Manual de instrucciones - Triton Tools

Manual de instrucciones - Triton Tools

Manual de instrucciones - Triton Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GB<br />

front panel for better clamp locations<br />

• If your bla<strong>de</strong> will not fit through the slot because you<br />

have a riving knife fitted to the saw: extend the slot<br />

towards the front of the insert by using a hacksaw<br />

bla<strong>de</strong> or a file on edge<br />

• If one of the clamps fouls the saw motor: replace it with<br />

one of the Temporary Saw Clamps (18) on a shortened<br />

coach bolt<br />

Saw bla<strong>de</strong> cannot be adjusted fully square to the<br />

table<br />

• First, check that the saw does not have a limit screw<br />

in the baseplate, un<strong>de</strong>rneath the angle quadrant, that<br />

is preventing you from reaching 0°. Check that nothing<br />

else is fouling the saw motor or top guard, and thus<br />

preventing full tilt<br />

• Check that the mountings between the saw baseplate<br />

and the motor housing are reasonably firm. Tighten<br />

them, if possible, or upgra<strong>de</strong> your saw<br />

• If you cannot find any other solution, remove your saw<br />

and insert a full length strip of thin packing between<br />

the narrow part of the baseplate and the table, to<br />

slightly tilt the saw. I<strong>de</strong>ally tape or glue the strip to the<br />

table, then re-tighten the clamp knobs<br />

Very thin saw bla<strong>de</strong>s (teeth approx. 1.5mm thick)<br />

Thin slitting bla<strong>de</strong>s can be fitted, though we<br />

recommend standard bla<strong>de</strong>s approx 2.5mm thick,<br />

because:<br />

• Thin bla<strong>de</strong>s are very flexible and are easily bent or<br />

twisted when fitting the saw, making them difficult to<br />

align<br />

• With a thin bla<strong>de</strong> the scales will only be accurate when<br />

the fence is set on the right hand si<strong>de</strong> of the bla<strong>de</strong>. You<br />

will have to make an allowance when setting the fence<br />

to the left<br />

• A thicker bla<strong>de</strong> will not cause the above problems,<br />

and should also give you smoother cuts, less flexing in<br />

<strong>de</strong>nse wood, and better results when planing<br />

NOTE: 1.5mm thin bla<strong>de</strong>s cut 2.0 to 2.2mm wi<strong>de</strong>.<br />

If fitting a thin bla<strong>de</strong> saw, insert a strip of 0.5mm<br />

cardboard between the bla<strong>de</strong> and the fence, as a<br />

temporary spacer, and hold the bla<strong>de</strong> against it whilst<br />

aligning the saw. You will not be able to spin the bla<strong>de</strong><br />

by hand.<br />

Protractor scale is slightly inaccurate<br />

• The scale pointer can be adjusted by using a small<br />

screwdriver to lever out the lens, and then prising the<br />

pointer si<strong>de</strong>ways<br />

• First, make test cuts and adjust the protractor angle<br />

setting until you are cutting exactly square. Then insert<br />

the screwdriver bla<strong>de</strong> into the appropriate slot besi<strong>de</strong><br />

the pointer, and twist until the tip of the pointer is<br />

exactly opposite 0°<br />

Workpiece binds on overhead guard support when<br />

ripping<br />

• First, check that the fence was set at i<strong>de</strong>ntical readings<br />

front and rear. If it was, try increasing the rear fence<br />

setting slightly (0.5mm – 1mm) and repeat the cut<br />

• Check that the saw bla<strong>de</strong> is correctly lined up with the<br />

overhead gui<strong>de</strong> support<br />

• Check that the overhead guard support is square to the<br />

table. To square it up: use a straight piece of material,<br />

such as a block of wood, to spread the load as you<br />

carefully bend it square<br />

• If the problem persists: try re-aligning the saw<br />

slightly so that the overhead guard support fits into the<br />

kerf of the bla<strong>de</strong> without jamming<br />

High spots, burn marks and re-cut damage on the<br />

workpiece<br />

If the back of the bla<strong>de</strong> re-cuts or burnishes the<br />

workpiece when you cross-cut against the protractor,<br />

or when you rip against the parallel fence, the most<br />

likely reason is that your saw is mounted slightly skew.<br />

Before realigning your saw, check a few other possible<br />

causes:<br />

• Remove the bla<strong>de</strong> from the saw, check that the arbour<br />

and washers are clean and that the bla<strong>de</strong> is well<br />

seated. If an arbour-reducing washer is fitted, make<br />

sure it is a snug fit and not proud of the bla<strong>de</strong> disc.<br />

• Check for bla<strong>de</strong> flatness with a metal straight<br />

edge at various points across the centre hole. If<br />

significantly buckled, replace the bla<strong>de</strong><br />

• Check for arbour float in your saw bearings by<br />

disconnecting the power, gripping the bla<strong>de</strong><br />

nut and pulling in and out in the direction of the<br />

shaft. Any movement is un<strong>de</strong>sirable. If you want<br />

perfectly square cuts, you may have to repair or<br />

replace your saw<br />

12<br />

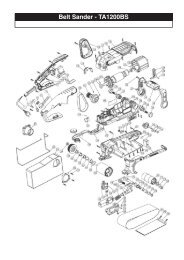

Assembly