Textile - Research @ VTU

Textile - Research @ VTU

Textile - Research @ VTU

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

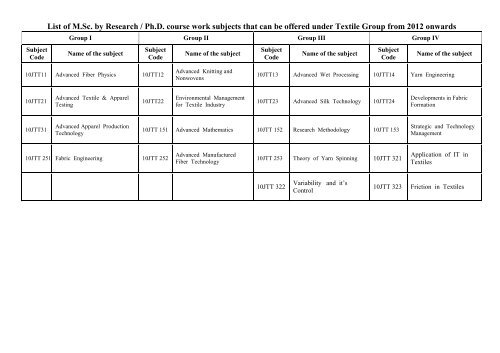

Subject<br />

Code<br />

List of M.Sc. by <strong>Research</strong> / Ph.D. course work subjects that can be offered under <strong>Textile</strong> Group from 2012 onwards<br />

Group I Group II Group III Group IV<br />

Name of the subject<br />

Subject<br />

Code<br />

10JTT11 Advanced Fiber Physics 10JTT12<br />

10JTT21<br />

10JTT31<br />

Advanced <strong>Textile</strong> & Apparel<br />

Testing<br />

Advanced Apparel Production<br />

Technology<br />

10JTT22<br />

10JTT 251 Fabric Engineering 10JTT 252<br />

Name of the subject<br />

Advanced Knitting and<br />

Nonwovens<br />

Environmental Management<br />

for <strong>Textile</strong> Industry<br />

Subject<br />

Code<br />

Name of the subject<br />

Subject<br />

Code<br />

Name of the subject<br />

10JTT13 Advanced Wet Processing 10JTT14 Yarn Engineering<br />

10JTT23 Advanced Silk Technology 10JTT24<br />

10JTT 151 Advanced Mathematics 10JTT 152 <strong>Research</strong> Methodology 10JTT 153<br />

Advanced Manufactured<br />

Fiber Technology<br />

10JTT 253 Theory of Yarn Spinning 10JTT 321<br />

10JTT 322<br />

Variability and it’s<br />

Control<br />

Developments in Fabric<br />

Formation<br />

Strategic and Technology<br />

Management<br />

Application of IT in<br />

<strong>Textile</strong>s<br />

10JTT 323 Friction in <strong>Textile</strong>s

Group Group Group I<br />

I<br />

10JTT11<br />

ADVANCED FIBER PHYSICS<br />

Introduction to macromolecular physics: the chemical structure of polymers,internal rotations, Configurations, and<br />

conformations, Flexibility of macromolecules, Morphology of Polymers; Modern concept of polymer structure.<br />

8 Hrs<br />

Physical methods of investigating structural characterization of fibres, viz., DGC, TEM, SEM, WAXS, SAXS, IRS,<br />

NMR, DSC and DTA. 8 Hrs<br />

Deformation of elastic solid, Generalized Hook’s Law, Component of Stress and strain. Deformation of viscose<br />

Bodies. Linear visco-elastic behavior of fibers. 8 Hrs<br />

Boltzmann superposition principle. Study of dynamic mechanical properties and their investigation in study of fibres.<br />

Introduction to mechanical properties of fiber composites. Temperature dependence of visco-elastic behavior. Time-<br />

Temperature Equivalence and superposition. WLF equation.<br />

8 Hrs<br />

Study of fiber stiffness and torsion. 4 Hrs<br />

Study of molecular theory of moisture hysterysis, 2 and 3 phase moisture adsorption theories. Theory of multi layer<br />

adsorption. Effect of moisture on mechanical properties of fibers.<br />

8 Hrs<br />

Study of optical properties, thermal, frictional, electrical, Di-electrical and static properties of fibers.<br />

8 Hrs<br />

REFERENCE BOOKS:<br />

1. Hunt and James, “Polymer characterization”, Chapman and Hall,London,1993<br />

2. I M Ward, “Mechanical properties of polymers”.<br />

3. Nielson, “Mechanical properties of polymers”, Vol I, II, III.<br />

4. W.R. Morton and J.W.S Hearle, “Physical properties of fibers”<br />

5. Campbell and Whitw, “Chaterization of polymers”.<br />

6. Aklonis, “Introduction to polymer viscoelasticity.”<br />

7. L.H.Sperling, “Physical polymer science.”<br />

---0000---<br />

10JTT21<br />

ADVANCED TEXTILE AND APPAREL TESTING<br />

2

Study of High Volume Instrument (HVI). Comparison of HVI and conventional testing Instruments. Advanced Fibre<br />

information system (AFIS). Comparison of AFIS with HVI System.<br />

8 Hrs<br />

Yarn Hairiness and its measurement. Uster spectrograph and its analysis. Properties desired in export yarns.<br />

