Machining and finishing of aluminium - BWB

Machining and finishing of aluminium - BWB

Machining and finishing of aluminium - BWB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SURFACE TREATMENT ENgINEERINg FOR<br />

ARCHITECTURE & DESIgN<br />

<strong>Machining</strong> <strong>and</strong> <strong>finishing</strong> <strong>of</strong> <strong>aluminium</strong>

02_ ANODISINg bY bwb<br />

THE ADVANTAgES OF<br />

ANODISINg

The <strong>BWB</strong> anodising procedures (electrolytic oxidation) combine the advantages<br />

<strong>of</strong> the electrochemically produced <strong>aluminium</strong> oxide layer with the aesthetic<br />

virtues <strong>of</strong> coloured <strong>aluminium</strong> in architecture <strong>and</strong> design. With the <strong>BWB</strong> anodising<br />

<strong>and</strong> colouration techniques, the <strong>aluminium</strong> retains its metallic nature.<br />

Corrosion resistance<br />

Anodising the <strong>aluminium</strong> produces a resilient<br />

<strong>and</strong> corrosionresistant protective layer. This<br />

ensures that components retain their value<br />

over decades.<br />

Colour retention<br />

With the <strong>BWB</strong> colouration techniques, the dye<br />

sits inside the pores <strong>of</strong> the anodised layer.<br />

Unique to the “Permalux” procedure, the<br />

colour effect is achieved by means <strong>of</strong> the integral<br />

layer structure. In the subsequent sealing<br />

process, all pores are closed. This results in<br />

extraordinarily high colourfastness.<br />

Light resistance<br />

The lightfastness <strong>of</strong> the dyes used is considerably<br />

higher than the highest value on the<br />

“Blue Scale” as per ISO 21352010 <strong>and</strong> complies<br />

with the EURAS guidelines.<br />

All colours exhibit excellent light resistance.<br />

Investment in the future<br />

The mechanical strength <strong>of</strong> anodised <strong>aluminium</strong><br />

is very high. Even during slightly<br />

abrasive cleaning <strong>of</strong> the <strong>aluminium</strong>, the surface<br />

is not damaged.<br />

With proper maintenance, anodised <strong>aluminium</strong><br />

parts retain their decorative value<br />

<strong>and</strong> metallic nature for decades.<br />

Ecology / recycling<br />

Comprehensive evaluation <strong>of</strong> economic <strong>and</strong><br />

ecological aspects speaks in favour <strong>of</strong> the<br />

use <strong>of</strong> anodised <strong>aluminium</strong> as a material in<br />

architecture.<br />

Anodised <strong>aluminium</strong> also st<strong>and</strong>s out due to<br />

lowemission colouration techniques, the high<br />

degree <strong>of</strong> recyclability <strong>and</strong> the very high stability<br />

<strong>of</strong> value.

04 _ SURFACE CONVERSION pROCEDURES<br />

SURFACE CONVERSION<br />

pROCEDURES<br />

FOR ARCHITECTURE AND DESIgN

<strong>BWB</strong> carries out a very wide range <strong>of</strong> surface conversion procedures on components<br />

for architecture <strong>and</strong> design, in order to satisfy a variety <strong>of</strong> requirements<br />

regarding function, aesthetics <strong>and</strong> corrosion protection.<br />

Anodising<br />

Electrolytic oxidation – also known as anodising<br />

– is an electrochemical process: the surface<br />

<strong>of</strong> the <strong>aluminium</strong> is converted into <strong>aluminium</strong><br />

oxide from the inside out. This oxide<br />

layer is solidly attached to the base material;<br />

to use a metaphor, it “gets under its skin”.<br />

An accurate topographical copy <strong>of</strong> the original<br />

structure is created, <strong>and</strong> the surface retains<br />

its metallic look.<br />

With the multitude <strong>of</strong> anodising procedures<br />

<strong>of</strong>fered by <strong>BWB</strong>, it is possible to produce oxide<br />

