NH90-NFH-Caiman_Erfahrungen der Französischen Marine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

French Navy Feedback<br />

June 2012 <strong>NH90</strong> User Group LT Duclos

Aircraft behaviour<br />

Embarkation Feedback<br />

• Good behaviour with cross wind and<br />

turbulences conditions<br />

• Homologation granted on Horizon frigates,<br />

LHD, CDG aircraft carrier<br />

Mooring<br />

• Step A<br />

25 mn to secure the aircraft<br />

AGE not suitable for ops<br />

• Step B improvements must be applicable<br />

on step A.

Folding<br />

Embarkation Feedback<br />

• Very poor reliability, 1 failure every 8 folding sequences<br />

NOGO for embarkation<br />

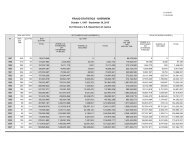

2010 2011 2012 Total<br />

ATFA 1 1<br />

ATLA 1 1<br />

MRBFA 4 6 10<br />

MRSLA 10 7 17<br />

MRIA 3 1 4<br />

FAC 3 1 4<br />

• MRSLA : intermediate solution on a/c 06 – 07<br />

• Cracks of spring support on fwd folding mechanism assembly<br />

(5 occurrences), new design in study<br />

• Hydraulic leak on swivel manifold seizure<br />

Creation monthly working group

Embarkation Feedback<br />

Traversing issue<br />

• SAMAHE vs AHS (Autonomous Handling system)<br />

Need to establish the Douglas Mantis – <strong>NH90</strong> interoperability stability<br />

envelop<br />

Caïman configuration<br />

• Deck lock and 5th pump<br />

• “Step B mooring” on Step A aircrafts (flyable mooring rings)<br />

• Step B Folding AGEs<br />

Received and tested during CW25.<br />

Will be embarqued during CW 28<br />

Technicians skills<br />

• Breaking cords<br />

• Composite repair<br />

• Environnemental control system<br />

• ...

Embarkation Feedback<br />

Maintenance at sea<br />

Servicing<br />

BFF and ALF usually done in the hangar<br />

Tar on the deck<br />

Maintenance<br />

Safety Inspection : 3hours. On the deck or in the hangar<br />

(including FCS Test)<br />

With an anti corrosion treatment : 4 hours<br />

Engine Removal and Installation

Embarkation Feedback<br />

Maintenance at sea : Next steps<br />

Jacking<br />

Removal and installation of :<br />

Front cowling<br />

Bracket<br />

Landing Gear<br />

Scheduled 100FH operations

Technical Feedback<br />

Maintainability<br />

• About 20 MMH/FH (including scheduled & unscheduled<br />

maintenance, servicing + 3 MMH/FH training)<br />

• Scheduled maintenance duration have to be reduced for<br />

deployment at sea (SI – 50FH – 100FH – 150FH & 30D)<br />

Necessity to get the master schedule for maintenance<br />

improvement (impact on human resources format)<br />

Unavailability of 60%<br />

• 45% for scheduled maintenance<br />

• 15% for unscheduled maintenance<br />

Electronic documentation maturity<br />

• IPRF integration in IETP : ratio too low and too long<br />

Short loops requested

Technical Feedback<br />

Rescue Hoist<br />

• Hoist cable jamming<br />

• Hydraulic leak : motor valve (3 occurrences)<br />

• Protection attachement<br />

• Ball bearing hook : Rotation impossible, corrosion issue<br />

(4 occurrences)<br />

Cargo hook<br />

• Unintended release in flight<br />

Necessity to stow the rope attached to the hook in the cabin<br />

while transiting for vertrep mission (no speed limitations)<br />

• Load measurement instability

Technical Feedback<br />

Floatation cover fraying<br />

• More than 15 occurrences<br />

• 17/06/2011, SR 1-6465495: « Industry works with its supplier on<br />

the improvement of the cover assembly. Tolerance and<br />

temporary repair are not conceivable for the moment »<br />

• Spare parts a short term solution, design improvement<br />

expected<br />

Breaking cords rupture on floatation device<br />

• New lacing behaviour required<br />

on the all fleet

Technical Feedback<br />

Wheel Brake Metering Valve (WBMV)<br />

• Untimely jamming on WBMV<br />

• FCC caution well-known and applied by aircrew<br />

• Major failure MLG brakes on 06 during running landing<br />

2011 2012 Total<br />

WBMV 1 5 6<br />

Heat Modulating Valve (HMV)<br />

• Internal seal wear<br />

• Mechanical command jamming<br />

• Design and logistic issues<br />

• Required for SAR operations<br />

2011 2012 Total<br />

HMV 5 5 10

Technical Feedback<br />

Rotor Brake Power Module (RBPM)<br />

• Weakness of the metallic clamp<br />

• Crack of RBPM support<br />

• Design issues<br />

Center Locking Mechanism (CLM)<br />

• Locking axis weakness : solved by new design<br />

• Locking lever lost (4 occurrences) : tyraps solution not satisfactory<br />

Impact on tow position during steering manoeuvre<br />

Main Avionic Bay Fan<br />

• Electrical motor issue<br />

• Stator fixation issue<br />

Design and logistic issues<br />

2011 2012 Total<br />

RBPM 3 6 9<br />

CLM 11 5 16<br />

MAB Fan 0 4 4

We need now to embark for maritime<br />

operations : worldwide and long deployments.

Questions ?