Magnetni zalistak indikator, Tip MKL Magnetic Flap Indicator, Type ...

Magnetni zalistak indikator, Tip MKL Magnetic Flap Indicator, Type ...

Magnetni zalistak indikator, Tip MKL Magnetic Flap Indicator, Type ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

190105.01<br />

BEZBEDNOSNA TEHNOLOGIJA<br />

ZA ZAŠTITU ŽIVOTNE SREDINE<br />

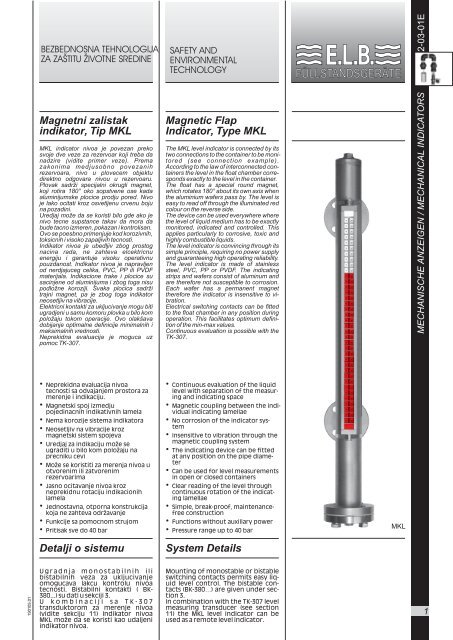

<strong>Magnetni</strong> <strong>zalistak</strong><br />

<strong>indikator</strong>, <strong>Tip</strong> <strong>MKL</strong><br />

<strong>MKL</strong> indicator nivoa je povezan preko<br />

svoje dve veze za rezervoar koji treba da<br />

nadzire (vidite primer veze). Prema<br />

zakonima medjusobno povezanih<br />

rezervoara, nivo u plovecem objektu<br />

direktno odgovara nivou u rezervoaru.<br />

Plovak sadrži specijalni okrugli magnet,<br />

koji rotira 180° oko sopstvene ose kada<br />

aluminijumske plocice prodju pored. Nivo<br />

je lako ocitati kroz osvetljenu crvenu boju<br />

na pozadini.<br />

Uredjaj može da se koristi bilo gde ako je<br />

nivo tecne supstance takav da mora da<br />

bude tacno izmeren, pokazan i kontrolisan.<br />

Ovo se poesbno primenjuje kod korozivnih,<br />

toksicnih i visoko zapaljivih tecnosti.<br />

Indikator nivoa je ubedljiv zbog prostog<br />

nacina rada, ne zahteva elcektricnu<br />

energiju i garantuje visoku operativnu<br />

pouzdanost. Indikator nivoa je napravljen<br />

od nerdjajuceg celika, PVC, PP ili PVDF<br />

materijala. Indikacione trake i plocice su<br />

sacinjene od aluminijuma i zbog toga nisu<br />

podložne koroziji. Svaka plocica sadrži<br />

trajni magnet, pa je zbog toga <strong>indikator</strong><br />

neosetljiv na vibracije.<br />

Elektricni kontakti za ukljucivanje mogu biti<br />

ugradjeni u samu komoru plovka u bilo kom<br />

položaju tokom operacije. Ovo olakšava<br />

dobijanje optimalne definicije minimalnih i<br />

maksimalnih vrednosti.<br />

Neprekidna evaluacija je moguca uz<br />

pomoc TK-307.<br />

� Neprekidna evaluacija nivoa<br />

tecnosti sa odvajanjem prostora za<br />

merenje i indikaciju.<br />

� Magnetski spoj izmedju<br />

pojedinacnih indikativnih lamela<br />

� Nema korozije sistema <strong>indikator</strong>a<br />

� Neosetljiv na vibracije kroz<br />

magnetski sistem spojeva<br />

� Uredjaj za indikaciju može se<br />

ugraditi u bilo kom položaju na<br />

precniku cevi<br />

� Može se koristiti za merenja nivoa u<br />

otvorenim ili zatvorenim<br />

rezervoarima<br />

� Jasno ocitavanje nivoa kroz<br />

neprekidnu rotaciju indikacionih<br />

lamela<br />

� Jednostavna, otporna konstrukcija<br />

koja ne zahteva održavanje<br />

� Funkcije sa pomocnom strujom<br />

� Pritisak sve do 40 bar<br />

SAFETY AND<br />

ENVIRONMENTAL<br />

TECHNOLOGY<br />

<strong>Magnetic</strong> <strong>Flap</strong><br />

<strong>Indicator</strong>, <strong>Type</strong> <strong>MKL</strong><br />

The <strong>MKL</strong> level indicator is connected by its<br />

two connections to the container to be monitored<br />

(see connection example).<br />

According to the law of interconnected containers<br />

the level in the float chamber corresponds<br />

exactly to the level in the container.<br />

The float has a special round magnet,<br />

which rotates 180° about its own axis when<br />

the aluminium wafers pass by. The level is<br />

easy to read off through the illuminated red<br />

colour on the reverse side.<br />

The device can be used everywhere where<br />

the level of liquid medium has to be exactly<br />

monitored, indicated and controlled. This<br />

applies particularly to corrosive, toxic and<br />