layers with very different properties. Thus,<br />

procedurespecific oxide layers with different<br />

thicknesses <strong>and</strong> colours can be manufactured<br />

to satisfy the respective requirements.<br />

Sealing<br />

With electrochemically produced oxide layers,<br />

the pores <strong>of</strong> the oxide layer are closed in a<br />

subsequent operation. This makes it very difficult<br />

for foreign matter, such as dust or dirt, to<br />

adhere to the surface, <strong>and</strong> causes the surface<br />

to become tackfree. Before sealing, adsorbed<br />

chromophoric materials are embedded <strong>and</strong><br />

fixed within the oxide layer. The wellsealed<br />

oxide layer is enormously important for a topquality<br />

surface on the work piece (weather<br />

resistance, etc.). For this reason, sealing is<br />

monitored in a correspondingly strict manner.<br />

<strong>BWB</strong> <strong>of</strong>fers the following electrolytic<br />

surface conversion procedures for<br />

architecture <strong>and</strong> design:<br />

• Anodising / electrolytic oxidation<br />

• Permalux colour hard anodising<br />

• Colouration<br />

– Sanodal<br />

– Bronze<br />

– S<strong>and</strong>alor<br />

– Colinal<br />

– Spectrocolor

06 _ pRE-TREATMENTS AND pOST-TREATMENTS FOR ANODISINg<br />

pRE-TREATMENTS AND<br />

pOST-TREATMENTS<br />

FOR ANODISINg – ALL FROM A SINgLE SOURCE

A clean surface on the work piece is a precondition for an even <strong>and</strong> stable<br />

surface finish. <strong>BWB</strong> <strong>of</strong>fers competent advice, for optimal fulfilment <strong>of</strong> the customer’s<br />

wishes <strong>and</strong> ideas.<br />

Mechanical pre-treatments<br />

A mechanical pretreatment is recommended<br />

in the event <strong>of</strong> damage, faults or irregularities<br />

in a surface. However, it is also used in order<br />

to achieve a special finish <strong>and</strong> implemented<br />

with the following surface processing procedures.<br />

The surface thus becomes matt or polished,<br />

depending on the selected procedure:<br />

• E1 grinding*<br />

(light grinding for matt etching)<br />

• E2 brushing*<br />

(light grinding <strong>and</strong> brushing)<br />

• E3 polishing*<br />

(polishing)<br />

• E4 grinding <strong>and</strong> brushing*<br />

(clean grinding <strong>and</strong> brushing)<br />

• E5 grinding <strong>and</strong> polishing*<br />

(clean grinding <strong>and</strong> polishing)<br />

Chemical pre-treatments<br />

Chemical or electrochemical <strong>finishing</strong> <strong>of</strong><br />

<strong>aluminium</strong> surfaces requires a suitable<br />

pretreatment. Contamination, corrosion or<br />

minor processing marks must be treated or<br />

concealed in a chemical pretreatment. Here,<br />

<strong>BWB</strong> <strong>of</strong>fers the following procedures:<br />

• E0 degreasing <strong>and</strong> deoxidising*<br />

(industry anodising)<br />

• E6 etching*<br />

(matt etching)<br />

Post-treatments<br />

<strong>BWB</strong> <strong>of</strong>fers the following posttreatment<br />

methods for components:<br />

• Antinoise coatings<br />

• Film coating<br />

Q labels<br />

• EGR7S<br />

• QUALANOD<br />

• British St<strong>and</strong>ard<br />

• SSG Structural Glazing<br />

* See glossary on page 11

08_ YOUR pARTNER FOR SURFACE TREATMENT ENgINEERINg<br />

YOUR pARTNER FOR<br />

SURFACE TREATMENT<br />

ENgINEERINg<br />

COMpETENT, RELIAbLE, EXpERIENCED

As a designer or planner, your requirements vary. Whether for purely functional<br />

aspects, for aesthetic criteria, or both combined: <strong>BWB</strong> <strong>of</strong>fers you comprehensive<br />

advice on material, colour, machining <strong>and</strong> structural design.<br />

Material selection<br />

<strong>BWB</strong> has longst<strong>and</strong>ing expertise in the selection<br />

<strong>and</strong> procurement <strong>of</strong> the right material<br />

for dem<strong>and</strong>ing projects in architecture <strong>and</strong><br />

design. We advise you when selecting material.<br />

For decorative applications, <strong>aluminium</strong><br />

alloys <strong>of</strong> anodising quality must be used.<br />

Structural design advice<br />

Early integration <strong>of</strong> <strong>BWB</strong> experts into the<br />

project guarantees a more successful implementation<br />

<strong>of</strong> surface <strong>finishing</strong>. This enables<br />

typical peculiarities <strong>of</strong> the respective procedures<br />

to be accounted for in the structural<br />

design <strong>and</strong> integrated into the project in<br />

good time.<br />

The bath sizes limit the dimensions <strong>of</strong> the<br />

work pieces to be finished. The <strong>BWB</strong> sales<br />

team provides you with competent advice in<br />

this regard. Special attention is also paid to<br />

welded structures.<br />

Special effects<br />

With the interplay <strong>of</strong> mechanical <strong>and</strong> chemical<br />

