Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

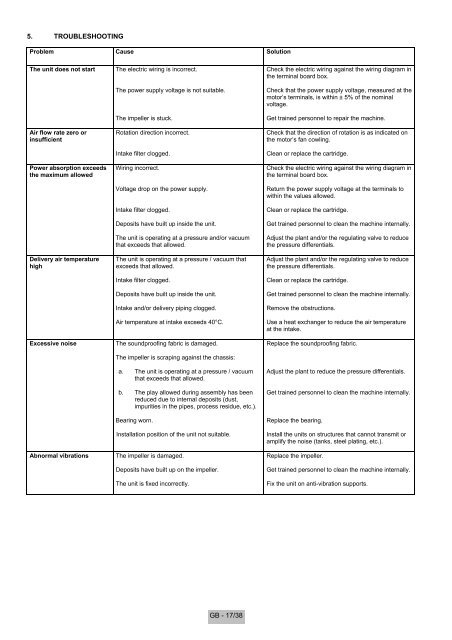

5. TROUBLESHOOTINGProblem Cause SolutionThe unit does not startAir flow rate zero orinsufficientPower absorption exceedsthe maximum allowedDelivery air temperaturehighExcessive noiseAbnormal vibrationsThe electric wiring is incorrect.The power supply voltage is not suitable.The impeller is stuck.Rotation direction incorrect.Intake filter clogged.Wiring incorrect.Voltage drop on the power supply.Intake filter clogged.Deposits have built up inside the unit.The unit is operating at a pressure and/or vacuumthat exceeds that allowed.The unit is operating at a pressure / vacuum thatexceeds that allowed.Intake filter clogged.Deposits have built up inside the unit.Intake and/or delivery piping clogged.Air temperature at intake exceeds 40°C.The soundproofing fabric is damaged.The impeller is scraping against the chassis:a. The unit is operating at a pressure / vacuumthat exceeds that allowed.b. The play allowed during assembly has beenreduced due to internal deposits (dust,impurities in the pipes, process residue, etc.).Bearing worn.Installation position of the unit not suitable.The impeller is damaged.Deposits have built up on the impeller.The unit is fixed incorrectly.Check the electric wiring against the wiring diagram inthe terminal board box.Check that the power supply voltage, measured at themotor’s terminals, is within ± 5% of the nominalvoltage.Get trained personnel to repair the machine.Check that the direction of rotation is as indicated onthe motor’s fan cowling.Clean or replace the cartridge.Check the electric wiring against the wiring diagram inthe terminal board box.Return the power supply voltage at the terminals towithin the values allowed.Clean or replace the cartridge.Get trained personnel to clean the machine internally.Adjust the plant and/or the regulating valve to reducethe pressure differentials.Adjust the plant and/or the regulating valve to reducethe pressure differentials.Clean or replace the cartridge.Get trained personnel to clean the machine internally.Remove the obstructions.Use a heat exchanger to reduce the air temperatureat the intake.Replace the soundproofing fabric.Adjust the plant to reduce the pressure differentials.Get trained personnel to clean the machine internally.Replace the bearing.Install the units on structures that cannot transmit oramplify the noise (tanks, steel plating, etc.).Replace the impeller.Get trained personnel to clean the machine internally.Fix the unit on anti-vibration supports.GB - 17/38