6 Hrs<br />

Objective evaluation of fabrix handle by KAWABATA Evaluation system, Fabric Assurance by Simple Testing and<br />

fabric extractions force technique. 8 Hrs<br />

The influence of chemical and mechanical finishes on fabric handle. 6 Hrs<br />

Apparel Testing- Introduction, raw material inspection, In-process Inspection - spreading, cutting, sewing, pressing.<br />

Final inspection. 6 Hrs<br />

Soil/Stain release testing, snagging, bonded and laminated apparel fabric, testing of fusible interlinings, buttons,<br />

zippers and sewing threads. Care labeling of apparel and textiles: American, International, British, Canadian and<br />

Japanese systems. 8 Hrs<br />

Quality Control Program: Planning for the quality control program, inspection and analysis of data. Tools of quality<br />

control. ISO 9000 series standards. Total quality management.<br />

10 Hrs<br />

REFERENCE BOOKS:<br />

1. “Principles of <strong>Textile</strong>s testing”, J.E. Booth.<br />

2. “Hand book of textile testing and quality control”, B. Glover,<br />

D.S. Hambi-Pu Wiley Estern.Ltd., Bangalore.<br />

3. “The measurement of Appearance”, Richard S. Hunter and<br />

Richard W. Harold, Wiley.Interscience.<br />

4. “An introduction to quality control for the apparel industry”,<br />

Pradip. V. Mehta.<br />

5. “International Apparel Quality manuals”, KES- F and FAST manuals.<br />

6. “Progress in <strong>Textile</strong> science and technology”, Vol-1, Ed. V.K. Kothari, IAFL, India 2000.<br />

---0000---<br />

10JTT31<br />

ADVANCED APPAREL PRODUCTION TECHNOLOGY<br />

The nature and scope of apparel manufacturing, types of apparel manufacture-fundaments of apparel production.<br />

Basic types of apparel production process - major function of apparel manufacturing – engineering functions,<br />

management functions- apparel trade association.<br />

6 Hrs<br />

Apparel design analysis, elements of apparel design, principles of drafting - principles of draping, computerized<br />

pattern making and grading. 5 Hrs<br />

3

Apparel production analysis- quality spreading tools and equipment for spreading, cutting equipment and quality<br />

cutting. Computerized cutting. Marker quality and geometric principle for calculating optimum marking design,<br />

principles of stitch, seam and their analysis, seam quality, computerized sewing, pressing and moulding.<br />

5 Hrs<br />

Packaging and ware housing: Type of packing and packing materials, quality specification, merchandise packing<br />

and shipping packing. Intra transport, ware housing, computerized storage systems.<br />

5 Hrs<br />

Apparel Engineering: Work study, method study and time study, operator’s efficiency distributions- methods time<br />

measurement and SAM calculations. 5 Hrs<br />

Production control: Production analysis, distribution of documents and records, types of control forms, producing<br />

many styles in one line and determining supervisory sections in production lines. Production control charts, reports,<br />

production grid principle for assigning partial production, line operators, evaluation.<br />

6 Hrs<br />

Plan layout: Type of layouts and problems criteria for evaluation, Evaluation scale, govt. regulation for plant layout.<br />

5 Hrs<br />

Organization and personnel - Type of organization, functions, personal classifications, personnel orientation, job<br />

evaluation, wages incentives, nature of incentives. 5 Hrs<br />

Indian apparel industry - Overview of technology in apparel manufacturing technology, usage, regional features and<br />

structures of the industry, Indian apparel export and important product category, domestic market and domestic<br />

brands, technology status and outlook. 5<br />

Hrs<br />

Apparel productivity- Apparel productivity in India and Western world, global comparison of Western world –<br />

Apparel productivity manufactures and characteristics of low, medium and high productivity manufactures and<br />

factors associated with productivity actions towards higher productivity.<br />

5 Hrs<br />

REFERENCE BOOKS:<br />

1. “Apparel manufacturing”, Hand book by Jacob-Solinger,j Bobbin Blonnelm -<br />

“Media Corporation”, Columbia<br />

2. “Managing productivity in the apparel industry”, Rajesh Bheda of CBP Publisher<br />

and distributors.<br />

3. “The Tech. of clothing manufacture”, Harold and Lafam of Blackwell Sceince<br />

Publishers<br />

4. “The management systems”, Pranak. K. R. - Guest publications<br />

5. “Seams productions and analysis”, Radh D Clock<br />

---0000---<br />

10JTT251<br />

FABRIC ENGINEERING<br />

<strong>Textile</strong> properties and textile structure – engineering concepts and approach to textile structure – classification of<br />

multidirectional textile structure – laminar and orthogonal.<br />

6 Hrs<br />

Geometry of fabric structure : pierce’s basis and modified models – painter – adom’s and love’s technique<br />

descriptive and mechanistic models. Kemp and Hamalton : Twin arc, politic – Olofson – Snowdens and other<br />

models. 10 Hrs<br />

4

The concept of similar cloth – application cloth geometry – maximum weavability equations.<br />

