You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

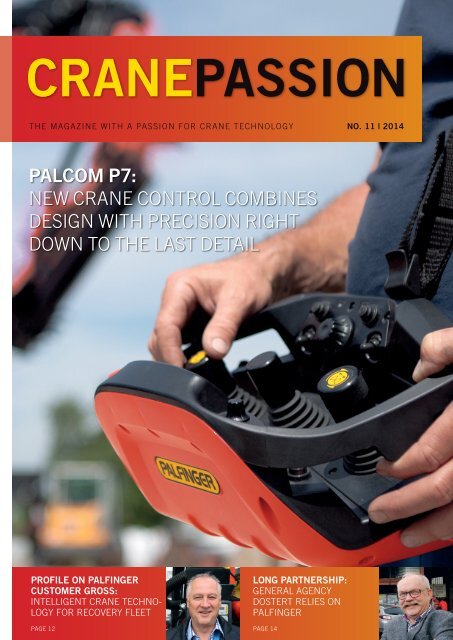

CRANEPASSION<br />

THE MAGAZINE WITH A PASSION FOR CRANE TECHNOLOGY NO. <strong>11</strong> | <strong>2014</strong><br />

PaLcom P7:<br />

NEW CRANE CoNTRoL CoMBINEs<br />

DEsIGN WITH PRECIsIoN RIGHT<br />

DoWN To THE LAsT DETAIL<br />

PROFILE ON PALFINGER<br />

CUSTOMER GROSS:<br />

INTELLIGENT CRANE TECHNO-<br />

LOGY FOR RECOVERY FLEET<br />

PAGE 12<br />

LONG PARTNERSHIP:<br />

GENERAL AGENCY<br />

DOSTERT RELIES ON<br />

PALFINGER<br />

PAGE 14

Contents | CRANE <strong>Passion</strong><br />

08<br />

PALcom P7<br />

04 NEWS<br />

News from the world of PALFINGER.<br />

06 L-crane<br />

PALFINGER will present the completely revamped<br />

L-crane model series as a highlight at IAA.<br />

07 P-Fold<br />

A new assistance system enabling cranes to be<br />

folded and unfolded in an automated fashion was<br />

presented at the IAA.<br />

<strong>11</strong> Job report Hörmann<br />

Hörmann is constructing halls<br />

across Germany with a fleet of modern cranes.<br />

12 Job report Gross<br />

The Gross group, Europe's largest ADAC partner, is<br />

placing its trust in intelligent crane technology for its<br />

fleet of recovery and towing vehicles.<br />

17 Mounting Competence Centre<br />

The MCC has developed a standardised and<br />

optimised compact crane assembly kit.<br />

14<br />

Dostert<br />

Imprint:<br />

Editor:<br />

PALFINGER AG,<br />

Franz-Wolfram-Scherer-Straße 24<br />

A 5020 Salzburg/Austria<br />

Telefon: +43 (0) 6 62/46 84-0<br />

www.palfinger.com<br />

18<br />

International<br />

Marketing:<br />

Hubert Meschnark, Anita Edtbauer<br />

Information for customers and partners<br />

of PALFINGER<br />

Text:<br />

Peter Lukas, Michael Völker, Paul Göttl, Oliver Willms<br />

Photos:<br />

PALFINGER AG, Oliver Willms<br />

Graphic:<br />

Simone Strobel<br />

Conception and implementation:<br />

Paul Göttl, ETMservices, a division of ETM Verlag, Stuttgart<br />

Publisher:<br />

ETM Verlag, Handwerkstrasse 15, 70565 Stuttgart, www.etmservices.de<br />

© by ETMservices <strong>2014</strong><br />

2

ESEarcH<br />

dEvELoPmENt<br />

cuStomEr bENEFit<br />

dEar PartNErS aNd FriENdS oF PaLFiNGEr!<br />

standing still is like taking a step backwards – this is particularly applicable to companies that<br />

aspire to be innovation leaders. We measure ourselves against this aspiration. The latest example is<br />

the PALcom P7, the entirely newly developed crane remote control for our loader cranes. our<br />

primary aim was to make this link between human and machine so simple and intuitive that it<br />

makes our customers' work even easier. In the end, the PALFINGER development department<br />

worked together with external experts, research institutes and practical workers. You can read<br />

about what the PALcom P7 can do, what ideas guided us during development and what our<br />

customers have to say in our cover story from page 8 onwards.<br />

"Ateliers mécaniques Dostert", our primary importer in Luxembourg, has been closely linked to<br />

