The worldwide construction equipment ... - Contractors World

The worldwide construction equipment ... - Contractors World

The worldwide construction equipment ... - Contractors World

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

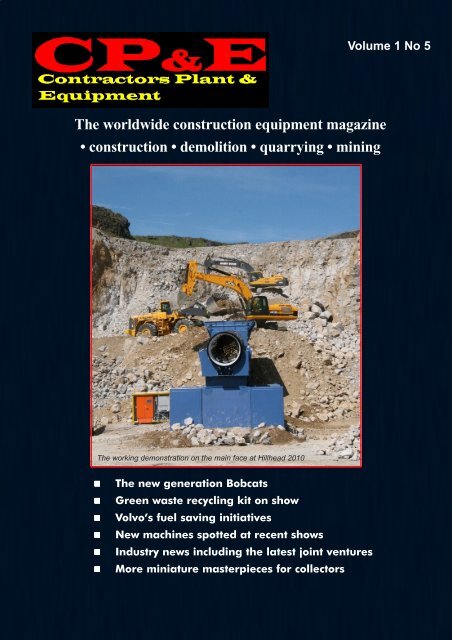

Volume 1 No 5<br />

<strong>The</strong> <strong>worldwide</strong> <strong>construction</strong> <strong>equipment</strong> magazine<br />

• <strong>construction</strong> demolition quarrying mining<br />

<strong>The</strong> working demonstration on the main face at Hillhead 2010<br />

����� <strong>The</strong> new generation Bobcats<br />

����� Green waste recycling kit on show<br />

����� Volvo’s fuel saving initiatives<br />

����� New machines spotted at recent shows<br />

����� Industry news including the latest joint ventures<br />

����� More miniature masterpieces for collectors

Page 2<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

CONTENTS<br />

CONTENTS<br />

4 Editorial Comment<br />

7 Industry News<br />

Including the new joint ventures between Caterpillar and Wacker Neuson and<br />

Perlini and Volvo Construction Equipment. ITT set to purchase Godwin Pumps,<br />

JCB predicts a better 2010, new owners for Barford site dumpers and Boss<br />

Space and CESAR aids recovery of stolen plant from Poland.<br />

12 Forward cabs enhance new Bobcats<br />

CP&E Plant Editor Nick Johnson visits the Bobcat Training Centre in Dobris,<br />

Czech Republic to try out the company’s latest compact plant including the<br />

new generation skid steers.<br />

17 Scottish display of green waste recycling machines<br />

Recently introduced compost turners, mobile picking stations, shredders,<br />

screens and trommels from Doppstadt, Backhus and Kiverco on demonstration<br />

in Scotland.<br />

20 Volvo focuses on fuel saving<br />

Nick Johnson checks out the advantages of Volvo’s OptiShift system and RBB<br />

(reverse by braking) function on a wheel loader being used in a large Swedish<br />

quarry.<br />

22 Seen at the Shows<br />

CP&E brings you more new machines and products that Nick Johnson spotted<br />

whilst visiting Bauma, the Hillhead 2010 quarry show and the Vertikal Days<br />

cranes and access event. Check out:<br />

ACE Plant<br />

Aggregate Processing Systems<br />

Anaconda<br />

Artic Cranes<br />

Ascendant Access<br />

Ausa<br />

BPH Sales<br />

Cartem<br />

Crushers UK<br />

Cumberland Access<br />

GenQuip<br />

Haulotte<br />

Hercules<br />

Hill Engineering<br />

Iona<br />

JCB<br />

Kubota<br />

Land & Water<br />

Liebherr<br />

Miller<br />

Niftylift<br />

Palazzani<br />

PB Lifttechnik<br />

Pioneer Pump<br />

Raptor<br />

Sandvik<br />

Selwood<br />

Simex<br />

Skako Falck Spider<br />

Snorkel<br />

Spillard Safety Systems<br />

Stocks Sweepers<br />

Terex Finlay<br />

Utranazz<br />

Volvo<br />

ZT Safety Systems<br />

40 Small Scale Bauma – the new models<br />

Having previously provided details of the new full size machines seen at<br />

Bauma, Nick Johnson turns his attention to the latest scale models which<br />

appeared at the big show in Munich.<br />

Page 3

EDIT EDITORIAL EDIT ORIAL COMMENT<br />

COMMENT<br />

<strong>The</strong> <strong>The</strong> challenge challenge of of going<br />

going<br />

‘green’<br />

‘green’<br />

<strong>The</strong> catastrophic blow-out of the oil well in the Gulf of<br />

Mexico graphically illustrates the difficulties involved in<br />

trying to tap the dwindling supplies of the fuel we are all<br />

now so dependant upon. <strong>The</strong> tragic loss of life and the<br />

ecological damage that have resulted from this dramatic<br />

incident should serve to make us all acutely aware of the<br />

need to conserve fuel and to protect the fragile fabric of<br />

our planet.<br />

One of the biggest challenges now being addressed by<br />

engine and <strong>construction</strong> machinery makers is to meet the<br />

demanding Tier 4 Interim / Stage IIIB emissions<br />

regulations that kick-in next year in the USA and Europe.<br />

<strong>The</strong> required 90% reduction in particulate matter (PM)<br />

emissions and 50% less NOx will benefit our environment<br />

and that must be, in the long term, a good thing.<br />

What is also important is to ensure that the next generation of machines are not only less polluting but also that<br />

they are more fuel-efficient. As fuel costs have increased dramatically around the world in recent years, having more<br />

fuel-efficient machines is not only a ‘green’ issue; it is also an economic necessity.<br />

It is encouraging that the development of hybrid machines is on the increase. Excavators carrying out cyclic work<br />

can particularly benefit from having fuel saving hybrid technology and companies such as Doosan, Kobelco and<br />

Komatsu already have either prototype or production machines in operation. Other types of machine being tested with<br />

hybrid technology include multi-purpose excavator loaders (Mecalac), wheel loaders (Volvo) and tandem vibrating<br />

rollers (Bomag). <strong>The</strong> British access platform maker Niftylift has, as covered in this issue, produced a hybrid boomlift<br />

that is now on sale.<br />

Such is the emphasis on fuel saving that Volvo recently staged a special event in a quarry in Sweden. As reported<br />

in this issue, the event highlighted the fuel saving that can result in adding new options such as the OptiShift and RBB<br />

(reverse by braking) to several of its most popular wheel loaders.<br />

Tests indicate that OptiShift and RBB can save as Reverse by Braking can achieve a very laudable fuel saving of<br />

up to 15% depending upon application. Volvo is also to be congratulated for its Eco Operator initiative. This practical<br />

programme is focused on training operators to develop an environmentally friendly style of driving – through less<br />

accelerating and braking and by using the most economical engine speed range. Better driving not only reduces<br />

emissions but can also cut fuel consumption by between 5% and 25% without affecting productivity.<br />

More training of machine operators will certainly be needed where new generation Tier 4 Interim / Stage IIIB<br />

emissions compliant machines have to use ultra low sulphur fuel. Putting conventional fuel in a machine designed to<br />

operate on ultra low sulphur fuel will adversely affect the emission control technology and could result in expensive<br />

engine damage.<br />

Operators and service staff will also need to be aware of which new generation machines will have to utilise ultra<br />

low ash engine oil. Another practical training issue will involve the requirement to periodically change the filter in the<br />

diesel particulate filter that will be an integral part of many of the new engines.<br />

Going ‘green’ is vitally important but implementing many of the new practical requirements on site will not be plain<br />

sailing.<br />

Page 4<br />

Nick Johnson<br />

Plant Editor<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

CP&E <strong>Contractors</strong><br />

CP&E<br />

Plant & Equipment Vol<br />

<strong>Contractors</strong> Plant & Equipment<br />

Page 5<br />

Page 5

Spreading the light around the word - for the benefit of all.<br />

A A word word of of encouragement encouragement to<br />

to<br />

Overseas Overseas branches branches - - - - Don Don Baldry<br />

Baldry<br />

In the early days of the Lighthouse Club, back in the no street lighting ‘50s, (whence came our name - St. Mary’s<br />

Light, Whitley Bay gave our somewhat mellow founders their illumination) the main purpose of the Club was<br />

networking. That purpose was underlined by our declared aim: <strong>The</strong> furtherance of<br />

