- Page 1 and 2: Pneudri MiDAS DAS 1 - DAS 7 User Gu

- Page 3 and 4: DAS1 - DAS7 1 Safety Information Im

- Page 5: DAS1 - DAS7 2.1.1 Dimensions Minimu

- Page 9 and 10: DAS1 - DAS7 4 Operating the equipme

- Page 11 and 12: DAS1 - DAS7 5.3 Service Kits Servic

- Page 13 and 14: CONTENTS 1 Veiligheidsinformatie...

- Page 15 and 16: 2 Beschrijving 15 NL Veiligheidsinf

- Page 17 and 18: 2.2 De apparatuur uitpakken Aanbevo

- Page 19 and 20: 3.4 Elektrische installatie 19 NL V

- Page 21 and 22: 5 Servicewerkzaamheden 21 NL Veilig

- Page 23 and 24: 6 Problemen oplossen 23 NL Veilighe

- Page 25 and 26: DAS1 - DAS7 1 Sicherheitshinweise W

- Page 27 and 28: DAS1 - DAS7 2.1.1 Abmessungen Minim

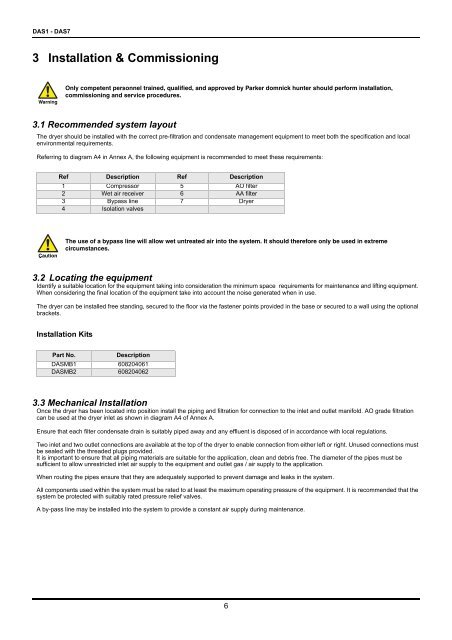

- Page 29 and 30: DAS1 - DAS7 3 Installation und Inbe

- Page 31 and 32: DAS1 - DAS7 4 Betrieb des Geräts 4

- Page 33 and 34: DAS1 - DAS7 5.3 Wartungssätze Wart

- Page 35 and 36: CONTENTS 1 Informations de sécurit

- Page 37 and 38: 2 Description 39 FR Informations de

- Page 39 and 40: 2.2 Déballage de l'appareil Il est

- Page 41 and 42: 3.4 Installation électrique 43 FR

- Page 43 and 44: 5 Entretien 45 FR Informations de s

- Page 45 and 46: 6 Dépannage 47 FR Informations de

- Page 47 and 48: DAS1 - DAS7 1 Turvallisuustietoja T

- Page 49 and 50: DAS1 - DAS7 2.1.1 Mitat Pienin toim

- Page 51 and 52: DAS1 - DAS7 3 Asennus ja käyttöö

- Page 53 and 54: DAS1 - DAS7 4 Laitteiston käyttö

- Page 55 and 56: DAS1 - DAS7 5.3 Huoltosarjat Huolto

- Page 57 and 58:

CONTENTS 1 Säkerhetsinformation...

- Page 59 and 60:

2 Beskrivning 63 SV Säkerhetsinfor

- Page 61 and 62:

2.2 Uppackning av utrustningen Vi r

- Page 63 and 64:

3.4 Elektrisk installation Alla ela

- Page 65 and 66:

5 Service 69 SV Säkerhetsinformati

- Page 67 and 68:

6 Felsökning 71 SV Säkerhetsinfor

- Page 69 and 70:

DAS1 - DAS7 1 Sikkerhetsinformasjon

- Page 71 and 72:

DAS1 - DAS7 2.1.1 Mål Minimum drif

- Page 73 and 74:

DAS1 - DAS7 3 Installasjon og idrif

- Page 75 and 76:

DAS1 - DAS7 4 Betjene utstyret 4.1

- Page 77 and 78:

DAS1 - DAS7 5.3 Servicesett Service

- Page 79 and 80:

CONTENTS 1 Sikkerhedsoplysninger...