6 Hrs<br />

Classification and standardization of fabrics. 6 Hrs<br />

Physical properties of fabrics – tensile deformation – heaps solution – pierces solution – geometrical solutions<br />

during extension of cloth – load extensional modules – tear – various models.<br />

8 Hrs<br />

Bending and tensional deformations – buckling, shear and drape of fabrics – theory various models – behavior.<br />

8 Hrs<br />

Geometry of knitted fabrics – weft and warp knits – various models – applications. Mechanics of knitted fabrics –<br />

theory – behavior. 8 Hrs<br />

REFERENCE BOOKS:<br />

1. “Structural mechanics of fibers, yarns and fabrics”, (Vol.I) S.Backer, P.grasberg<br />

and J.W.S. Herle – Pub. Wiley Intrsci. NewYork.<br />

2. “Fibers, yarns and Fabrics”, Kaswell – Pub. <strong>Textile</strong> Inst.<br />

3. “<strong>Textile</strong> mathematics”, Vol I, II, III – J. E. Booth – Pub, <strong>Textile</strong> Inst.<br />

4. “Woven cloth construction”, A.T. Robinson & R. Marks – Pub. <strong>Textile</strong> Inst.<br />

---0000---<br />

Group II<br />

10JTT12<br />

ADVANCED KNITTING AND NONWOVENS<br />

KNITTING : Direct warping for warp knitting spun and filament yarns. Warping calculations: Yarn to fabric ratio, runin<br />

racks, run-in ratio. Weft insertion Technique, fall plate technique, cut and miss press technique, laying in<br />

technique. 8 Hrs<br />

Terry fabric Production, sinker pile fabrics. 4 Hrs<br />

Raschel jacquard Machine, jacquard designing, jacquard production. 4 Hrs<br />

Use of electronics and computers in knitting machines. 4 Hrs<br />

Analysis of warp and weft knitting machines operations. 4 Hrs<br />

NONWOVENS: Classification of non-wovens, preparatory machines for non-wovens fabric production. Effects of<br />

fiber arrangements in the web. 4 Hrs<br />

Methods and technique used in non-woven production, needle punched, stitch bonded, adhesive bonded wet laid<br />

spun bonded, spun laced laminated and moulded fabrics.<br />

8 Hrs<br />

Classification of binders and their properties, effect of fiber properties on non-wovens. Modern developments in<br />

non-woven productions. 4 Hrs<br />

Structure of non-wovens: web geometry, fiber orientation curl factor, web density. Identification, properties and<br />

application of different non-wovens. 6 Hrs<br />

5

Methods of tests: porosity, tear strength, air permeability, tensile strength, 3-point bending test, fatigue test, CBR<br />

Loading, cone puncture test, Absorbency test, peeling test, pilling test, study of DIN standards.<br />

6 Hrs<br />

REFERENCE BOOKS:<br />

1. “Knitting technology” David j. Spencer.<br />

2. “Warp knitting” Ajgaonkar.<br />

3. “Non-woven fabrics” Banarjee.<br />

4. “Non-woven bonded fabrics” J. Lunescdors.<br />

5. “Non-woven fabrics – production and applications” M.L.Gulrajani.<br />

6. Non-woven technology – BTRA Conference papers.<br />

---0000---<br />

10JTT22<br />

ENVIRONMENTAL MANAGEMENT FOR TEXTILE INDUSTRY<br />

Source of water and their characteristics- surface water, ground water, rain water etc. Constituents of water and<br />

their effects on textile wet processing. Colour, turbidity, suspended solids, dissolved solids, PH value, acidity,<br />

alkalinity, hardness, iron and manganese, copper, chlorine organic growth.<br />

10 Hrs<br />

Quality requirements of water for silk reeling and textile processing. Conservation and reuse of water. Processing<br />

chemistry - fibres, chemicals, type of chemical processing.<br />

10 Hrs<br />

Introduction to textiles effluent, characteristics of textiles processing, dye manufacutre and synthetic fibres formation<br />

industries, Reduction and pollution control at mill state Methods and techniques used for effluent treatment.<br />

10 Hrs<br />

Standard regulations for effluents. Effluent testing parameters- colour and physical appearance, odour,<br />

temperature, PH value total suspended solids, total dissolved solids, BOD, COD.<br />

8 Hrs<br />

Bio-technology and its application in environmental industries. Plasma treatment. 6 Hrs<br />

Environmental management : Objectives, environmental impact assessment(EIA), elements of EIA process.<br />

Important environmental laws. Environmental pollution control norms.<br />

8 Hrs<br />

REFERENCE BOOKS:<br />

1. “<strong>Textile</strong>s effluent”, Padma Vankar, NCUTE Publications, IIT, Delhi.<br />

2. “Eco friendly processing”, NCUTE Publications.<br />

3. “Environmental problems in chemical processing of textiles”, NCUTE Publications.<br />

4. “Waste water.An introduction to environmental pollution”, Dr. B.K. Sharma, Krishna Prakashan, Media<br />