highly combustible liquids.<br />

The level indicator is convincing through its<br />

simple principle, requiring no power supply<br />

and guaranteeing high operating reliability.<br />

The level indicator is made of stainless<br />

steel, PVC, PP or PVDF. The indicating<br />

strips and wafers consist of aluminum and<br />

are therefore not susceptible to corrosion.<br />

Each wafer has a permanent magnet<br />

therefore the indicator is insensitive to vibration.<br />

Electrical switching contacts can be fitted<br />

to the float chamber in any position during<br />

operation. This facilitates optimum definition<br />

of the min-max values.<br />

Continuous evaluation is possible with the<br />

TK-307.<br />

� Continuous evaluation of the liquid<br />

level with separation of the measuring<br />

and indicating space<br />

� <strong>Magnetic</strong> coupling between the individual<br />

indicating lamellae<br />

� No corrosion of the indicator system<br />

� Insensitive to vibration through the<br />

magnetic coupling system<br />

� The indicating device can be fitted<br />

at any position on the pipe diameter<br />

� Can be used for level measurements<br />

in open or closed containers<br />

� Clear reading of the level through<br />

continuous rotation of the indicating<br />

lamellae<br />

� Simple, break-proof, maintenancefree<br />

construction<br />

� Functions without auxiliary power<br />

� Pressure range up to 40 bar<br />

Detalji o sistemu System Details<br />

U g r a d n j a m o n o s t a b i l n i h i l i<br />

bistabilnih veza za ukljucivanje<br />

omogucava lakcu kontrolu nivoa<br />

tecnosti. Bistabilni kontakti ( BK-<br />

380...) su dati u sekciji 3.<br />

U k o m b i n a c i j i s a T K - 3 0 7<br />

transduktorom za merenje nivoa<br />

(vidite sekciju 11) Indikator nivoa<br />

<strong>MKL</strong> može da se koristi kao udaljeni<br />

<strong>indikator</strong> nivoa.<br />

Mounting of monostable or bistable<br />

switching contacts permits easy liquid<br />

level control. The bistable contacts<br />

(BK-380…) are given under section<br />

3.<br />

In combination with the TK-307 level<br />

measuring transducer (see section<br />

11) the <strong>MKL</strong> level indicator can be<br />

used as a remote level indicator.<br />

<strong>MKL</strong><br />

02-03-01E<br />

MECHANISCHE ANZEIGEN / MECHANICAL INDICATORS<br />

1

02-03-01E<br />

MECHANISCHE ANZEIGEN / MECHANICAL INDICATORS<br />

2<br />

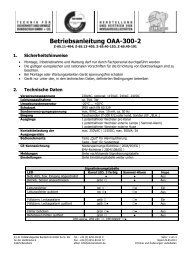

Tehnicki podaci<br />

Spoj Jezicak pocinje od DN 15<br />

Materijal Nerdjajuci celik,PVC, PPH,<br />

PVDF<br />

Materijal plovka Nerdjajuci celik,<br />

Titanijum, PVC, PPH, PVDF<br />

Operativna temp. Nerdjajuci celik:<br />

Max. +200°C<br />

PVC: Max. +60°C<br />

PPH: Max. +90°C<br />

PVDF: Max. +130°C<br />

Operativni pritisak Plastika: max. 4bar<br />

Nerdjajuci celik: max. 40 bar<br />

Gustina supstance Plovak od nerdjajuceg<br />

celika: ��� 0,75g/cm3<br />

Plovak od titanijuma:<br />

��� 0,50g/cm3<br />

PVC plovak:<br />

��� 0,77g/cm3<br />

PPH plovak:<br />

��� 0,66g/cm3<br />

PVDF plovak:<br />

��� 0,83g/cm3<br />

Broj veza proizvoljan<br />

Veza opterecenja Max. 10 VA, max. 230 V AC<br />

Dužina <strong>indikator</strong>a Max. 6m<br />

Technical Data<br />

Connector<br />

Material<br />

Material flange<br />

Material float<br />

Operating<br />

temperature<br />

Operating<br />

pressure<br />

Media density<br />

Number of<br />

contacts<br />

Contact load<br />

<strong>Indicator</strong> length<br />

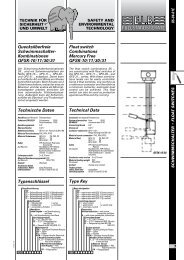

Kljuc tipa <strong>Type</strong> Key<br />

