WINDENERGY MAGAZINE 02 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

STARTUPS IN WIND WINDDAYS <strong>2018</strong><br />

CIRCULAR ENERGY<br />

QLAYERS<br />

Circular Energy plans to build an offshore installation that<br />

produces electricity directly from a gas field and supplies it<br />

via the electricity network at sea, where it can absorb the<br />

fluctuations in the production of wind energy. The CO 2<br />

that is<br />

released, is captured and stored in the gas field. Arnold Groot,<br />

CEO of Circular Energy:<br />

CAN YOU EXPLAIN YOUR TECHNOLOGY?<br />

We intend to supply flexible, CO 2<br />

-free electricity<br />

from natural gas via the electricity network at sea.<br />

This way the offshore electricity network is always<br />

used optimally and stable and fluctuations during<br />

periods of little wind can be absorbed properly, resulting<br />

in a balanced offshore grid. We achieve this<br />

by using an offshore gas-fired power station with<br />

CO 2<br />

capture and storage facility. In concrete terms:<br />

we are building an offshore platform with a gas<br />

extraction installation, a gas-fired power station<br />

and a CO 2<br />

-capture installation on top. The captured<br />

CO 2<br />

is stored in the gas field.<br />

WHAT MAKES YOUR IDEA DIFFERENT FROM OTHER<br />

COMPANIES WHO HAVE TRIED THE SAME?<br />

We do things slightly different and better. Firstly,<br />

Circular Energy properly cleans up the mess, that<br />

is CO 2<br />

, itself. Secondly, we are willing to wait a little<br />

longer for our Return on Investment. By integrating<br />

CO 2<br />

capture and storage into our business model<br />

and by doing everything at sea, our approach<br />

is slightly more expensive. However, we think we<br />

can develop a cost-effective method. Thirdly, we<br />

add value to small gas fields that would otherwise<br />

probably not be exploited.<br />

WHAT IS THE BIGGEST CHALLENGE FOR THE DUTCH<br />

WIND SECTOR?<br />

In our view, the biggest challenge lies in providing<br />

security of supply. Wind energy alone can’t offer<br />

it. The technology of Circular Energy makes it<br />

possible to offer flexible and yet very stable clean<br />

energy.<br />

DOES YOUR OFFER LOWER THE KWH PRICE OF WIND<br />

ENERGY?<br />

The average price for a kWh is not reduced by our<br />

plan, but we prevent the price on wind-poor days<br />

from increasing enormously.<br />

Qlayers, a startup from Delft, develops a robot printer for the automatic<br />

application of sharkskin coating, which makes wind turbines work more<br />

efficiently. Josefien Groot, Head of Business Development at Qlayers:<br />

WHAT IS YOUR INNOVATION?<br />

The automated application of a coating with microstructures,<br />

suitable for aircraft and wind turbines.<br />

We are working on the development of a sharkskin<br />

coating which ensures less frictional resistance.<br />

After that, we want to continue with self-cleaning,<br />

self-healing and anti-icing coatings.<br />

WHAT MAKES YOUR PRODUCT DIFFERENT FROM<br />

COMPETITORS?<br />

We actually only have one competitor, Fraunhofer,<br />

a big company. However, their way of applying coatings<br />

differs from how we do it. They use templates,<br />

a kind of rollers. We use a way of 3-D printing<br />

which is much more favourable for complex shapes<br />

such as airplanes and wind turbines. We receive a<br />

lot of interest for our product and we would now<br />

like to enter into a partnership with a wind turbine<br />

manufacturer so that we can test the lifespan of the<br />

coating offshore, for example.<br />

WHAT IS THE BIGGEST CHALLENGE IN WIND ENERGY?<br />

Maintenance will become very important in the<br />

coming period. Installation is now in full swing and<br />

the bill for maintenance will soon come up. For<br />

offshore this will be a hefty bill. I think that is the<br />

biggest challenge until 2030.<br />

WILL YOUR PRODUCT CONTRIBUTE TO REDUCING<br />

THE PRICE PER KWH OF WIND ENERGY?<br />

Yes, by applying a sharkskin microstructure to a<br />

2-megawatt wind turbine, the energy efficiency<br />

can be increased by 6 percent, which results in an<br />

increase in the efficiency of 264,000 kWh per year<br />

(per wind turbine). When applied to larger turbines<br />

the results are even higher. By automating the<br />

coating process, repairs can be carried out more<br />

safely and overspray can be reduced. Currently the<br />

coating is done by hand and sometimes twice as<br />

much paint is used than needed.<br />

IN FIVE YEARS WHERE DO YOU STAND AS A<br />

COMPANY?<br />

Qlayers will be the market leader in the application<br />

of functional coatings. By then we have automated<br />

the coating process for storage tanks, wind turbines<br />

and airplanes. In addition, we will have started<br />

with the application of the shark skin structure on<br />

aircrafts, ships and high-speed trains. Developing<br />

technology takes a lot of time, and our goals are<br />

ambitious but I think these are within reach.<br />

www.qlayers.com<br />

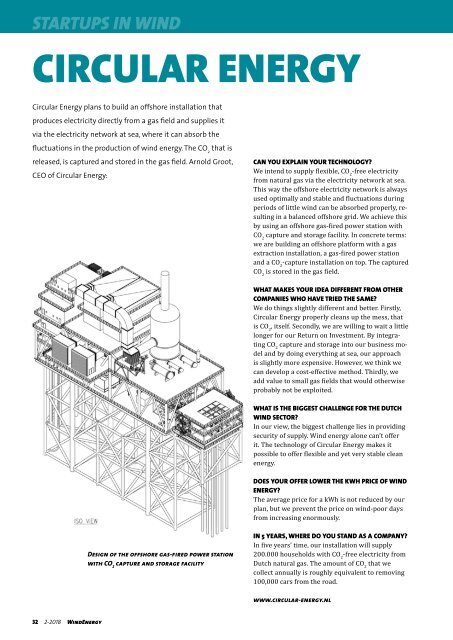

Design of the offshore gas- fired power station<br />

with CO 2<br />

capture and storage facility<br />

IN 5 YEARS, WHERE DO YOU STAND AS A COMPANY?<br />

In five years’ time, our installation will supply<br />

200.000 households with CO 2<br />

-free electricity from<br />

Dutch natural gas. The amount of CO 2<br />

that we<br />

collect annually is roughly equivalent to removing<br />

100,000 cars from the road.<br />

www.circular-energy.nl<br />

32 2-<strong>2018</strong> WindEnergy<br />

WindEnergy 2-<strong>2018</strong> 33