Good Fellowship among <strong>construction</strong> people.<br />

As we know, the Club developed very rapidly, branches were formed throughout<br />

the U.K. and Ireland and in 1962 the Lighthouse Club Benevolent Fund received<br />

official charitable status. And the Club began to spread it’s wings, in those times via<br />

BOAC and their Comet jet flights to the far east.<br />

Although our Lighthouse was adopted in the Netherlands very early on, theirs is a<br />

somewhat elite organisation. <strong>The</strong> first mirror image of our U.K. set up was formed in<br />

Hong Kong by the expat community, they too combined networking and charity. Now, more than twenty five years<br />

later, Hong Kong, with over 1,000 members and a very active benevolent fund, is the hub for our ten branches in<br />

the Asia/Pacific region and maintains close links with branches in Abu Dhabi and Dubai. In all there are well over<br />

4,000 members in these far flung centres of ‘Good fellowship’.<br />

Most of these branches organise monthly get-togethers, and for any member newly arrived in the locality these<br />

are a very useful source of friendship and local contacts. Monthly get-togethers are generally well attended, not<br />

surprising since, for instance, one venue in Kuala Lumpur was voted ‘Best Pub in Malaysia’ and the Dubai Offshore<br />

Sailing Club can’t be a bad destination for a night out!<br />

<strong>The</strong>re are, of course, much grander events. Earlier this year, Hong Kong’s International Gathering brought<br />

together 200 members from Asia/Pacific, the Gulf and U.K. all of whom enjoyed a great evening which raised<br />

HK$25,000 for their Benevolent Fund.<br />

Hong Kong, Saigon; Abu Dhabi, Kuala Lumpur; five decades on the friendship, fellowship and common<br />

interests of our Club’s founders that continue to enjoy wherever our lighthouse shines. It’s a brilliant light.<br />

See overseas branches here<br />

As the publisher of CONTRACTORS WORLD magazines, Roger Lindley is pleased to promote the aims,<br />

objectives and benefits of the Lighthouse Club around the world. Travelling around the world for over 30 years, I<br />

have been privileged to visit many job sites of every description. I also came to appreciate the camaraderie that<br />

makes being away from home more bearable - in my case just a few weeks. For many in the industry, many years.<br />

<strong>The</strong> <strong>construction</strong> industry <strong>worldwide</strong> is like one big club - people move from project to project, contractor to<br />

contractor <strong>The</strong> membership does not change, just the business card. This is why the Lighthouse Club can be a<br />

unifying organisation enabling like-minded people to get together and share experiences, while helping raise vitally<br />

needed funds for those locally who suffer hardship as a result an accident in the <strong>construction</strong> industry.<br />

Page 6<br />

Read latest<br />

International<br />

Liaison Report<br />

June 2010<br />

Support the Lighthouse Club - become or member or help by making a donation. Do it now.<br />

Read the current Lighthouse Club Newsletter on-line now<br />

Promote your company by sponsoring a tree in our virtual forest - all proceeds to the Lighthouse Club<br />

Latest newsletter<br />

Lighthouse Club<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

Industry Industry News<br />

News<br />

Caterpillar and Wacker Neuson plan mini ‘marriage’<br />

From the middle of next year,<br />

Wacker Neuson will be making new<br />

versions of its compact excavators<br />

(weighing up to 3.0 tonnes) to<br />

supply Caterpillar.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

In another example of the strategic product alliances being forged between rival<br />

plant manufacturers, Caterpillar and Wacker Neuson have announced a compact<br />

excavator deal. <strong>The</strong> two companies have signed a cooperation agreement<br />

regarding the exclusive design and manufacture of Caterpillar’s <strong>worldwide</strong> need<br />

(with exception of Japan) of small excavators (weighing up to three tonnes) by<br />

Wacker Neuson. <strong>The</strong> initial term of this surprise agreement is 20 years.<br />

<strong>The</strong> deal will provide Caterpillar with a greater number of small mini excavators<br />

including a sub one tonne micro machine (which it currently cannot provide).<br />

Currently the company makes its smallest mini excavators at its large factory at<br />

Desford, near Leicester, in the UK that has recently become the <strong>worldwide</strong> source<br />

of Caterpillar backhoe loaders.<br />

<strong>The</strong> agreement includes the development and manufacture of up to seven<br />

compact excavator models with operating weights from 800kg to 3.0 tonnes<br />

designed to Caterpillar’s specifications and brand requirements at Wacker<br />

Neuson’s factory in Linz, Austria. <strong>The</strong>se new compact excavators will be distributed<br />

through (and supported by) Caterpillar’s <strong>worldwide</strong> global dealer network, with the exception of Japan. It is stated that<br />

all the forthcoming Caterpillar models will be clearly differentiated from similarly sized Wacker Neuson machines.<br />

<strong>The</strong> partnership will enable both parties to spread the cost of developing and manufacturing across higher volumes<br />

and it will allow Caterpillar to increase the number of models offered to its distribution. <strong>The</strong> additional production<br />

volume for Wacker Neuson is expected to more than double the current production level of compact excavators<br />

weighing up to 3.0 tonnes that it makes in Linz. Production of the new Caterpillar machines is planned to commence<br />

in mid 2011.<br />

This is not the first time that Caterpillar has elected to update and expand a model range through an agreement<br />

with another manufacturer. In November 2005 the company announced that its telescopic handler line would<br />

subsequently be produced for it by JLG.<br />

ITT has agreed to purchase Godwin Pumps<br />

<strong>The</strong> large submersible pump maker, the ITT Corporation, has announced<br />

its intention to buy the automatic self-priming portable pump maker<br />

Godwin Pumps. ITT has agreed to purchase Godwin from its principal<br />

shareholders for $585 million. <strong>The</strong> transaction is expected to close in the<br />

third quarter of 2010, pending customary regulatory approvals.<br />

"This acquisition is another example of ITT's strategy to expand its<br />

core businesses and build on its strong global positions in water,<br />

wastewater and industrial process," said Gretchen McClain, President of<br />

ITT's Fluid and Motion Control group. "Godwin's business is a great<br />

complement to our existing fluid technology portfolio, and is expected to<br />

establish ITT among the leaders in the growing and profitable $3 billion<br />

global market for dewatering pumps and rental services."<br />

Godwin Pumps – which recently launched this<br />

new HL260M Dri-Prime pump – is being<br />

acquired by ITT.<br />

Godwin Pumps was founded in 1976 and currently has approximately 800 employees located throughout the<br />

United States and at its manufacturing facility in Gloucestershire, England. <strong>The</strong> company operates a US rental fleet of<br />

more than 6,000 pumps at 26 <strong>equipment</strong> rental facilities and it also has a network of approximately 50 distributors<br />

<strong>worldwide</strong>.<br />

Godwin's 2009 revenues were approximately $200 million, with full-year 2010 revenue projected to be about $235<br />

million. When combined with ITT's existing dewatering sales, the Godwin acquisition is expected to double ITT's<br />

revenues from dewatering <strong>equipment</strong> and services.<br />

"<strong>The</strong> acquisition presents a tremendous opportunity for ITT to grow its dewatering rental and services business<br />

internationally," said John Williamson, President of ITT's Water & Wastewater business. "We already have a solid<br />

history of partnership, with Godwin offering ITT's electric submersible pumps since 2003. Adding the specialized<br />

products and skills of the world-class Godwin team to ITT's broad Flygt and Grindex submersible pump portfolio and<br />

global sales network means our customers will have unsurpassed access to the broadest dewatering capabilities on<br />

the market."<br />

ITT today sells Flygt and Grindex brand dewatering pumps, and rents from its fleet of more than 11,000 pumps,<br />

through its global sales and distribution network serving customers in more than 140 countries. ITT's Flygt pumps are<br />

claimed to be the original submersible dewatering pumps, invented in 1948.<br />

Godwin Pumps<br />

Page 7

Industry Industry News<br />

News<br />

Volvo to distribute Perlini<br />

dumptrucks in Europe<br />

To provide its customers with a wider choice<br />

of haulers (and be able to secure more<br />

package <strong>equipment</strong> deals) Volvo Construction<br />

Equipment in Europe has signed a distribution<br />

deal with the Italian rigid dumptruck maker<br />

Perlini. <strong>The</strong> Volvo CE dealerships in Austria,<br />

Bosnia-Herzegovina, Croatia, Czech<br />

Republic, Hungary, Ireland, Moldavia, Norway,<br />

Portugal, Romania, Slovakia and Slovenia<br />

were the first to operate under the European<br />

umbrella agreement earlier this year.<br />

Subsequently the partnership was extended<br />

last month to include the Volvo owned<br />

dealership in Great Britain.<br />

Perlini is a family owned business which A significant number of Volvo Construction Equipment outlets in Europe are<br />

now offering Perlini rigid dumptrucks alongside the Volvo ADTs to satisfy the<br />

was started in 1957. It product range includes<br />

different operational requirements of more customers.<br />

the DP405, DP605, DP705 and DP905 rigid<br />

dumptrucks with payloads of 40 to 100<br />

tonnes. Perlini will continue to sell through its<br />

existing dealer in Italy and through its direct sales network in Spain.<br />

Under the new agreement with Volvo, the Perlini rigid dumptrucks do not become part of the Volvo range and they<br />

retain their white livery and Perlini branding. However, a full after market support for the Perlini trucks will be provided<br />

by Volvo Construction Equipment outlets in the countries covered by the distribution deal.<br />

