DRAFT IMECE2007-43427 - Czech Technical University in Prague

DRAFT IMECE2007-43427 - Czech Technical University in Prague

DRAFT IMECE2007-43427 - Czech Technical University in Prague

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

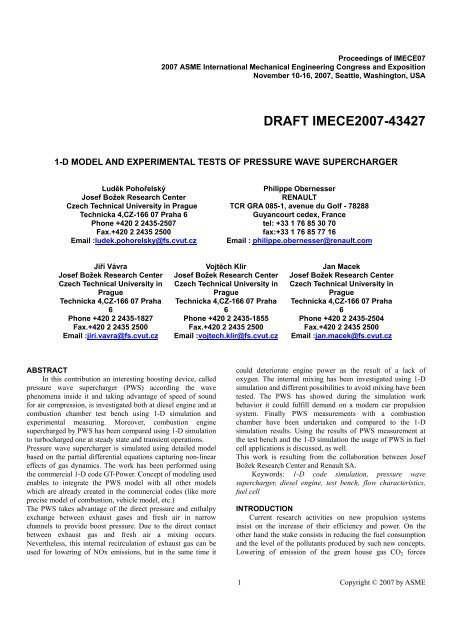

Proceed<strong>in</strong>gs of IMECE07<br />

2007 ASME International Mechanical Eng<strong>in</strong>eer<strong>in</strong>g Congress and Exposition<br />

November 10-16, 2007, Seattle, Wash<strong>in</strong>gton, USA<br />

<strong>DRAFT</strong> <strong>IMECE2007</strong>-<strong>43427</strong><br />

1-D MODEL AND EXPERIMENTAL TESTS OF PRESSURE WAVE SUPERCHARGER<br />

Luděk Pohořelský<br />

Josef Božek Research Center<br />

<strong>Czech</strong> <strong>Technical</strong> <strong>University</strong> <strong>in</strong> <strong>Prague</strong><br />

Technicka 4,CZ-166 07 Praha 6<br />

Phone +420 2 2435-2507<br />

Fax.+420 2 2435 2500<br />

Email :ludek.pohorelsky@fs.cvut.cz<br />

Jiří Vávra<br />

Josef Božek Research Center<br />

<strong>Czech</strong> <strong>Technical</strong> <strong>University</strong> <strong>in</strong><br />

<strong>Prague</strong><br />

Technicka 4,CZ-166 07 Praha<br />

6<br />

Phone +420 2 2435-1827<br />

Fax.+420 2 2435 2500<br />

Email :jiri.vavra@fs.cvut.cz<br />

ABSTRACT<br />

In this contribution an <strong>in</strong>terest<strong>in</strong>g boost<strong>in</strong>g device, called<br />

pressure wave supercharger (PWS) accord<strong>in</strong>g the wave<br />

phenomena <strong>in</strong>side it and tak<strong>in</strong>g advantage of speed of sound<br />

for air compression, is <strong>in</strong>vestigated both at diesel eng<strong>in</strong>e and at<br />

combustion chamber test bench us<strong>in</strong>g 1-D simulation and<br />

experimental measur<strong>in</strong>g. Moreover, combustion eng<strong>in</strong>e<br />

supercharged by PWS has been compared us<strong>in</strong>g 1-D simulation<br />

to turbocharged one at steady state and transient operations.<br />

Pressure wave supercharger is simulated us<strong>in</strong>g detailed model<br />

based on the partial differential equations captur<strong>in</strong>g non-l<strong>in</strong>ear<br />

effects of gas dynamics. The work has been performed us<strong>in</strong>g<br />

the commercial 1-D code GT-Power. Concept of model<strong>in</strong>g used<br />

enables to <strong>in</strong>tegrate the PWS model with all other models<br />

which are already created <strong>in</strong> the commercial codes (like more<br />

precise model of combustion, vehicle model, etc.)<br />

The PWS takes advantage of the direct pressure and enthalpy<br />

exchange between exhaust gases and fresh air <strong>in</strong> narrow<br />

channels to provide boost pressure. Due to the direct contact<br />

between exhaust gas and fresh air a mix<strong>in</strong>g occurs.<br />

Nevertheless, this <strong>in</strong>ternal recirculation of exhaust gas can be<br />

used for lower<strong>in</strong>g of NOx emissions, but <strong>in</strong> the same time it<br />

Philippe Obernesser<br />

RENAULT<br />

TCR GRA 085-1, avenue du Golf - 78288<br />

Guyancourt cedex, France<br />

tel: +33 1 76 85 30 70<br />

fax:+33 1 76 85 77 16<br />

Email : philippe.obernesser@renault.com<br />

Vojtěch Klír<br />

Josef Božek Research Center<br />

<strong>Czech</strong> <strong>Technical</strong> <strong>University</strong> <strong>in</strong><br />

<strong>Prague</strong><br />

Technicka 4,CZ-166 07 Praha<br />

6<br />

Phone +420 2 2435-1855<br />

Fax.+420 2 2435 2500<br />

Email :vojtech.klir@fs.cvut.cz<br />

Jan Macek<br />

Josef Božek Research Center<br />

<strong>Czech</strong> <strong>Technical</strong> <strong>University</strong> <strong>in</strong><br />

<strong>Prague</strong><br />

Technicka 4,CZ-166 07 Praha<br />

6<br />

Phone +420 2 2435-2504<br />

Fax.+420 2 2435 2500<br />

Email :jan.macek@fs.cvut.cz<br />

could deteriorate eng<strong>in</strong>e power as the result of a lack of<br />

oxygen. The <strong>in</strong>ternal mix<strong>in</strong>g has been <strong>in</strong>vestigated us<strong>in</strong>g 1-D<br />

simulation and different possibilities to avoid mix<strong>in</strong>g have been<br />

tested. The PWS has showed dur<strong>in</strong>g the simulation work<br />

behavior it could fulfill demand on a modern car propulsion<br />

system. F<strong>in</strong>ally PWS measurements with a combustion<br />

chamber have been undertaken and compared to the 1-D<br />

simulation results. Us<strong>in</strong>g the results of PWS measurement at<br />

the test bench and the 1-D simulation the usage of PWS <strong>in</strong> fuel<br />

cell applications is discussed, as well.<br />

This work is result<strong>in</strong>g from the collaboration between Josef<br />

Božek Research Center and Renault SA.<br />

Keywords: 1-D code simulation, pressure wave<br />

supercharger, diesel eng<strong>in</strong>e, test bench, flow characteristics,<br />

fuel cell<br />

INTRODUCTION<br />

Current research activities on new propulsion systems<br />

<strong>in</strong>sist on the <strong>in</strong>crease of their efficiency and power. On the<br />

other hand the stake consists <strong>in</strong> reduc<strong>in</strong>g the fuel consumption<br />

and the level of the pollutants produced by such new concepts.<br />

Lower<strong>in</strong>g of emission of the green house gas CO2 forces<br />

1 Copyright © 2007 by ASME

manufactures to develop more economical vehicle and<br />

therefore more efficient eng<strong>in</strong>es. Moreover, <strong>in</strong> case of car<br />

propulsion systems the satisfactory driveability to satisfy<br />

driver’s demands dur<strong>in</strong>g the accelerations has to be provided at<br />

the same time. An approach of utilization of downsized<br />

propulsion systems may lead successfully up to these aims. The<br />

ma<strong>in</strong> idea of downsiz<strong>in</strong>g is the reduction of the swept volume<br />

of the eng<strong>in</strong>e without lower<strong>in</strong>g the orig<strong>in</strong>al output power. The<br />

performance <strong>in</strong>crease of the downsized eng<strong>in</strong>e to the same<br />

power level of the orig<strong>in</strong>al one is achieved by boost<strong>in</strong>g devices.<br />

Eng<strong>in</strong>e researchers and developers are nowadays wonder<strong>in</strong>g,<br />

which boost<strong>in</strong>g devices are the most suitable and so are try<strong>in</strong>g<br />

to f<strong>in</strong>d compromises with regards to costs, packag<strong>in</strong>g, eng<strong>in</strong>e<br />

behavior and emission regulations. In addition to commonly<br />

utilized turbocharger mechanical superchargers as for <strong>in</strong>stance<br />

Roots-type supercharger are more and more placed on the<br />

market. In comparison with these boost<strong>in</strong>g devices the pressure<br />

wave supercharger (PWS) with usage of today’s control<br />

possibilities represents ma<strong>in</strong>ly <strong>in</strong> transient and low-end torque<br />

behavior an extraord<strong>in</strong>ary possibility. The PWS takes<br />

advantages of a unique pr<strong>in</strong>ciple of direct pressure energy<br />

exchange between the exhaust gas and the fresh air <strong>in</strong> a narrow<br />

channel us<strong>in</strong>g nearly 1-D unsteady flow with a dist<strong>in</strong>ctive<br />

contact surface between the both gases.<br />

The idea of the energy exchange between two mediums without<br />

any separation goes down to the beg<strong>in</strong>n<strong>in</strong>g of the 20 th century.<br />

