Presentations Fr. 22.06.2012 - Hosokawa Alpine Aktiengesellschaft

Presentations Fr. 22.06.2012 - Hosokawa Alpine Aktiengesellschaft

Presentations Fr. 22.06.2012 - Hosokawa Alpine Aktiengesellschaft

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

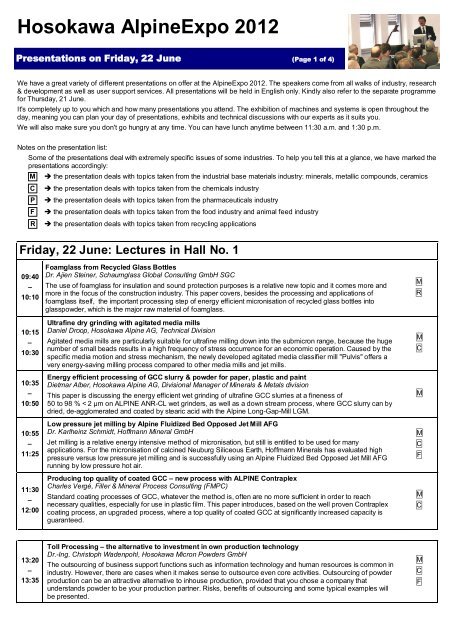

<strong>Hosokawa</strong> <strong>Alpine</strong>Expo 2012<br />

<strong>Presentations</strong> on <strong>Fr</strong>iday, 22 June (Page 1 of 4)<br />

We have a great variety of different presentations on offer at the <strong>Alpine</strong>Expo 2012. The speakers come from all walks of industry, research<br />

& development as well as user support services. All presentations will be held in English only. Kindly also refer to the separate programme<br />

for Thursday, 21 June.<br />

It's completely up to you which and how many presentations you attend. The exhibition of machines and systems is open throughout the<br />

day, meaning you can plan your day of presentations, exhibits and technical discussions with our experts as it suits you.<br />

We will also make sure you don't go hungry at any time. You can have lunch anytime between 11:30 a.m. and 1:30 p.m.<br />

Notes on the presentation list:<br />

Some of the presentations deal with extremely specific issues of some industries. To help you tell this at a glance, we have marked the<br />

presentations accordingly:<br />

M<br />

C<br />

� the presentation deals with topics taken from the industrial base materials industry: minerals, metallic compounds, ceramics<br />

� the presentation deals with topics taken from the chemicals industry<br />

� the presentation deals with topics taken from the pharmaceuticals industry<br />

� the presentation deals with topics taken from the food industry and animal feed industry<br />

� the presentation deals with topics taken from recycling applications<br />

<strong>Fr</strong>iday, 22 June: Lectures in Hall No. 1<br />

09:40<br />

–<br />

10:10<br />

10:15<br />

–<br />

10:30<br />

10:35<br />

–<br />

10:50<br />

10:55<br />

–<br />

11:25<br />

11:30<br />

–<br />

P<br />

F<br />

R<br />

12:00<br />

13:20<br />

–<br />

13:35<br />

Foamglass from Recycled Glass Bottles<br />

Dr. Ajien Steiner, Schaumglass Global Consulting GmbH SGC<br />

The use of foamglass for insulation and sound protection purposes is a relative new topic and it comes more and<br />

more in the focus of the construction industry. This paper covers, besides the processing and applications of<br />

foamglass itself, the important processing step of energy efficient micronisation of recycled glass bottles into<br />

glasspowder, which is the major raw material of foamglass.<br />

Ultrafine dry grinding with agitated media mills<br />

Daniel Droop, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Technical Division<br />

Agitated media mills are particularly suitable for ultrafine milling down into the submicron range, because the huge<br />

number of small beads results in a high frequency of stress occurrence for an economic operation. Caused by the<br />

specific media motion and stress mechanism, the newly developed agitated media classifier mill "Pulvis" offers a<br />

very energy-saving milling process compared to other media mills and jet mills.<br />

Energy efficient processing of GCC slurry & powder for paper, plastic and paint<br />

Dietmar Alber, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Divisional Manager of Minerals & Metals division<br />

This paper is discussing the energy efficient wet grinding of ultrafine GCC slurries at a fineness of<br />

50 to 98 % < 2 µm on ALPINE ANR-CL wet grinders, as well as a down stream process, where GCC slurry can by<br />

dried, de-agglomerated and coated by stearic acid with the <strong>Alpine</strong> Long-Gap-Mill LGM.<br />

Low pressure jet milling by <strong>Alpine</strong> Fluidized Bed Opposed Jet Mill AFG<br />

