ProfiClear Premium Moving Bed Modul

ProfiClear Premium Moving Bed Modul

ProfiClear Premium Moving Bed Modul

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3 Safety information<br />

- GB -<br />

The company OASE has built this unit according to the state of the art and the valid safety regulations.<br />

Despite the above, hazards for persons and assets can emanate from this unit if it is used in an<br />

improper manner or not in accordance with its intended use, or if the safety instructions are ignored.<br />

For safety reasons, children and young persons under 16 years of age as well as persons who<br />

cannot recognise possible danger or who are not familiar with these operating instructions, are<br />

not permitted to use the unit. Keep children under supervision to ensure that they do not play<br />

with the unit.<br />

4 Installation<br />

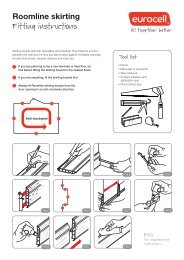

The following tools are required:<br />

10 mm ring spanner<br />

7 mm socket spanner<br />

PZ3 Phillips screwdriver<br />

Cordless drill/screwdriver with PZ3 bit (do not set to "drill"!)<br />

4.1 Preparing the unit connection<br />

Before installing, connecting and starting up the unit, perform the following tasks:<br />

1 Fit 1× DN 75 slide valve ( A 9)<br />

5.<br />

5.<br />

2 Fit 2× 180 mm inlets ( A 4)<br />

2 Fit 2× DN 150 outlets ( A 7)<br />

2 Fit 2× meshed tubes ( A 6)<br />

Remove the container cover.<br />

Fitting the DN 75 slide valve<br />

How to proceed:<br />

B<br />

1. Fit the slide valve into the connecting sleeve and secure with a hose clip.<br />

2. Fit the connecting sleeve onto the connection.<br />

3. Secure the holding plate of the slide valve to the outside of the container with cap nuts.<br />

4. Secure the hose clip on the connection.<br />

Fitting the 180 mm inlet<br />

How to proceed:<br />

C<br />

1. If not already done: Fit the sealing ring into the wall of the container from the outside.<br />

Ensure that the raised marking is at the top and aligned in relation to the hole pattern.<br />

2. Fit the inlet to the sealing ring.<br />

Ensure that the raised marking is at the top and aligned in relation to the hole pattern.<br />

3. Fasten the sealing ring and inlet from the inside with oval head screws.<br />

Tighten all screws diagonally using the cordless screwdriver to ensure that the sealing ring is<br />

uniformly applied. Further tighten the screws using a Phillips screwdriver.<br />

4. Fit the rubber sleeve over the inlet and fasten with a hose clip.<br />

Turn the hose clip so that the screw is accessible from the side. This facilitates later installation<br />

work.<br />

21