- Page 81 and 82:

2 Beskrivelse 87 DA Sikkerhedsoplys

- Page 83 and 84:

2.2 Udpakning af udstyret Det anbef

- Page 85 and 86:

3.4 Elektrisk installation Alt elar

- Page 87 and 88:

5 Vedligeholdelse 93 DA Sikkerhedso

- Page 89 and 90:

6 Fejlfinding 95 DA Sikkerhedsoplys

- Page 91 and 92:

DAS1 - DAS7 1 :

- Page 93 and 94:

DAS1 - DAS7 2.1.1 E M M

- Page 95 and 96:

DAS1 - DAS7 3 Warning , ,

- Page 97 and 98:

DAS1 - DAS7 4 4.1 : 4

- Page 99 and 100:

DAS1 - DAS7 5.3 . A5

- Page 101 and 102:

CONTENTS 1 Información de segurida

- Page 103 and 104:

2 Descripción 111 ES Información

- Page 105 and 106:

2.2 Desembalaje del equipo Se recom

- Page 107 and 108:

3.4 Instalación eléctrica 115 ES

- Page 109 and 110:

5 Mantenimiento 117 ES Información

- Page 111 and 112:

6 Detección y reparación de aver

- Page 113 and 114:

DAS1 - DAS7 1 Informações de Segu

- Page 115 and 116:

DAS1 - DAS7 2.1.1 Dimensões Minima

- Page 117 and 118:

DAS1 - DAS7 3 Instalação e Comiss

- Page 119 and 120:

DAS1 - DAS7 4 Utilização do equip

- Page 121 and 122:

DAS1 - DAS7 5.3 Kits de Manutençã

- Page 123 and 124:

CONTENTS 1 Informazioni di sicurezz

- Page 125 and 126:

2 Descrizione 135 IT Informazioni d

- Page 127 and 128:

3 Installazione e messa in esercizi

- Page 129 and 130:

4 Utilizzo della macchina 4.1 Panor

- Page 131 and 132:

5.3 Kit di manutenzione Kit di manu

- Page 133 and 134:

CONTENTS 1 Zasady bezpieczestwa....

- Page 135 and 136:

2 Opis 145 PL Zasady bezpieczestwa

- Page 137 and 138:

2.2 Rozpakowanie urzdzenia Zaleca s

- Page 139 and 140:

3.4 Instalacja elektryczna 149 PL Z

- Page 141 and 142:

5 Serwisowanie 151 PL Zasady bezpie

- Page 143 and 144:

6 Rozwizywanie problemów 153 PL Za

- Page 145 and 146:

DAS1 - DAS7 1 Bezpenostné informá

- Page 147 and 148:

DAS1 - DAS7 2.1.1 Rozmery Minimáln

- Page 149 and 150:

DAS1 - DAS7 3 Inštalácia a uveden

- Page 151 and 152:

DAS1 - DAS7 4 Obsluha zariadenia 4.

- Page 153 and 154:

DAS1 - DAS7 5.3 Servisné súpravy

- Page 155 and 156:

CONTENTS 1 Bezpenostní informace .

- Page 157 and 158:

2 Popis 169 CS Bezpenostní informa

- Page 159 and 160:

2.2 Vybalení zaízení Doporuujeme

- Page 161 and 162:

3.4 Elektrické zapojení Všechny

- Page 163 and 164:

5 Servis 175 CS Bezpenostní inform

- Page 165 and 166:

6 Odstraování problém 177 CS Bez

- Page 167 and 168:

DAS1 - DAS7 1 Ohutusteave Tähtis:

- Page 169 and 170:

DAS1 - DAS7 2.1.1 Mõõtmed Minimaa

- Page 171 and 172:

DAS1 - DAS7 3 Paigaldamine ja käik

- Page 173 and 174:

DAS1 - DAS7 4 Seadmega töötamine

- Page 175 and 176:

DAS1 - DAS7 5.3 Teeninduskomplektid

- Page 177 and 178:

1 Munkavédelmi elírások 191 HU M

- Page 179 and 180:

2.1.1 Méretek Legkisebb üzemi nyo

- Page 181 and 182:

3 Telepítés és üzembe helyezés

- Page 183 and 184:

4 A berendezés használata 4.1 A k

- Page 185 and 186:

5.3 Szervizcsomagok Szervizcsomag L

- Page 187 and 188:

201 HU Munkavédelmi elírások

- Page 189 and 190:

DAS1 - DAS7 1 Informcija par darba

- Page 191 and 192:

DAS1 - DAS7 2.1.1 Izmri Minimlais d

- Page 193 and 194:

DAS1 - DAS7 3 Uzstdšana un nodoša

- Page 195 and 196:

DAS1 - DAS7 4 Iekrtas ekspluatcija

- Page 197 and 198:

DAS1 - DAS7 5.3 Tehnisks apkopes ko

- Page 199 and 200:

CONTENTS 1 Saugos informacija .....

- Page 201 and 202:

2 Aprašymas 217 LT Saugos informac

- Page 203 and 204:

2.2 rangos išpakavimas Rekomenduoj

- Page 205 and 206:

3.4 Elektros sistemos rengimas 221

- Page 207 and 208:

5 Techninis aptarnavimas 223 LT Sau

- Page 209 and 210:

6 Triki šalinimas 225 LT Saugos in

- Page 211 and 212:

DAS1 - DAS7 1 ! ,

- Page 213 and 214:

DAS1 - DAS7 2.1.1

- Page 215 and 216:

DAS1 - DAS7 3 Warning ,

- Page 217 and 218:

DAS1 - DAS7 4 4.1 . 4.

- Page 219 and 220:

DAS1 - DAS7 5.3 A : 60831

- Page 221 and 222:

CONTENTS 1 Varnostne informacije ..

- Page 223 and 224:

2 Opis 241 SL Varnostne informacije

- Page 225 and 226:

2.2 Odpiranje opreme Priporoamo, da

- Page 227 and 228:

3.4 Elektrina namestitev Vso z elek

- Page 229 and 230:

5 Servisiranje 247 SL Varnostne inf

- Page 231 and 232:

6 Odpravljanje težav 249 SL Varnos

- Page 233 and 234:

DAS1 - DAS7 1 Güvenlik Bilgileri

- Page 235 and 236:

DAS1 - DAS7 2.1.1 Boyutlar Asgari

- Page 237 and 238:

DAS1 - DAS7 3 Kurulum ve Hizmete Al

- Page 239 and 240:

DAS1 - DAS7 4 Ekipmann çaltrlmas 4

- Page 241 and 242:

DAS1 - DAS7 5.3 Service Setleri Ser

- Page 243 and 244:

CONTENTS 1 Tagrif dwar is-Sigurtà.

- Page 245 and 246:

2 Deskrizzjoni 265 MT Tag±rif dwar

- Page 247 and 248:

2.2 ru ta’ l-apparat mill-imballa

- Page 249 and 250:

3.4 Installazzjoni ta' l-Elettriku

- Page 251 and 252:

5 Servis 271 MT Tag±rif dwar is-Si

- Page 253 and 254:

6 Solvien tal-problemi 273 MT Tag±

- Page 255 and 256:

5 8 3 4 7 1 6 2 A2 A3 275 1 Yellow

- Page 257 and 258:

D E E E A5 277 E A MT Tag±rif dwar

- Page 259 and 260:

Verklaring van Conformiteit NL Park

- Page 261 and 262:

Declaración de conformidad ES Park

- Page 263 and 264:

Atbilstbas deklarcija LV Parker Han

- Page 265:

GOST Certificates (Purification Pro