pretreatments <strong>and</strong> the different anodising<br />

procedures, various special effects are<br />

achieved. The <strong>BWB</strong> advisors are happy to<br />

help you.<br />

Sampling<br />

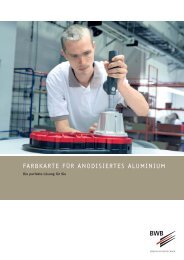

The colour chart on the next page can be<br />

used for initial selection <strong>of</strong> the colour tone. In<br />

order to determine the exact colour tone, a<br />

st<strong>and</strong>ard h<strong>and</strong> sample may be necessary.<br />

For object sampling, it is advisable to define<br />

not only the mechanical <strong>and</strong> chemical pretreatment,<br />

but also the anodising <strong>and</strong> colouration<br />

with the original material.

<strong>BWB</strong> Natural Colour<br />

colourless)<br />

• Layer thicknesses 10, 15, 20, 25 µm<br />

• Costefficient, environmentally friendly procedure<br />

<strong>BWB</strong> Permalux* Integral colouration procedure<br />

<strong>BWB</strong> Spectrocolor*<br />

• Maximum durability, colourplay/lightplay, no chalking<br />

• The Permalux colours are created during the oxidation<br />

process <strong>and</strong> are extraordinarily hard, durable <strong>and</strong><br />

corrosionresistant.<br />

<strong>BWB</strong> Colinal Electrolytic colouration procedure<br />

<strong>BWB</strong> S<strong>and</strong>alor Basis*<br />

<strong>BWB</strong> S<strong>and</strong>alor Combi*<br />

<strong>BWB</strong> Sanodal<br />

<strong>BWB</strong> Bronze<br />

10 _ ALUMINIUM COLOUR CHART<br />

• Very good colour equality, no chalking<br />

Adsorptive colouration procedure<br />

• Bright colours, no chalking<br />

A combined electrolytic-adsorptive<br />

colouration procedure<br />

• Distinctive colours, no chalking<br />

Adsorptive colouration procedure<br />

• No chalking<br />

Combined electrolytic-adsorptive<br />

colouration procedure<br />

• Distinctive colours, no chalking<br />

Interference (colouration procedure)<br />

• Bright colours, colourplay/lightplay, no chalking<br />

Natural Colour (colourless)<br />

EV1<br />

<strong>BWB</strong> Permalux P1 <strong>BWB</strong> Permalux P2 <strong>BWB</strong> Permalux P3<br />

<strong>BWB</strong> Colinal 3115<br />

( ≈ Euras C 31)<br />

<strong>BWB</strong> Spectrocolor<br />

<strong>BWB</strong> Colinal 3145<br />

( ≈ Euras C 32)<br />

<strong>BWB</strong> S<strong>and</strong>alor C60 1 <strong>BWB</strong> S<strong>and</strong>alor C62 1<br />

<strong>BWB</strong> Colinal 3165<br />

( ≈ Euras C 33)<br />

<strong>BWB</strong> S<strong>and</strong>alor<br />

C60 2 C60 3 C60 4 C62 2 C62 3 C62 4<br />

<strong>BWB</strong> Argentan 2 <strong>BWB</strong> Brass 2.5 <strong>BWB</strong> Gold 3<br />

<strong>BWB</strong> Bronze 3 <strong>BWB</strong> Bronze 4 <strong>BWB</strong> Bronze 5<br />

Interference effect<br />

With the interference colouration procedure Spectrocolor, <strong>aluminium</strong> surfaces can be given many colours with dazzling lightplay. Surfaces<br />

with this finish can be used both indoors <strong>and</strong> outdoors. In order to determine the exact colouring, comprehensive object sampling with<br />

original material must be carried out.<br />

* Manufacture in Altenrhein only

<strong>BWB</strong> Permalux P4<br />

<strong>BWB</strong> Colinal 3175 <strong>BWB</strong> Colinal 3178<br />

( ≈ Euras C 34)<br />

<strong>BWB</strong> Colinal 3180<br />

( ≈ Euras C 35)<br />

<strong>BWB</strong> S<strong>and</strong>alor C63 1 <strong>BWB</strong> S<strong>and</strong>alor C64 1 <strong>BWB</strong> S<strong>and</strong>alor C66 1 <strong>BWB</strong> S<strong>and</strong>alor C671<br />

