The worldwide construction equipment ... - Contractors World

The worldwide construction equipment ... - Contractors World

The worldwide construction equipment ... - Contractors World

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

machine’s mechanical power<br />

transmission features direct chain<br />

wheel drive, with geared motors at<br />

the drum surface, and the variable<br />

speed provides optimum adjustment<br />

for regulation of the screening<br />

quality.<br />

Compost and soil turning <strong>equipment</strong> from the German maker Backhus was well represented at the Scottish<br />

demonstration days. Blue Scotland reports that the new 16.30 Compost Turner and the model 16.50 Straddle Turner<br />

gained particular interest while working the compost windrows on site.<br />

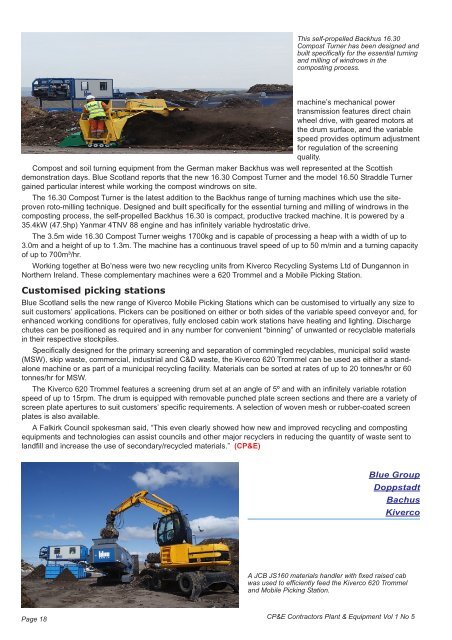

<strong>The</strong> 16.30 Compost Turner is the latest addition to the Backhus range of turning machines which use the siteproven<br />

roto-milling technique. Designed and built specifically for the essential turning and milling of windrows in the<br />

composting process, the self-propelled Backhus 16.30 is compact, productive tracked machine. It is powered by a<br />

35.4kW (47.5hp) Yanmar 4TNV 88 engine and has infinitely variable hydrostatic drive.<br />

<strong>The</strong> 3.5m wide 16.30 Compost Turner weighs 1700kg and is capable of processing a heap with a width of up to<br />

3.0m and a height of up to 1.3m. <strong>The</strong> machine has a continuous travel speed of up to 50 m/min and a turning capacity<br />

of up to 700m³/hr.<br />

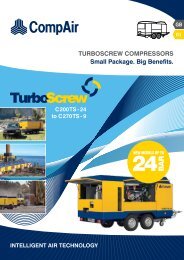

Working together at Bo’ness were two new recycling units from Kiverco Recycling Systems Ltd of Dungannon in<br />

Northern Ireland. <strong>The</strong>se complementary machines were a 620 Trommel and a Mobile Picking Station.<br />

Customised picking stations<br />

Blue Scotland sells the new range of Kiverco Mobile Picking Stations which can be customised to virtually any size to<br />

suit customers’ applications. Pickers can be positioned on either or both sides of the variable speed conveyor and, for<br />

enhanced working conditions for operatives, fully enclosed cabin work stations have heating and lighting. Discharge<br />

chutes can be positioned as required and in any number for convenient “binning” of unwanted or recyclable materials<br />

in their respective stockpiles.<br />

Specifically designed for the primary screening and separation of commingled recyclables, municipal solid waste<br />

(MSW), skip waste, commercial, industrial and C&D waste, the Kiverco 620 Trommel can be used as either a standalone<br />

machine or as part of a municipal recycling facility. Materials can be sorted at rates of up to 20 tonnes/hr or 60<br />

tonnes/hr for MSW.<br />

<strong>The</strong> Kiverco 620 Trommel features a screening drum set at an angle of 5º and with an infinitely variable rotation<br />

speed of up to 15rpm. <strong>The</strong> drum is equipped with removable punched plate screen sections and there are a variety of<br />

screen plate apertures to suit customers’ specific requirements. A selection of woven mesh or rubber-coated screen<br />

plates is also available.<br />

A Falkirk Council spokesman said, “This even clearly showed how new and improved recycling and composting<br />

<strong>equipment</strong>s and technologies can assist councils and other major recyclers in reducing the quantity of waste sent to<br />

landfill and increase the use of secondary/recycled materials.” (CP&E)<br />

Page 18<br />

This self-propelled Backhus 16.30<br />

Compost Turner has been designed and<br />

built specifically for the essential turning<br />

and milling of windrows in the<br />

composting process.<br />

Blue Group<br />

Doppstadt<br />

Bachus<br />

Kiverco<br />

A JCB JS160 materials handler with fixed raised cab<br />

was used to efficiently feed the Kiverco 620 Trommel<br />

and Mobile Picking Station.<br />

CP&E <strong>Contractors</strong> Plant & Equipment Vol 1 No 5