Namely <strong>in</strong> its second decade, along the longitud<strong>in</strong>al axis<br />

perforated drum, a channeled rotor, has been patented by the<br />

German eng<strong>in</strong>eer Burghard - [24] - a mach<strong>in</strong>e deliver<strong>in</strong>g an<br />

un<strong>in</strong>terrupted mass flow of the pressurized air. As the unsteady<br />

flow theory, a necessity for the development of a usable<br />

mach<strong>in</strong>e has not been developed until the 1920’s and 1930’s,<br />

the Burghard’s <strong>in</strong>vention did not succeed to an available<br />

device.<br />

In the 1940’s, the Brown Boveri (BBC, today ABB)<br />

turbocharger eng<strong>in</strong>eer Seippel designed a pressure exchanger<br />

as an air compressor of a gas turb<strong>in</strong>e used as the propulsion of<br />

an experimental locomotive - [28]. He started to call this<br />

exchanger COMPREX accord<strong>in</strong>g to the processes <strong>in</strong> the rotor –<br />

“compression-expansion”.<br />

In the 1950’s took place first experimental attempts <strong>in</strong> us<strong>in</strong>g<br />

COMPREX for supercharg<strong>in</strong>g of truck diesel eng<strong>in</strong>es - [12],<br />

[26], <strong>in</strong> framework of partnership among the ETH Zürich, the<br />

I-T-E Circuit Breaker Company, the BBC and the Saurer<br />

Company.<br />

In the 1970‘s, first experiments of COMPREX supercharged<br />

car diesel eng<strong>in</strong>es followed (partnership between BBC and<br />

Mercedes-Benz) – [30]. In 1979 BBC developed a race version<br />

of PWS for supercharg<strong>in</strong>g of F1 eng<strong>in</strong>e [10], which has been<br />

used only for the practice runs. In 1995, the Swissauto Wenko<br />

Company, which is deal<strong>in</strong>g with development of pressure wave<br />

supercharger up to now - [19], designed for the environmental<br />

organization Greenpeace a so-called SmiLE car with SI eng<strong>in</strong>e<br />

with displacement of 360cm 3 and PWS supercharg<strong>in</strong>g – [20].<br />

Moreover, <strong>in</strong> 1980’s many companies tested the COMPREX -<br />

supercharged diesel eng<strong>in</strong>es, but only two started the serial<br />

production. The Opel Company sold <strong>in</strong> a special Opel Senator<br />

set of about 700 units with 2.3l diesel eng<strong>in</strong>e and pressure<br />

wave supercharg<strong>in</strong>g – [31] whereas Mazda sold about 150 000<br />

COMPREX diesel passenger cars – [4].<br />

Recently, several Universities (ETH Zürich, Indiana <strong>University</strong><br />

Purdue <strong>University</strong> Indianapolis, Michigan State <strong>University</strong>,<br />

<strong>University</strong> of Tokyo, Warsaw <strong>University</strong> and Beij<strong>in</strong>g<br />

<strong>University</strong> of Technology), companies (Swissauto Eng<strong>in</strong>eer<strong>in</strong>g<br />

S.A., Rolls Royce Alison) and governmental research centers<br />

(NASA) <strong>in</strong>vestigate pressure wave process <strong>in</strong>tensively for<br />

various thermal applications. In [4] a comprehensive review of<br />

past and current research <strong>in</strong> develop<strong>in</strong>g of wave rotor<br />

technology is expla<strong>in</strong>ed <strong>in</strong> more details and <strong>in</strong> a well arranged<br />

way.<br />

In framework of our study the PWS has been <strong>in</strong>vestigated and<br />

analyzed at first us<strong>in</strong>g 1-D diesel eng<strong>in</strong>e simulation. Then by<br />

means of experimental tests at the test bench to f<strong>in</strong>d out<br />

whether the pressure wave supercharg<strong>in</strong>g with regard to<br />

today’s state of art <strong>in</strong> control, actuation, materials and<br />

technology could fulfill requirements on a modern and<br />

perspective car propulsion system and become a serious<br />

competitor to current boost<strong>in</strong>g systems.<br />

1-D SIMULATION OF PWS SUPERCHARGED DIESEL<br />

ENGINE<br />

For the study the Renault 1.5 diesel eng<strong>in</strong>e has been used<br />

for 1-D <strong>in</strong>vestigations to compare PWS supercharged eng<strong>in</strong>e to<br />

the turbocharged one.<br />

Stroke 80.5 mm<br />

Bore 76 mm<br />

Total swept volume 1461 cm3<br />

Number of cyl<strong>in</strong>ders 4<br />

Compression ratio 16:1<br />

Combustion system 2valves/cyl<strong>in</strong>der<br />

Direct <strong>in</strong>jection<br />

Table 1: Diesel eng<strong>in</strong>e parameters<br />

1-D model of PWS used, whose qualitative reaction to changes<br />

<strong>in</strong> design are <strong>in</strong> good agreement with published sources [1],[2]<br />

and with a simple model based on the theory of adiabatic shock<br />

waves and on the l<strong>in</strong>ear gas dynamics pr<strong>in</strong>ciples, has been<br />

created <strong>in</strong> commercial code GT-Power and is <strong>in</strong>troduced and<br />

described <strong>in</strong> detail <strong>in</strong> [37].<br />

Simulation of Full Load of Eng<strong>in</strong>e with PWS<br />

Diagrams <strong>in</strong> Figure 1-Figure 7 po<strong>in</strong>t out comparisons of<br />

PWS supercharged eng<strong>in</strong>es with turbocharged one. PWSs with<br />

unity length-to-diameter ratio of rotor (quadratic design) have<br />

been simulated. The PWS sucks more air <strong>in</strong>to its channeled<br />

rotor than it compresses and delivers to the eng<strong>in</strong>e cyl<strong>in</strong>der<br />

[25]. This fresh air scavenges and cools down the rotor and<br />

2 Copyright © 2007 by ASME

flows direct to the low pressure part of exhaust manifold PWS<br />

downstream. Therefore, the diameter of fresh air pip<strong>in</strong>gs and<br />

diameter of exhaust pip<strong>in</strong>gs PWS downstream have been<br />

enlarged <strong>in</strong> comparison to turbocharged eng<strong>in</strong>e. (In this study<br />

the diameter of particular pip<strong>in</strong>gs equals to 75% of PWS rotor<br />

diameter.)<br />

Air fuel ratio for PWS supercharged eng<strong>in</strong>es has been kept the<br />

same as for turbocharged eng<strong>in</strong>e.<br />

Proper function of PWS depends on the control geometry (i.e.<br />

location of <strong>in</strong>let and outlet orifices at the air and exhaust<br />

flanges of PWS).Two different types of control geometry have<br />

been simulated: control geometry previously optimized by<br />

method of characteristics based on the l<strong>in</strong>ear gas dynamics [37]<br />

and patented geometry from Swissauto Eng<strong>in</strong>eer<strong>in</strong>g S.A. [7]<br />

The PWS speed has been optimized to reach maximum eng<strong>in</strong>e<br />

torque at each operation po<strong>in</strong>t.<br />

Boost pressure behavior is presented <strong>in</strong> Figure 1. The smaller<br />

the PWS the higher boost pressure can be achieved. The<br />

PWS70 (i.e. with rotor diameter and rotor length of 70 mm)<br />

achieves the highest boost pressure. The usage of the control<br />

geometry from Swissauto Company at PWS83 and PWS95<br />

<strong>in</strong>creased the boost pressure significantly.<br />

Boost pressure [bar]<br />

3.2<br />

3<br />

2.8<br />

2.6<br />

2.4<br />

2.2<br />

2<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

Boost pressure comparison<br />

PWS83<br />

PWS83_patented_Swissauto_geometry<br />

PWS70<br />

PWS95<br />

Turbo<br />

PWS95_patented_Swissauto_geometry<br />

1<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 1: Comparison of PWS and turbocharger boost pressure<br />

In comparison to boost pressure, the eng<strong>in</strong>e torque (Figure 2)<br />

of PWS supercharged eng<strong>in</strong>es falls down at highest eng<strong>in</strong>e<br />

speeds. This is caused by <strong>in</strong>ternal exhaust gas recirculation<br />

(Figure 3) over the channeled rotor of PWS, which deteriorates<br />

the eng<strong>in</strong>e torque. Due to the direct contact of exhaust gas and<br />

fresh air, the exhaust gas can be delivered direct to the eng<strong>in</strong>e<br />

cyl<strong>in</strong>der together with the compressed air. The smaller PWS the<br />

higher <strong>in</strong>ternal exhaust gas recirculation.<br />

Torque [N.m]<br />

260<br />

240<br />

220<br />

200<br />

180<br />

160<br />

Eng<strong>in</strong>e torque comparison<br />

140<br />

PWS83<br />

PWS83_patented_Swissauto_geometry<br />

120<br />

PWS70<br />

PWS95<br />

100<br />

Turbo<br />

80<br />

PWS95_patented_Swissauto_geometry<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 2: Comparison of eng<strong>in</strong>e torque<br />

Figure 4 presents the <strong>in</strong>dicated specific fuel consumption. As<br />

the computation model of combustion for PWS supercharged<br />

eng<strong>in</strong>es was the same as <strong>in</strong> case of turbocharged eng<strong>in</strong>e (i.e. it<br />

did not take <strong>in</strong>to account the <strong>in</strong>creased amount of exhaust gas<br />

<strong>in</strong> the eng<strong>in</strong>e cyl<strong>in</strong>der) the differences <strong>in</strong> <strong>in</strong>dicated specific fuel<br />

consumption are given only by pump<strong>in</strong>g work dur<strong>in</strong>g the<br />

cyl<strong>in</strong>der exchange. Figure 4 and Figure 5 demonstrate<br />

favorable behavior of the exhaust back pressure of the PWS<br />

supercharged eng<strong>in</strong>es. Up to the middle eng<strong>in</strong>e speed the boost<br />

pressure is dist<strong>in</strong>ctly higher than the back pressure.<br />

EGR [%]<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Exhaust gas recirculation <strong>in</strong>to eng<strong>in</strong>e cyl<strong>in</strong>der<br />