(P)Ltd., Meerut.<br />

5. “Water pollution”, V.P. Kudesia, Pragathi Prakashan, Meerut.<br />

---0000---<br />

6

10JTT151<br />

ADVANCED MATHEMATICS<br />

Fourier seriers: Periodic functions -Fourier series of functions with periods 2 and 21 half range - Fourier cosine<br />

and sine series - odd and even functions. 8 Hrs<br />

Partial differential equations of first order: Formation Lagrange’s methods for linear equations, standard types of<br />

non linear equations -Charpits methods- Fourier series solutions of one dimensional wave.<br />

8 Hrs<br />

Special functions: Beta and Gamma functions - relation between beta and Gamma functions standard properties<br />

and problems. Complex variables: Complex functions - limits, continuity and derivatives of functions - analytical<br />

itemann equations of cartesian and polar forms.<br />

10 Hrs<br />

Calculus of variables: Variation of fundamental of a single variable with fixed boundary, Euler’s equation,<br />

application to isoperimetric and minimal surface problems .Variations of functional dependent on higher derivatives.<br />

Simple problems. 10 Hrs<br />

Finite differences: Differences table interpolation. Newton's forward and backward formale, sterling, Bassel, Evert<br />

and Langrange's Formulae. Newton- Rosphon methods<br />

of solution of equations. Iterative methods. Computation of Eigen value of a square matrix by power method and<br />

Jacobi’s method. 8 Hrs<br />

Numerical solutions of differential equations: Numerical differentiation, Numerical integration, Simson’s rule,<br />

Euler's and modified Euler’s method. Taylor's, Runga Kutta's and Midne's method.<br />

8 Hrs<br />

REFERENCE BOOKS:<br />

1. I.N.Snaddon: “Special functions of mathematical physics and Chemistry” ELBS.<br />

2. Murray R.Spigal. “Complex variables” Pub. Sham series.<br />

3. Murray R.Spigal .”Advanced calculus” Pub. Sham series.<br />

4. E.El's Golts “differential equation with calculus of variations”, Mir Publications Mascow.<br />

5. F.Shield “Numerical Analysis” Pub. Sham series.<br />

6. S.S. Shastry – “Numerical Analysis”<br />

---0000---<br />

7

10JTT252<br />

ADVANCED MANUFACTURED FIBRE TECHNOLOGY<br />

Structual principles of fibre forming polymers. Reology and hydrodynamics in MMF spinning. Development of fibre<br />

structure during man-made fibre spining. Study of various variables in melt spining effect of various parameters on<br />

linear density of fibres. 8 Hrs<br />

High speed melt spinning: One step (SP) and two step spinning (TSP) process. Study of fluid flow in spin line.<br />

Modifications to be done in spinning, mechanism for high speed melt spinning. Recent developments in dry and wet<br />

technology. Study of various types of spinnerettes, orifices used for MMF spinning. Simulation in melt spinning for<br />

fibre production. Process control in man-made fibre spinning. Mechanism of crystallization during MMF spinning.<br />

10 Hrs<br />

Melt spinning of Hollow, multicomponent, Ultra fine and Nano fibres. Spin finish application: Composition of spin<br />

finish, various methods of spin finish application, spin finish for staple fibre production, textured yarn Technology of<br />

drawing of synthetic fibres, detailed study of mechanism of heat setting of synthetic fibres. Study of property<br />

changes in synthetic fibres during heat setting.<br />

10 Hrs<br />

Study of chemistry of major manmade fibres Viz. PET, N6, N66,PAN, PP, Viscose rayon, tencel, modal, lyocell.<br />

Study of various physical and chemical methods of modifications of these fibres.<br />

8 Hrs<br />

New fibres: Introduction to various high performance fibres, Kevlar-LCP Behaviour, dry jet spining of Kevlar fibres,<br />

Carbon fibres, raw materials, chemistry of production, surface treatments. Recent trends in production of high<br />

performance fibres like Boron, Sic,, Glass, PBI, aromatic polyester PBI etc. High touch fibres, Biomimetric chemistry<br />

and fibres, Biotechnology and fibres, electronics and fibres, Biotechnology and fibres, electronics and fibres, fibres<br />

in sports, fibres in ocean. 10 Hrs<br />

Study of various requirements for blending of MMFS with other fibres, optimization of blend ratio, factors affecting<br />

