />

the absorbent storage tank. A small stream of air and residual<br />

vapor exits the top of the absorber and is recycled to the<br />

on stream carbon bed for re-adsorption.<br />

A lean absorbent supply pump and a rich absorbent return<br />

pump are provided to circulate the required absorbent.<br />

www.johnzink.com

CArbon Adsorption – Absorption proCess witH liQuid rinG vACuum pump<br />

Liquid ring VRU systems operate along the same principles as the dry<br />

system previously described. However, this system includes a liquid ring<br />

vacuum pump (LRVP) to regenerate the carbon beds. LRVPs are robust<br />

and relatively inexpensive, with a proven history of successful operation.<br />

1<br />

2<br />

The LRVP strips the<br />

rich hydrocarbon<br />

vapor stream from<br />

the adsorber and<br />

discharges it into a<br />

three-phase separator.<br />

Each LRVP requires<br />

a specially blended<br />

ethylene glycol-based<br />

sealing fluid to operate.<br />

The separator is<br />

provided to allow<br />

efficient separation<br />

between the vacuum<br />

pump’s seal fluid,<br />

hydrocarbon<br />

condensate, and<br />

the non-condensed<br />

hydrocarbon vapor.<br />

The non-condensed<br />

hydrocarbon vapor is<br />

discharged from the<br />

separator vessel and<br />

recovered by means<br />

of a packed-bed<br />

absorber column in<br />

the same manner as<br />

previously described.<br />

ABSORBENT &<br />

RECOVERED PRODUCT<br />

HYDRO<strong>CARBON</strong> <strong>VAPOR</strong><br />

AIR<br />

PRODUCT<br />

LOADING RACK<br />

PRODUCT<br />

LOADING<br />

PUMP<br />

SEAL FLUID<br />

VALVE OPEN<br />

VALVE CLOSED<br />

CONDENSATE<br />

COLLECTION<br />

STORAGE TANK<br />

ADSORBER<br />

(REGENERATION MODE)<br />

LEAN ABSORBENT SUPPLY PUMP<br />

ABSORBER<br />

SEAL<br />

FLUID<br />

PUMP<br />

They are available in a variety of configurations so the system can be<br />

tailored to fit your specific needs. John Zink has made available its<br />

own specially formulated vacuum pump seal fluid – Z-SEAL – for use<br />

in this serivce.<br />

3<br />

RICH<br />

ABSORBENT<br />

RETURN PUMP<br />

AIR VENT TO<br />

ATMOSPHERE<br />

PURGE AIR<br />

VACUUM<br />

BOOSTER<br />

BLOWER<br />

SEPARATOR<br />

2<br />

The seal fluid is<br />

pumped from the<br />

separator through a<br />

seal fluid cooler to<br />

remove the heat of<br />

compression.<br />

SEAL<br />

FLUID<br />

COOLER<br />

4<br />

1<br />

3<br />

ADSORBER<br />

(<strong>ADSORPTION</strong> MODE)<br />

AS<br />

REQUIRED<br />

LIQUID RING<br />

VACUUM PUMP<br />

4<br />

The ADAB VRU based<br />

upon either dry<br />

vacuum pump or liquid<br />

ring vacuum pump<br />

technology may be<br />

provided with a high<br />

efficiency (HE-ADAB)<br />

vacuum system. The<br />

enhanced vacuum<br />

system consists of a<br />

rotary-lobed vacuum<br />

booster blower<br />

operating in series with<br />

the vacuum pump.<br />

The addition of the<br />

booster blower allows<br />

the carbon beds to<br />

be regenerated under<br />

a higher vacuum<br />

(lower absolute<br />

pressure) and provides<br />

significantly higher<br />

pumping capacity at<br />

high vacuums than is<br />

possible through the<br />

use of only the vacuum<br />

pump. An enhanced<br />

vacuum system more<br />

thoroughly regenerates<br />

the activated carbon<br />

and can, as a result,<br />

provide several potential<br />

benefits including<br />

use of less carbon,<br />

the achievement of<br />

lower emission levels,<br />

reduced system power<br />

requirement, and less<br />

overall capital cost.

modulAr system<br />

John Zink’s VRU design is<br />

configured in modular packages to<br />

help meet customer needs.<br />

• convenient, flexible<br />

equipment installation<br />

• Fits in varied plot spaces<br />

• Ample space for<br />

equipment maintenance<br />

• Greater ease of<br />

retrofitting the system<br />

Continuous emission monitorinG system<br />

As an optional feature, John Zink offers a Continuous Emission<br />

Monitoring System (CEMS) that includes an analyzer to measure<br />

hydrocarbon content in the VRU vent stream.<br />

The CEMS performs emission data averaging and can achieve VRU<br />

energy savings when utilizing the CEM Start mode of operation. The carbon<br />

beds are left on stream until their effective adsorption capacities have been<br />

