A EVOLUÃÃO DA INDÃSTRIA DE CELULOSE E ... - Revista O Papel

A EVOLUÃÃO DA INDÃSTRIA DE CELULOSE E ... - Revista O Papel

A EVOLUÃÃO DA INDÃSTRIA DE CELULOSE E ... - Revista O Papel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

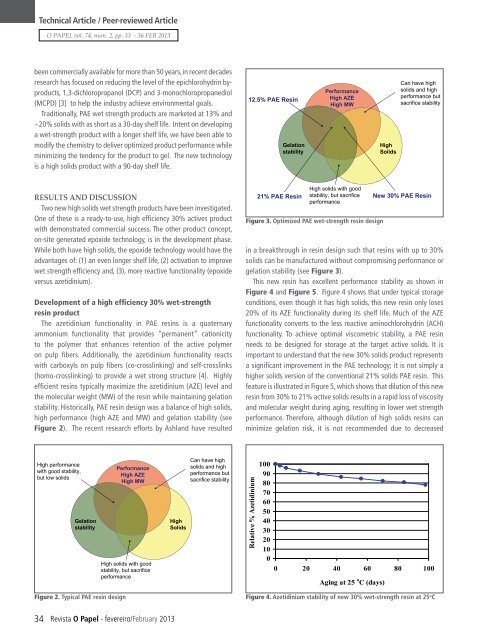

Technical Article / Peer-reviewed ArticleO PAPEL vol. 74, num. 2, pp. 33 - 36 FEB 2013been commercially available for more than 50 years, in recent decadesresearch has focused on reducing the level of the epichlorohydrin byproducts,1,3-dichloropropanol (DCP) and 3-monochloropropanediol(MCPD) [3] to help the industry achieve environmental goals.Traditionally, PAE wet strength products are marketed at 13% and~20% solids with as short as a 30-day shelf life. Intent on developinga wet-strength product with a longer shelf life, we have been able tomodify the chemistry to deliver optimized product performance whileminimizing the tendency for the product to gel. The new technologyis a high solids product with a 90-day shelf life.RESULTS AND DISCUSSIONTwo new high solids wet strength products have been investigated.One of these is a ready-to-use, high efficiency 30% actives productwith demonstrated commercial success. The other product concept,on-site generated epoxide technology, is in the development phase.While both have high solids, the epoxide technology would have theadvantages of: (1) an even longer shelf life, (2) activation to improvewet strength efficiency and, (3), more reactive functionality (epoxideversus azetidinium).Development of a high efficiency 30% wet-strengthresin productThe azetidinium functionality in PAE resins is a quaternaryammonium functionality that provides “permanent” cationicityto the polymer that enhances retention of the active polymeron pulp fibers. Additionally, the azetidinium functionality reactswith carboxyls on pulp fibers (co-crosslinking) and self-crosslinks(homo-crosslinking) to provide a wet strong structure [4]. Highlyefficient resins typically maximize the azetidinium (AZE) level andthe molecular weight (MW) of the resin while maintaining gelationstability. Historically, PAE resin design was a balance of high solids,high performance (high AZE and MW) and gelation stability (seeFigure 2). The recent research efforts by Ashland have resultedFigure 3. Optimized PAE wet-strength resin designin a breakthrough in resin design such that resins with up to 30%solids can be manufactured without compromising performance orgelation stability (see Figure 3).This new resin has excellent performance stability as shown inFigure 4 and Figure 5. Figure 4 shows that under typical storageconditions, even though it has high solids, this new resin only loses20% of its AZE functionality during its shelf life. Much of the AZEfunctionality converts to the less reactive aminochlorohydrin (ACH)functionality. To achieve optimal viscometric stability, a PAE resinneeds to be designed for storage at the target active solids. It isimportant to understand that the new 30% solids product representsa significant improvement in the PAE technology; it is not simply ahigher solids version of the conventional 21% solids PAE resin. Thisfeature is illustrated in Figure 5, which shows that dilution of this newresin from 30% to 21% active solids results in a rapid loss of viscosityand molecular weight during aging, resulting in lower wet strengthperformance. Therefore, although dilution of high solids resins canminimize gelation risk, it is not recommended due to decreasedFigure 2. Typical PAE resin designFigure 4. Azetidinium stability of new 30% wet-strength resin at 25 o C34 <strong>Revista</strong> O <strong>Papel</strong> - fevereiro/February 2013