PWS83<br />

PWS83_patented_Swissauto_geometry<br />

PWS70<br />

PWS95<br />

PWS95_patented_Swissauto_geometry<br />

0<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 3: Exhaust gas recirculation <strong>in</strong>to eng<strong>in</strong>e cyl<strong>in</strong>der of<br />

PWS eng<strong>in</strong>es<br />

ISFC [g/kW/h]<br />

240<br />

230<br />

220<br />

210<br />

200<br />

190<br />

Idicated specific fuel consumption<br />

PWS83<br />

PWS83_patented_Swissauto_geometry<br />

PWS70<br />

PWS95<br />

Turbo<br />

PWS95_patented_Swissauto_geometry<br />

180<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 4: Comparison of <strong>in</strong>dicated specific fuel consumption<br />

3 Copyright © 2007 by ASME

Pressure [bar]<br />

3.4<br />

3.2<br />

3<br />

2.8<br />

2.6<br />

2.4<br />

2.2<br />

2<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

Boost pressure and exhaust back pressure<br />

Turbo-boost pressure<br />

PWS95_patented_Swissauto_geometry-boost pressure<br />

Turbo-back pressure<br />

PWS95_patented_Swissauto_geometry-back pressure<br />

1<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 5: Boost pressure and back pressure behavior<br />

PWS Speed<br />

Figure 6 shows the PWS speed characteristics. As the time<br />

of pressure wave propagation from exhaust to air side<br />

decreases with the reduction of the PWS size, the smallest<br />

PWS achieves the highest speeds.<br />

Diagrams on Figure 7 present dependences of the eng<strong>in</strong>e toque,<br />

boost pressure, <strong>in</strong>dicated specific fuel consumption and the<br />

exhaust gas recirculation on the PWS speed. Each observed<br />

quantity achieves its optimum at a certa<strong>in</strong> PWS speed. The<br />

<strong>in</strong>crease of the PWS speed contributes to the lower<strong>in</strong>g of the<br />

exhaust gas recirculation.<br />

PWS speed [1/m<strong>in</strong>]<br />

15000<br />

14000<br />

13000<br />

12000<br />

11000<br />

10000<br />

9000<br />

PWS speed optimized for maximum eng<strong>in</strong>e torque<br />

PWS83<br />

PWS70<br />

PWS95<br />

8000<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 6: PWS speed characteristics<br />

Influence of PWS speed on eng<strong>in</strong>e parameters<br />

200<br />

1.9<br />

1.8<br />

1.7<br />

1.6<br />

1.5<br />

150<br />

1.4<br />

PWS83-eng<strong>in</strong>e torque<br />

1.3<br />

PWS83-boost pressure<br />

1.2<br />

1.1<br />

100<br />

1<br />

10000 11000 12000 13000 14000 15000 16000<br />

PWS speed [1/m<strong>in</strong>]<br />

Eng<strong>in</strong>e torque [N.m]<br />

Boost pressure [bar]<br />

ISFC [g/kW/h]<br />

230<br />

225<br />

220<br />

215<br />

Influence of PWS speed on eng<strong>in</strong>e parameters<br />

PWS83-ISFC<br />

PWS83-EGR<br />

10000 11000 12000 13000 14000 15000 16000<br />

PWS speed [1/m<strong>in</strong>]<br />

Figure 7: Dependence of eng<strong>in</strong>e parameters on PWS speed for<br />

eng<strong>in</strong>e speed of 1500rpm<br />

Variable Gas Pocket<br />

In order to extend the operat<strong>in</strong>g range of the PWS, so<br />

called pocket <strong>in</strong> the <strong>in</strong>ner face of air and exhaust flanges have<br />

been patented by BBC <strong>in</strong> the 1960’s. Compression pocket,<br />

expansion pocket and gas pocket (Figure 8) by pass the gas<br />

between the channels and the control orifices and thus improve<br />

13<br />

11<br />

9<br />

7<br />

5<br />

3<br />

1<br />

EGR [%]<br />

the operation of the supercharger away from the optimum<br />

(tuned) po<strong>in</strong>t. Moreover, the gas pocket can be used <strong>in</strong> function<br />

of the waste-gate for control of the boost pressure.<br />

Variable Gas Pocket<br />

Exhaust <strong>in</strong>let orifice<br />

Exhaust outlet orifice<br />

Exhaust<br />

Flange<br />

Channel<br />

Low-Pressure<br />

part<br />

Air <strong>in</strong>let orifice<br />

Expansion Pocket<br />

Air outlet orifice<br />

High-Pressure<br />

part<br />

Compression<br />

Pocket<br />

Air Flange<br />

Figure 8: Pressure wave diagram and variable gas pocket <strong>in</strong><br />

function of waste gate<br />

The variable gas pocket bypasses pressurized exhaust gas to the<br />

exhaust outlet via the rotor channel. The bypassed exhaust gas<br />

amplifies the expansion wave <strong>in</strong> the low-pressure part, which<br />

provides better fresh air suction <strong>in</strong>to channeled rotor.<br />

The function and efficiency of the variable gas pocket have<br />

been confirmed by means of the simulation. Simulation results<br />

presented <strong>in</strong> Figure 1-Figure 7 show turbocharger controlled by<br />

the variable turb<strong>in</strong>e geometry, whereas the boost pressure of<br />

PWS has not been controlled.<br />

Diagrams on Figure 9 show results of boost pressure control<br />

for PWS95 with the variable gas pocket at highest eng<strong>in</strong>e<br />

speeds (Figure 9 left). Moreover, utilization of the variable gas<br />

pocket for boost pressure control contributes to the lower<strong>in</strong>g of<br />

the <strong>in</strong>ternal exhaust gas recirculation (Figure 9 right).<br />

Boost pressure [bar]<br />

2.9<br />

2.8<br />

2.7<br />

2.6<br />

2.5<br />

Boost pressure control by variable gas pocket<br />

PWS95 w/o VGP control<br />

PWS with VGP<br />

2.4<br />

3500 3600 3700 3800 3900 4000 4100 4200 4300 4400 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Influence of gas pocket control on the <strong>in</strong>ternal gas<br />

recirculation<br />

20<br />

19<br />

18<br />

17<br />

16<br />

PWS95 w/o VGP control<br />

15<br />

14<br />

13<br />

12<br />

PWS with VGP<br />

3500 3600 3700 3800 3900 4000 4100 4200 4300 4400 4500<br />

EGR [%]<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 9: Influence of variable gas pocket control (VGP) on<br />

the boost pressure and <strong>in</strong>ternal exhaust gas recirculation<br />

Influence of Flow Losses<br />

Figure 10 describes <strong>in</strong>fluence of flow losses on the PWS<br />

behavior. Flow losses have been <strong>in</strong>creased by chang<strong>in</strong>g <strong>in</strong>let<br />

(Air <strong>in</strong>let orifice upstream -Figure 8) and outlet (Exhaust outlet<br />

orifice downstream -Figure 8) pip<strong>in</strong>gs diameters from 75% to<br />

40% of PWS rotor diameter.<br />

From the 1-D simulation follows that to throttle the air <strong>in</strong>let and<br />

exhaust outlet of PWS deteriorates scaveng<strong>in</strong>g of the PWS<br />

4 Copyright © 2007 by ASME

otor by <strong>in</strong>creas<strong>in</strong>g <strong>in</strong>ternal exhaust gas recirculation, and<br />

consequently lowers eng<strong>in</strong>e torque considerably.<br />

Torque [N.m]<br />

230<br />

210<br />

190<br />

170<br />

150<br />

130<br />

110<br />

90<br />

Eng<strong>in</strong>e torque comparison<br />

70<br />

PWS83_pip<strong>in</strong>gs with diameter of 75% of PWS rotor diameter<br />

50 PWS83_pip<strong>in</strong>gs with diameter of 50% of PWS rotor diameter<br />

30<br />

PWS83_pip<strong>in</strong>gs with diameter of 40% of PWS rotor diameter<br />

1000 1500 2000 2500 3000 3500 4000 4500<br />

Eng<strong>in</strong>e speed [1/m<strong>in</strong>]<br />

Figure 10: Influence of flow losses on the PWS eng<strong>in</strong>e torque<br />

Transient Simulation of Eng<strong>in</strong>e with PWS<br />

To <strong>in</strong>vestigate the transient response of PWS<br />

supercharged eng<strong>in</strong>e the eng<strong>in</strong>e torque vary from the low load<br />

to full load at a constant eng<strong>in</strong>e speed. The load of eng<strong>in</strong>e was<br />

def<strong>in</strong>ed to be equal to the <strong>in</strong>stantaneous eng<strong>in</strong>e torque, which<br />

prevents speed changes. S<strong>in</strong>ce the eng<strong>in</strong>e torque rises dur<strong>in</strong>g<br />

the load step faster than the eng<strong>in</strong>e speed, this test of dynamic<br />

behavior corresponds to the first <strong>in</strong>stant of vehicle acceleration.<br />

Boost pressure [bar]<br />

1.8<br />

1.7<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

Boost pressure response<br />

PWS83<br />

Turbo<br />

1<br />

1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0<br />

Time [sec]<br />

Figure 11: Boost pressure response for 1.5 diesel eng<strong>in</strong>e with<br />

