4.3.2. Identifikasi Kuantitatif dan Kualitatif Fasa BaFe Co Zn O

4.3.2. Identifikasi Kuantitatif dan Kualitatif Fasa BaFe Co Zn O

4.3.2. Identifikasi Kuantitatif dan Kualitatif Fasa BaFe Co Zn O

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

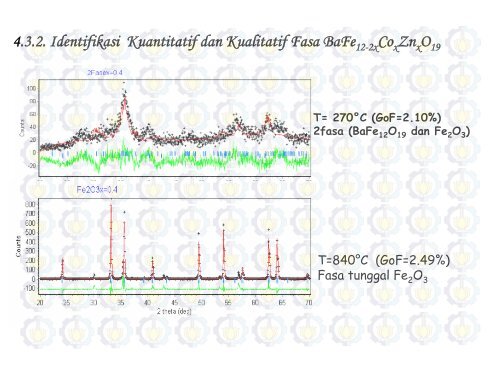

<strong>4.3.2.</strong> <strong>Identifikasi</strong> <strong>Kuantitatif</strong> <strong>dan</strong> <strong>Kualitatif</strong> <strong>Fasa</strong> <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19 T= 270°C (GoF=2.10%)<br />

2fasa (<strong>BaFe</strong>12O19 <strong>dan</strong><br />

Fe2O3 T=840°C (GoF=2.49%)<br />

<strong>Fasa</strong> tunggal<br />

Fe2O3 )

<strong>4.3.2.</strong> <strong>Identifikasi</strong> <strong>Kuantitatif</strong> <strong>dan</strong> <strong>Kualitatif</strong> <strong>Fasa</strong> <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19 Intensitas<br />

M<br />

1200°Cα<br />

M<br />

1000°C<br />

900°C<br />

840°C<br />

700°C<br />

270°C<br />

200°C<br />

80°C<br />

20 25 30 35 40 45 50 55 60 65 70<br />

Tipe-M<br />

α-Fe2O3 Tipe-W<br />

M<br />

W α M<br />

W α M<br />

M<br />

α M α α M<br />

W M α<br />

W αMα 20 25 30 35 40 45 50 55 60 65 70<br />

Pola difraksi XRD precursor <strong>BaFe</strong> 11.2 <strong>Co</strong> 0.4 <strong>Zn</strong> 0.4 O 19 yang di sintering pada berbagai temperatur<br />

α

<strong>4.3.2.</strong> <strong>Identifikasi</strong> <strong>Kuantitatif</strong> <strong>dan</strong> <strong>Kualitatif</strong> <strong>Fasa</strong> <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19 Keluaran hasil refenement Maud<br />

T= 840°C (Sig=1.37%)<br />

pada precursor <strong>BaFe</strong>10.4<strong>Co</strong>0.8<strong>Zn</strong>0.8O19

4.4 Analisis Mikrostruktur Barium M-Hexaferrit<br />

M Hexaferrit <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19)<br />

<strong>BaFe</strong>12 2x<strong>Co</strong>x<strong>Zn</strong>xO19)<br />

(a)<br />

Foto TEM prekursor <strong>BaFe</strong> 12-2x <strong>Co</strong> x <strong>Zn</strong> x O 19 pada (a) x=0.4 T=270°C (b) x=0.6 T=840°C,<br />

(c) x=0.6 T=900°C <strong>dan</strong> (d) x=0.4 T=1200°C.<br />

(b)<br />

(c) (d)

4.4 Analisis Mikrostruktur Barium M-Hexaferrit<br />

M Hexaferrit <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19)<br />

<strong>BaFe</strong>12 2x<strong>Co</strong>x<strong>Zn</strong>xO19)<br />

(a) (b)<br />

Foto SEM prekursor <strong>BaFe</strong> 12-2x <strong>Co</strong> x <strong>Zn</strong> x O 19 pada komposisi substitusi (a) x=0.2, (b) x=0.6, <strong>dan</strong> (c) x=0.8<br />

(c)

4.5 Interprestasi Proses Substitusi Ion Dopan <strong>Co</strong>/<strong>Zn</strong> terhadap<br />

Struktur Kristal (<strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19) Tabel Puncak transmisi FTIR (1/λ=cm-1 ) precursor <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19 T=80°C 2 jam<br />

x=0.6<br />

421 (s)<br />

687 (s)<br />

841 (m)<br />

1080(w)<br />

1408(w)<br />

1628(m)<br />

3383(s)<br />

T=270°C 4 jam T=840°C 4 jam<br />

x=0 x=0.4 x=1<br />

482(m )<br />

574 (s)<br />

1084(w)<br />

1385(w)<br />

1647(w)<br />

3422(w)<br />

3448(w)<br />

421 (s)<br />

436 (s)<br />

575 (w)<br />

1080(w)<br />

1408(w)<br />

1628(m)<br />

3422(s)<br />

421(s)<br />

575(s)<br />

849(m)<br />

1088(m)<br />

1254(w)<br />

1408(w)<br />

1628(m)<br />

3387(s)<br />

3421(s)<br />

x=0.4<br />

478 (s)<br />

575 (s)<br />

1076 (w)<br />

1520 (w)<br />

1640 (w)<br />

3449 (w)<br />

T=900°C 4 jam<br />

x=0.6<br />

478 (s)<br />

552 (s)<br />

575 (s)<br />

3422(w)

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Kesimpulan<br />

Sintesis barium M-hexaferrit <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19 dengan metode<br />

kopresipitasi mempunyai konsentrasi yang tinggi pada substitusi<br />

x=0.4.<br />

Berdasarkan analisis DTA/TGA <strong>dan</strong> XRD, proses sentering pada<br />

T≥740°C cenderung membentuk fasa hematite (α-Fe2O3) Proses sintesis barium M-hexaferrit <strong>BaFe</strong>12-2x<strong>Co</strong>x<strong>Zn</strong>xO19 dengan<br />

metode kopresipitasi mempunyai rata-rata orde partikel 50 nm.<br />

Pendopingan ion dopan <strong>Co</strong>/<strong>Zn</strong> pada sintesis barium M-hexaferrit<br />

tidak merubah struktur dasar kristal (hexagonal).<br />

Peningkatan variabel ion dopan <strong>Co</strong>/<strong>Zn</strong> akan menyebabkan<br />

peningkatan ukuran partikel prekursor barium M-hexaferrit.