Cerámica serie Life Profiles, Ceranco, Porcelanosa ... - Venespa

Cerámica serie Life Profiles, Ceranco, Porcelanosa ... - Venespa

Cerámica serie Life Profiles, Ceranco, Porcelanosa ... - Venespa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

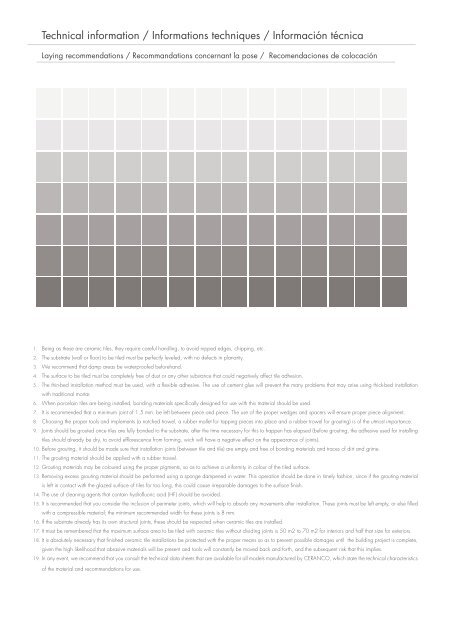

Technical information / Informations techniques / Información técnica<br />

Laying recommendations / Recommandations concernant la pose / Recomendaciones de colocación<br />

1. Being as these are ceramic tiles, they require careful handling, to avoid nipped edges, chipping, etc.<br />

2. The substrate (wall or floor) to be tiled must be perfectly leveled, with no defects in planarity.<br />

3. We recommend that damp areas be waterproofed beforehand.<br />

4. The surface to be tiled must be completely free of dust or any other substance that could negatively affect tile adhesion.<br />

5. The thin-bed installation method must be used, with a flexible adhesive. The use of cement glue will prevent the many problems that may arise using thick-bed installation<br />

with traditional mortar.<br />

6. When porcelain tiles are being installed, bonding materials specifically designed for use with this material should be used.<br />

7. It is recommended that a minimum joint of 1.5 mm. be left between piece and piece. The use of the proper wedges and spacers will ensure proper piece alignment.<br />

8. Choosing the proper tools and implements (a notched trowel, a rubber mallet for tapping pieces into place and a rubber trowel for grouting) is of the utmost importance.<br />

9. Joints should be grouted once tiles are fully bonded to the substrate, after the time necessary for this to happen has elapsed (before grouting, the adhesive used for installing<br />

tiles should already be dry, to avoid efflorescence from forming, wich will have a negative effect on the appearance of joints).<br />

10. Before grouting, it should be made sure that installation joints (between tile and tile) are empty and free of bonding materials and traces of dirt and grime.<br />

11. The grouting material should be applied with a rubber trowel.<br />

12. Grouting materials may be coloured using the proper pigments, so as to achieve a uniformity in colour of the tiled surface.<br />

13. Removing excess grouting material should be performed using a sponge dampened in water. This operation should be done in timely fashion, since if the grouting material<br />

is left in contact with the glazed surface of tiles for too long, this could cause irreparable damages to the surface finish.<br />

14. The use of cleaning agents that contain hydrofluoric acid (HF) should be avoided.<br />

15. It is recommended that you consider the inclusion of perimeter joints, which will help to absorb any movements after installation. These joints must be left empty, or else filled<br />

with a compressible material; the minimum recommended width for these joints is 8 mm.<br />

16. If the substrate already has its own structural joints, these should be respected when ceramic tiles are installed.<br />

17. It must be remembered that the maximum surface area to be tiled with ceramic tiles without dividing joints is 50 m2 to 70 m2 for interiors and half that size for exteriors.<br />

18. It is absolutely necessary that finished ceramic tile installations be protected with the proper means so as to prevent possible damages until the building project is complete,<br />

given the high likelihood that abrasive materials will be present and tools will constantly be moved back and forth, and the subsequent risk that this implies.<br />

19. In any event, we recommend that you consult the technical data sheets that are available for all models manufactured by CERANCO, which state the technical characteristics<br />

of the material and recommendations for use.