Dr Maurizio Perlini, who is responsible for the Italian company’s commercial affairs, says, “Sales of Perlini<br />

<strong>equipment</strong> will be opened up to many new countries thanks to Volvo's extensive network.” Perlini states, “We can now<br />

enter countries such as Greece and Cyprus where our brand is not so well known."<br />

Moldavia is one of the countries where Volvo has a strong presence. "We expect a significant volume of sales in<br />

the next two years."<br />

Nick Rose, responsible for Business Development in Volvo CE Europe, says, “<strong>The</strong> Perlini products can now<br />

effectively plug a previous gap in the Volvo range to allow our distribution network to offer complete solutions to our<br />

quarrying and aggregate customers.” Val Ledden, the Managing Director of Volvo Construction Equipment Ltd in<br />

Great Britain, says, “Adding the range of Perlini rigid trucks to our portfolio gives us the opportunity of offering a one<br />

stop shop to customers where rigid haulers are required together with packages of other Volvo <strong>equipment</strong> such as our<br />

larger wheeled loaders and excavators.”<br />

Interestingly rigid dumptrucks were part of the Volvo product offering in the past when Volvo and Euclid (along with<br />

Michigan) were working together as VME. Subsequently, the Michigan wheel loaders were absorbed into the Volvo<br />

line-up and the Euclid rigid dumptrucks were sold to Hitachi.<br />

Page 8<br />

Volvo Construction Equipment<br />

Caterpillar plans return to large mining<br />

shovel market<br />

<strong>The</strong> decision of the Terex Corporation to sell its large mining<br />

machinery business to Bucyrus International at the end of last year<br />

appears to have been the catalyst for Caterpillar to decide to reenter<br />

the large mining shovel market. Back in 2003, Caterpillar<br />

discontinued its former big mining shovels – the 180 tonne class<br />

5130B and the 360 tonne class 5230B – when there was a plan to<br />

swap assets with Terex.<br />

In recent years the biggest hydraulic excavator in the Caterpillar<br />

portfolio has been the 88 tonne class 385C. To supply packages of<br />

larger excavators with the big Caterpillar mining trucks, a significant<br />

number of Caterpillar dealers around the world also sold the large<br />

Having pulled out of the mining excavator market in 2003 (when this<br />

5130B was in the range), Caterpillar now intends to re-enter the market<br />

with new models weighing up to 800 tons.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

Industry Industry News<br />

News<br />

O&K derived Terex excavators through the Terex Corporation. Now that the popular Terex O&K designs have passed<br />

to Bucyrus, Caterpillar has decided to enhance its big machine offering through an investment of nearly $700 million<br />

over the next four years.<br />

Caterpillar states that it intends to produce a full range of mining shovels, ranging from a 125 ton model through to<br />

an 800 ton model. <strong>The</strong> company has selected its factory in Aurora, USA for the initial production of the new product<br />

range and it is conducting a study of additional production sources in other parts of the world. Pilot production of the<br />

new 125 ton class shovel is scheduled to begin in early 2011.<br />

<strong>The</strong> first commercial shovels produced in Aurora are expected to be available later in 2011. <strong>The</strong> larger shovels are<br />

planned for commercial availability beginning in 2013 and through 2014. <strong>The</strong>n the new excavator range will give<br />

customers a direct match for loading Caterpillar’s industry leading mining trucks—from the 100 ton class 777F through<br />

the 400 ton class 797F. “As we discuss solutions with our global mining customers, it’s clear they want a complete line<br />

of Caterpillar shovels to best match the full range of Caterpillar trucks operating at their mines,” said Chris Curfman,<br />

President of Caterpillar Global Mining.<br />

Caterpillar is also accelerating its previously announced capacity expansion plans for trucks in Decatur, USA, with<br />

the nearly 30% additional capacity expected to come on line beginning in 2011. Decatur produces Caterpillar’s largest<br />

mining trucks, including the flagship 797F series truck, which has a maximum capacity of 400 tons.<br />

In addition, Caterpillar plans to increase capacity for 60 and 100 ton rigid dumptrucks at its existing manufacturing<br />

facility near Chennai, India. <strong>The</strong> capacity expansion would more than double truck production capabilities in India.<br />

<strong>The</strong> expansion for its 100 ton 777D and 60 ton 773E trucks in India should be completed by early 2012.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

Caterpillar<br />

Administrator sells<br />

Wordsworth Group<br />

businesses<br />

Business operations that formed part of the<br />

Grantham, UK based Wordsworth Holdings<br />

Group that went into administration earlier<br />

this year have gained new owners. Amongst<br />

the Wordsworth Holdings business sales are<br />

several – including Barford site dumpers and<br />

Fruehauf tipping trailers - to the Bowden<br />

Investment Group headed up by<br />

entrepreneur Saul Loggenberg.<br />

With Joint Managing Directors James<br />

Kearsey and David Snowdin, production has<br />

recommenced on the Grantham site where<br />

Terry Wyman is Production Director.<br />

According to Sales Manager Brad O’Hara,<br />

Managing Director Graham Stansfield (left) and Director Tim Allan of the<br />

Barford site dumpers – with payloads from 2<br />

new revitalised Boss Space business were promoting their Comfort<br />

to 10 tonnes – are now being produced to<br />

Space welfare unit at the Hillhead Quarry Show in June.<br />

order and there are plans to complete<br />

previously exhibited special developments, particularly the Big Jaw mobile crusher carried on a Barford dumper<br />

chassis.<br />

In a separate development, the administrators of Barford Holdings have sold the Boss Space portable<br />

accommodation unit business to new owners. Now run by Managing Director Graham Stansfield and Director Tim<br />

Allan, the company now trading as Boss Space Ltd, has relocated to on the Lime Square Business Park in Grantham.<br />

Graham Stansfield says that Boss Space is now focussing on producing and selling its mobile welfare units for the<br />

<strong>construction</strong> industry. <strong>The</strong> company’s latest product is its ‘Comfort Space' mobile welfare unit which can<br />

accommodate up to six persons. <strong>The</strong> Comfort Space welfare unit is a towable anti-vandal cabin that has a gross<br />

weight of 1800kg. Security on site is aided by the ability to hydraulically lower the cabin down to hide its road wheels<br />

and the ability to cover the tow bar with a lockable steel shroud.<br />

<strong>The</strong> 3.6m long by 2.3m wide Comfort Space welfare unit features a canteen/rest area, a toilet / washroom, a drying<br />

room and a ‘super silent’ diesel generator. <strong>The</strong> generator provides lighting, warm water and the power for the<br />

microwave used for food preparation. Amongst the options is an Eco Version running an invertor which allows battery<br />

usage for up to 20 hours.<br />

Invictas Group Boss Space<br />

Page 9

Industry Industry News<br />

News<br />

JCB increased profits in 2009 and expects a significant improvement in<br />

sales and profits in 2010 as it launches a its new generation backhoe.<br />

This first of the new backhoes is seen here in a special Union Jack livery<br />

outside the Houses of Parliament in London.<br />

telehandler market also makes it world market leader for these machines.<br />

Page 10<br />

JCB remains profitable<br />

in 2009 and predicts<br />

a better 2010<br />

Despite seeing its sales drop by a third to<br />

£1.35 billion last year, JCB has<br />

announced that it was able to increase<br />

profit before tax marginally to £29 million<br />

(its corresponding figure in 2008 was £28<br />

million). In the face of a global<br />

<strong>construction</strong> <strong>equipment</strong> market which fell<br />

by 46% in 2009, JCB states that its total<br />

sales were 36,000 machines.<br />

This achievement leads JCB to claim<br />

that it has increased its market share to an<br />

all-time high of 12.2% - thereby reinforcing<br />

its stated position as the world’s third<br />

largest <strong>construction</strong> <strong>equipment</strong><br />

manufacturer. JCB reports that its marketleading<br />

share of the global backhoe<br />

loader market has risen to more than 40%<br />

whilst its a 28% share of the global<br />

JCB Chairman Sir Anthony Bamford says, “2009 was hugely challenging for the <strong>construction</strong> <strong>equipment</strong> industry.<br />