Dr. Karlheinz Schmidt, Hoffmann Mineral GmbH<br />

Jet milling is a relative energy intensive method of micronisation, but still is entitled to be used for many<br />

applications. For the micronisation of calcined Neuburg Siliceous Earth, Hoffmann Minerals has evaluated high<br />

pressure versus low pressure jet milling and is successfully using an <strong>Alpine</strong> Fluidized Bed Opposed Jet Mill AFG<br />

running by low pressure hot air.<br />

Producing top quality of coated GCC – new process with ALPINE Contraplex<br />

Charles Vergé, Filler & Mineral Process Consulting (FMPC)<br />

Standard coating processes of GCC, whatever the method is, often are no more sufficient in order to reach<br />

necessary qualities, especially for use in plastic film. This paper introduces, based on the well proven Contraplex<br />

coating process, an upgraded process, where a top quality of coated GCC at significantly increased capacity is<br />

guaranteed.<br />

Toll Processing – the alternative to investment in own production technology<br />

Dr.-Ing. Christoph Wadenpohl, <strong>Hosokawa</strong> Micron Powders GmbH<br />

The outsourcing of business support functions such as information technology and human resources is common in<br />

industry. However, there are cases when it makes sense to outsource even core activities. Outsourcing of powder<br />

production can be an attractive alternative to inhouse production, provided that you chose a company that<br />

understands powder to be your production partner. Risks, benefits of outsourcing and some typical examples will<br />

be presented.<br />

M<br />

R<br />

M<br />

C<br />

M<br />

M<br />

C<br />

F<br />

M<br />

C<br />

M<br />

C<br />

F

<strong>Hosokawa</strong> <strong>Alpine</strong>Expo 2012<br />

<strong>Presentations</strong> on <strong>Fr</strong>iday, 22 June (Page 2 of 4)<br />

<strong>Fr</strong>iday, 22 June: Lectures in Hall No. 1<br />

13:40<br />

–<br />

13:55<br />

14:00<br />

–<br />

14:30<br />

14:40<br />

–<br />

15:10<br />

15:15<br />

–<br />

15:35<br />

15:40<br />

–<br />

15:55<br />

16:00<br />

–<br />

16:30<br />

Continous improvement of energy efficiency<br />

Tobias Ruta, Endress+Hauser Messtechnik GmbH & Co. KG<br />

Accurate and reliable metering ensures the analysis of energy flows and assist in the Detectability of savings.<br />

Independent energy consultancy and realization of projects ensures the achievement of targets.<br />

Energy efficient, resource preservating processes and renewable materials – a nucleus for innovations in<br />

process engineering<br />

Prof. Dr.-Ing. Wolfgang Rommel, Head of Master Course Environmental and Process Technology of Augsburg<br />

University of Applied Sciences, Managing Director of bifa Environmental Institute, Augsburg<br />

The world-wide demographic development combined with increasing standards of life caused an exponentially<br />

increase of natural resource consumption. The ecological limits of quantitative growth have been reached! In<br />

general, that means that the resource intensity and efficiency have to be dramatically increased. This is due for<br />

almost all production processes. Mechanical and comminution processes play a very important role in feed stock<br />

and raw material exploitation, material production and processing as well as in recycling processes. On one hand,<br />

these processes are rather energy consuming and on the other hand they are part of the material supply chain and<br />

thus determine the material efficiency significantly. Hence, major task in process engineering is to increase the<br />

degree of efficiency of comminution and material handling operations. Certainly, this is a big challenge, but it also<br />

offers a lot of options and thus will be the nucleus for innovations in process engineering.<br />

This lecture will give some selected samples:<br />

� preparation and processing of biomass for bio-degradable plastics, solid and liquid bio fuel<br />

� separation of material composites<br />

� crushing of carbon-fiber-composite parts as a pre-step for pyrolysis recycling<br />

Fine particle processing and Energy saving – a contradiction?<br />

Dr. Jürgen Stein, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Technical Division<br />

Actual discussions about energy saving in all areas of life and industry marks fine particle processes due to the low<br />

efficiency as archaic. To increase the efficiency a new approach is necessary. In principle three areas can be<br />

defined to optimize a fine particle processing system: machine technology, process control and product properties.<br />

A significant energy reduction can be reached by intelligent linking of all these aspects and parameters.<br />

Fine particle processing and Energy saving by intelligent process control<br />

Gerhard Kiederle, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Technical Division<br />

A key to increase the energy efficiency of a fine particle process is an intelligent process control. For intelligent<br />

process controls a lot of theoretical approaches are on the market. Most tend to be complicated. <strong>Hosokawa</strong> <strong>Alpine</strong><br />

developed a practical solution, which allows an intelligent control of a fine particle process with a manageable<br />

effort.<br />

Fine particle processing and Energy saving by inline particle size measurement<br />

Hans Kaiser, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Technical Division<br />