PALFINGER for 40 years. since the early days, owner Franz Dostert has sworn by the products from<br />

salzburg – partly due to the fact that PALFINGER is a technological leader. A nice compliment for<br />

us from a long-standing partner. You can read about what else links Dostert and PALFINGER in our<br />

portrait from page 15 onwards.<br />

of course, PALFINGER makes its expertise available worldwide. With lifting solutions tailored to the<br />

country and use in question, our aim is to make our customers' work even more cost-effective and<br />

simple. More than 4,500 sales and service support points in over 130 countries spread across all<br />

continents ensure that we are always close to our customers. Current examples of how our<br />

products are used around the world can be found from page 18 onwards. But you can also reach us<br />

on the Internet, at any time and from anywhere in the world. our activities in this area are<br />

summarised for you on page 5.<br />

I hope that reading CRANE PAssIoN provides you with plenty of ideas for your work.<br />

Wolfgang Pilz (CMo)<br />

3

NEWS | CRANE <strong>Passion</strong><br />

Recognising<br />

quality<br />

Assembly training for the sales team<br />

UNDER THE SLOGAN "Recognising quality", the<br />

majority of the sales team took advantage of the<br />

opportunity to witness first-hand the individual<br />

steps involved in the production of our PALFINGER<br />

cranes. For a whole week, we swapped theory for<br />

practice and assumed the role of an assembly operator.<br />

Following a general introductory training<br />

session led by training officer Paul Grubits, we<br />

were immediately faced with the task of assembling<br />

the extension boom system. Under the expert<br />

eyes of the assembly team, we had the opportunity<br />

to look at and assemble the many detailed<br />

solutions and quality characteristics. "It's a perfect<br />

opportunity to gain an understanding of the<br />

quality that goes into each and every component<br />

of a PALFINGER crane. That will undoubtedly help<br />

us in our day-to-day dealings with customers,"<br />

says Bernhard Kletzl, a member of the sales team.<br />

From the assembly of extension booms, control<br />

valves and knuckle booms to the "marriage" (connection<br />

of the arm assembly to the base), as well<br />

as the electronic assembly and inspection of the<br />

crane, we were able to witness the entire process<br />

involved in the crane manufacture, first hand.<br />

PALFINGER awarded "Green Brands"<br />

PALFINGER is the first company in Austria to be awarded the "Green Brands Austria <strong>2014</strong>/15" seal for its commitment to sustainability<br />

and the conservation of resources. Green Brands is an independent international organisation based in Ireland. Following a three-stage<br />

awarding process carried out by the Green Brands organisation, Herbert Ortner, CEO of PALFINGER AG, had the honour of receiving the<br />

award. "We have invested a great deal in making our entire value chain eco-efficient over recent years and intend to carry on optimising it.<br />

We are proud to be a Green Brand," said Ortner when he was presented with the seal. Any company that wishes to receive the quality seal<br />

needs to practise environmental sustainability and live by this both inwardly and outwardly. The following measures implemented by<br />

PALFINGER were just some of those that played a key role in the decision:<br />

• Use of (environmental) management systems at manufacturing and assembly locations<br />

• Preparation of internal energy saving guidelines<br />

• Use of painting systems with water-based or high-solid solvent-based paints<br />

• Regular analysis and ongoing improvement of energy consumption<br />

• Use of waste optimisation programmes<br />

• Reduction of hazardous waste<br />

• Promotion of products for environmental and social purposes and sustainable products<br />

and equipment such as the PALFINGER Hybrid<br />

4

StabLE aNd<br />

oPErator-FriENdLy<br />

iN ordEr to ENSurE optimum lifting capacity combined with perfect highperformance<br />

stability control for cranes between four and twelve metre tonnes,<br />

PALFINGER has put together a special offer: PALpackage Comfort.<br />

A total of 16 crane models from PK 4501 to PK 12502 sH can be equipped with<br />

this system. The package includes the intelligent HPsC (high-performance<br />

stability control) system and a halogen work light. The HPsC system ensures<br />

maximum utilisation of the crane's lifting capacity at every point on the stability<br />

control curve. Fully variable stabiliser positioning ensures operation even in difficult<br />