<strong>The</strong> entire JCB organisation pulled together magnificently to respond decisively to the unprecedented downturn, which<br />

was particularly severe in the first half of the year. Tough action was taken to adjust our cost base to align it to a much<br />

reduced level of demand, and this resulted in an improving profit trend as the year progressed. We have created a<br />

strong platform for renewed profitable growth."<br />

JCB has now embarked on a £20 million investment in a new generation of its iconic backhoe loader, the machine<br />

with an excavator arm at the rear and shovel at the front. <strong>The</strong> first of the new eco-range of the British-built diggers<br />

rolled off the company’s Staffordshire production line in Union Jack colours and embarked on a tour of famous London<br />

landmarks to celebrate its launch and the company’s approaching 65th anniversary in October.<br />

Sir Anthony Bamford also said that, in the first half of 2010, the <strong>construction</strong> <strong>equipment</strong> industry has seen a “strong<br />

recovery” in emerging markets such as India, Brazil and China, although the traditional markets of Western Europe<br />

and North America remain weak. On balance, he expects to see a significant improvement in both sales and profits<br />

this year compared to 2009.<br />

On the personnel front, JCB has appointed Michael Mohan – who previously worked for Jaguar and Land Rover as<br />

its new Group Engineering Director. He replaces Tim Leverton who left JCB to join Tata Motors earlier this year.<br />

New Holland concludes<br />

Juventus sponsorship<br />

<strong>The</strong> three year sponsorship between the<br />

Fiat-owned company New Holland and the<br />

famous Turin-based football club Juventus<br />

has come to an end. To commemorate the<br />

conclusion of this promotional partnership,<br />

New Holland recently took pictures of<br />

Juventus team members beside an E135B<br />

tracked excavator that is produced in the<br />

company’s Turin factory.<br />

Members of the famous Juventus team pose with<br />

a New Holland E135B tracked excavator to mark<br />

the end of a successful promotional partnership<br />

between the football club and the <strong>construction</strong><br />

machinery maker.<br />

JCB<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

Industry Industry News<br />

News<br />

New Holland states that its three year partnership with Juventus helped raise the profile of its brand not only<br />

amongst sector operators also with sports fans - thereby establishing a successful link between the Turin company<br />

and football. <strong>The</strong> sponsorship deal also provided over 7000 Italian and European clients and dealers with the chance<br />

to go along to watch top football matches in the Coppa Italia, Champions and Europa League.<br />

Since 2007, New Holland has benefited from a series of different initiatives linked to its sponsorship of Juventus.<br />

<strong>The</strong>se ranged from auctioning a ‘Dream Machine’ wheel loader painted in the Bianconeri team colours (to raise money<br />

for the Italian charity ‘Fondazione Crescere Insieme al Sant’Anna’) to the Juventus woodland sustainability project in<br />

Pinzolo, planted with a view to offsetting the CO emissions produced during the team’s summer camp.<br />

2<br />

Stolen JCB machines have been recovered in Poland thanks to Datatag<br />

technology and the CESAR plant registration scheme. This picture<br />

shows the triangular CESAR identification tag on a JCB telehandler<br />

and the Datatag scanner reading a hidden responder.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

New Holland<br />

CESAR ‘fingerprints’ aid recovery<br />

of stolen machines in Poland<br />

Three stolen items of <strong>construction</strong> plant have<br />

been returned to the UK from Poland thanks to<br />

their unique CESAR ‘fingerprint’ and Datatag<br />

technology. Police in Poland suspected that two<br />

JCB Loadall telescopic handlers and a JCB<br />

backhoe loader were stolen but, as the thieves<br />

had removed every single trace of identity and<br />

‘cloned’ the machines with a new identity, the<br />

officers could not prove it.<br />

However, Datatag technology and CESAR<br />

registration quickly identified that all three JCB<br />

machines had been stolen, from leading plant hire<br />

companies, in the South East of England during<br />

2008 and 2009. <strong>The</strong> machines are now the<br />

property of the insurance companies who settled<br />

the losses. JCB was one of the first of many major<br />

manufacturers to adopt CESAR and it has been<br />

fitting the system to UK machines for three years.<br />

A qualified police vehicle examiner, who flew to<br />

Poland especially for this mission, was easily able<br />

to verify the true identity of the machines using<br />

state of the art Datatag ID technology. Just like a human fingerprint the CESAR version categorically identifies a<br />

specific machine as no two CESAR fingerprints are alike. <strong>The</strong> thieves had been able to remove the manufacturer’s<br />

visible identity of the machines but they could not eradicate the hidden and permanent CESAR fingerprint. As a<br />

consequence the gang face lengthy prison sentences for theft and handling stolen property.<br />

Kevin Howells, Director of Datatag ID, and an expert on plant theft prevention and recovery, comments, “This latest<br />

recovery of valuable <strong>equipment</strong> really does show the effectiveness of the unique Datatag ‘fingerprint’ that every<br />

CESAR registered machine is given. Even after several years we were able to categorically identify all three stolen<br />

machines which has led to their repatriation and a substantial financial recovery for the insurance companies<br />

concerned.”<br />

Datatag security technology is used in a unique and innovative way to permanently identify a given machine.<br />

CESAR security devices, fitted to every machine on the register, include several tamper proof triangular registration<br />

plates (with a unique number for each machine), a number of radio-frequency identification (RFID) tags hidden in the<br />

machine, forensic liquid DNA, and thousands of microscopic Datadots. Datatag contends that it is impossible for<br />

thieves to remove all the traces of its identification technology from a CESAR registered machine, which is one reason<br />

why recovery rates are higher than for unprotected and secured machines.<br />

CESAR Scheme<br />

Page 11

An important feature of the new<br />

generation Bobcat skid steer and<br />

compact tracked loaders is the lower<br />

and more forward mounted cab that<br />

greatly enhances visibility to the front.<br />

Page 12<br />

Plant Editor Nick Johnson reports from Dobris in<br />

the Czech Republic where Bobcat had its new skid<br />

steer loaders, compact tracked loader and latest<br />

mini excavators ready for inspection.<br />

Forw orw orward orw ard cabs cabs enhance enhance new<br />

new<br />

Bobcats<br />

Bobcats<br />

When the company whose name is synonymous with skid steer<br />

loaders introduces new generation machines it is an important event.<br />

So the arrival of the first new 600 series Bobcat skid steers prompted a<br />

trip to the company’s Training Centre at Dobris in the Czech Republic<br />

to check out exactly what has changed.<br />

As well as the new S630 and S650 wheeled skid steer loaders,<br />

Bobcat has also introduced a new generation T650 compact tracked<br />

loader together with some new attachments for them. Other new<br />

models include the E45 and E50 mini excavators together with new<br />

rotary telescopic handlers. So there was plenty of new product to<br />

check out.<br />

Bobcat was purchased by the South Korean company Doosan in<br />

2007 and now, as part of Doosan Infracore Construction Equipment,<br />

the brand sensibly retains its own well known name and livery.<br />

Generally Doosan orange is used on larger machines with the white,<br />

black and red Bobcats predominating in the lighter weight <strong>equipment</strong>.<br />

