Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ferm<br />

connected to the terminal which is marked<br />

with the letter N or coloured black.<br />

The wire which is coloured brown must be<br />

connected to the terminal which is marked<br />

with the letter L or coloured red.<br />

Technical data<br />

Mains voltage<br />

230-240V~<br />

Mains frequency<br />

50Hz<br />

Power input 1,500W<br />

No-load speed<br />

350 - 800 /min<br />

Impact rate<br />

1100 - 2700 /min<br />

Max. drilling diameter<br />

Wood<br />

40 mm<br />

Steel<br />

13 mm<br />

Concrete<br />

36 mm<br />

Weight<br />

6 kg<br />

Noise and vibration<br />

Hammer position<br />

Sound pressure (Lpa)<br />

98.5 dB(A)<br />

Acoustic power (Lwa)<br />

109.5 dB(A)<br />

Uncertainty (K)<br />

3 dB(A)<br />

Vibration main handle 19.819 m/s 2<br />

Uncertainty (K) 1.5 m/s 2<br />

Hammer/drill position<br />

Sound pressure (Lpa)<br />

96.88 dB(A)<br />

Acoustic power (Lwa)<br />

107.88 dB(A)<br />

Uncertainty (K)<br />

3 dB(A)<br />

Vibration main handle 24.847 m/s 2<br />

Uncertainty (K) 1.5 m/s 2<br />

Wear hearing protection.<br />

Vibration level<br />

The vibration emission level stated in this<br />

instruction manual has been measured in<br />

accordance with a standardised test given in EN<br />

60745; it may be used to compare one tool with<br />

another and as a preliminary assessment of<br />

exposure to vibration when using the tool for the<br />

applications mentioned<br />

<br />

<br />

using the tool for different applications, or with<br />

different or poorly maintainted accessories,<br />

may significantly increase the exposure level<br />

the times when the tool is switched off or when<br />

it is running but not actually doing the job, may<br />

signifi cantly reduce the exposure level<br />

Protect yourself against the effects of vibration by<br />

maintaining the tool and its accessories, keeping<br />

your hands warm, and organizing your work<br />

patterns<br />

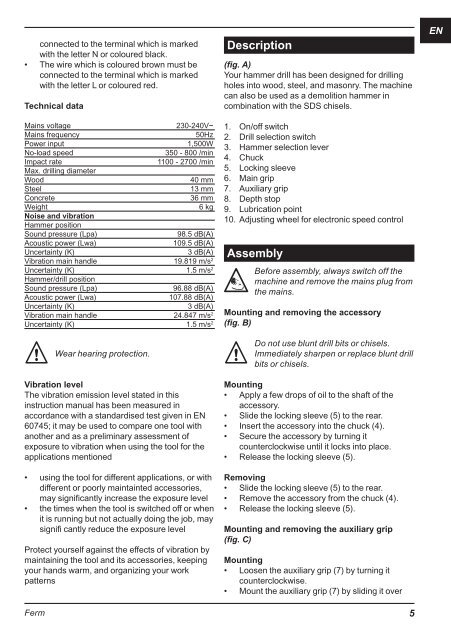

Description<br />

(fig. A)<br />

Your hammer drill has been designed for drilling<br />

holes into wood, steel, and masonry. The machine<br />

can also be used as a demolition hammer in<br />

combination with the SDS chisels.<br />

1. On/off switch<br />

2. Drill selection switch<br />

3. Hammer selection lever<br />

4. Chuck<br />

5. Locking sleeve<br />

6. Main grip<br />

7. Auxiliary grip<br />

8. Depth stop<br />

9. Lubrication point<br />

10. Adjusting wheel for electronic speed control<br />

<br />

Before assembly, always switch off the<br />

machine and remove the mains plug from<br />

the mains.<br />

<br />

(fig. B)<br />

Do not use blunt drill bits or chisels.<br />

Immediately sharpen or replace blunt drill<br />

bits or chisels.<br />

Mounting<br />

Apply a few drops of oil to the shaft of the<br />

accessory.<br />

Slide the locking sleeve (5) to the rear.<br />

Insert the accessory into the chuck (4).<br />

Secure the accessory by turning it<br />

counterclockwise until it locks into place.<br />

Release the locking sleeve (5).<br />

Removing<br />

Slide the locking sleeve (5) to the rear.<br />

Remove the accessory from the chuck (4).<br />

Release the locking sleeve (5).<br />

<br />

(fig. C)<br />

Mounting<br />

Loosen the auxiliary grip (7) by turning it<br />

counterclockwise.<br />

Mount the auxiliary grip (7) by sliding it over<br />

5<br />

EN