PWS83 at eng<strong>in</strong>e speed of 1250 rpm<br />

The PWS boost pressure <strong>in</strong>creases steeper than the<br />

turbocharger one (Figure 11). Dur<strong>in</strong>g the load step an <strong>in</strong>creased<br />

<strong>in</strong>ternal exhaust gas recirculation appears (Figure 13), this is<br />

the reason of the decreas<strong>in</strong>g delay at the middle of the load step<br />

between the PWS supercharged and turbocharged eng<strong>in</strong>e<br />

(Figure 12).<br />

Eng<strong>in</strong>e torque [N.m]<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Eng<strong>in</strong>e torque response<br />

PWS83<br />

Turbo<br />

0<br />

1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0<br />

Time [sec]<br />

Figure 12: Torque response for 1.5 diesel eng<strong>in</strong>e with PWS83<br />

at eng<strong>in</strong>e speed of 1250 rpm<br />

EGR [%]<br />

26<br />

21<br />

16<br />

11<br />

6<br />

Internal exhasut gas recirculation dur<strong>in</strong>g transient<br />

PWS83<br />

1<br />

1.5 2.0 2.5 3.0 3.5 4.0<br />

Time [sec]<br />

Figure 13: Internal exhaust gas recirculation <strong>in</strong> transient<br />

operation<br />

Dur<strong>in</strong>g the simulation of spark-ignited eng<strong>in</strong>e, presented <strong>in</strong><br />

[38], more considerable deterioration of eng<strong>in</strong>e torque appeared<br />

than <strong>in</strong> case of 1.5 diesel eng<strong>in</strong>e. Change of PWS speed<br />

(Figure 14 right) dur<strong>in</strong>g the transient operation was an efficient<br />

remedy to improve eng<strong>in</strong>e torque behavior (Figure 14 left) and<br />

to decrease the <strong>in</strong>ternal exhaust gas recirculation <strong>in</strong> transient<br />

operation.<br />

Eng<strong>in</strong>e torque [N.m]<br />

200<br />

150<br />

100<br />

50<br />

0<br />

1.2 SI Eng<strong>in</strong>e torque response<br />

PWS83_constant_speed<br />

Turbo<br />

PWS83_with_speed_control<br />

1 1.5 2 2.5 3 3.5 4 4.5 5<br />

Time [s]<br />

PWS speed [rpm]<br />

PWS speed control dur<strong>in</strong>g the load step<br />

19000<br />

18000<br />

17000<br />

16000<br />

15000<br />

14000<br />

13000<br />

12000<br />

1 1.5 2 2.5 3 3.5 4 4.5 5<br />

Time [s]<br />

Figure 14: Eng<strong>in</strong>e torque and its remedy dur<strong>in</strong>g the load step<br />

of spark ignited 1.2l eng<strong>in</strong>e at eng<strong>in</strong>e speed of 2000rpm from<br />

[38]<br />

EXPERIMENTAL TESTS ON PWS<br />

For the eng<strong>in</strong>e 1-D simulation, presented <strong>in</strong> this paper, a<br />

PWS model has been used, whose physical behavior was<br />

representative enough. From the 1-D eng<strong>in</strong>e simulation a<br />

favorable PWS low end torque behavior and transient response<br />

arise. Moreover, the PWS could be with advantage used for<br />

control of quantity of recycled exhaust gas to combustion<br />

eng<strong>in</strong>e. However, the <strong>in</strong>ternal exhaust gas recirculation, boost<br />

pressure and mass flow value should be checked and settled to<br />

enable the model. Therefore, to keep develop<strong>in</strong>g 1-D model of<br />

supercharg<strong>in</strong>g system with PWS the PWS operat<strong>in</strong>g po<strong>in</strong>ts<br />

have been tested and measured at the combustion chamber test<br />

bench with open circuit (Figure 15). The specimen of tested<br />

PWS was model CX93 used by Mazda Company for<br />

supercharg<strong>in</strong>g of 2.0l diesel eng<strong>in</strong>e [27].<br />

In framework of experimental test<strong>in</strong>g of PWS the mass flow<br />

range at PWS air <strong>in</strong>let (AI), air outlet (AO) and exhaust <strong>in</strong>let<br />

(EI), the PWS speed range and range of the PWS exhaust <strong>in</strong>let<br />

(EI) temperature have been largely explored.<br />

5 Copyright © 2007 by ASME

Electrical motor<br />

Mass flow control<br />

m2<br />

(0 to 200g/s)<br />

p2<br />

T2<br />

(RPMc from 0 to 20000)<br />

p1<br />

m2, C<br />

AO<br />

AI<br />

m1<br />

p1 pressure control (1 to 3b)<br />

Tatm<br />

Noise<br />

Figure 15: Scheme of the test bed<br />

p3 T3<br />

EI<br />

EO<br />

Mass flow control<br />

m3<br />

(0 to 200g/s)<br />

p4<br />

m3, C<br />

Backpressure<br />

floodgate<br />

p4 pressure control (1 to 3 b)<br />

The PWS test bench has been created us<strong>in</strong>g the exist<strong>in</strong>g<br />

turbocharger test bench (equipped with the combustion<br />

chamber and the external source of constant boost air pressure<br />

of 350 kPa and mass flow up to approximately 1000 kg/h) and<br />

its adopt<strong>in</strong>g for PWS tests at Josef Božek Research Center<br />

(JBRC) - Figure 16.<br />

AI<br />

Figure 16: PWS at the combustion chamber test bed<br />

Mass flow and temperature have been enforced at the exhaust<br />

<strong>in</strong>let (EI). EI mass flow was cont<strong>in</strong>uous and has been varied<br />

between 0-200 g/s. Air outlet (AO) and exhaust <strong>in</strong>let (EI) mass<br />

flows have been controlled separately by means of remotely<br />

controlled slide valves enabl<strong>in</strong>g precise tun<strong>in</strong>g of flows. Mass<br />

flow at air outlet (AO) has been controlled at the same value as<br />

that of exhaust <strong>in</strong>let (EI). The temperature has been scanned<br />

from 800K to 1050K at exhaust <strong>in</strong>let.<br />

Measur<strong>in</strong>g of EI and AO mass flows has been performed us<strong>in</strong>g<br />

meter<strong>in</strong>g orifices <strong>in</strong> pipel<strong>in</strong>es. AI mass flow has been measured<br />

us<strong>in</strong>g <strong>in</strong>take nozzle.<br />

EI<br />

AO<br />

EO<br />

All temperature measurements have been carried out by<br />

electrically isolated thermocouples. The most problematic<br />

temperature measurement was the temperature T3 at EI after the<br />

combustion chamber. Therefore, five thermocouples have been<br />

utilized to obta<strong>in</strong> the temperature distribution with<strong>in</strong> the<br />

manifold.<br />

To estimate the <strong>in</strong>ternal exhaust gas recirculation of PWS molar<br />

fractions of CO2 at EI and AO have been measured by means of<br />

exhaust gas analyzer.<br />

The PWS has been driven directly by electrical motor, whose<br />

speed has been controlled by frequency converter and could<br />

vary between 0-20000 rpm. The PWS speed has been measured<br />

us<strong>in</strong>g optical sensor. As the PWS had to be braked <strong>in</strong> specific<br />

operation regimes, the brake resistors had to be additionally<br />

connected to the frequency converter.<br />

In framework of this project a new automated data acquisition<br />

system has been developed under the Testpo<strong>in</strong>t development<br />

environment, which enabled to display all <strong>in</strong>stant measured<br />

values and control panel with diagrams show<strong>in</strong>g their trends<br />

(Figure 17).<br />

DAQ Control Panel<br />

with time history<br />

diagram for settl<strong>in</strong>g<br />

identification<br />

Gas analyzer<br />

display<br />

Figure 17: Displays of measured values and DAQ software<br />

control panel with time history diagrams.<br />

Performance maps of measured PWS<br />

Diagrams on Figure 18-Figure 23 show performance maps for<br />

exhaust <strong>in</strong>let temperature of 900K. The total PWS efficiency,<br />

AO temperature, <strong>in</strong>ternal exhaust gas recirculation, air <strong>in</strong>let<br />

mass flow and electrical <strong>in</strong>put to PWS are depicted legible <strong>in</strong><br />

form commonly used for turbochargers, so these maps can be<br />

with advantage used for direct comparison to turbochargers<br />

maps.<br />

From the flow characteristics diagram on Figure 18 the<br />

<strong>in</strong>fluence of PWS speed on boost pressure ratio is clearly<br />

visible. For PWS speed from 14000 rpm to 18000 rpm the<br />

highest PWS total efficiencies are achieved (Figure 19).<br />

Lower<strong>in</strong>g of the PWS speed decreases the PWS efficiency and<br />

<strong>in</strong>creases the boost pressure (Figure 18). From a certa<strong>in</strong> mass<br />

flow, here for mass flow higher than 550kg/h, the PWS boost<br />

pressure ratio falls abruptly down.<br />

6 Copyright © 2007 by ASME

Figure 18: PWS performance map of PWS speed for EI<br />

temperature of 900K<br />

Internal exhaust gas recirculation over the channeled rotor is<br />

presented <strong>in</strong> Figure 20. In the PWS speed range from<br />

10000rpm to 20000rpm no recirculation appears up to the mass<br />

flow of 400kg/h.<br />

The AO temperatures traces are shown <strong>in</strong> Figure 21. Up to the<br />