Some mini excavators are still sold around the world as orange<br />

Doosans but Bobcats are now the only skid steers produced by the<br />

company – its former Doosan range from South Korea having been<br />

discontinued.<br />

As soon as the two new generation Bobcat skid steers and the new<br />

compact track loader are seen it is obvious that they represent a significant step forward. With Bobcat, Doosan claims<br />

to be number one in the world in compact loaders and with these new designs it clearly intends to strengthen this<br />

leading position.<br />

Better forward view from roomier cab<br />

<strong>The</strong> most apparent feature of the new loaders is that their cabs are roomier and are positioned further forward than<br />

has been the norm on previous Bobcats. This ‘cab forward’ change greatly improves visibility – particularly to the<br />

bucket or other attachment being used at the front of the machine.<br />

<strong>The</strong> new S630 is a radial arm skid steer loader with a rated operating capacity of 989kg which effectively replaces<br />

the S220 model. <strong>The</strong> 1220kg capacity S650 is a vertical lift path machine set to supersede the S250 and the tracked<br />

T650 (with a 1166kg capacity) replaces the T250.<br />

<strong>The</strong>se new machines set the style of future Bobcat skid steer and compact tracked loader updates and additions,<br />

<strong>The</strong> next new generation models – not<br />

seen at Dobris – will be the new top-of-therange<br />

S850 skid steer and its tracked<br />

counterpart, the T870. <strong>The</strong>se machines are<br />

expected to arrive later this year with<br />

operating capacities of 1758kg and 1508kg<br />

respectively.<br />

Bobcat says that the development of<br />

the new generation skid steer and compact<br />

tracked loaders is based on feedback from<br />

customers. <strong>The</strong> designers were given the<br />

brief to improve visibility, enhance<br />

performance and improve operator<br />

comfort, serviceability and durability. As a<br />

result the latest models have their cabs<br />

<strong>The</strong> rear protection provided by the new rear<br />

bumper can clearly be seen on this picture of an<br />

S650 skid steer equipped with an industrial<br />

grapple.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

BA BAUMA BA UMA 2010 2010 REVIEW<br />

REVIEW<br />

placed lower and further forward to improve access and enhance forward<br />

visibility.<br />

Easier entry into quieter machine<br />

I certainly found it easier to get into the pressurised cab due to the lower<br />

threshold and once inside the 10% increase in internal space was immediately<br />

apparent. Operators will also appreciate the reduction in internal noise levels –<br />

Bobcat claims a 5dB(A) improvement in what traditionally has not been the<br />

quietest of machine types.<br />

<strong>The</strong> view from the seat has certainly improved compared to earlier Bobcat<br />

skid steer models. <strong>The</strong> overall height of the rear loader arm support towers<br />

has been reduced (for both the radial and vertical lift versions) and the glazed<br />

area of the door on the new generation machines is 45% larger than on the<br />

previous models.<br />

Overall visibility is said to be 30% better aided by a larger rear window (and sloping top to the engine<br />

compartment), 16% larger side windows and a 34% bigger roof window. Sensibly, the windows are mounted on the<br />

outside of the Roll-Over Protection Structure<br />

(ROPS) to make cleaning easier and to provide<br />

more elbow space inside the cab.<br />

To take advantage of the more spacious cab, the<br />

adjustable seat now has 50mm more longitudinal<br />

adjustment. Control options include the traditional<br />

Bobcat hands and feet, AHC (hands only), ACS<br />

(choice of hands and feet or just hands) and SJC<br />

(Selectable Joystick Controls) where the joystick<br />

mounts can be adjusted independently of the seat.<br />

Better heating and air<br />

conditioning<br />

<strong>The</strong> pressurised cab has a new one-piece seal that<br />

goes all the way round the door, to reduce the<br />

ingress of dirt and dust that might enter the cab. <strong>The</strong><br />

performance of the optional heating and air<br />

conditioning system has been increased by 35%<br />

and the controls are fully illuminated so the<br />

temperature settings can be chosen in low light<br />

conditions.<br />

<strong>The</strong> view from the seat of the new generation Bobcat skid steer and<br />

compact tracked loaders has certainly improved compared the<br />

company’s previous models.<br />

<strong>The</strong> neat, integrated auxiliary hydraulic circuit hose connectors in the<br />

nearside loader arm can be clearly seen as this T650 operates with<br />

the power angle and tilt dozer blade attachment.<br />

All the new generation loaders are designed for field installation of a radio, with placeholders for the radio and<br />

speakers. <strong>The</strong>re is also a 12 V power accessory<br />

for charging a mobile phone, iPod or other<br />

devices.<br />

<strong>The</strong> three new 600 series machines are<br />

powered by fuel-efficient Kubota V3307-DI-TE3<br />

turbocharged four-cylinder diesel engines rated<br />

at 55.4kW (74.3hp). <strong>The</strong>se transversely mounted<br />

interim Tier IV emissions compliant engines are<br />

carried on three mounts to improve balance and<br />

reduce vibrations. <strong>The</strong> size of the fuel tank in the<br />

two new skid steer models has been increased<br />

by 18%.<br />

<strong>The</strong> air filter, engine dip stick, engine oil filler,<br />

alternators, fuel fill engine oil drain, fuel filter, engine<br />

oil filter, starter motor and battery are all accessible<br />

from the back of the machine when the rear access<br />

door is opened.<br />

Page 13

<strong>The</strong> hydrostatic transmission on the new skid steer<br />

loaders provides a 20% increase in tractive effort that<br />

provides better digging performance and pushing<br />

force. <strong>The</strong>re are two travel speed ranges on the S630<br />

and S650 – up to 11.4 km/h in low range and a<br />

maximum of 19.8 km/h when high range is selected.<br />

Higher tractive effort on tracked<br />

machine<br />

Tractive effort from the hydrostatic transmission in the<br />

T650 compact tracked loader is 15% more than the<br />

previous model. This increase aids digging and the extra pushing power is particularly apparent when using the<br />

BA BAUMA BA UMA 2010 2010 REVIEW<br />

REVIEW<br />

machine equipped with the useful power angle and tilt dozer blade attachment.<br />

An effective improvement is that the quick connect auxiliary circuit hose couplings are now neatly integrated into<br />

the nearside loader arm. This arrangement means that they are very accessible whilst being better protected from<br />

possible site damage. A new, removable hydraulic hose guide makes it easier to change attachments. Care has been<br />

taken to place hoses inside the footprint of the machine to keep them out of harms way.<br />

New hydraulic circuits provide more hydraulic pressure and flow which contributes to the 18% faster dump/roll back<br />

cycle times. <strong>The</strong>re are now two 10-micron filters to provide much better hydraulic filtration. To increase reliability, the<br />

number of hydraulic connections has been reduced and there are less angled fittings.<br />

When the machine is purchased with standard flow hydraulics, the flow rate is 87.1 l/min at a pressure of 241 bar.<br />

If the optional factory fitted high flow hydraulics are selected, the flow rate is increased to 115.5 l/min at a pressure of<br />

241.3 bar – to allow use of a greater range of powered attachments.<br />

Charge oil hydraulic system cooling<br />

<strong>The</strong> cooling system for the hydraulics is now carried out on the charge oil rather than the implement oil, providing<br />

significantly improved cooling efficiency. <strong>The</strong> flow rate through the oil cooler is much steadier as it is not affected by<br />

the operation of the cylinders or attachments. <strong>The</strong> oil cooler, which is now made of aluminium, swings up, allowing the<br />

operator to quickly clean the area between the oil cooler and the radiator.<br />

Improved serviceability is aided by having the tailgate open form the offside of the machine. This arrangement<br />

allows better accessibility for refuelling when the machine is transported on a trailer. <strong>The</strong>re is enhanced access to the<br />

battery and the hydraulic filter is now better place at a higher level. On the offside of the machine there is now a seethrough<br />

hydraulic oil sight level gauge.<br />

Amongst the new attachments now available for use with the new generation skid steer and compact tracked<br />

loaders are two heavy-duty graders with blade widths of 2440mm and 2740mm. At Dobris a unit, complete with a<br />

hydraulic side shift blade and a laser system sourced from Trimble was fitted to a tracked T650.<br />

