- Page 1 and 2:

MOUNTED Bearings Catalog Katalog ei

- Page 3 and 4:

BALL BEARING UNITS KUGELLAGER-EINHE

- Page 5 and 6:

B1-3 Ball Bearing E-Z KLEEN SOLIDLU

- Page 7 and 8:

SC, SCM SXR GT, GTM Setscrew Lockin

- Page 9 and 10:

Housings • Gehäuse • Paliers

- Page 11 and 12:

SEALING oPTIoNS ABdIcHTUNGSmÖGLIcH

- Page 13 and 14:

Para usar las tablas de selección

- Page 15 and 16:

SELEcTIoN TABLE • AUSWAHLTABELLE

- Page 17 and 18:

P2B Housings • Gehäuse • Palie

- Page 19 and 20:

P2B Housings • Gehäuse • Palie

- Page 21 and 22:

P2B Housings • Gehäuse • Palie

- Page 23 and 24:

TB Housings • Gehäuse • Palier

- Page 25 and 26:

F2B Housings • Gehäuse • Palie

- Page 27 and 28:

F4B Housings • Gehäuse • Palie

- Page 29 and 30:

Fc Housings • Gehäuse • Palier

- Page 31 and 32:

WSTU Housings • Gehäuse • Pali

- Page 33 and 34:

P2B Housings • Gehäuse • Palie

- Page 35 and 36: F2B Housings • Gehäuse • Palie

- Page 37 and 38: F4B Housings • Gehäuse • Palie

- Page 39 and 40: Fc Housings • Gehäuse • Palier

- Page 41 and 42: WSTU Housings • Gehäuse • Pali

- Page 43 and 44: BEARING INSERT Sc Bearing Inserts w

- Page 45 and 46: BEARING INSERT SXR/ LAGEREINSATZ SX

- Page 47 and 48: BEARING INSERT Scm / LAGEREINSATZ S

- Page 49 and 50: BEARING INSERT GT Bearing Inserts L

- Page 51 and 52: BEARING INSERT GTm Bearing Inserts

- Page 53 and 54: GT AdAPTERS AdAPTER GT AdAPTATEURS

- Page 55 and 56: E-Z KLEEN Features/Benefits . . . .

- Page 57 and 58: E-Z KLEEN Polymer & Stainless Steel

- Page 59 and 60: E-Z KLEEN SCEZ Setscrew Locking Two

- Page 61 and 62: NOMENCLATURE NOMENKLATUR NOMENCLATU

- Page 63 and 64: E-Z KLEEN P2B-PCR Housings • Geh

- Page 65 and 66: E-Z KLEEN P2B-SHCR Housings • Geh

- Page 67 and 68: E-Z KLEEN TB-PCR Housings • Gehä

- Page 69 and 70: E-Z KLEEN F2B-PCR Housings • Geh

- Page 71 and 72: E-Z KLEEN F2B-SHCR Housings • Geh

- Page 73 and 74: E-Z KLEEN F4B-PCR Housings • Geh

- Page 75 and 76: E-Z KLEEN F4B-SHCR Housings • Geh

- Page 77 and 78: E-Z KLEEN WSTU-PCR Housings • Geh

- Page 79 and 80: PSEZ BEARING INSERTS Sleeve bearing

- Page 81 and 82: GTEZ BEARING INSERTS Bearing Insert

- Page 83 and 84: E-Z KLEEN Polymer and Stainless Ste

- Page 85: SOLIDLUBE Features/Benefits . . . .

