USA001 - Gabion Mats -Erosion Control -NM - Maccaferri

USA001 - Gabion Mats -Erosion Control -NM - Maccaferri

USA001 - Gabion Mats -Erosion Control -NM - Maccaferri

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EROSION CONTROL CHANNEL LINING<br />

Product: <strong>Gabion</strong> <strong>Mats</strong><br />

Problem<br />

The owner of a mining claim in central New Mexico elected to<br />

close the property because of declining commodity prices.<br />

In order to close the mining operation it was necessary to install<br />

a spillway ‘overflow’ over the existing dam to control the volume<br />

of impounded water.<br />

The existing dam was of a clay core construction. The spillway<br />

had to be designed to limit the significant shear forces and<br />

erosion in the overflow channel. Also any erosion control solution<br />

had to accommodate local differential settlements. The expected<br />

shear forces would exceed that offered by a high performance<br />

permanent erosion control mat, and a more robust solution was<br />

required. The strength and flexibility of double twisted mesh<br />

gabion mats offered an ideal solution.<br />

Solution<br />

With the assistance of <strong>Maccaferri</strong>’s Technical Department, the<br />

project engineer detailed a series of eight connecting gabion<br />

drop structures. These controlled the water level over a 24 foot<br />

change in elevation from the dam crest to the flow level in the<br />

existing drainage channel. By converting kinetic to potential<br />

energy, the erosion shear forces were reduced.<br />

The drop structures were designed in part using <strong>Maccaferri</strong><br />

design software; “Macra 2” for the drop structures, and “Macra<br />

1” for the channel. “Macra 1” is available to designers and<br />

contractors if required<br />

Following discussions with the project team, <strong>Maccaferri</strong><br />

manufactured 99’ long <strong>Gabion</strong> <strong>Mats</strong> with 3’x3’ cells to reduce<br />

the cost and time of the installation through economies of scale.<br />

In addition, 27’ and 51’ long <strong>Gabion</strong> <strong>Mats</strong> were also specially<br />

manufactured to suit the site requirements, further helping the<br />

contractor.<br />

Designer:<br />

Client name:<br />

MACCAFERRI INC.<br />

Product used:<br />

GABION MATS, RENO MATTRESSES, MACTEX MX275<br />

Date of building:<br />

SUMMER 2001<br />

CASE HISTORY<br />

Ref: <strong>USA001</strong> - Rev: 001, Issue Date 12.12.2003<br />

EROSION CONTROL OF MINE SPILLWAY<br />

MARQUEZ, NEW MEXICO, USA<br />

Channel & terrace preparation<br />

Drop structure detail<br />

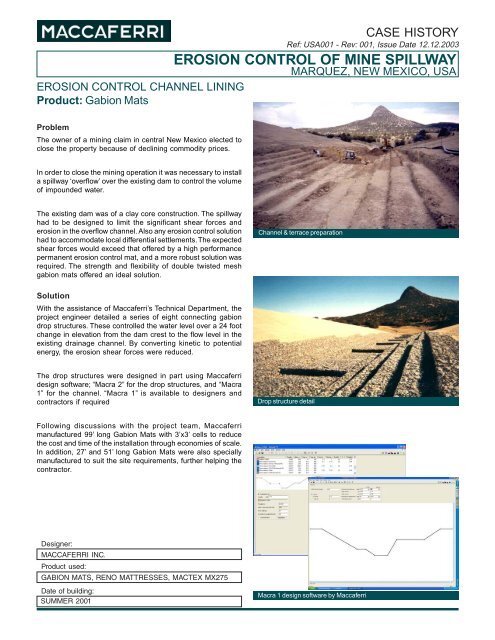

Macra 1 design software by <strong>Maccaferri</strong>

4.5'<br />

Typical long section through a drop structure<br />

Retention pond at low water<br />

Drop structure at low water<br />

Headquarters - East Coast<br />

10303 Governor Lane Blvd, Williamsport, MD, 21795<br />

Tel.: (301) 223 6910 Fax: (301) 223 4356<br />

6' 30' 3' 12'<br />

3'<br />

1.5 ft. thick <strong>Gabion</strong> 1.5 ft. thick <strong>Gabion</strong><br />

1.0 ft. thick <strong>Gabion</strong> Filter Fabric<br />

Mactex MX 275<br />

MACCAFERRI INC.<br />

E-mail: hdqtrs@maccaferri-usa.com<br />

Web site: www.maccaferri.com<br />

1.5'<br />

The <strong>Gabion</strong> <strong>Mats</strong> were constructed upon a non-woven<br />

needlepunched geotextile - <strong>Maccaferri</strong> MacTex MX275. This acts<br />

as a separation and filtration layer between the foundation<br />

material and the gabion erosion protection. The geotextile limits<br />

the “wash-out” of fine material from beneath the <strong>Gabion</strong> Mat<br />

under high flows and storm conditions.<br />

If local erosion does occur beneath the mats, the flexibility of<br />

the double twist mesh allows the gabion to settle and continue<br />

protection without sustaining damage.<br />

The <strong>Maccaferri</strong> double twist hexagonal mesh was PVC coated<br />

due to the water environment. Double twist mesh is very robust,<br />

and can accommodate large differential settlement without<br />

rupturing or ‘unzipping’. The junction strength, or weave, between<br />

adjacent wires in the mesh is as strong as the wire itself.<br />

Stresses in the mesh can therefore be dissipated in two<br />

dimensions throughout the mesh. This ability continues even if<br />

wires are cut or damaged.<br />

This is a vital characteristic particularly in critical infrastructure<br />

applications where there is the potential for differential<br />

settlement.<br />

Working with <strong>Maccaferri</strong><br />

For over 120 years, <strong>Maccaferri</strong> has provided engineering<br />

expertise to clients around the world. We believe that<br />

the combination of our professionalism, design software,<br />

technical and site assistance service and our aim of<br />

providing the best products in the market, sets us apart<br />

from our competition. We hope you agree.<br />

West Coast<br />

3650 Seaport Blvd, West Sacramento, CA 95691<br />

Tel.: (916) 371 5805 Fax: (916) 371 0764<br />

Copyright 2004 <strong>Maccaferri</strong> Inc.