expended before regeneration occurs. Typical energy savings using this<br />

mode of operation have ranged between 30 to 50%.<br />

Pictured above is a VRU inlet header skid, ready for shipment.<br />

All motor operated switching valves are located near grade for<br />

easier maintenance.<br />

Booster Blower Platform<br />

Vacuum Pump Skid<br />

Regeneration Skid<br />

www.johnzink.com

John Zink introduces VaporWatch, a new vapor control remote<br />

monitoring system.<br />

With VaporWatch, operators can securely access real-time online<br />

operating data directly from their desktops or from a personal computer<br />

anywhere around the world. This remote access capability ultimately results<br />

in more efficient equipment operation, reduced downtime for loading terminal<br />

operations, and lower operating and maintenance costs.<br />

Ability to monitor key system<br />

parameters simultaneously<br />

View real-time data with excellent<br />

ability to observe trends<br />

An enhanced maintenance package is also available that includes a<br />

proactive service plan that generates customized equipment performance<br />

reports and a dedicated monitoring system for customer equipment.<br />

The enhanced version also maintains data on the pressures, temperatures,<br />

emissions, and other vapor control performance. Technicians can reference<br />

these reports to help diagnose and eliminate operational difficulties, predict<br />

equipment failures, and service equipment.<br />

View historical data<br />

and trends; keep<br />

stored data for up to<br />

10 years<br />

Hands-on maintenance tool<br />

to recognize problems before<br />

they occur

exCeptionAl serviCe eQuipment rentAls<br />

John Zink’s worldwide service organization is the largest, most technically<br />

savvy team of its kind. Our service technicians are trained in the latest<br />

technologies to evaluate existing systems for upgrades and retrofits, to<br />

troubleshoot operations, and to help plan your next turnaround.<br />

• scheduled preventative maintenance<br />

• Emergency call-out available 24 hours a day, 7 days a week<br />

• Equipment retrofit packages<br />

• carbon screening, testing, and replacement services<br />

• start-up assistance<br />

• Installation assistance<br />

• Operator training<br />

• Equipment relocation<br />

• Annual vapor control course available at the<br />

JOHn ZInk InsTITuTE sM<br />

Avoid loading rack downtime with John Zink’s Portable Emission Control<br />

System (PECS ® ). The PECS is a self-contained, trailer-mounted vapor combustor<br />

that ensures stable, smokeless combustion and maintains temperature control<br />

over a wide range of vapor combustion. This cost-effective, temporary solution<br />

helps regulate operational issues at transport loading terminals.<br />

The PECS is equipped with a vapor blower for low-pressure applications,<br />

anti-flashback burners, and flame and detonation arrestors. Bundle a PECS<br />

rental with other John Zink services such as installation, start-up, on-site<br />

operator assistance and training, or dismantling to save both time and money.<br />

worldwide serviCe And support<br />

www.johnzink.com

CLEAN COMBUSTION. CLEAR SOLUTIONS. <br />

www.johnzink.com vaporcontrol@johnzink.com<br />

u.s.A.<br />

cAnAdA<br />

John Zink<br />

World Headquarters<br />

John Zink Company, LLC<br />

11920 East Apache<br />

Tulsa, Oklahoma 74116<br />

UNITED STATES OF AMERICA<br />

Tel: +1-918-234-1800<br />

+1-800-421-9242<br />

Fax +1-918-234-2700<br />

© 2009 John Zink Company, LLC 09-4415<br />

EuROPE<br />

MIddLE EAsT<br />

AFRIcA<br />

John Zink Europe<br />

Headquarters<br />

John Zink Int. Luxembourg S.à r.l.<br />

Zone Industrielle 'Riedgen'<br />

L-3401 Dudelange<br />

LUXEMBOURG<br />

Tel: +352-518991<br />

Fax: +352-518611<br />

Other:<br />

UNITED KINGDOM<br />

FRANCE<br />

ITALY<br />

SPAIN<br />

THE NETHERLANDS<br />

GERMANY<br />

INDIA<br />

AsIA-PAcIFIc<br />

John Zink Asia-Pacific<br />

Headquarters<br />

John Zink Asia-Pacific,<br />

a division of Koch Asia-Pacific, Inc.<br />

4th Floor, Takanawa Muse Building<br />

3-14-13, Higashi-Gotanda,<br />

Shinagawa-ku, Tokyo 141-0022<br />

JAPAN<br />

Tel: +81-3-4332-5550<br />

Fax: +81-3-5423-1627<br />

Other:<br />

SINGAPORE<br />

AUSTRALIA<br />

PEOPLE'S REPUBLIC OF CHINA<br />

LATIn<br />

AMERIcA<br />

John Zink Latin America<br />

Headquarters<br />

Koch Tecnologia Química LTDA.<br />

Rua Tanabi nr. 276<br />

Água Branca<br />

CEP 05002-010 - São Paulo-SP<br />

BRAZIL<br />

Tel: +55-11-3865-3571<br />

Fax: +55-11-3871-0405<br />

Other:<br />

ARGENTINA<br />

MEXICO