Specially strengthened for use on compact tracked loaders, the new heavy-duty graders have a 6-way blade plus<br />

hydraulic side-shift of up to 330mm left or right. <strong>The</strong>y have a proportional hydraulic valve which enables the operator<br />

to make fine adjustments as required.<br />

Simple conversion to laser grader<br />

<strong>The</strong> new graders can be<br />

converted from a standard<br />

grader into a laser grader<br />

quickly and easily. <strong>The</strong><br />

operator only needs to<br />

mount the receiver poles,<br />

clamp the laser receivers<br />

onto the poles and plug in<br />

the harnesses. In operation<br />

a super bright grade<br />

display with green ‘ongrade’<br />

LEDs provides clear<br />

depth/elevation indication.<br />

Another T650 with high<br />

flow hydraulics at the<br />

Page 14<br />

<strong>The</strong> tracked T650 in action with the new heavyduty<br />

grader attachment complete with hydraulic<br />

side shift on the blade and a laser system sourced<br />

from Trimble.<br />

New Generation Bobcat Skid Steer and Compact Tracked<br />

Loader<br />

Model Operating Tipping Operating Power Width with<br />

Capacity Load Weight Standard Bucket<br />

(kg) (kg) (kg) (kW) (mm)<br />

S630 989 1978 3496* 55.4 1880<br />

S650 1220 2440 3777* 55.4 1880<br />

T650+ 1166 3331 4282* 55.4 1880<br />

* Base machine with bucket, operator and full fuel tank<br />

+ Compact tracked loader<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

Dobris Training Centre was fitted with a WS24 wheel saw attachment.<br />

Suitable for cutting a trench up to 610mm deep, this saw weighs<br />

846kg and has hydraulic side shift. A bigger WS32 wheel saw<br />

(sourced from Simex in Italy) will join the range at the end of this year.<br />

<strong>The</strong> WS24 cuts a clean trench through concrete or asphalt to<br />

allow the installation of water or gas pipes or electric or fibre-optic<br />

cables. This is a very demanding application but the T650<br />

demonstrated that it has more than enough power and hydraulic flow<br />

and pressure to accomplish the job efficiently. <strong>The</strong> tracked<br />

undercarriage of the T650 provides a very stable carrier to facilitate<br />

an accurate cut.<br />

Having previously introduced both larger and smaller new<br />

generation compact excavators, Bobcat has now launched the new<br />

E45 and E50 models with operating weights of around 4.6 and 4.9<br />

tonnes respectively. <strong>The</strong> 1960mm wide E45 is a genuine zero tail<br />

swing machine whilst the rear superstructure of the bigger E50 only<br />

protrudes beyond its 1960mm track width by 17mm.<br />

Both the E45 and E50 are produced in Gwinner, North Dakota,<br />

USA. Maximum digging depths are 3300mm and 3524mm<br />

respectively with the standard dipper arm. <strong>The</strong>se depths can be<br />

increased to 3600mm and 3923mm when the long arm option is<br />

selected. <strong>The</strong> E50 can also be fitted with an additional rear<br />

counterweight to maximise stability when used with the long arm.<br />

Compared to the 337, 345 and 435 models they replace, the new E45 and E50 have been designed to provide<br />

superior operator comfort, enhanced reliability and stability as well as reduced noise. <strong>The</strong>y are both powered a 4cylinder<br />

Kubota V2403-M-DI-TE38-BC turbo-charged Tier III diesel engine rated, respectively, at 30.2kW (40.5hp) and<br />

35.4kW (47.5hp).<br />

New auto idle to save fuel<br />

To conserve fuel, there is a new auto idle which causes the engine revs to drop to tick-over if the excavator functions<br />

are not used for a period of about four seconds. <strong>The</strong> engine automatically returns to the pre-set throttle position when<br />

the operator moves a joystick or a travel function.<br />

<strong>The</strong> hydraulic system of each excavator has a load sensing piston<br />

pump and a closed centre valve which, it was found, provide smooth<br />

and precise operation. Another plus point is that both the boom and<br />

dipper arm cylinders are cushioned to provide a smooth, end-of stroke<br />

operation. To make backfilling and site leveling operations easier,<br />

dozer blade float is standard.<br />

<strong>The</strong> new design cab provides plenty of foot space and it is<br />

equipped as standard with heating and ventilation. Air conditioning is<br />

available as an option. Inside the operator noise level is a good<br />

79dB(A) for the E45 and 81dB(A) for the E50. <strong>The</strong> hinged cab door<br />

opens wide and can be latched neatly back against the superstructure<br />

whilst safely remaining within the machine’s slewing radius.<br />

Matched tiltrotator and controls<br />

Within the cab, the boom offset and the first and second (optional)<br />

auxiliary hydraulic controls are integrated in the joysticks. <strong>The</strong> high<br />

hydraulic flow (75.7 l/min) in the auxiliary line, in combination with the<br />

machine’s good stability, has increased the range of attachments now<br />

offered by Bobcat. At Dobris, an E45 was equipped with a versatile<br />

Bobcat TR25 tiltrotator (produced for the company by Engcon) and an<br />

Engcon SK05 grapple.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

<strong>The</strong> new T650 powering a WS24 road saw – the<br />

forward mounted cab provides the operator with a<br />

good view of the attachment and the front of each<br />

track.<br />

<strong>The</strong> new 4.9 tonne E50 is the larger of<br />

Bobcat’s two new generation mini<br />

excavators whose cab doors hinge right<br />

back safely within the slewing radius.<br />

Page 15

<strong>The</strong> new 4.6 tonne class zero tail swing mini<br />

excavator demonstrates the extra versatility it<br />

gains when fitted with a tiltrotator.<br />

<strong>The</strong> wide opening tailgate and hinge up side<br />

panel on the E45 allows access to the filters,<br />

the battery and radiator as well as<br />

centralised grease points.<br />

Page 16<br />

<strong>The</strong> wide opening tailgate and hinge up side panel on the E45<br />

and E50 allows access to the filters, the battery and radiator as well<br />

as centralised grease points. <strong>The</strong> air conditioning condenser and<br />

hydraulic cooler can be easily separated for cleaning purposes,<br />

without need for tools. Greater service access can be obtained by<br />

completely removing the tailgate, the side panel and the<br />

counterweight.<br />

<strong>The</strong> arrival of the E45 and E50 to join the other new generation<br />

E08, E10, E32, E35, E42, E60 and E80 gives Bobcat a formidable<br />

range of modern machines. Whilst the Bobcat name is still<br />

particularly associated with skid steer loaders, these units will help<br />

the company become a bigger player in the wider compact plant<br />

business as the market improves.<br />

Back into rotating telehandlers<br />

Bobcat is also intent on becoming a greater force in telescopic<br />

handlers. To this end it has reintroduced rotary telehandlers having<br />

dropped its own designs some years ago. <strong>The</strong> newcomers are four<br />

modern models sourced from Dieci in Italy. <strong>The</strong>y offer lifting<br />

capacities from 3.5 to 5.0 tonnes and lifting heights from 15.7m to<br />

24.5m.<br />

<strong>The</strong> smallest rotary model, the TR35160, offers a maximum<br />

lifting height of 15.7 m and features a three-section telescopic<br />

boom. It is the simplest model in the range with an Iveco engine,<br />

400° non-continuous rotation and angle down stabilisers.<br />

<strong>The</strong> larger TR45190, TR50210 and TR40250 models have foursection<br />

booms, to provide maximum lifting heights of 18.7m, 20.5m<br />

and 24.5m respectively. <strong>The</strong>se models feature Perkins engines,<br />

360° continuous rotation and out and down stabilisers. Attachment<br />

options include pallet forks, loader buckets, extension jibs,<br />

hydraulic winch and access platforms.<br />

<strong>The</strong> arrival of the new rotary telehandlers, together with the<br />

introduction of a new cab on Bobcat’s own rigid frame machines,<br />

shows that Doosan Infracore is intent on maximizing the potential of<br />

its Bobcat brand. This is good news for the many loyal Bobcat<br />

customers around the world. (CP&E)<br />

Bobcat<br />

This 20.5m TR50210 is<br />

one of a new four model<br />

range of rotating<br />

telescopic handlers that<br />

are being produced by<br />

Dieci in Italy for Bobcat.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

A two day practical<br />

demonstration event in<br />

a Scottish recycling<br />

centre was used by<br />

dealer Blue Scotland to<br />

promote some of the<br />

latest compost turners,<br />

mobile picking stations,<br />

shredders, screens and<br />

trommels from the<br />

makers Backhus,<br />

Doppstadt and Kiverco.<br />

Scottish Scottish displa display displa y of of green green w wwaste<br />

w aste recy recycling recy cling machines<br />

machines<br />

Two environmentally friendly organics recycling and biomass open days were staged earlier this year by machinery<br />

distributor Blue Scotland. Working in partnership with Falkirk Council, the ‘green’ event was held at the 2.5 hectares<br />