the compatibility of blend 6 Hrs<br />

REFERENCE BOOKS:<br />

1. Ziabicki “A High speed fibre spinning”, Wiley NY.1985.<br />

2. Ziabicki “A. Fundaments of fibre formation”, Wiley NY.1976.<br />

3. Marl Atlas, “Manmade fibres science and technology”. Vol.I, II and III.<br />

4. V. B. Gupta, Kotari V.K. “Manufactured fibre technology”,<br />

Chapman and Hal, London, 1997.<br />

5. T. Hongu, “New fibres”, Ellis Horwood, New York 1990.<br />

6. Levis. E .M. Pearce, J .Preston, “Hand book of fibre science and Technology Vol-4”,<br />

Marcel Dekkar, New York 1989.<br />

7. Donnet J. B. Bansol “R .C Carbofibres”, Marcel Dekkar, New York 1990.<br />

8. Vaidya “A. Production of synthetic fibres”, Prantice Hall, New Delhi 1985.<br />

9 Goswamy “R. C <strong>Textile</strong> Yarns”, Wiley and sons N Y1980.<br />

10. “Progress in textile”, Vol-2, Ed V. K .Kothari, IAFL N D.<br />

11. “Spinning of man made fibres and blends on cotton systems”, K<br />

R Salhotra, The textile Association, India 2004.<br />

12. J. Of textile institute, Vol-91, Part-3 textile institute-2000.<br />

---0000---<br />

Group III<br />

10JTT13<br />

ADVANCED WET PROCESSING<br />

8

Dye-Fiber Interaction. Kinetics of Dyeing. The diffusion of dye inside the fiber. Fick's laws of diffusion. Theoretical<br />

basis for dye absorption. Theories of dyeing of protein and other fibres using suitable dyes.<br />

10 Hrs<br />

Red listed textile chemicals, their sources and remedies. Pollution aspects of textile dyeing. Modern approaches to<br />

Eco-friendly wet processing of woven and knitted textiles. Eco-friendly dyes and their method of dyeing.<br />

8 Hrs<br />

Methods of analysis of formaldehyde, Pentachloro Phenol (PCP) chlorine compounds and heavy metals in<br />

processed and finished fabrics. Eco-labeling and various Eco-standards.<br />

8 Hrs<br />

Modern developments in garment dyeing. Methods and machines. Low temperature dyeing of garments. Finishing<br />

of garments using different chemicals and auxiliaries.<br />

8 Hrs<br />

Modern developments in finishing of natural and synthetic textiles. Finishing of textiles with various specialty<br />

chemicals. 6 Hrs<br />

Modern developments in textile and garment printing, colour measurement and computer colour matching<br />

concepts. 6 Hrs<br />

Latest development in natural dyes and their application on various fibres. 6 Hrs<br />

REFERENCE BOOKS:<br />

1. “<strong>Textile</strong> colouration” C.L.BIRD.<br />

2. “Printing by Miles.”<br />

3. “Chemical technology of <strong>Textile</strong> fibers” - Troatman.<br />

4. “Dyeing and printing with natural dyes” - M.L.Gulrajani.<br />

5. Deepti Gupta – “NCUTE Publication.”<br />

6. “Eco-friendly <strong>Textile</strong> wet processing-coordinator”<br />

7. Dr. R.Ashokan-“NCUTE Publication”.<br />

8. “Environment Problems in chemical processing “of <strong>Textile</strong>s -Dr.A.Asokan, Ms.<br />

Yogita, NCUTE<br />

9. “Finishing of khadi garments” Dr.R.B.Chavan, R.Chattopadhyay, R.P.Tewari, IIT<br />

Delhi.<br />

10. “Instrumental Colour measurement and computer aided colour matching for<br />

textiles “- H.S.Shah & R.S.Gandhi.<br />

PRACTICALS<br />

Collection of functional wet processed samples. Application and use of colour spectrophotometer. Evaluation of<br />

dyes and finishes. Study of mechanism and kinetics of dying. Energy consumption and environmental impact of<br />

wet processing industry.<br />

---0000---<br />

10JTT23<br />

ADVANCED SILK TECHNOLOGY<br />

International and Indian silk production, problems and prospects of silk industries. Recent methods of silk cocoon<br />

production. Modern techniques in cocoon character evaluation.<br />

6 Hrs<br />

Modern developments in cocoon stifling, cooking and silk reeling. Technological changes in machineries and<br />

methods to increase productivity in raw silk production. Recent trends in spun silk yarn production.<br />

6 Hrs<br />

Technological innovation in cottage silk yarn production. Production and properties of soft silk, crepe, georgette,<br />

chiffon, brocade, damask production of silk knits wear and lingerie’s.<br />

6 Hrs<br />

9

Recent trends in silk wet processing, scouring, bleaching, dyeing, and finishing. Modern methods of imparting<br />

specially / functional finishes on silk and its blends. 6 Hrs<br />

Techniques of imparting wrinkle resistant finishes, stain repellent finish, anti- microbial finish and other specialty<br />

finishes applicable to silk and its blend. 6 Hrs<br />

Developments in machineries and chemicals, auxiliaries used for silk processing. 6 Hrs<br />

Modern trends in silk garment production. Application of silk in fashion accessories and trims.<br />