Intelligent measurement systems help to increase the understanding of powder production processes. One of<br />

these systems is an inline particle measurement. How this knowledge can be used to optimize a powder process is<br />

shown on different case studies.<br />

Efficiency in flue gas cleaning with NaHCO3 by activation by grinding<br />

Dr. Bernd Morun, DrySoTec GmbH<br />

Long term experience with: -dependency of activity from the grade of grinding; - particle uniformity after grinding;<br />

-maintenance and problems gained in practice.<br />

M<br />

C<br />

F<br />

R<br />

M<br />

C<br />

F<br />

R<br />

M<br />

C<br />

P<br />

F<br />

M<br />

C<br />

P<br />

F<br />

M<br />

C<br />

P<br />

F<br />

C

<strong>Hosokawa</strong> <strong>Alpine</strong>Expo 2012<br />

<strong>Presentations</strong> on <strong>Fr</strong>iday, 22 June (Page 3 of 4)<br />

<strong>Fr</strong>iday, 22 June: Lectures in Hall No. 2<br />

09:20<br />

–<br />

09:35<br />

09:40<br />

–<br />

10:10<br />

10:15<br />

–<br />

10:30<br />

10:35<br />

–<br />

10:50<br />

10:55<br />

–<br />

11:25<br />

11:30<br />

–<br />

12:00<br />

12:05<br />

–<br />

12:20<br />

Rotary blowers – the way from single units to blower stations<br />

Dietmar Liebig, KAESER Kompressoren AG<br />

KAESER rotary blowers deliver the means for conveying powder and granulate material (also for nitrogen<br />

environments), either by suction or blowing (description and function). New rotary blowers complete ready for<br />

operation with integrated electric and control. Blower stations as centralised, highly efficient sources of high quality<br />

blowing, suction or cooling air. KAESER management systems are able to control and coordinate operation of<br />

several units within a blower station.<br />

Cryogen Fine Grinding and Cryogen Separation of Composite Materials<br />

Dipl.-Ing. (FH) Oliver Dietrich, Messer Group GmbH<br />

Cold grinding process with a counter rotating pin mill. Detailed descriptions of<br />

- fine grinding process with rubber and thermoplastic materials,<br />

- the separation of composite materials as garden hoses (fibre reinforced soft PVC) and<br />

- examples of food and spice grinding processes.<br />

The use of Zetapotential measurement for the charactisation of dispersion stability<br />

Dr. Mark Wingfield, Malvern Instruments GmbH<br />

Electrostatic stabilisation of particles is commonly used in the formulation of dispersions and wet milling techniques.<br />

The measurement of Zetapotential to characterise electrostatic interactions of particles will be described and the<br />

characterisation of dispersion stability will be discussed.<br />

Production of Reproductive Energy by means of Compaction<br />

Robert Rosen, <strong>Hosokawa</strong> Bepex GmbH<br />

Wood chips are used to generate energy at smaller power stations. Due to high demand, lack of sources and price<br />

increase is already noticed. By means of a new developed process harvested maize from corn is crushed, dried and<br />

compacted. So called slaps have a higher density and a 40 % higher calorific value compared with wood chips.<br />

Technologies for Particle Shape Design<br />

Dr. Jürgen Stein, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Technical Division<br />

Beside fineness and particle size distribution, the particle shape becomes increasingly important for many<br />

applications. If milling or synthesis do not create a functional particle shape or morphology, it is necessary to apply<br />

further processing steps. Particle shape can be modified by either mechanical or thermal treatment or a combination<br />

of it. The presentation will show different technologies for the production of particles with tailored shape and some<br />

examples of application.<br />

Graphite Powder Processing - A Key Element for High Performance Li-Ion Batteries<br />

Dr.-Ing. Oswin Öttinger, U. Bosch, B. Ketterer, SGL CARBON GmbH<br />

Today, lithium-ion technology finds its largest growth potential in the upcoming electromobility market. Within the<br />

battery of an electric car, several kilograms of graphite powder are used as an active intercalation material to store<br />

lithium. The performance of the battery (e.g., efficiency, cycling stability, lifetime, and safety) depends to a large<br />

extent on the quality and the characteristics of the graphite material. Therefore, graphite powder processing is<br />

regarded as one key element in the production chain for high-grade Li-ion cells.<br />

Process Technology for High Performance Battery materials<br />

Dr. Yoshiyuki Inoue, <strong>Hosokawa</strong> Micron Corp. (Japan)<br />

Powder processing is important technology for manufacturing the high performance battery materials (for anode and<br />

cathode). Two major technologies are introduced in this presentation:<br />

1. Fine milling without metal contamination with high throughput<br />

2. Economic surface enhancement for improvement the electric conductivity, cyclic performance, heat stability,<br />

capacity, etc,<br />

M<br />

C<br />

F<br />

R<br />

C<br />

P<br />

F<br />

M<br />

C<br />

P<br />

F<br />

F<br />

R<br />

M<br />

C<br />

P<br />

M<br />

C<br />

M<br />

C

<strong>Hosokawa</strong> <strong>Alpine</strong>Expo 2012<br />

<strong>Presentations</strong> on <strong>Fr</strong>iday, 22 June (Page 4 of 4)<br />