Kinneil Kerse Recycling Centre in Bo’ness, Scotland.<br />

Over 200 people attended the open days including many members of AfOR (the Association for Organics<br />

Recycling) who have a particular interest in this important aspect of recycling and composting technologies. Of the 12<br />

machines specially brought to the site, five of them were recent additions to the Blue product portfolio.<br />

Notable amongst the new recycling <strong>equipment</strong> being demonstrated was the recently launched DW-3060 Bio Power<br />

slow-speed shredder from the German company Doppstadt. This trailer mounted machine with its 350kW (500hp)<br />

Mercedes-Benz OM 460 LA engine has a shredding rotor with 42 teeth that enables wood waste to be shredded to<br />

specification in a single pass.<br />

Economical biomass production<br />

When set up with all the available comb extensions, the DW-3060 Bio Power can process material at the rate of up to<br />

50 tonnes per hour with 54% at -80mm. With minimal screening of oversize, the shredded wood waste is ready for<br />

direct supply to the fast-growing bio fuel market. This is said to be an extremely economical way of processing large<br />

volumes of biomass from recycled wood, generating significant savings on processing costs per tonne.<br />

Green waste can also be shredded with the new Bio Power to the same particle size produced by a high-speed<br />

shredder. <strong>The</strong> advantage of the new Doppstadt machine is said to be its considerably longer wearpart life, extended<br />

maintenance intervals and an impressive reduction in comparative running costs.<br />

Also seen in action was the new Doppstadt SM-620 Star Screen. This self-contained trailer mounted unit features a<br />

proven screening drum <strong>construction</strong> with<br />

an interior helix, which enables a spacesaving<br />

horizontal machine installation.<br />

Designed and built for the shredding of<br />

domestic, green, C&D waste and wood<br />

waste, this machine can also effectively<br />

produce biomass and RDF.<br />

Replaceable screening drums, a<br />

variety of ancillary <strong>equipment</strong> and choice<br />

of mesh sizes allows the flexible SM-620<br />

Star Screen to be adjusted and<br />

reconfigured for a wide variety of<br />

screening tasks and feed material. <strong>The</strong><br />

A JCB Loadall telescopic handler charges<br />

the hopper of the Doppstadt SM-620 Star<br />

Screen which can be configured for a wide<br />

variety of screening tasks and feed material.<br />

One of the highlights of the Open<br />

Days demonstrations staged by Blue<br />

Scotland was this recently introduced<br />

DW-3060 Bio Power slow-speed<br />

shredder from Doppstadt in Germany.<br />

Page 17

machine’s mechanical power<br />

transmission features direct chain<br />

wheel drive, with geared motors at<br />

the drum surface, and the variable<br />

speed provides optimum adjustment<br />

for regulation of the screening<br />

quality.<br />

Compost and soil turning <strong>equipment</strong> from the German maker Backhus was well represented at the Scottish<br />

demonstration days. Blue Scotland reports that the new 16.30 Compost Turner and the model 16.50 Straddle Turner<br />

gained particular interest while working the compost windrows on site.<br />

<strong>The</strong> 16.30 Compost Turner is the latest addition to the Backhus range of turning machines which use the siteproven<br />

roto-milling technique. Designed and built specifically for the essential turning and milling of windrows in the<br />

composting process, the self-propelled Backhus 16.30 is compact, productive tracked machine. It is powered by a<br />

35.4kW (47.5hp) Yanmar 4TNV 88 engine and has infinitely variable hydrostatic drive.<br />

<strong>The</strong> 3.5m wide 16.30 Compost Turner weighs 1700kg and is capable of processing a heap with a width of up to<br />

3.0m and a height of up to 1.3m. <strong>The</strong> machine has a continuous travel speed of up to 50 m/min and a turning capacity<br />

of up to 700m³/hr.<br />

Working together at Bo’ness were two new recycling units from Kiverco Recycling Systems Ltd of Dungannon in<br />

Northern Ireland. <strong>The</strong>se complementary machines were a 620 Trommel and a Mobile Picking Station.<br />

Customised picking stations<br />

Blue Scotland sells the new range of Kiverco Mobile Picking Stations which can be customised to virtually any size to<br />

suit customers’ applications. Pickers can be positioned on either or both sides of the variable speed conveyor and, for<br />

enhanced working conditions for operatives, fully enclosed cabin work stations have heating and lighting. Discharge<br />

chutes can be positioned as required and in any number for convenient “binning” of unwanted or recyclable materials<br />

in their respective stockpiles.<br />

Specifically designed for the primary screening and separation of commingled recyclables, municipal solid waste<br />

(MSW), skip waste, commercial, industrial and C&D waste, the Kiverco 620 Trommel can be used as either a standalone<br />

machine or as part of a municipal recycling facility. Materials can be sorted at rates of up to 20 tonnes/hr or 60<br />

tonnes/hr for MSW.<br />

<strong>The</strong> Kiverco 620 Trommel features a screening drum set at an angle of 5º and with an infinitely variable rotation<br />

speed of up to 15rpm. <strong>The</strong> drum is equipped with removable punched plate screen sections and there are a variety of<br />

screen plate apertures to suit customers’ specific requirements. A selection of woven mesh or rubber-coated screen<br />

plates is also available.<br />

A Falkirk Council spokesman said, “This even clearly showed how new and improved recycling and composting<br />

<strong>equipment</strong>s and technologies can assist councils and other major recyclers in reducing the quantity of waste sent to<br />

landfill and increase the use of secondary/recycled materials.” (CP&E)<br />

Page 18<br />

This self-propelled Backhus 16.30<br />

Compost Turner has been designed and<br />

built specifically for the essential turning<br />

and milling of windrows in the<br />

composting process.<br />

Blue Group<br />

Doppstadt<br />

Bachus<br />

Kiverco<br />

A JCB JS160 materials handler with fixed raised cab<br />

was used to efficiently feed the Kiverco 620 Trommel<br />

and Mobile Picking Station.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

With Bauma and all the travel problems associated with the volcanic ash cloud<br />

now behind us, plant makers are looking forward and selecting which of<br />

he forthcoming big shows they will attend in anticipation of improving<br />

markets around the world.<br />

Bey Beyond Bey ond Bauma Bauma other other shows shows are are gearing gearing up<br />

up<br />

As the world’s biggest <strong>construction</strong> <strong>equipment</strong> show, Bauma should be good. <strong>The</strong> 2010 event was, but it was<br />

noticeable that many exhibitors had subtly scaled back their stand expenditure as a reaction to the global market<br />

downturn.<br />

That said, Bauma was still bigger than ever but that is one of the exhibitions drawbacks. It is simply too large to be<br />

manageable for visitors on a tight timetable. Okay, so one can schedule to stay longer but then one encounters the<br />

show’s other major drawback – the exorbitant hike in the price of Munich hotel rooms during the period of the<br />

exhibition.<br />

Given these problems and the fact that the air travel<br />

restrictions during Bauma 2010, other major shows that<br />

can provide a more manageable and cost effective<br />

experience for their visitors should be able to benefit in the<br />

next year from the prospect of better market conditions.<br />

Construction <strong>equipment</strong> buyers from the USA<br />

and South America whose travel plans to Bauma<br />

were thwarted by the volcano will be looking<br />

forward to seeing latest machines at Conexpo in<br />

Las Vegas next March.<br />

As part of their plan to make the SMOPYC show more<br />

attractive to international exhibitors and visitors, its<br />

organisers are instigating a more attractive pricing<br />

policy and substantial improvements to facilities and<br />

services.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5<br />

<strong>The</strong>re are still plenty of significant <strong>construction</strong><br />

<strong>equipment</strong> shows to choose from in the next 12 months.<br />

China remains a positive market and that bodes well for the<br />

success of Bauma China 2010 that will take place during<br />

23- 26 November 2010 at the Shanghai New International<br />

Expo Centre. This important show (www.baumachina.com)<br />

is run by the Bauma organisers Messe<br />

Muenchen International in association with MMI (Shanghai)<br />

Co Ltd, CCMA (China Construction Machinery<br />

Association), CCPIT-MSC (China Council for the Promotion<br />

of International Trade - Machinery Sub-Council) and<br />

CNCMC) China Construction Machinery Co Ltd. <strong>The</strong><br />

organisers state that the 215,000m² of exhibition space has<br />

already been fully booked by 1,700 exhibitors.<br />

Early in 2011 there will be two significant shows at the<br />

Convention Centre in Las Vegas, USA. <strong>The</strong> more<br />

specialised <strong>World</strong> of Concrete (www.worldofconcrete.com)<br />

will run from 18-21 January whilst the 2011 world<br />

<strong>construction</strong> <strong>equipment</strong> exhibition CONEXPO-CON/AGG<br />