PWS speed of 16000 rpm the <strong>in</strong>crease of PWS speed decreases<br />

the AO temperature. AO temperature starts to rise significantly<br />

bellow the PWS speed of 10000 rpm.<br />

The PWS sucks <strong>in</strong> AI much more fresh air than it delivers to<br />

the air outlet. Amount of sucked fresh air <strong>in</strong>creases with the<br />

<strong>in</strong>crease of the AO mass flow (Figure 22) whereas for the EI<br />

mass flows from 400 to 650 kg/h there is no considerable<br />

difference between the sucked amounts of fresh air <strong>in</strong>to PWS.<br />

The diagram on Figure 23 presents power <strong>in</strong>put to the electrical<br />

motor, which drives the PWS. The negative sign of the power<br />

<strong>in</strong>put means that the PWS drives the el. motor.<br />

Figure 19: PWS performance map of PWS total efficiency for<br />

EI temperature of 900K<br />

Figure 20: PWS performance map of <strong>in</strong>ternal exhaust gas<br />

recirculation for EI temperature of 900K<br />

Figure 21: PWS performance map of air outlet (AO)<br />

temperature for EI temperature of 900K<br />

Figure 22: PWS performance map for air <strong>in</strong>let mass flow for<br />

EI temperature of 900K<br />

7 Copyright © 2007 by ASME

Figure 23: PWS performance map for electrical power<br />

<strong>in</strong>put/output of PWS for temperature of 900K<br />

Influence of the temperature at PWS exhaust <strong>in</strong>let<br />

Diagrams <strong>in</strong> Figure 24-Figure 27 present <strong>in</strong>fluence of the<br />

EI temperature for four different levels of EI pressure p3 (1.5,<br />

2, 2.5 and 3 bar - absolute). The PWS operation po<strong>in</strong>ts have<br />

been measured for EI temperature of 800K, 900K and 1050K.<br />

The <strong>in</strong>crease of the EI temperature <strong>in</strong>creases the boost pressure.<br />

The highest EI temperature of 1050K extended the range where<br />

the boost pressure is higher than the back pressure p3 (Figure<br />

24).<br />

p2 [kPa]<br />

200<br />

150<br />

100<br />

50<br />

Relative pressures<br />

0<br />

0 5000 10000 15000 20000 25000<br />

PWS speed [rpm]<br />

p3=50kPa T3=800K p3=100kPa T3=800K p3=150kPa T3=800K p3=200kPa T3=800K<br />

p3=50kPa T3=900K p3=100kPa T3=900K p3=150kPa T3=900K p3=200kPa T3=900K<br />

p3=50kPa T3=1050K p3=100kPa T3=1050K p3=150kPa T3=1050K p3=200kPa T3=1050K<br />

Figure 24: Boost pressure <strong>in</strong> dependence on the EI temperature<br />

m3 [kg/h]<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

0 5000 10000 15000 20000 25000<br />

PWS speed [rpm]<br />

p3=50kPa T3=800K p3=100kPa T3=800K p3=150kPa T3=800K p3=200kPa T3=800K<br />

p3=50kPa T3=900K p3=100kPa T3=900K p3=150kPa T3=900K p3=200kPa T3=900K<br />

p3=50kPa T3=1050K p3=100kPa T3=1050K p3=150kPa T3=1050K p3=200kPa T3=1050K<br />

Figure 25: EI mass flow <strong>in</strong> dependence on the EI temperature<br />

A lower EI mass flow is necessary with EI temperature <strong>in</strong>crease<br />

to achieve the same EI pressure (Figure 25). The <strong>in</strong>crease <strong>in</strong> EI<br />

temperature decreases the <strong>in</strong>ternal exhaust gas recirculation<br />

(Figure 26) and deteriorates the PWS efficiency (Figure 27).<br />

egr [1]<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

0 5000 10000 15000 20000 25000<br />

PWS speed [rpm]<br />

p3=50kPa T3=800K p3=100kPa T3=800K p3=150kPa T3=800K p3=200kPa T3=800K<br />

p3=50kPa T3=900K p3=100kPa T3=900K p3=150kPa T3=900K p3=200kPa T3=900K<br />

p3=50kPa T3=1050K p3=100kPa T3=1050K p3=150kPa T3=1050K p3=200kPa T3=1050K<br />

Figure 26: Internal exhaust gas recirculation <strong>in</strong> dependence on<br />

EI temperature<br />

etaPWS [1]<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0 5000 10000 15000 20000 25000<br />

PWS speed [rpm]<br />

p3=100kPa T3=800K p3=100kPa T3=900K p3=100kPa T3=1050K<br />

Figure 27: Total efficiency of PWS <strong>in</strong> dependence on EI<br />

temperature<br />

Influence of Flow Losses <strong>in</strong> Air Inlet<br />

The <strong>in</strong>fluence of the flow losses <strong>in</strong> AI has been<br />

<strong>in</strong>vestigated at EI temperature of 900K and PWS speed of<br />

15000 rpm for two orifice plates with diameters of 35 mm and<br />

50 mm (orig<strong>in</strong> AI manifold diameter of 100 mm).<br />

The orifice with diameter 35 mm deteriorates the boost<br />

pressure significantly above the mass flow of 400 kg/h. The<br />

throttl<strong>in</strong>g of the AI mass flow <strong>in</strong>creases the AO and EO<br />

temperatures and the <strong>in</strong>ternal exhaust gas recirculation. On the<br />

other hand, the reduction of the AI mass flow improves the<br />

PWS efficiency at low EI mass flow rates (Figure 29 left).<br />

All diagrams described <strong>in</strong> above paragraphs have been<br />

measured without boost pressure control us<strong>in</strong>g waste gate<br />

(WG). Diagrams <strong>in</strong> Figure 28 and Figure 29 show <strong>in</strong>fluence of<br />

waste gate control on PWS operation, as well. The waste gate<br />

trims the boost pressure and tries to keep it approx. constant<br />

(Figure 28 left). The waste gate does not <strong>in</strong>fluence the <strong>in</strong>ternal<br />

exhaust gas recirculation (Figure 29 right).<br />

8 Copyright © 2007 by ASME

πC [1]<br />

2.60<br />

2.40<br />

2.20<br />

2.00<br />

1.80<br />

1.60<br />

1.40<br />

1.20<br />

1.00<br />

dia 35 mm<br />

dia 50 mm<br />

WG<br />

w / o Loss<br />

0 100 200 300 400 500 600 700<br />

m 2red [kg/h]<br />

p1 [kPa]<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

dia 35 mm<br />

3<br />

2<br />

1<br />

dia 50 mm<br />

0 100 200 300 400<br />

m3 [kg/h]<br />

500 600 700<br />

Figure 28: Influence of pressure losses (right) and waste gate<br />

on pressure ratio <strong>in</strong> dependence on reduced AO mass flow<br />

etaPWS [1]<br />

0.50<br />

0.45<br />

0.40<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

dia 35 mm<br />

0.15<br />

dia 50 mm<br />

0.10<br />

0.05<br />

0.00<br />

WG<br />

w / o Loss<br />

0 100 200 300 400 500 600 700<br />

m2, m3 [kg/h]<br />

egr [1]<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

0.00<br />

dia 35 mm<br />

dia 50 mm<br />

WG<br />

w / o Loss<br />

0 100 200 300 400 500 600 700<br />

m2, m3 [kg/h]<br />

Figure 29: Influence of pressure losses <strong>in</strong> AI manifold on PWS<br />

efficiency and <strong>in</strong>ternal egr<br />

Influence of Flow Losses <strong>in</strong> Exhaust Outlet<br />

The EO pressure has been <strong>in</strong>creased us<strong>in</strong>g throttle which has<br />

been controlled by stepper electric motor. A snail gear box has<br />

been placed between the throttle and the electrical motor to<br />

prevent throttle flapp<strong>in</strong>g by EO flow.<br />

PWS<br />

EO<br />

Flow losses<br />

Figure 30: EO throttle controlled by stepper electrical motor<br />

with snail box<br />

Diagrams <strong>in</strong> Figure 31 and Figure 32 present the sensitivity of<br />

the PWS on the EO pressure for EI mass flows of (100,300,400<br />

and 500) kg/h and for EI temperature of 900K. The PWS speed<br />

has been kept at 15 000rpm. The change <strong>in</strong> EO pressure by<br />

2kPa deteriorates the boost pressure significantly (Figure 31).<br />

The <strong>in</strong>creased EO pressure lowers the amount of sucked AI<br />

mass flow and <strong>in</strong>creases the <strong>in</strong>ternal exhaust gas recirculation<br />

rises (Figure 32).<br />

Moreover, <strong>in</strong>creased EO pressure may cause the back flow of<br />

the exhaust gas to the AI.<br />

Relative pressure p2 [kPa]<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

100kg/h 300kg/h 400kg/h 500kg/h<br />

0<br />

95.5 96 96.5 97 97.5 98 98.5 99 99.5<br />

Absolute pressure p4 [kPa]<br />

Figure 31: Influence of the EO pressure on the boost pressure<br />

egr [1]<br />

0.45<br />

0.4<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

100kg/h 300kg/h 400kg/h 500kg/h<br />

0<br />

95.5 96 96.5 97 97.5 98 98.5 99 99.5<br />

Absolute pressure p4 [kPa]<br />

Figure 32: Influence of the EO pressure on the AI mass flow<br />

Supercharg<strong>in</strong>g of the PWS<br />

In framework of the measurement the feasibility of the<br />

PWS for the two stage supercharg<strong>in</strong>g has been <strong>in</strong>vestigated.<br />