<strong>Fr</strong>iday, 22 June: Lectures in Hall No. 2<br />

13:30<br />

–<br />

14:00<br />

14:05<br />

–<br />

14:20<br />

14:25<br />

–<br />

14:40<br />

14:45<br />

–<br />

15:00<br />

15:05<br />

–<br />

15:35<br />

15:40<br />

–<br />

15:55<br />

16:00<br />

–<br />

16:15<br />

16:20<br />

–<br />

16:35<br />

Protective Systems for Explosion Protection - When do we really need them<br />

Dr. Bernd Broeckmann, INBUREX Consulting GmbH<br />

Protective Systems for explosion protection are sometimes seen as investment cost and intensive additional means.<br />

The presentation will line out under which conditions these protective systems are either legally required, required<br />

by physics due to specific effects or required by risk management considerations.<br />

The new standard DIN EN 16009 – flameless explosion protection, a benefit for the clients<br />

Dipl.-Ing. Roland Bunse, REMBE® GMBH SAFETY + CONTROL, Head of Explosion Protection Department<br />

EN standard 16009 provides the customer with yet another seal of quality. The EC-Type Examination Certificate<br />

according to EN standards 16009 should be the most important criterion when selecting a product for flameless<br />

explosion venting. This presentation shows the performance of the Flameless Venting device during the DIN EN<br />

16009 certification and outlines the benefits for the customers in cost saving e.g. maintenance costs.<br />

The <strong>Alpine</strong> Long-Gap-Mill LGM: Applications from the Chemical, Food, Mineral & Recycling industry<br />

Christof Barth, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Minerals & Metals division<br />

The ALPINE Long-Gap-Mill LGM is a universal mill, which is used in a very wide field of applications for grinding,<br />

drying, de-agglomeration, simultaneous grinding & drying or coating in all kind of industries. This paper is<br />

presenting selected applications from the chemical, food, mineral & recycling industry by use of the LGM mill.<br />

Energy saving new developed ALPINE ultrafine classifier TurboTwinDouble TTD. Revamping of existing<br />

ball mill classifier loops by TTD.<br />

Dietmar Alber, <strong>Hosokawa</strong> <strong>Alpine</strong> AG, Divisional Manager of Minerals & Metals division<br />

Energy saving is not only a topic in the Western World, but also becomes a topic in countries, where energy<br />

traditionally was considered as relative cheap. ALPINE has developed a new ultrafine classifier, with the target of<br />

saving energy and reaching high finenesses & high capacity on a classifier based on the patented single wheel<br />

solid body rotation principal. This new classifier is ideal for replacing older classifiers consuming high energy and at<br />

same time optimizing the capacity, especially for closed ball mill classifier loops.<br />

Processing and applications of ultrafine mineral based cement additives<br />

Dr. Christian Artelt, Heidelberger Zement<br />

Ultrafine mineral based cement additives are used to achieve special properties in the use of cement. Differently to<br />

the standard cement products these additives are much finer, as the basis of their function is a much higher<br />

surface area. These fine additives are produced by the use of heavy wear protected ultrafine air classifiers as the<br />

ALPINE Turboplex Multiwheel Air Classifiers ATP.<br />

Using premixes of additions simplifies and reduce cost in production<br />

<strong>Fr</strong>ank Maringer, Matcon Ltd., Business Development Manager<br />

With the use of IBCs offline, premix preparation can be made safely and as a centralised activity. This helps<br />

making the entire production site safe, contamination free and efficient.<br />

Instant wet agglomeration: sticking chemicals together<br />

Ing. Marc Jacobs, <strong>Hosokawa</strong> Micron BV, Application Engineer in the Chemicals, Metals & Minerals industry<br />

After introducing instant wet continuous agglomeration using Flexomix technology, several chemical applications<br />

are presented.<br />

Evaporate liquid instead of money<br />

Ing. Gertjan Teekman, <strong>Hosokawa</strong> Micron BV, Application Manager in the Chemicals, Metals & Minerals industry<br />

Staying competitive in producing a dry product means also saving energy. Therefore it really pays off to investigate<br />

which drying process solution is the best for your product. We present continuous drying with a focus on the DMR<br />

High temperature drying.<br />

C<br />

P<br />

F<br />

C<br />

P<br />

F<br />

M<br />

C<br />

F<br />

R<br />

M<br />

F<br />

M<br />

C<br />

P<br />

F<br />

C<br />

F<br />

M<br />

C<br />

F