<strong>BWB</strong> Argentan 6 <strong>BWB</strong> Argentan 7 <strong>BWB</strong> Brass 8<br />

The colour samples shown in this colour chart<br />

serve only as orientation. For technical reasons,<br />

it is impossible to print an exact reproduction <strong>of</strong><br />

how the material appears after anodising <strong>and</strong><br />

colouration <strong>of</strong> the <strong>aluminium</strong>. For sampling <strong>of</strong><br />

<strong>aluminium</strong> components for architecture, contact<br />

our customer service team. Please note that the<br />

appearance <strong>of</strong> metal sheets <strong>and</strong> pr<strong>of</strong>iles can<br />

vary, even with the same treatment <strong>and</strong> dye. In<br />

addition, we refer to the guidelines <strong>and</strong> quality<br />

regulations 41.06 for anodised <strong>aluminium</strong> facade<br />

components, from the Swiss Centre for Windows<br />

<strong>and</strong> Facades (SZFF), as well as DIN 17611.<br />

<strong>BWB</strong> S<strong>and</strong>alor<br />

C63 2 C63 3 C63 4 C64 2 C64 3 C66 2 C66 3 C66 4 C67 2 C67 3 C67 4<br />

<strong>BWB</strong> Bronze 21<br />

Glossary<br />

DIN 17611<br />

Anodised products <strong>of</strong> wrought<br />

<strong>aluminium</strong> alloys – technical<br />

conditions for delivery<br />

E0<br />

Degreasing<br />

<strong>and</strong> deoxidising<br />

<strong>BWB</strong> terminology Industry<br />

anodising<br />

E1<br />

Grinding<br />

Light grinding<br />

for matt etching<br />

E2<br />

Brushing<br />

Light grinding<br />

<strong>and</strong> brushing<br />

<strong>BWB</strong> Gold 9<br />

E3<br />

Polishing<br />

E4<br />

Grinding <strong>and</strong><br />

brushing<br />

Polishing Clean grinding<br />

<strong>and</strong> brushing<br />

Colour selection<br />

For architecture, the <strong>BWB</strong> Group <strong>of</strong>fers you a<br />

broad palette <strong>of</strong> colours to choose from, as<br />

shown on this page. However, in order to evaluate<br />

colours correctly, we recommend that you<br />

get us to carry out sampling with original parts<br />

<strong>and</strong> with the designated <strong>aluminium</strong> alloy.<br />

Do you have any questions?<br />

You will find answers at www.bwbgroup.com<br />

by selecting a site under “Contact details”<br />

<strong>and</strong> clicking on “Range <strong>of</strong> services”.<br />

E5<br />

Grinding <strong>and</strong><br />

polishing<br />

Clean grinding<br />

<strong>and</strong> polishing<br />

E6<br />

Etching<br />

Matt etching

12 _ www.bwb-gROUp.COM<br />

<strong>BWB</strong> Group<br />

www.bwb-group.com<br />

YOUR CONTACT p ARTNERS<br />

<strong>BWB</strong> is happy to advise you on material selection <strong>and</strong> procedures<br />

The <strong>BWB</strong> Group is your partner for the machining<br />

<strong>and</strong> <strong>finishing</strong> <strong>of</strong> <strong>aluminium</strong><br />

Due to our wealth <strong>of</strong> experience in surface treatment engineering, we <strong>of</strong>fer economical<br />

allinone solutions for architecture, industry <strong>and</strong> design – from competent<br />

advice, to material procurement, right through to implementation, delivery <strong>and</strong><br />

assembly. With our production sites, we have good regional support <strong>and</strong> are always<br />

where you need us.<br />

Büren Bätterkinden<br />

Niederwangen<br />

StansOberdorf<br />

<strong>BWB</strong>-Bürox AG<br />

Industriestrasse 15<br />

CH3294 Büren a.A.<br />

T +41 32 352 04 40<br />

F +41 32 352 04 49<br />

bueren@bwbgroup.com<br />

Schlieren<br />

Altenrhein<br />

Gregor Kern<br />

Sales Manager<br />

<strong>BWB</strong>-Altenrhein AG<br />

I & G Park<br />

CH9423 Altenrhein<br />

T +41 71 858 61 46<br />

F +41 71 858 61 71<br />

gregor.kern@bwbgroup.com<br />

concept by www.stier.ch 092.11EN