To enable pressure <strong>in</strong>crease <strong>in</strong> AI the test bench has been<br />

equipped with <strong>in</strong>let pipel<strong>in</strong>e of pressurized air (Figure 33).<br />

External source could deliver constant boost air pressure of<br />

350kPa and mass flow approx. of 1000kg/h <strong>in</strong>to AI. AI mass<br />

flow has been controlled us<strong>in</strong>g slide valve, which has been<br />

actuated by an electric stepper motor. Moreover, meter<strong>in</strong>g<br />

orifice has been placed <strong>in</strong>to the AI pipel<strong>in</strong>e.<br />

The measurement has been performed for EI mass flow of 300<br />

kg/h and for two different PWS speeds of 15000 rpm (Figure<br />

34) and 10000 rpm (Figure 35). As <strong>in</strong> the all previous<br />

paragraphs the mass flow at air outlet (AO) has been controlled<br />

at the same value as that of exhaust <strong>in</strong>let (EI). The EI<br />

temperature has been kept at 900K. For the fully opened EO<br />

throttle (Figure 30) the air <strong>in</strong>let mass flow has been set to be<br />

the same as the naturally aspirated mass flow for this PWS<br />

operation po<strong>in</strong>t. By adjust<strong>in</strong>g of the EO throttle the EO and AI<br />

pressures have been <strong>in</strong>creased.<br />

9 Copyright © 2007 by ASME

Figure 33: Supercharg<strong>in</strong>g of PWS<br />

The boost pressure and EI pressure rise with the AI pressure<br />

<strong>in</strong>crease both for 10000 rpm and 15000rpm (Figure 34 and<br />

Figure 35 left).The boost pressure <strong>in</strong>creases by the same value<br />

as that set at AI.<br />

The AI mass flow did not change with the AI pressure <strong>in</strong>crease<br />

(Figure 34 and Figure 35 right). No <strong>in</strong>ternal exhaust gas<br />

recirculation appeared at both cases.<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Relative pressures [kPa]<br />

PWS Supercharg<strong>in</strong>g<br />

15 000 rpm, m2=m3=300 kg/h, T3=900K<br />

p2_300<br />

p3_300<br />

p4_300<br />

0 10 20 30 40 50 60 70<br />

Relative pressure p1 [kPa]<br />

m1, m2, m3 [kg/h]<br />

580<br />

530<br />

480<br />

430<br />

380<br />

330<br />

280<br />

230<br />

180<br />

Mass flows<br />

m1<br />

m2<br />

m3<br />

0 10 20 30 40 50 60 70<br />

Relative pressure p1 [kPa]<br />

Figure 34: Influence of AI pressure on AO, EI and EO<br />

pressures and on AI mass flow for PWS speed of 15000 rpm<br />

Relative pressures [kPa]<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Pipel<strong>in</strong>e of pressurized<br />

air to PWS air <strong>in</strong>let<br />

PWS Supercharg<strong>in</strong>g<br />

10 000 rpm, m2=m3=300 kg/h, T3=900K<br />

p2_300<br />

p3_300<br />

p4_300<br />

0 20 40 60 80 100 120<br />

Relative pressure p1 [kPa]<br />

m1, m2, m3 [kg/h]<br />

580<br />

530<br />

480<br />

430<br />

380<br />

330<br />

280<br />

230<br />

180<br />

Mass flows<br />

m1<br />

m2<br />

m3<br />

0 20 40 60 80 100 120<br />

Relative pressure p1 [kPa]<br />

Figure 35: Influence of AI pressure on AO, EI and EO<br />

pressures and on AI mass flow for PWS speed of 10000 rpm<br />

COMPARISON OF 1-D MODEL SIMULATION TO<br />

MEASUREMENT<br />

To compare the simulation results to measurements a 1-D<br />

model of the tested PWS at the test bench has been developped<br />

<strong>in</strong> GT-Power, whereas the PWS without pockets has been<br />

simulated. Analogous to experiment the mass flow at air outlet<br />

(AO <strong>in</strong> Figure 15) has been controlled at the same value as that<br />

of exhaust <strong>in</strong>let (EI).<br />

Diagrams on Figure 36 and Figure 37 present comparison of<br />

boost pressure p2, back pressure p3, air <strong>in</strong>let mass flow and<br />

<strong>in</strong>ternal exhaust gas recirculation for constant exhaust <strong>in</strong>let<br />

mass flow of 300kg/h. (In Annex A the same comparison is<br />

shown for EI mass flows of 100kg/h, 400kg/h and 500kg/h.)<br />

The 1-D model predicts maximal boost pressure higher than the<br />

measured one (Figure 36). The simulated difference between<br />

boost pressure and back pressure is higher and <strong>in</strong> larger PWS<br />

speed range than measured one. 1-D PWS model recirculates<br />

more exhaust gas than the real PWS (Figure 37 right).<br />

Boost and back pressure comparison<br />

2.50<br />

2.40<br />

2.30<br />

2.20<br />

2.10<br />

2.00<br />

1.90<br />

1.80<br />

1.70<br />

1.60<br />

1.50<br />

1.40<br />

1.30<br />

1.20<br />

1.10<br />

1.00<br />

0 5000 10000 15000 20000<br />

PWS speed [rpm]<br />

p2-300kg/h-measured p3-300kg/h measured<br />

p2-300kg/h 1-D model without pockets p3-300kg/h 1-D model without pockets<br />

Absolute pressure [bar]<br />

Figure 36: Comparison of measured and computed pressures<br />

for EI mass flow of 300kg/h<br />

Mass flow comparison<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 5000 10000 15000 20000<br />

PWS speed [rpm]<br />

m1-300kg/h-measured m1-300kg/h 1-D model without pockets<br />

m2-300kg/h 1-D model without pockets m3-300kg/h 1-D model without pockets<br />

Mass flow [g/sec]<br />

EGR [1]<br />

Internal exhaust gas recirculation<br />

0.4<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

0<br />

0 5000 10000 15000 20000<br />

PWS speed [rpm]<br />

egr-300kg/h-measured egr-300kg/h 1-D model without pockets<br />

Figure 37: Comparison of measured and computed AI mass<br />

flow and <strong>in</strong>ternal exhaust gas recirculation for EI mass flow of<br />

300kg/h<br />

Diagrams on Figure 38 - Figure 41 compare 1-D simulation<br />

results for three different EI temperatures (800K, 900K and<br />

1050K) and for constant EI pressure of 2 barAbsolute. The<br />

qualitative reaction of the 1-D model on EI temperature change<br />

is <strong>in</strong> a good agreement with the measurement for every<br />

observed quantity. The boost pressure <strong>in</strong>creases with the EI<br />

temperature. The maximal simulated boost pressure is for every<br />

temperature higher than the EI pressure (Figure 38). An<br />

<strong>in</strong>crease of EI temperature <strong>in</strong>creases the amount of fresh air<br />

which is sucked <strong>in</strong>to the PWS (Figure 40) and decreases the<br />

<strong>in</strong>ternal exhaust gas recirculation (Figure 41).<br />

p2 [bar]<br />

2.40<br />

2.30<br />

2.20<br />

2.10<br />

2.00<br />

1.90<br />

1.80<br />

1.70<br />

1.60<br />

1.50<br />

Absolute boost pressure<br />

for absolute back pressure of p3=2bar<br />

0 5000 10000<br />

PWS speed [rpm]<br />

15000 20000<br />

p3=2bar T3=800K measured p3=2bar T3=900K measured<br />

p3=2bar T3=1050K measured p3=2bar T3=800K 1-D model w/o pockets<br />

p3=2bar T3=900K 1-D model w/o pockets p3=2bar T3=1050K 1-D model w/o pockets<br />

Figure 38: Comparison of measured and computed boost<br />

pressures for tree different EI temperatures and constant EI<br />

absolute pressure of 2bar<br />

10 Copyright © 2007 by ASME

m2 [g/s]<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Air outlet mass flow<br />

for absolute back pressure of p3=2bar<br />

p3=2bar T3=800K measured<br />

p3=2bar T3=900K measured<br />

p3=2bar T3=1050K measured<br />

p3=2bar T3=800K 1D model w/o pockets<br />

p3=2bar T3=900K 1D model w/o pockets<br />

p3=2bar T3=1050K 1D model w/o pockets<br />

0 5000 10000<br />

PWS speed [rpm]<br />

15000 20000<br />

Figure 39: Comparison of measured and computed air outlet<br />

mass flows for tree different EI temperatures and constant EI<br />

pressure of 2bar<br />

m1 [g/s]<br />

160<br />

140<br />

120<br />

100<br />

80<br />

Air <strong>in</strong>let mass flow<br />

for absolute back pressure of p3=2bar<br />

60<br />

0 5000 10000<br />

PWS speed [rpm]<br />

15000 20000<br />

p3=2bar T3=800K measured p3=2bar T3=900K measured<br />

p3=2bar T3=1050K measured p3=2bar T3=800K 1D model w/o pockets<br />

p3=2bar T3=900K 1D model w/o pockets p3=2bar T3=1050K 1D model w/o pocktes<br />

Figure 40: Comparison of measured and computed air <strong>in</strong>let<br />

mass flows for tree different EI temperatures and constant EI<br />

absolute pressure of 2bar<br />

EGR [%]<br />

0.30<br />

0.20<br />

0.10<br />

Internal exhaust gas recirculation<br />

for absolute back pressure of p3=2bar<br />

0.00<br />

0 5000 10000<br />

PWS speed [rpm]<br />

15000 20000<br />

p3=2bar T3=800K measured p3=2bar T3=900K measured<br />

p3=2bar T3=1050K measured p3=2bar T3=800K 1D model w/o pockets<br />

p3=2bar T3=900K 1D model w/o pockets p3=2bar T3=1050K 1D model w/o pockets<br />

Figure 41: Comparison of measured and computed <strong>in</strong>ternal<br />

exhaust gas recirculations for tree different EI temperatures and<br />

constant EI absolute pressure of 2bar<br />

PWS model with all pockets has been simulated, as well (see<br />

diagrams on Figure 42 and Figure 43). Pockets extended the<br />

work<strong>in</strong>g range of the PWS model. Nevertheless, the modeled<br />

pockets <strong>in</strong>creased the boost pressure <strong>in</strong> low PWS speed too<br />