6 Hrs<br />

Weaving - Different effects in simple structured fabric - Seersucker, plain, satin/sateen, double layer etc. and<br />

variation in drawing -in - draft and reed in plan. Unconventional woven structures : Pile, tuck fabrics, toilet quality<br />

fabrics. 10 Hrs<br />

REFERENCE BOOKS:<br />

1. FAO Manual on silk.<br />

2. “Silk man companion” CSB.<br />

3. “Silk wet processing” Dr. M. L. Gulrajani, IIT Publication.<br />

4. “Silk dyeing” Dr. V. A. Shenai, Sewak publications.<br />

5. “Silk finishing” (Chinese Translatory SDC Publication).<br />

6. “The technology of clothing manufacture” Harold and Lafeman- Bachwell Scheme Pub.<br />

7. “Watsons advanced textile design”, I. J. Grosaicki.<br />

8. “Grammar of <strong>Textile</strong> design”, H. N.<br />

---0000---<br />

10JTT152<br />

RESEARCH METHODOLOGY<br />

<strong>Research</strong> Methodology: Introduction, meaning of research, objectives, types and significance of research, defining<br />

a research problem, formulation of a hypothesis, research design and features of good design, methods of data<br />

collection, primary and secondary data, designing a questionnaire. Interpretation of results and report writing.<br />

8 Hrs<br />

Descriptive Statistics, Probability and Distribution: Basic statistical concepts, Measures of central tendency and<br />

dispersion. Elements of Probability, Addition and multiplication theorems of probability, Examples, probability<br />

distributions. Binomial, Poisson and normal Distributions<br />

6 Hrs<br />

Sampling Techniques: Random sampling, simple random sampling and stratified random sampling. Non-sampling<br />

errors. 6 Hrs<br />

Correlation and Regression: Problem of related variables. Product moment correlation coefficient and its<br />

properties. Simple linear regression and multiple linear regression. Coefficient of determination.<br />

6 Hrs<br />

Statistical Inference: Statistical hypotheses,Type-1 and Type-2 errors, level of significance, size and power of a<br />

test. Definition of Chi-square, t and F distributions. Central limit theorem. Tests for the mean, equality of two means,<br />

variance (for large and small samples), Large sample tests for proportions, Chi-square test for goodness of fit and<br />

independence of attributes in contingency tables. Confidence interval.<br />

8 Hrs<br />

10

Design of Experiments: Analysis of variance. One way and 2 way classified data. Design of Experiments .Analysis<br />

of completely randomized, randomized block. Factorial experiments -22 and 23 factorial experiments, Yates<br />

technique. 8 Hrs<br />

Multivariate Data Analysis: Introduction. Multivariate normal distributions. Mean vector, variance, covariance<br />

matrix and correlation matrix and their estimation for multivariate data. Step wise regression. Selection of best<br />

subject of variables. Classification and discrimination problems. Factor analysis .Principal component analysis.<br />

Illustrative examples, Multivaraiate data analysis using SPSS software. Illustrative examples.<br />

10 Hrs<br />

REFERENCE BOOKS:<br />

1. Ronald E Walpole & Raymond H Myers, Sharon L Myers: “Probability & Statistics<br />

for Engineers and Scientists Sixth Edition”, Prentice Hall.<br />

2. Gupta,S.C and Kapoor,1 V.K: “Fundamentals of mathematical statistics”,<br />

Sultan chand & L Co. New Delhi.<br />

3. Gupta,S.C. and Kapoor, V. K: “Fundamentals of Applied statistics”, Sultan chand<br />

& L Co. New Delhi.<br />

4. S. M. Ross: “Introduction to probability and statistics for engineers and scientists.3/e” Elsevier.<br />

5. D. C. Montogomery: “Probability and Applied Statistics for Engineers”<br />

.Wiley International Student Ed.<br />

6. Miller and Freund: “Probability and Statistics for engineers. EEE”<br />

7. Johnson .R and Wichern (1992).”Applied multivariate statistical analysis”. Third Ed. Prentice Hall India.<br />

---0000---<br />

10JTT253<br />

THEORY OF YARN SPINNING<br />

FIBRE DISPERSION: Ginning of cotton; the necessity of fibre-individualization; fibre opening in blow- room<br />

machinery; the mechanism of fibre-dispersion during carding operation; the minimum requirements during carding<br />

and the new approaches to improve fibre-dispersion in carding operation. Neps formation and theory of hook<br />

formation.<br />

8 Hrs<br />

ATTENUATION: Principle of rollers drafting and its application in yarn production; drafting irregularities-their causes<br />

and remedies; the function of aprons in roller drafting; limitation of apron-drafting and the scope for improvement;<br />

mechanism of wire-point drafting and its application in yarn production; merits and demerits of wire-point drafting;<br />

comparison of wire-point drafting with roller drafting.<br />

10 Hrs<br />

TWISTING: Effect of twisting of staple-fibre strand on its strength ;meaning of twist multiplier and the basis of<br />

selection of required twist ;fundamental requirement to create real twist in a strand; mechanism of different twisting<br />

principle-ring-twisting, open-end twisting, air-jet twisting, up-twisting, twofor- one twisting, hollow-spindle twisting.<br />