conditions. The halogen work light provides the operator with a clear view,<br />

even in poor light conditions. You can find out what else the PALpackage Comfort<br />

can do from the details given on the back of this issue of <strong>Crane</strong> <strong>Passion</strong>, or<br />

you can find further information on our homepage at www.palfinger.com.<br />

PaLFiNGEr at tHE iaa<br />

at tHiS yEar'S iaa, PALFINGER will present a wide range of<br />

innovations at its stand in Hall 26, D16, and in the K44 outdoor<br />

exhibition area. In addition to a large<br />

number of solutions for industries<br />

such as the construction sector and Zukunft bewegen<br />

forestry, PALFINGER will also unveil<br />

several product firsts. It's well worth a<br />

visit – anyone who is unable to attend<br />

will find a description of the highlights<br />

on the next pages.<br />

25. SEPTEMBER – 02. OKTOBER <strong>2014</strong><br />

HANNOVER<br />

PALFINGER oNLINE<br />

PaLcom P7 coNtroLS raciNG truck<br />

The truck racing driver Jochen Hahn, the new<br />

PALcom P7 crane control and a young boy are the<br />

stars of a new viral video that has appeared on You-<br />

Tube and can be viewed at www.palfinger.com. In<br />

this short tongue-in-cheek video that is well worth a<br />

watch, the boy is playing with a remote control model<br />

racing truck. Jochen Hahn suddenly appears with<br />

a real racing truck weighing in at five tonnes with<br />

1,200 hp – and<br />

controls it using<br />

the PALcom P7.<br />

The scene takes<br />

an exciting twist,<br />

but we won't<br />

give too much<br />

away here. Tip from the editorial team: make sure<br />

you watch the video at http://www.youtube.com/user/<br />

PALFINGERAG and enjoy.<br />

cHooSiNG a craNE ovEr tHE iNtErNEt<br />

The new Loader <strong>Crane</strong> Finder on PALFINGER's website<br />

makes choosing a crane child's play: Customers<br />

start by selecting their industry and then enter the<br />

load they want to lift and in what range. The<br />

PALFINGER Loader <strong>Crane</strong> Finder then displays the<br />

models that meet the customer's requirements. This<br />

platform also allows customers to compare technical<br />

data and select additional equipment. As soon as<br />

a selection has been made, the local dealer will<br />

receive a non-binding information request.<br />

youtubE cHaNNEL WitH uSEr vaLuE<br />

PALFINGER's YouTube channels provide users with<br />

useful clips: As well as product presentations and<br />

trade fair images, the channels also include image<br />

videos and animations. The PALFINGER AG product<br />

channel is the main channel (www.youtube.com/<br />

PALFINGERAG), and there are also channels for different<br />

countries. It's definitely worth taking a look.<br />

PLaNt viSit From tHE comFort<br />

oF your dESk<br />

The virtual plant tour provides an innovative example<br />

of how the Internet can be used. Here, viewers<br />

can see the precision and meticulous care that go<br />

into creating the innovation leader's products.<br />

PALFINGER plants can be visited online via the<br />

homepage at http://virtualtour.palfinger.com. The<br />

tour gives visitors an in-depth look behind the<br />

scenes. Users will find a detailed presentation of<br />

worldwide production facilities and product groups<br />

as well as hot spot videos on modern, innovative production<br />

methods, points of interest and other additional<br />

information. A virtual tour is also possible in<br />

selected plants, where users can take a look around<br />

the entire plant. Further content is added to the tool<br />

on an ongoing basis – particularly hot spot videos.<br />

5

L-CRANe <br />

| CRANE <strong>Passion</strong><br />

PALFINGER L-crane series<br />

The best<br />

BECOMES<br />

even better<br />

PALFINGER will unveil another highlight at IAA in the form of the completely redesigned L-crane<br />

model series. The new generation offers impressive performance capacity and ergonomics.<br />