much <strong>in</strong> comparison to measurement.<br />

Absolute pressure [bar]<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

Absolute pressure comparison<br />

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000<br />

PWS speed [rpm]<br />

p3-300kg/h with pockets p2-300kg/h with pockets<br />

p2-300kg/h-measured p3-300kg/h-measured<br />

p2-300kg/h without pockets p3-300kg/h without pockets<br />

Figure 42: Comparison of measured and computed pressures<br />

for EI mass flow of 300kg/h and 1-D PWS model with pockets<br />

Mass flow [g/sec]<br />

Mass flow comparison<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

m3-300kg/h with pockets m2-300kg/h with pockets<br />

20<br />

0<br />

m1-300kg/h with pockets<br />

m1-300kg/h without pockets<br />

m1-300kg/h-measured<br />

0 5000 10000<br />

PWS speed [rpm]<br />

15000 20000<br />

EGR [1]<br />

EGR comparison<br />

1<br />

0.9<br />

egr-300kg/h with pockets egr-300kg/h-measured<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

egr-300kg/h without pockets<br />

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000<br />

PWS speed [rpm]<br />

Figure 43: Comparison of measured and computed AI mass<br />

flow and <strong>in</strong>ternal exhaust gas recirculation for EI mass flow of<br />

300kg/h and 1-D PWS model with pockets<br />

Presented and described comparisons <strong>in</strong> diagrams above<br />

<strong>in</strong>dicate that the flow losses <strong>in</strong> the 1-D model of PWS rotor<br />

channel should be tuned with regard to pressure traces to come<br />

closer to the measurement. Follow<strong>in</strong>g paragraph discusses the<br />

problematic of <strong>in</strong>creased simulated exhaust gas recirculation <strong>in</strong><br />

comparison to measurement.<br />

In the channel of the PWS rotor the fresh air and exhaust gas<br />

are <strong>in</strong> direct contact. GT-Power is based on the f<strong>in</strong>ite volume<br />

method. Thus, the 1-D model is discretized <strong>in</strong>to many volumes<br />

and the solution is carried out by time <strong>in</strong>tegration of equations<br />

of cont<strong>in</strong>uity, energy and momentum. F<strong>in</strong>er discretization<br />

results <strong>in</strong> better accuracy and extends the computation time<br />

vice versa.<br />

Diagrams <strong>in</strong> Figure 44 and Figure 45 show <strong>in</strong>fluence of the<br />

discretization length on the simulated results. The <strong>in</strong>fluence has<br />

been <strong>in</strong>vestigated for constant mass flow of 300kg/h and EI<br />

temperature of 900K. By lower<strong>in</strong>g of the dicretization length<br />

by one third of the orig<strong>in</strong>al length (here to 5mm) the <strong>in</strong>ternal<br />

exhaust gas recirculation decreased by 10% (Figure 45) and the<br />

simulated boost pressure <strong>in</strong>creased by 5%. At the same time the<br />

computation time has been 1.8 times longer than the orig<strong>in</strong>al<br />

one.<br />

11 Copyright © 2007 by ASME

2.50<br />

2.40<br />

2.30<br />

2.20<br />

2.10<br />

2.00<br />

1.90<br />

1.80<br />

1.70<br />

1.60<br />

1.50<br />

1.40<br />

1.30<br />

1.20<br />

1.10<br />

1.00<br />

Absolute pressure [bar]<br />

Absolute pressure comparison<br />

p2-300kg/h-measured<br />

p3-300kg/h measured<br />

p2-300kg/h 1-D model without pockets<br />

p3-300kg/h 1-D model without pockets<br />

p2-300kg/h 1-D model without pockets with dx=5mm<br />

p3-300kg/h 1-D model without pockets with dx=5mm<br />

0 5000 10000 15000 20000<br />

PWS speed [rpm]<br />

Figure 44: Influence of discretization length of PWS rotor<br />

channel on pressure traces<br />

Mass flow [g/sec]<br />

Mass flow comparison<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

m1-300kg/h-measured<br />

40<br />

m1-300kg/h 1-D model without pockets<br />

m2-300kg/h 1-D model without pockets<br />

20<br />

m3-300kg/h 1-D model without pockets<br />

0<br />

m1-300kg/h 1-D model without pockets with dx=5mm<br />

0 5000 10000<br />

PWS speed [rpm]<br />

15000 20000<br />

0.5<br />

0.45<br />

0.4<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

0<br />

EGR [1]<br />

EGR comparison<br />

egr-300kg/h-measured<br />

egr-300kg/h 1-D model without pockets<br />

egr-300kg/h 1-D model without pockets with dx=5mm<br />

5000 7000 9000 11000 13000 15000 17000 19000<br />

PWS speed [rpm]<br />

Figure 45: Influence of discretization length of PWS rotor<br />

channel on computed mass flow and <strong>in</strong>ternal exhaust gas<br />

recirculation<br />

PWS IN FUEL CELL APPLICATIONS<br />

Fuel cells are among the most promis<strong>in</strong>g alternative<br />

energy sources of the future with regard to clean and efficient<br />

power generation [33]. Hydrogen reacts with oxygen produc<strong>in</strong>g<br />

water, electric current and heat. Runn<strong>in</strong>g of the fuel cell at<br />

higher pressure <strong>in</strong>creases the power due to the polarization<br />

curve improvement [32], [35] and reduces the cell dimensions.<br />

Therefore, the fuel cells of 10kW or more utilize boost<strong>in</strong>g<br />

device for air compression to <strong>in</strong>crease oxygen partial pressure<br />

[32]. As the flow through the fuel cell can be described as the<br />

flow through a throttle the boost pressure has to be higher than<br />

the back pressure. The proton exchange membrane (PEM) fuel<br />

cell, the most preferred fuel cell type for automotive systems,<br />

must have sufficient water content <strong>in</strong> the polymer electrolyte<br />

and the humidity of the air must be carefully controlled [32].<br />

From the combustion chamber measurement of the tested PWS<br />

model CX93 follows (Figure 24) that its boost pressure is<br />

higher than the back pressure for EI temperature higher than<br />

900K. This makes a burner PWS upstream necessary to have<br />

enough energy for air compression. Due to the direct contact of<br />

air and vapor <strong>in</strong> the rotor channel, the PWS could be of<br />

advantage if used for air humidification realized by throttl<strong>in</strong>g at<br />

AI of PWS (Figure 29).<br />

Us<strong>in</strong>g the 1-D simulation the PWS93 with <strong>in</strong> [7] patented<br />

geometry, which provided significantly <strong>in</strong>creased boost<br />

pressure (Figure 1), has been computed at the test bench for<br />

back pressure of 2barAbsolute and EI temperatures of 150°C and<br />

500°C. From the diagrams (Figure 46 and Figure 47) is visible<br />

that at the lower temperature of 150°C the PWS is unsuitable<br />

for full cell applications. At the temperature of 500°C the boost<br />

pressure surpass the back pressure. Another way of us<strong>in</strong>g PWS<br />

for this purpose would be a comb<strong>in</strong>ation with serial connected,<br />

electric driven, compressor, which is necessary as a starter <strong>in</strong><br />

any case.<br />

Absolute boost pressure for absolute back pressure<br />

of 2bar<br />

2.2<br />

2.1<br />

2<br />

1.9<br />

1.8<br />

1.7<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1<br />

6000 6500 7000 7500 8000<br />

PWS speed [rpm]<br />

8500 9000 9500 10000<br />

Absolute pressure p2 [bar]<br />

p3=2bar T3=150degC 1-D model without pockets<br />

p3=2bar T3=500degC 1-D model without pockets<br />

Figure 46: Computed boost pressure for back pressure of 2bar<br />

and two different temperatures<br />

Air outlet mass flow for absolute back pressure of<br />

2bar<br />

131<br />

121<br />

111<br />

101<br />

91<br />

81<br />

71<br />

61<br />

51<br />

41<br />

31<br />

21<br />

11<br />

1<br />

6000 6500 7000 7500 8000<br />

PWS speed [rpm]<br />

8500 9000 9500 10000<br />

AO mass flow m2 [g/sec]<br />

p3=2bar T3=150degC 1-D model without pockets<br />

p3=2bar T3=500degC 1-D model without pockets<br />

Figure 47: Computed air outlet mass flow for back pressure of<br />

2bar and two different temperatures<br />

CONCLUSIONS<br />

In framework of the study presented <strong>in</strong> this paper the<br />

pressure wave supercharger (PWS) has been <strong>in</strong>vestigated us<strong>in</strong>g<br />

1-D eng<strong>in</strong>e simulation and experimental measurement at the<br />

combustion chamber test bench.<br />

1-D simulation of different PWS sizes contributed to<br />

understand<strong>in</strong>g of PWS behavior <strong>in</strong> eng<strong>in</strong>e application. The<br />