8 Hrs<br />

FIBRE BLENDING: Important of fibre-mix homogeneity on yarn quality; types of mixing during spinning preparatory<br />

process; assessment of blend efficiency. 8 Hrs<br />

LEVELLING: Influence of intermediate product uniformity on yarn uniformity; methods of leveling adopted during<br />

spinning processes. 6 Hrs<br />

FIBRE CLEANING: Methods adopted to clean the fibre from trash, short fibres and neps; role of blow-room, card<br />

and comber in fibre cleaning.<br />

6 Hrs<br />

FIBRE STRAIGHTENING: Definition of fibre-extent; influence of fibre-extent on yarn quality; improvement of fibreextent<br />

by straightening actions in carding, drafting and combing.<br />

6 Hrs<br />

REFERENCE BOOKS:<br />

1. Oxtoby E, “Spun Yarn Technology”, Butterworth's, London, 1987.<br />

2. Klein W, “The Technology of Short-staple Spinning”, the <strong>Textile</strong> Institute,<br />

Manchester, 1998. ISBN: 1870812980<br />

3. Klein W, A practical Guide to Opening and Carding, the <strong>Textile</strong><br />

4. Institute, Manchester, 1999. ISBN: 1870812999.<br />

11

5. Klein W, “A practical Guide to Combing”, Drawing and the Roving Frame, the<br />

<strong>Textile</strong>s Institute, Manchester, 1999. ISBN 1870372287.<br />

6. Klein W, “A practical Guide to Ring Spinning”, the <strong>Textile</strong>s Institute, Manchester,<br />

1999. ISBN: 1870372298.<br />

---0000---<br />

10JTT322<br />

VARIABILITY AND ITS CONTROL<br />

Lap formation and control of lap uniformity. Irregularities of carded, drawn and combed silver- their control.<br />

Irregularities of roving and yarns- their control. 12 Hrs<br />

Influence of different materials and their blends on irregularity. Index of blend irregularity.<br />

10 Hrs<br />

Influence of ambient conditions on the irregularity of material at various stages of processing restricted to spinning<br />

of cotton and its blends. 10 Hrs<br />

Irregularities of yarns produced on ring, rotor, friction and airjet spun systems. 10 Hrs<br />

.<br />

Instruments used for measurement of irregularity – analysis and interpretation of data and graphs remedial<br />

measures. 10 Hrs<br />

REFERENCE BOOKS:<br />

1. “<strong>Textile</strong> yarns”, B.C. Goswamy, J.C. Martindale-Willey Intersci.<br />

2. “Manual of cotton spinning”, Vol IV. Part -1-Foster <strong>Textile</strong> Inst.<br />

3. “An introduction to study of spinning”-Morton-London<br />

4. “Roller drafting” -Nogeera<br />

---0000---<br />

12

Group Group IV IV<br />

IV<br />

10JTT14<br />

YARN ENGINEERING<br />

Designing yarns for specific end-uses. Selection of fibre /filament, structure of fibre / filament, spun yarns,<br />

multifilament yarns, textured yarns and micro denier multi filament. Functional properties of end products.<br />

8 Hrs<br />

Twist contraction and retraction. Practical applications. Twist migration and segment length in spun and filament<br />

yarns -Theoretical analysis of yarn irregularity - blend irregularity.<br />

8 Hrs<br />

Geometrical properties of single and folded yarns. Derivations of related equations. Open & hexagonal packing and<br />

their merits and demerits. 8 Hrs<br />

Yarn diameter derivation of Pierce, Grosberg and Dickson formulae. 6 Hrs<br />

.<br />

Transmission of force from fibre to fibre in spun yarns - mechanism of yarn breakage.<br />

8 Hrs<br />

Effect of fibre properties and their geometrical configuration on tensile properties of yarns. Concept of elongation.<br />

8 Hrs<br />

Effect of properties of constituent fibres and their. composition on the behavior of blended yarns.<br />

REFERENCE BOOKS:<br />

1. “<strong>Textile</strong> yarns” P.C. Goswamy, J.G. Martindale—Wiley Interscience .<br />

2. “Strctural mechanics of fibres”, yarns, fabrics J.W.S. Hearle, P Grosberg, S. Backer-Wiley Interscience.<br />

3. “Spun yarn technology” Oxtoby--Butter Worth.<br />

4. “Technology of short fibre spinning” Vol., W. Klein—<strong>Textile</strong> Institute.<br />

---0000---<br />

10JTT24<br />

DEVELOPMENTS IN FABRIC FORMATION<br />

Yarn quality norms for unconventional weaving. Preparatory process to unconventional Weaving. Salient features of<br />

unconventional looms. 8 Hrs<br />

6 Hrs<br />

13

Study of factors in unconventional looms with respect to weft velocity, rate of weft insertion, range of weft pattering<br />

and type of selvedge formations. 8 Hrs<br />

Shed geometry, theory of weft insertion, weft consumption, weft unwinding tension.<br />

