PROCESS PUMPS TYPE SLM NK TO DIN / ISO SLM ... - Klaus Union

PROCESS PUMPS TYPE SLM NK TO DIN / ISO SLM ... - Klaus Union

PROCESS PUMPS TYPE SLM NK TO DIN / ISO SLM ... - Klaus Union

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Production range<br />

pumps:<br />

Pumps with magnet drive<br />

E Centrifugal pumps<br />

according to <strong>DIN</strong> EN <strong>ISO</strong> 2858<br />

and to <strong>DIN</strong> EN <strong>ISO</strong> 15783<br />

E Centrifugal pumps<br />

according to ANSI B73.3<br />

E Centrifugal pumps for refinery<br />

and petrochemical applications<br />

according to API 685<br />

E Centrifugal pumps for high<br />

pressure applications<br />

E Centrifugal pumps for high<br />

temperature applications<br />

E Centrifugal pumps for liquid<br />

containing solids<br />

E Centrifugal pumps, self-priming<br />

E Multistage pumps, tension-rod or<br />

barrel-type construction<br />

E Side channel pumps, self-priming<br />

E Screw pumps<br />

E Submerged centrifugal pumps<br />

E Double suction centrifugal pumps<br />

E Plastic-lined pumps<br />

<strong>Klaus</strong> <strong>Union</strong> GmbH & Co. KG<br />

Blumenfeldstr. 18<br />

44795 Bochum<br />

Germany<br />

Phone +49 234 45 95 - 0<br />

Fax +49 234 45 95 - 7000<br />

E-Mail info@klaus-union.de<br />

Internet www.klaus-union.de<br />

Pumps with shaft sealing<br />

E Centrifugal pumps<br />

according to <strong>DIN</strong> EN <strong>ISO</strong> 2858<br />

and to <strong>DIN</strong> EN <strong>ISO</strong> 5199<br />

E Multistage pumps, tension-rod or<br />

barrel-type construction<br />

E Horizontal and vertical propeller pumps<br />

E Bottom-flange propeller pumps<br />

E Submerged centrifugal pumps<br />

E Double-suction chemical pumps<br />

Production range<br />

valves:<br />

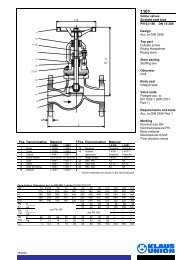

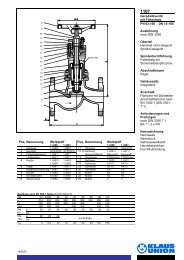

E Valves, T-pattern<br />

E Valves, Y-pattern<br />

E Gate valves, isomorphous<br />

construction series<br />

E Gate valves, wedge or wedge plates<br />

E Relief valves<br />

E Check valves<br />

E Sight glasses<br />

E Strainers<br />

E Filters<br />

E Bottom valves<br />

KU_<strong>NK</strong>/AK_ENG_05/12_0001<br />

S E R V I C E<br />

<strong>PROCESS</strong> <strong>PUMPS</strong> <strong>TYPE</strong><br />

<strong>SLM</strong> <strong>NK</strong> <strong>TO</strong> <strong>DIN</strong> / <strong>ISO</strong><br />

<strong>SLM</strong> AK <strong>TO</strong> ANSI / ASME<br />

WITH MAGNETIC DRIVE

2<br />

Performance data<br />

Fields of application for lined magnetic<br />

drive process pumps<br />

Leckage-free process pumps are particularly<br />

suitable for pumping corrosive, environmentally<br />

critical and high-purity liquids:<br />

E In the chemical industry<br />

E In the pharmaceutical industry<br />

E In the petrochemical industry<br />

E In the semiconductor industry<br />

E In the pulp and metal industry<br />

E In the food processing industry<br />

E In the waste disposal/recycling industry<br />

The <strong>SLM</strong> <strong>NK</strong> (<strong>ISO</strong>/<strong>DIN</strong>) and <strong>SLM</strong> AK (ASME/<br />

ANSI) series were developed for use with liquids<br />

where stainless steel and conventional<br />

plastics such as PE, PP etc. do not have sufficient<br />

corrosion resistance.<br />

They are also an alternative to:<br />

E pumps made of expensive long-lead-time<br />

metals (Alloy C, titanium, nickel, etc.)<br />

E mechanical seal pumps<br />

E full plastic pumps<br />

E metal pumps with double mechanical<br />

seals and liquid sealing or quenching<br />

systems<br />

E and stainless steel magnetic drive pumps.<br />

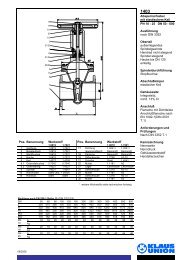

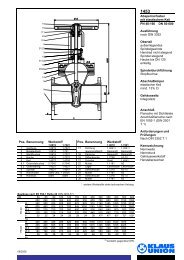

Design<br />

E Sealless, fluoroplastic-lined, magnet drive<br />

centrifugal pumps<br />

E Dimensions and performance data to <strong>DIN</strong><br />

EN <strong>ISO</strong> 2858 und ASME / ANSI B73.3<br />

E Close-coupled and frame-mounted designs<br />

E No dynamic seal<br />

E Isolation shell without eddy current losses<br />

Bearing support: <strong>ISO</strong> / <strong>DIN</strong> <strong>SLM</strong> <strong>NK</strong>S<br />