Osnovne oznake Basic designation<br />

Materijal<br />

3 = Nerdjajuci celik 1.4571 (PN 16)<br />

jezicak lateralni<br />

5 = Nerdjajuci celik 1.4571 (PN 16)<br />

jezicak na vrhu / ispod<br />

6 = Nerdjajuci celik 1.4571 (PN 40)<br />

jezicak lateralni<br />

7 = PVC (PN 6)<br />

8 = PPH (PN 6)<br />

9 = PVDF (PN 6)<br />

Veza jezicka<br />

bez indikacije = papravljeno pod specifikacijom<br />

„Material”<br />

V4A = vezni jezicak, nerdjajuci celik 1.4571<br />

C22 = jezicak od C22.8<br />

(samo na 3,5, 6)<br />

Veza procesa<br />

DN 15<br />

DN 20<br />

DN 25<br />

DN 32<br />

DN 40<br />

DN 50<br />

specijalni dizajn = na zahtev<br />

Plovak<br />

1 = Nerdjajuci celik<br />

2 = Titanijum<br />

7 = PVC<br />

8 = PPH<br />

9 = PVDF<br />

Zavrtanj odvoda<br />

A = ½” (standardni)<br />

Displej<br />

0 = bez displeja<br />

1 = Aluminijumska traka za<br />

staklom od makrolona<br />

Srednja udaljenost<br />

L = __mm (L min. = 500 mm)<br />

<strong>MKL</strong> <strong>MKL</strong><br />

Zadržana prava izmene bez najave.<br />

Flange starting from DN 15<br />

Stainless steel, PVC, PPH,<br />

PVDF<br />

Stainless steel 1.4571, C 22.8<br />

Stainless steel, Titan, PVC, PPH,<br />

PVDF<br />

Stainless steel: max. 200 °C<br />

PVC: max. 60 °C<br />

PPH: max. 90 °C<br />

PVDF: max. 130 °C<br />

Plastic: max. 4 bar<br />

Stainless steel: max. 40 bar<br />

Float of Stainless steel:<br />

��� 0,75 g/cm³<br />

Float of Titan:<br />

��� 0,50 g/cm³<br />

Float of PVC:<br />

��� 0,77 g/cm³<br />

Float of PPH:<br />

��� 0,66 g/cm³<br />

Float of PVDF:<br />

��� 0,83 g/cm³<br />

arbitrary<br />

max. 10 VA, max. 230 V AC<br />

max. 6 m<br />

Material<br />

3 = Stainless steel 1.4571 (PN 16)<br />

flanges laterally<br />

5 = Stainless steel 1.4571 (PN 16)<br />

flanges at the top / below<br />

6 = Stainless steel 1.4571 (PN 40)<br />

flanges laterally<br />

7 = PVC (PN 6)<br />

8 = PPH (PN 6)<br />

9 = PVDF (PN 6)<br />

Connection flange<br />

without indication = flange material like<br />

“Material”<br />

V4A = Connection flange Stainless steel 1.4571<br />

C22 = Connection flange made of C 22.8<br />

(only at 3, 5, 6)<br />

Process connection<br />

DN 15<br />

DN 20<br />

DN 25<br />

DN 32<br />

DN 40<br />

DN 50<br />

Special design on request<br />

Float<br />

1 = Stainless steel<br />

2 = Titanium<br />

7 = PVC<br />

8 = PPH<br />

9 = PVDF<br />

Drain screw<br />

A = ½” (Standard)<br />

Display<br />

0 = without display rail<br />

1 = Aluminum rail with<br />

window made of Makrolon<br />

Midst distance<br />

L = __mm (L min. = 500 mm)<br />

Subject to change without prior notice,<br />

errors excepted.<br />

KOLTEX D.O.O.<br />

Kralja Milana 21<br />

1 1 0 0 0 B e o g r a d<br />

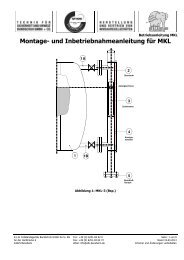

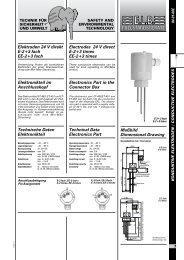

Dimenzioni crtez<br />

Dimensional Drawing<br />

Centralna udaljenost L / Center distance L 130<br />

240<br />

110<br />

Ø 60.3x2<br />

Primer veza<br />

Connection Example<br />

Veza<br />

Connection 1A<br />

Ø 115<br />

Dimenzije u mm / Dimensioning in mm<br />

Rezervoar Veza<br />

Container 1 1B Connection<br />

NW<br />

110<br />

Dimenzije u mm / Dimensioning in mm<br />

Ø 60,3 x 2<br />

Komora 2<br />

plovka<br />

Floatchamber<br />

Indikator<br />

<strong>Indicator</strong><br />

Plovak 3<br />

Float<br />

130<br />

L<br />

Plocice 4<br />

<strong>indikator</strong>a /<br />

<strong>Indicator</strong><br />

wafers<br />

240<br />

Telefon+<br />

381 ( 0)11/3232-687<br />

Fax + 381 ( 0)11/3343-740<br />

E-Mail: Koltexdoo@ptt.yu<br />

Info: Www.elb-bensheim.de<br />

101105.01