8 Hrs<br />

Mechanics of beat - up. Principle of let-off, take-up and cloth windup systems. 8 Hrs<br />

Combinations of weaving and knitting techniques. 8 Hrs<br />

Techno economics of unconventional weaving. 6 Hrs<br />

Review of recent developments. 6 Hrs<br />

REFERENCE BOOKS:<br />

1. “Principles of weaving”, Robinson & Marks, <strong>Textile</strong>s Institute.<br />

2. “Modern weaving preparatory”, Ormerold - Buttaerworth.<br />

3. “Shuttleless weaving machines”, Aldrich, Talavasek & Vladimir -Elsvier Scientific.<br />

4. Handbook of weaving - Sabit Adanur.<br />

---0000---<br />

10JTT153<br />

STRATEGIC AND TECHNOLOGY MANAGEMENT<br />

Management information system: Introduction and background frame work-information needed economics<br />

System view - role of MIS on various levels - structure of MIS – Information net work - system life cycle - data flow -<br />

decision trees. 10 Hrs<br />

Corporate strategy and planning: Concept of frame work, corporate management, role, function skill.<br />

6 Hrs<br />

Strategic analysis: cost dynamics - portfolio analysis – financial analysis, Strategic choices. Alternating -<br />

diversification-mergers and acquisition implementation and evaluation of strategy.<br />

10 Hrs<br />

Strategic management and leadership: Role of leadership - process of leadership - line structure, styles.<br />

10 Hrs<br />

14

Technology management : Technology life cycle – transformation – alternatives –appropriate technology -<br />

technology change – technology transfer – models. 10 Hrs<br />

Technology absorption: Assessment – evaluation - diffusion. 6 Hrs<br />

REFERENCE BOOKS:<br />

1. David G.B. - M. S. “Concept ional foundation, Structure and development”, McGra hill New York<br />

2. Adair John “skills of leadership”, Gower Aldershot Haerle<br />

3. Hill Charles WC and Ganalk K Jones “Strategic Management – an integrated approach”, Houghton Nihlin<br />

Boston.<br />

---0000---<br />

10JTT321<br />

APPLICATION OF IT IN TEXTILES<br />

Introduction to IT in <strong>Textile</strong>s, information technology and the web paradigam, E-business application for textile<br />

industry. 8 Hrs<br />

Enterprise resource planning: Structure of ERP, General Principles involved in the application of ERP ,ERP models<br />

,ERP selections for the textile industry. 10 Hrs<br />

Internet and internet concepts, Internet based manufacturing EDI for textile businesses, logistics management,<br />

management information systems in spinning, weaving and wet processing sections.<br />

10 Hrs<br />

Application of CAD \ CAM in <strong>Textile</strong>s. 8 Hrs<br />

Information technology in fashion and garment industry. 8 Hrs<br />

Total quality management and information technology. 8 Hrs<br />

REFERENCE BOOKS:<br />

1. “Texinfotech - 99, Resume of papers” , IT in <strong>Textile</strong>s in the New Millenium, July<br />

1999, IIT,Delhi.<br />

2. “Texinfotech-2000,International Conference”, Resume of papers, New Delhi, 2000.<br />

3. “E-Commerce”, Kamalesh k.Bajaj-Debjani, Nag-TATA, McGRAW HILL Co.Ltd,<br />

New Delhi.<br />

4. “Electronic Commerce”,Gray P.Schncider, James.T.Perry, Thomson Course<br />

Technology.<br />

10JTT323<br />

FRICTION IN TEXTILES<br />

Introduction to fibre friction. Study of surface properties of cotton, Wool and synthetic fibres. Scanning electron<br />

microscopy of various fibres. 8 Hrs<br />

General mechanism of friction Laws of friction, theories of friction, friction in various textile processes like spinning,<br />

weaving and chemical processing etc. Detailed study of various methods of measurement of fibre friction in textiles.<br />

Role of friction in the mechanical behavior of fabrics.<br />

10 Hrs<br />

15

Study of surface geometry of synthetic fibres. Spin finish application to synthetic fibres, Theory of spin finish<br />

application, various methods of spin finish application, spin finish composition for synthetic filaments, staple fibres<br />

and textured yarns. 10 Hrs<br />

Abrasion of textile surfaces measurement of abrasion resistance, factors affecting the abrasion resistance.<br />

8 Hrs<br />

Resistivity and static behaviour of textile surfaces, effect of photochemical and environmental degradation on the<br />

surface properties of textile fibres. Soil release from the textile surface, stain and water repellency of textile<br />

surfaces. 8 Hrs<br />

Role of fiber friction in garment making, Effect of friction on comfort property of textiles. Generation of static charges<br />

in textile process and their remedies. 8 Hrs<br />

REFERENCES:<br />

1. “Surface characteristics of fibre and textile”, M.J.Schick<br />

2. “Friction in textiles”, Howell<br />

---0000---<br />

16