Improved working<br />

conditions:<br />

the top seat models<br />

have an ergonomically<br />

designed seat from<br />

which the operator<br />

can see the entire<br />

working area.<br />

PALFINGER<br />

is demonstrating<br />

the fine art of<br />

making an outstanding<br />

product even better with the new<br />

generation of the brick and block<br />

crane series. The new models will<br />

make their début at IAA <strong>2014</strong> in<br />

Hanover.<br />

The L-crane series has already gone beyond its competitors<br />

in the rear-mounted brick and block crane segment.<br />

Features such as the 440˚ tiltable range and an<br />

excellent loading height set the crane models in this<br />

series apart.<br />

The advantages of the new all-rounder for demanding<br />

loading and supply operations on the construction site<br />

include its ease of servicing. The entire slewing mechanism<br />

runs through an oil bath right up to the head bearing,<br />

ensuring permanent lubrication. Therefore extensive<br />

maintenance of the lubrication system is no longer necessary.<br />

The new internal hose routing system also saves on<br />

operating costs. The protected installation of hydraulic<br />

hoses prevents damage and allows for compact set-up<br />

dimensions.<br />

The new L-series offers improved working conditions for<br />

crane operators as well. The top seat models offer an<br />

ergonomically designed top seat and a new joystick<br />

control. The redesigned workstation allows operators to<br />

work in a relaxed environment over a longer period of time<br />

and provides a perfect view of the entire working area.<br />

The workstation can be equipped with a weatherproof<br />

roof and an LED or halogen work light if required.<br />

A Danfoss control valve is available as an optional extra,<br />

which enables manifold controllability and optimised<br />

working.<br />

The lifting moment is up to 15% higher than previous<br />

models while the crane weight is virtually the same,<br />

which improves the performance capacity of the new<br />

L-crane series. This has extended the working range of<br />

the crane and actively helps to ensure economically<br />

viable operation.<br />

The performance range of the four new L-crane types<br />

extends from the PK 20501 L with 19.7 metre tonnes and<br />

the PK 22001 L with 21.8 metre tonnes of lifting moment<br />

– each with a maximum range of 13.7 metres – to the<br />

PK 23001 L with 22.9 metre tonnes and the PK 26001 L<br />

with 25.3 metre tonnes of lifting moment – each with a<br />

maximum range of 16.2 metres. The PK 22001 L and<br />

PK 26001 L are both equipped with S-HPLS technology<br />

and are supplied with the new PALcom P7 remote<br />

control.<br />

6

CRANE <strong>Passion</strong> | P-Fold<br />

Perfectly<br />

set up<br />

with fingertip movement<br />

With the P-Fold assistance<br />

system, another product<br />

innovation from PALFINGER<br />

will celebrate its world premiere<br />

at IAA <strong>2014</strong>. <strong>Crane</strong>s can be<br />

folded and unfolded easily by<br />

using the P-Fold.<br />

Comfort, safety and efficiency – PALFINGER<br />

offers these strengths with the new PALcom P7 loader<br />

crane remote control. As an additional function of the<br />

PALcom P7, PALFINGER is launching the new P-Fold<br />

assistance system on the market exclusively for all cranes<br />

in the SH model series, from the PK 42002 SH to the<br />

flagship PK 200002 L SH.<br />

The crane operator activates P-Fold using the PALcom P7<br />

operating menu. After the assistance system is activated,<br />

the crane is set in motion by moving just one control lever.<br />

The intelligent P-Fold controls take over coordination of<br />

the crane movements until a defined working position is<br />

reached.<br />

After operation has ended, the crane can be folded down<br />

from any working position. P-Fold then takes over coordination<br />

of all crane movements again and controls the<br />

additional foldable knuckle boom and rope winch as<br />

well. The operator controls the innovative system with just<br />

one control lever while the crane is folded down fully. Of<br />

course, the P-Fold system also works together with the<br />

new RTC (Rope Tension Control) system. Both systems<br />

perfectly support the crane's set-up processes. This<br />

reduces set-up times to a minimum and prevents damage<br />

to the vehicle, load, rope and surrounding area.<br />

In addition to the significant increase in operator comfort<br />

and the prevention of costly damage, the new assistance<br />

system significantly reduces the crane's set-up times.<br />

This conserves valuable working and service life, which<br />

directly benefits the productivity of PALFINGER cranes.<br />

The P-Fold assistance system offers a unique method of<br />

operation and will be launched on the market for all<br />

SH cranes from PK 42002 SH to PK 200002 L SH in<br />

combination with the new PALcom P7 remote control at<br />

the end of <strong>2014</strong>.<br />

P-Fold:<br />

the controls take over coordination of<br />

the crane movements until a defined<br />

working position is reached.