PWS has higher boost pressure at low eng<strong>in</strong>e speeds than the<br />

turbocharger. Us<strong>in</strong>g the variable transmission ratio between the<br />

PWS and the eng<strong>in</strong>e the boost pressure can be hold on high<br />

level over the whole eng<strong>in</strong>e speed range. Whereas the eng<strong>in</strong>e<br />

speed <strong>in</strong>creases the scaveng<strong>in</strong>g of the PWS rotor decreases. At<br />

the highest eng<strong>in</strong>e speeds the <strong>in</strong>ternal exhaust gas recirculation<br />

rises and deteriorates the eng<strong>in</strong>e power. The variable gas pocket<br />

improves the rotor scaveng<strong>in</strong>g and can be with advantage used<br />

for boost pressure control. Dur<strong>in</strong>g the transient operation the<br />

<strong>in</strong>creased <strong>in</strong>ternal exhaust gas recirculation appeared. Change<br />

of PWS speed dur<strong>in</strong>g the load step improved transient<br />

behavior.<br />

The PWS has been largely explored at the combustion chamber<br />

test bench and performance maps of measured PWS created.<br />

The measurement showed high sensitivity of PWS on flow<br />

losses ma<strong>in</strong>ly <strong>in</strong> exhaust outlet. Pressure <strong>in</strong>crease <strong>in</strong> air <strong>in</strong>let of<br />

PWS <strong>in</strong>creases the boost pressure by the same pressure.<br />

12 Copyright © 2007 by ASME

The 1-D model of PWS at the test bench has been created to<br />

compare simulation to experiment. The established database of<br />

measured data creates very good basis for further 1-D model<br />

calibration. The qualitative reaction of PWS model is <strong>in</strong> a very<br />

good agreement with the measurement. The 1-D model predicts<br />

higher difference between boost pressure and back pressure and<br />

<strong>in</strong> larger PWS speed range than measurements. In next steps<br />

ma<strong>in</strong>ly the flow losses <strong>in</strong> the model should be tuned to calibrate<br />

the model.<br />

Utilization of the PWS <strong>in</strong> the fuel cell application makes a<br />

burner PWS upstream necessary. 1-D model and measured<br />

database could be with advantage used for further<br />

<strong>in</strong>vestigations on this topic.<br />

NOMENCLATURE<br />

AI Air <strong>in</strong>let<br />

AO Air outlet<br />

C Molar fraction of CO2<br />

EI Exhaust <strong>in</strong>let<br />

EO Exhaust outlet<br />

etaPWS Total efficiency of PWS<br />

ISFC Indicated specific fuel consumption [g/kW/h]<br />

m1 Mass flow <strong>in</strong> AI [kg/h]<br />

m2 Mass flow <strong>in</strong> AO [kg/h]<br />

m2red Reduced air mass flow <strong>in</strong> AO [kg/h]<br />

m3 Air mass flow <strong>in</strong> EI [kg/h]<br />

p0 Ambient pressure [kPa]<br />

p2 Relative boost pressure [kPa]<br />

p3 Relative EI pressure [kPa]<br />

p4 Relative EO pressure [kPa]<br />

piC Pressure ratio [1]<br />

PWS Pressure wave supercharger<br />

t0 Ambient temperature<br />

t1 Inlet temperature [deg C]<br />

t2 AO temperature [deg C]<br />

t3 EI average temperature [deg C]<br />

t4 EO temperature [deg C]<br />

ACKNOWLEDGMENTS<br />

The authors would like to express their grateful thanks to<br />

<strong>Czech</strong> turbocharger maker ČZ a.s., division Turbo, namely to<br />

Mr. Stulík, Mr. Havelka, Mr. Mach and division director Mr.<br />

P<strong>in</strong>kas for fruitful cooperation and support throughout the<br />

project. Special thank belongs to prof. Takats from JBRC for<br />

his k<strong>in</strong>dly help with tak<strong>in</strong>g CO2 measurement <strong>in</strong>to operation.<br />

Additional thanks belong also to author’s colleges from JBRC<br />

prof. Uhlíř and prof. Novák for their k<strong>in</strong>d help with tak<strong>in</strong>g of<br />

PWS electric drive <strong>in</strong>to operation.<br />

.<br />

REFERENCES<br />

[1] Spr<strong>in</strong>g, P.: Model<strong>in</strong>g and Control of Pressure-Wave<br />

Supercharged Eng<strong>in</strong>e Systems. Dissertation ETH Zürich 2006,<br />

No.16490<br />

[2] Weber, F., Guzzella, L.: Control Oriented Model<strong>in</strong>g of a<br />

Pressure Wave Supercharger. SAE Paper 2000-01-0567, 2000,<br />

pp. 91-100<br />

[3] Spr<strong>in</strong>g, P., Guzzella, L., Onder, C.: Optimal Control<br />

Strategy for a Pressure-Wave Supercharged SI Eng<strong>in</strong>e.<br />

<strong>Technical</strong> Paper, ICES2003-645, Spr<strong>in</strong>g <strong>Technical</strong> Conference<br />

of the ASME International Combustion Eng<strong>in</strong>e Division,<br />

Salzburg, Austria, 2003<br />

[4] Akbari, P., Nalim R., Müller,N.: A Review of Wave Rotor<br />

Technology and its Applications. IMECE2004-60082, 2004<br />

ASME International Mechanical Eng<strong>in</strong>eer<strong>in</strong>g Congress,<br />

Anaheim, California USA<br />

[5] Akbari, P., Müller,N.: Wave Rotor Research Program at<br />

Michigan State <strong>University</strong>. AIAA 2005-3844, 41 st<br />

AIAA/ASME/SAE/ASEE Jo<strong>in</strong>t Propulsion Conference and<br />

Exhibit, Tucson, Arizona<br />

[6] Iancu, F.: Integration of a Wave Rotor to an Ultra-Micro<br />

Gas Turb<strong>in</strong>e. Dissertation Michigan State <strong>University</strong> 2005,<br />

[7] Wenger, U., Mart<strong>in</strong>, R., Swissauto Eng. S.A.: Gas-Dynamic<br />

Pressure Mach<strong>in</strong>e. International Patent No.: WO 99/11913<br />

[8] Mart<strong>in</strong>, R., Wenger, U., Swissauto Eng S.A.:<br />

Gasdynamische Druckwellenmasch<strong>in</strong>e. European Patent, EP<br />

0 899 434 A1<br />

[9] Wenger, U., Mart<strong>in</strong>, R., Swissauto Eng S.A.: Verfahren zur<br />

Regelung e<strong>in</strong>er Verbrennungsmasch<strong>in</strong>e mit e<strong>in</strong>er<br />

gasdynamischen Druckwellenmasch<strong>in</strong>e. European Patent, EP<br />

1 375 858 A1<br />

[10] Oguri, Y., Suzuki, T., Yoshida, M., Cho, M.: Research on<br />

Adaptation of Pressure Wave Supercharger (PWS) to Gasol<strong>in</strong>e<br />

Eng<strong>in</strong>e. SAE Paper 2001-01-0368, 2001, pp. 101-107<br />

[11] Jenny, E.: Berechnungen und Modellversuche über<br />

Druckwellen grosser Amplituden <strong>in</strong> Auspuff-Leitungen.<br />

Dissertation ETH Zürich, Ameba Druck Basel 1949<br />

[12] Berchtold, M.: Druckwellenaufladung für kle<strong>in</strong>e<br />

Fahrzeug-Dieselmotoren. Schweizerische Bauzeitung 79, No.<br />

46, Switzerland, 1961, pp. 801-808<br />

[13] Shapiro, A. H.: The Dynamics and Thermodynamics of<br />

Compressible Fluid Flow. The Ronald Press Comp., New York<br />

1953<br />

[14] Piechna, J., Lisewski, P.: Numerical Analysis of Unsteady<br />

Two–Dimensional Flow Effects <strong>in</strong> the Comprex Supercharger.<br />

The Archive of Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Vol. XLV, No. 4,<br />

1998, pp. 341-351<br />

[15] Piechna, J.: Numerical Simulation of the Pressure Wave<br />

Supercharger – Effect of Pockets on the Comprex Supercharger<br />

Characteristics. The Archive of Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Vol.<br />

XLV, No. 4, 1998, pp. 305-323<br />

[16] Selerowicz, W., Piechna, J.: Comprex Type Supercharger<br />

as a Pressure-Wave Transformer Flow Characteristics. The<br />

Archive of Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Vol. XLVI, No. 1, 1999,<br />

pp. 57-77<br />

[17] Piechna, J.: Numerical Simulation of the Comprex Type of<br />

Supercharger: Comparison of Two Models of Boundary<br />

Condition. The Archive of Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Vol. XLV,<br />

No. 3, 1998, pp. 233-250<br />

13 Copyright © 2007 by ASME

[18] Zehnder, G.: Berechnung von Druckwellen <strong>in</strong> der<br />

Aufladetechnik. Brown Boveri Mitteilung, 4/5, 1971<br />

[19] Flückiger, L., Tafel, S., Spr<strong>in</strong>g, P.: Hochaufladung mit<br />

Druckwellenlader für Ottomotoren. MTZ 12, 2006, pp. 946-<br />

954<br />

[20] Guzzella, L., Mart<strong>in</strong>, R.: Das SAVE-Motorkonzept. MTZ<br />

10, 1998, pp. 644-650<br />