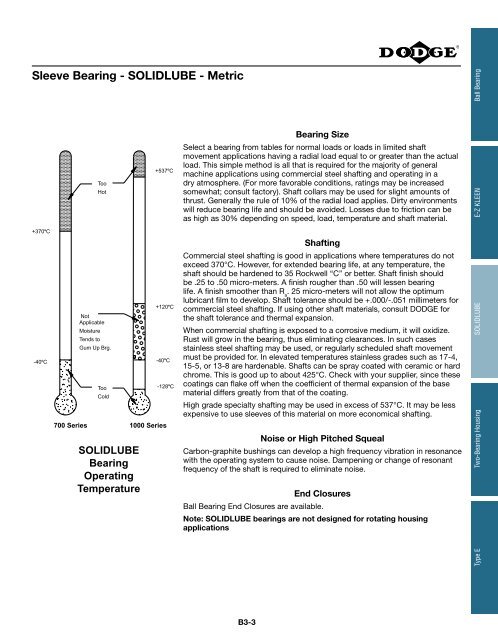

- Page 89 and 90: Sleeve Bearing - SOLIDLUBE - Metric

- Page 91 and 92: Sleeve Bearing - SOLIDLUBE - Metric

- Page 93 and 94: SELECTION TABLE • AUSWAHLTABELLE

- Page 95 and 96: P2B Housings • Gehäuse • Palie

- Page 97 and 98: F4B Housings • Gehäuse • Palie

- Page 99 and 100: Two-Bearing Housings Blocklagergeh

- Page 101 and 102: BLO, DFL, DFLS ④ The PDNF, BL-W a

- Page 103 and 104: Two-bearing housings PDNF, BL-W and

- Page 105 and 106: DFLS TWO-BEARING HOUSINGS - complet

- Page 107 and 108: DFL & DFL HT TWO-BEARING HOUSINGS -

- Page 109 and 110: PDNF KPL Complete with bearings and

- Page 111 and 112: BL-W KPL Housing complete with bear

- Page 113 and 114: BLO-A KPL Housing complete with bea

- Page 115 and 116: Type E / Typ E / Type E /Tipo E / T

- Page 117 and 118: Type E / Typ E / Type E /Tipo E / T

- Page 119 and 120: Type E / Typ E / Type E /Tipo E / T

- Page 121 and 122: Type E / Typ E / Type E /Tipo E / T

- Page 123 and 124: Type E METRIC / Typ E METRISCH / Ty

- Page 125 and 126: Type E METRIC / Typ E METRISCH / Ty

- Page 127 and 128: Type E METRIC / Typ E METRISCH / Ty

- Page 129 and 130: Type E METRIC / Typ E METRISCH / Ty

- Page 131 and 132: Type E METRIC / Typ E METRISCH / Ty

- Page 133 and 134: Type E METRIC / Typ E METRISCH / Ty

- Page 135 and 136: Type E METRIC / Typ E METRISCH / Ty

- Page 137 and 138:

Type E METRIC / Typ E METRISCH / Ty

- Page 139 and 140:

Type E METRIC / Typ E METRISCH / Ty

- Page 141 and 142:

Type E PLUMMER BLOCK - METRIC / Typ

- Page 143 and 144:

Type E PLUMMER BLOCK - INCH / Typ E

- Page 145 and 146:

Type E PLUMMER BLOCK - INCH / Typ E

- Page 147 and 148:

Type E FLANGE BEARING - INCH / Typ

- Page 149 and 150:

ISN Features/Benefits . . . . . . .

- Page 151 and 152:

ISN DODGE ISN SNX SNX ISN Dimension

- Page 153 and 154:

ISN BEARING NOMENCLATURE / ISN LAGE

- Page 155 and 156:

ISN EASY SELECTION / EINFACHE ISN A

- Page 157 and 158:

ISN EASY SELECTION / EINFACHE ISN A

- Page 159 and 160:

ISN CAPLOAD / ISN - GEHÄUSBELASTUN

- Page 161 and 162:

ISN DIMENSIONS / ISN-STEHLAGERABMES

- Page 163 and 164:

ISN PLUMMER BLOCKS DIMENSIONS / ISN

- Page 165 and 166:

ISN END COVER / ISN ABSCHLUSSDECKEL

- Page 167 and 168:

SN SERIES SN SERIE SÉRIE SN SERIE

- Page 169 and 170:

SNX Oil equalization passage: allow

- Page 171 and 172:

SNF PLUS / SNF PLUS / SNF PLUS / SN

- Page 173 and 174:

SEALS / DICHTUNGEN / jOINTS / jUNTA

- Page 175 and 176:

SSND CAP LOAD / SNX DECKELBELASTUNG

- Page 177 and 178:

SDX & SDXD CAP LOADS / DECKELBELAST

- Page 179 and 180:

SNX 200 - TS/TT Plummer Blocks for

- Page 181 and 182:

SNX 200 - LD/FS/DK Dimensions in mm

- Page 183 and 184:

SNX 200 - LD/FS/DK Housing GG Spher

- Page 185 and 186:

SNX 500 S-1 Shaft Size Wellengroße

- Page 187 and 188:

SNX 500 Spherical Roller Bearing Pe

- Page 189 and 190:

SNX 500 Self-aligning Ball Bearings

- Page 191 and 192:

SNX 300 S-1 S-2 Dimensions in mm Ab

- Page 193 and 194:

SNX 300 Spherical Roller Bearing Fi

- Page 195 and 196:

SNX 600 Dimensions in mm Abmessunge

- Page 197 and 198:

SNX 600 Spherical roller bearing Fi

- Page 199 and 200:

SSND 200 SSND 200 Series A (With Se

- Page 201 and 202:

SSND 200 Spherical roller bearing F

- Page 203 and 204:

SSND 500 Dimensions in mm Abmessung

- Page 205 and 206:

SSND 500 Spherical roller bearing F

- Page 207 and 208:

SSND 500 Self-aligning ball bearing

- Page 209 and 210:

SSND 300 Dimensions in mm Abmessung

- Page 211 and 212:

SSND 300 Spherical roller bearing F

- Page 213 and 214:

SSND 600 Dimensions in mm Abmessung

- Page 215 and 216:

SSND 600 Spherical roller bearing F

- Page 217 and 218:

SNF 500 PLUS Housing w/o accessorie

- Page 219 and 220:

SNF 500 PLUS Spherical roller beari

- Page 221 and 222:

SNF 500 PLUS Housing w/o accessorie

- Page 223 and 224:

SNF 500 PLUS Self-aligning ball bea

- Page 225 and 226:

SNX 30 Housing LD Seal FS Seal VR S

- Page 227 and 228:

SDX 3000 Housing Labyrinth Seal Tri

- Page 229 and 230:

SDX 3100 Housing Labyrinth Seal Tri

- Page 231 and 232:

SDXD 3000 Housing Labyrinth Seal Tr

- Page 233 and 234:

SDXD 3100 Housing Labyrinth Seal Tr

- Page 235 and 236:

HFO Features/Benefits . . . . . . .

- Page 237 and 238:

HFO Available in GG; for 22200, 222

- Page 239 and 240:

HFO OIL & SPEED DATA / HFO ÖL & GE

- Page 241 and 242:

HFO CAP LOADS GGG / HFO DECKELBELAS

- Page 243 and 244:

HFO 200 Complete Housing Unit in GG

- Page 245 and 246:

HFO 200 MOD 2 x d Complete Housing

- Page 247 and 248:

HFO 200 MOD S1 Complete Housing Uni

- Page 249 and 250:

HFO 200 MOD KS Complete Housing Uni

- Page 251 and 252:

HFO 500 Complete Housing Unit in GG

- Page 253 and 254:

HFO 300 Complete Housing Unit in GG

- Page 255 and 256:

HFO 600 Complete Housing Unit in GG

- Page 257 and 258:

Bearings and Sleeves Lager und Hül

- Page 259 and 260:

Bearings & Sleeves / Lager & Hülse

- Page 261 and 262:

Bearings & Sleeves / Lager & Hülse

- Page 263 and 264:

22200-22200K Selection Tables Auswa

- Page 265 and 266:

23000K-23100K Selection Tables Ausw

- Page 267 and 268:

2200 - 2200K Selection Tables Auswa

- Page 269 and 270:

22200K SPHERICAL ROLLER BEARINGS PE

- Page 271 and 272:

22300K SPHERICAL ROLLER BEARINGS PE

- Page 273 and 274:

23100K SPHERICAL ROLLER BEARINGS PE

- Page 275 and 276:

1200K & 2200K Self-aligning ball be

- Page 277 and 278:

H3100 Adapter sleeve Spannhülse Ma

- Page 279 and 280:

KM LOCKNUT WELLENMUTTERN ÉCROUS DE

- Page 281 and 282:

SLEEVOIL Features/Benefits . . . .