ASME / ANSI <strong>SLM</strong> AKO<br />

Close-coupled: <strong>ISO</strong> / <strong>DIN</strong> <strong>SLM</strong> <strong>NK</strong>B<br />

ASME / ANSI <strong>SLM</strong> AKB<br />

Lining: Perfluoralkoxy (PFA)<br />

ATEX and TA-Luft<br />

conformity (clean air act)<br />

Safety and environmental<br />

protection<br />

Quality assurance<br />

A major component of our Company ethos is<br />

to ensure the highest quality of our products.<br />

This quality assurance system, developed on<br />

modern principles, complies with the requirements<br />

of international regulations. <strong>Klaus</strong><br />

<strong>Union</strong> is a <strong>DIN</strong> EN <strong>ISO</strong> 9001 certified Company.<br />

Operating range<br />

50 Hz<br />

operation<br />

60 Hz<br />

operation<br />

<strong>SLM</strong> <strong>NK</strong><br />

Flowrate Head<br />

0,1-120 m³ /h up to 70 m Fl. S<br />

0,4-530 USpgm up to 230 ft<br />

<strong>SLM</strong> AK<br />

Flowrate Head<br />

0,1-150 m³ /h up to 110 m Fl. S<br />

0,4-660 USpgm up to 360 ft<br />

<strong>SLM</strong> <strong>NK</strong><br />

Flowrate Head<br />

0,1-130 m³ /h up to 100 m Fl. S<br />

0,4-570 USpgm up to 330 ft<br />

<strong>SLM</strong> AK<br />

Flowrate Head<br />

0,1-180 m³ /h up to 155 m Fl. S<br />

0,4-750 USpgm up to 500 ft<br />

Temperature: -30°C up to +150°C<br />

-20°F up to +300°F<br />

Pressure: up to 20 bar<br />

up to 290 psi<br />

Capability of handling liquids containing<br />

solids depending on shape, hardness<br />

and size of the solids. Please contact<br />

manufacturer.<br />

3

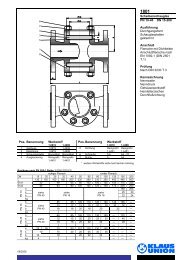

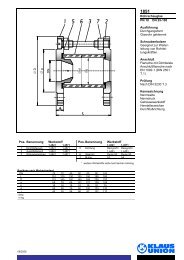

4<br />

6.<br />

1.<br />

6.<br />

3.<br />

2.<br />

10.<br />

8.<br />

9.<br />

7.<br />

5.<br />

4.<br />

Construction details <strong>SLM</strong> <strong>NK</strong> / <strong>SLM</strong> AK<br />

