You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ntnamericas.com<br />

APPENDICES<br />

Technical Data<br />

INSTALLATION<br />

12. Handling of the <strong>Bearing</strong> Unit<br />

MOUNTING OF THE HOUSING<br />

Pillow Block and Flange Types<br />

Although an advantage of the <strong>NTN</strong> bearing unit is that it<br />

can be fitted easily and will function efficiently on any part<br />

of a machine, attention must be paid to the following points<br />

in order to ensure its normal service life.<br />

1) The surface on which the housing is mounted must be<br />

sufficiently rigid.<br />

2) The surface on which the housing is mounted should be<br />

as flat as possible (The housing should set firmly in its<br />

position). Deformation of the housing caused by<br />

incorrect mounting will in turn cause deformation of the<br />

bearing, leading to its premature breakdown (Fig. 12).<br />

12.1 Mounting of the housing<br />

12. Handling of the <strong>Bearing</strong> Unit<br />

12.1.1 Pillow block type and flange type<br />

Although an advantage of the <strong>NTN</strong> bearing unit is that it<br />

3) It is desirable that the angle between the surface<br />

can 12.1 be Mounting fitted easily of and the will housing function efficiently on any part<br />

on which the housing is mounted and the shaft be<br />

of a machine, attention must be paid to the following points<br />

12.1.1 maintained Pillow block to a tolerance type and of ±2° flange (Fig. type 13 and 14).<br />

in order to ensure its normal service life.<br />

Although an advantage of the <strong>NTN</strong> bearing unit is that it<br />

1) The surface on which the housing is mounted must be<br />

can 4) Excessive be fitted easily tightening and of will the function mounting efficiently bolts may on cause any part<br />

sufficiently rigid.<br />

of a the machine, housing attention to deform. must Tightening be paid the to bolts the following to the proper points<br />

2) The surface on which the housing is mounted should be<br />

in order torque can ensure avoid its this normal issue. service Also, <strong>NTN</strong> life.<br />

as flat as possible (Flatness:0.05 max. recommends The housing<br />

1) The using surface a washer on with which the the bolt housing when mounting is mounted the housing must be<br />

should set firmly in its position). Deformation of the<br />

sufficiently<br />

as the bolt<br />

rigid.<br />

housing caused alone by may incorrect cause damage mounting to the will housing.<br />

turn cause<br />

2) The surface on which the housing is mounted should be<br />

deformation of the bearing, leading to its premature<br />

as flat as possible (Flatness:0.05 max. The housing<br />

Cartridge breakdown. Type<br />

should set firmly in its position). Deformation of the<br />

3) The Angle inside error diameter between of the housing mounting into which face a cartridge and shaft is<br />

housing caused by incorrect mounting will in turn cause<br />

type desirable unit is to inserted be within should ± be 2˚ H7 ( ± under 1˚ for general outer ring operating narrow<br />

deformation of the bearing, leading to its premature<br />

conditions. width type)<br />

breakdown.<br />

It from should relationship be so furnished with replenishment as to permit the of grease.<br />

3) bearing For unit<br />

Angle unit with<br />

error to cover,<br />

between move freely the angle<br />

housing the error<br />

mounting axial direction. is desirable to be as<br />

face and shaft is<br />

small as possible within ± 1˚ to ensure the sealing<br />

desirable to be within ± 2˚ ( ± 1˚ for outer ring narrow<br />

performance for the cover.<br />

width type) from relationship with replenishment of grease.<br />

For unit with cover, the angle error is desirable to be as<br />

small as possible within ± 1˚ to ensure the sealing<br />

performance for the cover.<br />

Fig. 12<br />

±2˚<br />

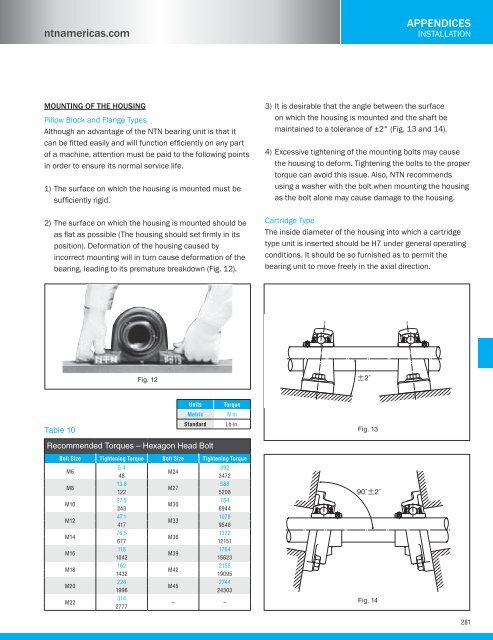

Table 10<br />

Recommended Torques – Hexagon Head Bolt<br />

Units Torque<br />

Metric N . m<br />

Standard Lb . in.<br />

Bolt Size Tightening Torque Bolt Size Tightening Torque<br />

M6<br />

5.4<br />

392<br />

M24<br />

48 3472<br />

M8<br />

13.8<br />

588<br />

M27<br />

122 5208<br />

M10<br />

27.5<br />

784<br />

M30<br />

243 6944<br />

M12<br />

47.1<br />

1078<br />

M33<br />

417 9548<br />

M14<br />

76.5<br />

1372<br />

M36<br />

677 12151<br />

M16<br />

118<br />

1764<br />

M39<br />

1042 15623<br />

M18<br />

162<br />

2156<br />

M42<br />

1432 19095<br />

M20<br />

226<br />

2744<br />

M45<br />

1996 24303<br />

M22<br />

314<br />

2777<br />

– –<br />

Fig. ±2˚ 12.1<br />

Fig. 13<br />

Fig.<br />

90˚±2˚<br />

12.1<br />

90˚±2˚<br />

Fig. 12.2<br />

Fig. 12.2<br />

Fig. 14<br />

281