- Page 283 and 284:

RTL Les caractéristiques comprenne

- Page 285 and 286:

RXT den Einsatz sowohl mit integrie

- Page 287 and 288:

DODGE OLF ® DODGE OLF Oil level &

- Page 289 and 290:

DODGE Cool Lube System / DODGE kalt

- Page 291 and 292:

NOMENCLATURE NOMENKLATUR RTL - TPK

- Page 293 and 294:

NOMENCLATURA STD Serie standard PLW

- Page 295 and 296:

SLEEVOIL GERMAN B10-15 ISN SN Serie

- Page 297 and 298:

SLEEVOIL SPANISH B10-17 ISN SN Seri

- Page 299 and 300:

SLEEVOIL 1 . Bore size and name of

- Page 301 and 302:

SLEEVOIL FRENCH B10-21 ISN SN Serie

- Page 303 and 304:

SLEEVOIL ITALIAN B10-23 ISN SN Seri

- Page 305 and 306:

RTL SLEEVOIL 3-7/16 - 12” Housing

- Page 307 and 308:

RTL SLEEVOIL 3-7/16 - 12” Dimensi

- Page 309 and 310:

RXT SLEEVOIL 6” - 12” Housing S

- Page 311 and 312:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 313 and 314:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 315 and 316:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 317 and 318:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 319 and 320:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 321 and 322:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 323 and 324:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 325 and 326:

SLEEVOIL - R Series / SLEEVOIL - R

- Page 327 and 328:

SLEEVOIL Für alle SLEEVOIL-Lager s

- Page 329 and 330:

SLEEVOIL END CAP KITS /ENDVERSCHLUS

- Page 331 and 332:

SLEEVOIL AUXILARY SEAL KITS / SLEEV

- Page 333 and 334:

SLEEVOIL REPLACEMENT OIL RINGS / ER

- Page 335 and 336:

SLEEVOIL VIBRATION DETECTOR ADAPTER

- Page 337 and 338:

SLEEVOIL CIRCULATION OIL SYTEMS /

- Page 339 and 340:

SLEEVOIL CIRCULATION OIL SYTEMS /

- Page 341 and 342:

SLEEVOIL CIRCULATION OIL SYTEMS /

- Page 343 and 344:

SLEEVOIL OIL LEVEL AND FILTRATION S

- Page 345 and 346:

FOOTNOTES / FUSSNOTEN / NOTES DE BA

- Page 347 and 348:

FOOTNOTES / FUSSNOTEN / NOTES DE BA

- Page 349 and 350:

Part No. Page Part No. Page Part No

- Page 351 and 352:

Part No. Page Part No. Page Part No

- Page 353 and 354:

Part No. Page Part No. Page Part No

- Page 355 and 356:

Part No. Page Part No. Page Part No

- Page 357 and 358:

Part No. Page Part No. Page Part No

- Page 359 and 360:

Part No. Page Part No. Page Part No

- Page 361 and 362:

Part No. Page Part No. Page Part No

- Page 363 and 364:

Part No. Page Part No. Page Part No

- Page 365 and 366:

Part No. Page Part No. Page Part No

- Page 367 and 368:

Part No. Page Part No. Page Part No

- Page 369 and 370:

Part No. Page Part No. Page Part No

- Page 371 and 372:

Part No. Page Part No. Page Part No

- Page 373 and 374:

Part No. Page Part No. Page Part No

- Page 375 and 376:

Part No. Page Part No. Page Part No

- Page 377 and 378:

Notes INDEX-29 Part Number Index