1. Virgin PFA lining without fillers – perfect<br />

lining quality with steady lining thickness<br />

E Highest chemical resistance<br />

E Temperatures up to 150 °C (300 °F)<br />

E Full FDA conformity<br />

E Neutral to pure and high-purity fluids in<br />

pharmaceutical, fine chemical and semiconductor<br />

applications<br />

E Superb permeation resistance<br />

E Wall thickness of at least 3 to 5 mm<br />

(0.1 to 0.2 inch)<br />

E Vacuum-proof anchored housing lining *<br />

2. Journal bearing<br />

E Journal bearing and axle carrier are made of<br />

silicon carbide (SSiC). The proprietary<br />

surface impregnation is extremely wear and<br />

chemical resistant<br />

3. Capable of handling fluids containing solids<br />

E Solids restriction rings in the housing and rotor<br />

prevent critical solid particles from entering the<br />

isolation shell area<br />

4. Axially thrust-optimised rotating unit: Smooth<br />

running even under critical load conditions<br />

E The shaft made of SSiC is optimally supported<br />

in the isolation shell and in the spider without<br />

any shaft deflection<br />

E The large space between the SSiC sleeve bearings<br />

provides reliable distribution of the radial<br />

forces<br />

E Closed impeller<br />

5. Easy of maintenance<br />

E Double “back pull-out” design for easy maintenance<br />

without releasing the system pressure<br />

E Few components only: a service-friendly pump<br />

* For vacuum services please contact manufacturer<br />

6. Solid design for dimensional stability even at<br />

high temperatures<br />

E Full-surface ductile cast iron EN-JS 1049/ASTM<br />

A395 absorbs pipework forces and eliminates<br />

need for expansion joints<br />

E Impeller magnet assembly with large metal<br />

core<br />

7. Non-metallic double isolation shell system<br />

E Wetted: thick-walled virgin PTFE<br />

E Pressure-containing: carbon-fibre, with high<br />

safety margin<br />

E No eddy current losses: no heating of fluid,<br />

no waste of energy<br />

E Integral flow breakers prevent abrasive<br />

circulation in the isolation shell<br />

8. High-performance NdFeB (neodymium iron<br />

boron) and SmCo (samarium cobalt) permanent<br />

magnets<br />

E Consistent magnetic energy density even at<br />

high operating temperatures<br />

E Patented magnet fixation underneath the<br />

PFA lining<br />

9. Outer magnet carrier with rub ring<br />

E In event of roller bearing failure the isolation<br />

shell will be reliably protected against damage<br />

by a possibly tumbling outer magnet carrier<br />

10. Impeller/inner magnet carrier assembly<br />

of two pieces<br />

E In case of torque adjustment or wear the wetted<br />

rotor components can be replaced individually.<br />

This enhances cost-efficiency<br />

E Completely homogenous PFA lining<br />

E No weldings<br />

5

6<br />

Performance curves <strong>SLM</strong> <strong>NK</strong> / <strong>SLM</strong> AK<br />

<strong>SLM</strong> <strong>NK</strong> (<strong>ISO</strong>/<strong>DIN</strong>) <strong>SLM</strong> AK (ASME/ANSI)<br />

Head – 2900 rpm (50 Hz)<br />

Head – 3500 rpm (60 Hz)<br />

(ft)<br />

240<br />

160<br />

80<br />

0<br />

(ft)<br />

320<br />

240<br />

160<br />

80<br />

0<br />

0<br />

(m)<br />

60<br />

0<br />

100<br />

40<br />

040-025-160<br />

20<br />

040-025-125<br />

0<br />

20<br />

050-032-200<br />

50<br />

200 300 400 500<br />

40 60 80 100 120<br />

065-040-200<br />

080-050-160<br />

080-050-200<br />

050-032-160<br />

0 050-032-125<br />

0 10 20 30 40 50 60<br />

0<br />

(m)<br />

100<br />

80<br />

60<br />

40<br />

040-025-125<br />

20<br />

0<br />

100<br />

20<br />

100 150 200 250<br />

200 300 400 500 600<br />

0 050-032-125<br />

050-032-160<br />

0 10 20 30 40 50 60 70<br />

0<br />

050-032-200<br />

040-025-160<br />

50<br />

Flowrate – 2900 rpm (50 Hz)<br />

Flowrate – 1450 rpm (50 Hz)<br />

Flowrate – 3500 rpm (60 Hz)<br />

(USgpm)<br />

(m3 /h)<br />

(m)<br />

15<br />

10<br />

5<br />

(m3 0<br />

/h)<br />

(USgpm)<br />

(USgpm)<br />

(m3 40 60 80 100 120 140 /h)<br />

(m)<br />

065-040-200<br />

080-050-160<br />

080-050-200<br />

100 150 200 250 300<br />

Flowrate – 1750 rpm (60 Hz)<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

(m3 /h)<br />

(USgpm)<br />

(ft)<br />

60<br />

40<br />

20<br />

0<br />

(ft)<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Head– 1450 rpm (50 Hz)<br />

Head – 1750 rpm (60 Hz)<br />

Head – 2900 rpm (50 Hz)<br />

Head – 3500 rpm (60 Hz)<br />

(ft)<br />

320<br />

240<br />

160<br />

80<br />

0<br />

(ft)<br />

480<br />

400<br />

320<br />

240<br />

160<br />

80<br />

0<br />

(m)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0<br />

0<br />

100<br />

20<br />

1.5 x 1 x 8“<br />

1.5 x 1 x 6“<br />

50<br />

200 300 400 500 600<br />

40 60 80 100 120 140<br />

3 x 2 x 10“<br />

3 x 1.5 x 8“<br />

3 x 2 x 8“<br />

4 x 3 x 8“<br />

0<br />

3 x 1.5 x 6“<br />

3 x 2 x 6“<br />

0 10 20 30 40 50 60 70<br />

0<br />

0<br />

(m)<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

0<br />

100<br />

20<br />

1.5 x 1 x 8“<br />

1.5 x 1 x 6“<br />

50<br />

Flowrate – 2900 rpm (50 Hz)<br />

100 150 200 250 300<br />

Flowrate – 1450 rpm (50 Hz)<br />

Flowrate – 3500 rpm (60 Hz)<br />

200 300 400 500 600 700 800<br />

40 60 80 100 120 140 160 180<br />

3 x 2 x 10“<br />

3 x 1.5 x 8“<br />

3 x 2 x 8“ 4 x 3 x 8“<br />

20<br />

0<br />

3 x 1.5 x 6“ 3 x 2 x 6“<br />

0 10 20 30 40 50 60 70 80 90<br />

100 150 200 250 300 350 400<br />

Flowrate – 1750 rpm (60 Hz)<br />

(USgpm)<br />

(m 3 /h)<br />

(m)<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

(m3 /h)<br />

(USgpm)<br />

(ft)<br />

80<br />

60<br />

40<br />

20<br />

0<br />

(USgpm)<br />

(m3 /h)<br />

(m) (ft)<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0 0<br />

(m3 /h)<br />

(USgpm)<br />

Head – 1450 rpm (50 Hz)<br />

Head – 1750 rpm (60 Hz)<br />

7