2011 follows on during 22-26 March.<br />

<strong>The</strong> Conexpo organisers report strong space sales and<br />

the UK-based CEA (Construction Equipment Association)<br />

reinforces this positive news by stating that the space in its<br />

UK Pavilion at Conexpo sold out within three days of going<br />

on sale.<br />

<strong>The</strong> CEA thinks that this rush for space at Conexpo<br />

reflects the fact that so many people from the USA and<br />

South America could not travel to Bauma because of the<br />

volcanic ash. Given the increased number of hotel rooms<br />

now available in Las Vegas, it is to be hoped that room<br />

rates will be reasonable during the shows so as not to put<br />

off potential visitors.<br />

Other significant <strong>construction</strong> <strong>equipment</strong> shows vying for<br />

support from both exhibitors and visitors next year include bCIndia, in Mumbai, India during 8-11 February, Samoter<br />

2011 (www.samoter.com) in Verona, Italy during 2-6 March and SMOPYC 2011 that will be held in Zaragoza, Spain<br />

from 5 to 9 April.<br />

<strong>The</strong> organisers of SMOPYC 2011 state that their show next year will benefit from Intensified international<br />

promotion, a more attractive pricing policy and substantial improvements to facilities and services. <strong>The</strong> intention is to<br />

make SMOPYC much more international than in the past and the visitor experience next April will be enhanced by the<br />

organisation, in conjunction with industry associations, of many useful business meetings, conferences and work<br />

seminars during the show. (CP&E)<br />

Page 19

Nick Johnson reports from the largest quarry in the west of<br />

Sweden where Volvo Construction Equipment recently<br />

reinforced its green credentials by sharing its latest<br />

strategies for saving fuel and lowering emissions.<br />

V VVolv<br />

V olv olvo olv o focuses focuses on on fuel fuel sa saving sa ving<br />

<strong>The</strong> high cost of fuel is making machine<br />

users much more receptive to fuel saving<br />

initiatives like the new OptiShift system<br />

from Volvo.<br />

<strong>The</strong> high cost of fuel has certainly focused the minds of machine users and manufacturers alike. Fuel represents a<br />

very significant proportion of the total cost of ownership of a machine and so any new initiative designed to reduce fuel<br />

consumption is worth serious consideration.<br />

One machine manufacturer that is clearly committed to further improving the fuel efficiency of its products is Volvo<br />

Construction Equipment. <strong>The</strong> company recently staged a special event in a big quarry near Gothenburg, Sweden to<br />

highlight its four-pronged approach to tackling the issue using a range of fuel saving solutions that encompass<br />

engines, systems, operator behaviour and future technology.<br />

Volvo has a long tradition of introducing useful features to improve operational efficiency on its machines such as<br />

wheel loaders. <strong>The</strong>se include speed and power dependent APS (Automatic Power Shift) in 1978 and load sensing<br />

hydraulics (with variable flow piston pumps) on its wheel loaders in the early 1980s.<br />

This year, Volvo Construction Equipment used the Bauma exhibition in Munich to launch its new OptiShift system<br />

as an option for its 210kW (286hp) L150F, 235kW (320hp) L180F and 261kW (355hp) L220F wheel loaders. Fully<br />

integrated into the well-proven Volvo APS equipped driveline, OptiShift utilises a new torque converter with lock-up<br />

and a free wheel stator together with a clever, Volvo patented, RBB (reverse by braking) function.<br />

Up to 15% less fuel<br />

Extensive testing on OptiShift equipped wheel loaders in Sweden, Germany, Turkey and the UK have led Volvo to<br />

confidently claim that the system can save up to 15% of fuel without compromising productivity. Developed over three<br />

years, OptiShift has proved to be particularly effective when a wheel loader is used for repetitive operations such as<br />

load and carry – in applications like rehandling and timber handling – as well as in short cycle loading.<br />

As Volvo produces all its own engines and driveline components, it was simpler for the company’s engineers to<br />

incorporate the new OptiShift as a fully matched system. When the operator of an OptiShift equipped wheel loader<br />

turns the system on, the perceivable benefits include<br />

better drive response, faster loading cycles, a more<br />

comfortable ride and increased hill climbing<br />

performance. <strong>The</strong> interval between fuel refills should be<br />

longer and long term repair costs ought to be lower as<br />

there should be less loading stress on the torque<br />

converter and transmission.<br />

In a wheel loader, the increase in torque provided<br />

by a torque converter proves invaluable when digging<br />

Page 20<br />

In the Jehander quarry in Sweden, it was soon apparent that<br />

the Volvo wheel loader with the OptiShift function activated<br />

was able to provide smoother deceleration and direction<br />

changes.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5

<strong>The</strong> OptiShift system has a drive clutch that mechanically locks the pump rotator and the turbine<br />

rotator, thereby minimising losses.<br />

into a pile or accelerating away with a full bucket. But the benefits derived from the<br />

torque converter reduce dramatically from the point where the turbine rotor<br />

reaches the same rotation speed as the pump rotor. By adding a drive clutch<br />

that mechanically locks the pump rotator and the turbine rotator, Volvo<br />

contends that losses are eliminated.<br />

Automatic lock-up in second, third and fourth gears<br />

A short test drive of an L180F with the OptiShift transmission switched on revealed<br />

smooth shifting with automatic lock up in second, third and fourth gears. <strong>The</strong> system is<br />

responsive and it allows the operator to concentrate on fully filling the bucket and then<br />

steering the machine during each cycle.<br />

Traditionally, in short cycle loading with a wheel loader, it is common to use the gear shift control to change<br />

between reverse and forward without applying the brakes – deceleration is handled by the torque converter. However,<br />

Volvo states that this method is less efficient than using the brakes, results in energy loss and places undue strain on<br />

the torque converter.<br />

Volvo’s new RBB system is a braking feature that automatically assists machine deceleration by using the standard<br />

service brakes instead of the torque converter. <strong>The</strong> operator handles the machine in the same way as normal but,<br />

when he switches from forwards to reverse using the shift control, the RBB system recognises the speed, direction<br />

and throttle position and applies the service brake to slow the machine.<br />

This provides a smoother deceleration and direction change and, since the converter is no longer used for braking,<br />

wear and fuel consumption are both reduced. During the test drive it was found that the RBB worked seamlessly with<br />

the OptiShift system.<br />

Favourable response from Swedish quarry company<br />

<strong>The</strong> new technology had also impressed the experienced wheel loader operators at the Gothenburg quarry run by<br />

Jehander, part of the Heidelberg Cement Group. Regional Manager Niklas Osvaldsson said that initial impressions of<br />

an L180F with OptiShift and RBB were very favourable. His opeators have reported easier driving and good control in<br />

working cycles. He confirmed that big reduction in fuel consumption – as much as 15% - has already been observed.<br />

Jehander is also very positive about another of Volvo’s fuel saving initiatives. This is the Eco Operator programme<br />

whereby experienced Volvo trainers visit customers like Jehander at their own sites and discuss with both<br />

management and operators how to run the operation in a better way.<br />

<strong>The</strong> Eco Operator is focused on training operators to develop an environmentally friendly style of driving –<br />

through less accelerating and braking and by using the most economical<br />

engine speed range. This not only reduces emissions, but<br />

also cuts fuel consumption without affecting productivity.<br />

Hybrid wheel loader still being<br />

developed<br />

Volvo is also continuing its development programme for<br />

hybrid wheel loaders. It has shown a prototype machine at<br />

exhibitions in the past but its launch has been delayed as the<br />

concept continues to be refined due to the rapid advances being<br />

made in the relevant technology.<br />

Meanwhile the company has announced its strategy for the<br />

next generation Volvo diesel engines needed to comply with the<br />

new Tier 4 Interim / Stage IIIB emissions regulations next year. To<br />