You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>GIESSE</strong> <strong>GOS</strong>-S T-<strong>REX</strong> <strong>SYSTEM</strong><br />

System Components<br />

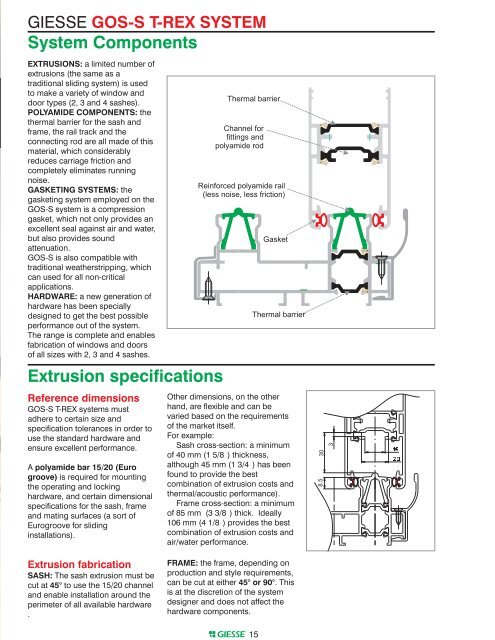

EXTRUSIONS: a limited number of<br />

extrusions (the same as a<br />

traditional sliding system) is used<br />

to make a variety of window and<br />

door types (2, 3 and 4 sashes).<br />

POLYAMIDE COMPONENTS: the<br />

thermal barrier for the sash and<br />

frame, the rail track and the<br />

connecting rod are all made of this<br />

material, which considerably<br />

reduces carriage friction and<br />

completely eliminates running<br />

noise.<br />

GASKETING <strong>SYSTEM</strong>S: the<br />

gasketing system employed on the<br />

<strong>GOS</strong>-S system is a compression<br />

gasket, which not only provides an<br />

excellent seal against air and water,<br />

but also provides sound<br />

attenuation.<br />

<strong>GOS</strong>-S is also compatible with<br />

traditional weatherstripping, which<br />

can used for all non-critical<br />

applications.<br />

HARDWARE: a new generation of<br />

hardware has been specially<br />

designed to get the best possible<br />

performance out of the system.<br />

The range is complete and enables<br />

fabrication of windows and doors<br />

of all sizes with 2, 3 and 4 sashes.<br />

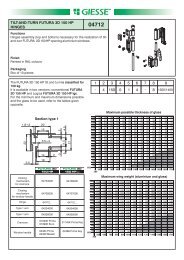

Extrusion specifications<br />

Reference dimensions<br />

<strong>GOS</strong>-S T-<strong>REX</strong> systems must<br />

adhere to certain size and<br />

specification tolerances in order to<br />

use the standard hardware and<br />

ensure excellent performance.<br />

A polyamide bar 15/20 (Euro<br />

groove) is required for mounting<br />

the operating and locking<br />

hardware, and certain dimensional<br />

specifications for the sash, frame<br />

and mating surfaces (a sort of<br />

Eurogroove for sliding<br />

installations).<br />

Extrusion fabrication<br />

SASH: The sash extrusion must be<br />

cut at 45° to use the 15/20 channel<br />

and enable installation around the<br />

perimeter of all available hardware<br />

.<br />

Thermal barrier<br />

Channel for<br />

fittings and<br />

polyamide rod<br />

Reinforced polyamide rail<br />

(less noise, less friction)<br />

Gasket<br />

Thermal barrier<br />

Other dimensions, on the other<br />

hand, are flexible and can be<br />

varied based on the requirements<br />

of the market itself.<br />

For example:<br />

Sash cross-section: a minimum<br />

of 40 mm (1 5/8 ) thickness,<br />

although 45 mm (1 3/4 ) has been<br />

found to provide the best<br />

combination of extrusion costs and<br />

thermal/acoustic performance).<br />

Frame cross-section: a minimum<br />

of 85 mm (3 3/8 ) thick. Ideally<br />

106 mm (4 1/8 ) provides the best<br />

combination of extrusion costs and<br />

air/water performance.<br />

FRAME: the frame, depending on<br />

production and style requirements,<br />

can be cut at either 45° or 90° . This<br />

is at the discretion of the system<br />

designer and does not affect the<br />

hardware components.<br />

15<br />

15<br />

20