PaLcom P7<br />

PrEmiErE<br />

HumaN aNd macHiNE<br />

bEcomE oNE<br />

The PALFINGER loader crane radio remote<br />

control PALcom P7 is an entirely new<br />

development that combines the highest<br />

level of operator-friendliness, safety and<br />

working efficiency with innovative design.

PErFEct Form For<br />

PErFEct FuNctioN<br />

CRANE PAssIoN | PaLcom P7<br />

The design of the new PALcom P7 crane remote control<br />

from the team of designers at formquadrat constitutes a<br />

highlight for a range of industries. As the most important link<br />

between crane and operator, the control requires ergonomics<br />

and intuitive usability to be as close to perfect as possible.<br />

"The goal will only be achieved when the user and control<br />

merge together to become one and the control functions<br />

as an extended arm for the operator," explains formquadrat<br />

CEo and Chief Designer Mario Zeppetzauer.<br />

The designers focused on the intuitive operation of the new<br />

PALdrive rotary push switch and ergonomically shaped control<br />

lever in order to achieve this. Circumferential lines in a<br />

red-and-black PALFINGER design characterise the styling.<br />

The "running boards" on the base bring out the control's<br />

robust construction.<br />

ELEctroNic maStErPiEcE:<br />

the perfect industrial design of<br />

the new palcom p7 remote control<br />

comBines optimum ergonomics with<br />

modern, intuitive operating logic.<br />

aS tHE moSt imPortaNt link between the operator<br />

and crane, the crane remote control takes on a central<br />

role when it comes to loading or assembly work. With the<br />

innovative PALcom P7 loader crane radio remote control,<br />

PALFINGER is setting new benchmarks in the industry.<br />

Maximum ergonomics for precise, fatigue-free working is<br />

just as much a development objective as easy readability<br />

of information and a long battery life. Working together<br />

with external experts, research institutes and crane operators,<br />

the PALFINGER development department took a<br />

leading role in designing a completely new type of radio<br />

remote control that is perfectly suited to loader cranes.<br />

This allows the clearly structured display to inform operators<br />

about all important operating conditions during each<br />

work step. The operator is not distracted from operating<br />

the crane. Furthermore, the hand rests and layout of the<br />

control levers are carefully chosen to enable fatigue-free<br />

work.<br />

When it came to the key task of designing the operating<br />

elements, the ambitious development team specifically<br />

explored a new approach. For example, the control ergonomics<br />

are consciously based on intuitive use by the operator,<br />

thereby ensuring maximum operational safety<br />

even over long working times. As a result, the key functions<br />

can virtually be operated "while blindfolded" after a<br />

brief training period. The centrally located "PALdrive"<br />

control knob constitutes a further highlight of the new<br />

PALFINGER PALcom P7. The control element, known<br />

from luxury-class cars, and the intuitive menu with a clear<br />

graphic design ensure particularly easy and safe operation.<br />

This sees a central 4.1-inch TFT colour display with transflective<br />

technology used in the new PALcom P7 for the<br />

first time in the crane sector.<br />

„<br />

the neW crane controL From<br />

PaLFinger has been rigorousLy<br />

designed to imProve ergonomics<br />

in many PrototyPe stePs. the<br />

chaLLenge Was to combine oPerating<br />

eLements, ergonomics and<br />

saFety With a stand-aLone design<br />

scheme.<br />

“<br />

mario zEPPEtzauEr, cEo oF<br />

Formquadrat GmbH, LiNz<br />

9

oNEPaLcom<br />

PaLcom P7 | CRANE PAssIoN<br />

HumaN<br />

aNd<br />

macHiNE<br />

bEcomE<br />

New and innovative safety concepts were integrated during<br />

the development of the PALcom P7 radio remote control.<br />

safety features such as rollover and acceleration<br />

sensors prevent unintentional crane movements. operational<br />

safety is the key focus at all times. For example, if<br />

the control handset exceeds a certain inclination angle or<br />

the radio console falls to the ground, the function of the<br />

control lever is deactivated.<br />

With the new PALcom P7, PALFINGER is exploring a new<br />

approach in terms of energy management as well. Before<br />

quick charging, the in telligent charging station checks the<br />

charge state, need for refreshment and the temperature<br />

of the batteries. From all of this information, the charging<br />

device inputs the optimum charging current. This provides<br />

a sustained increase to the service life of the batteries<br />

over the long term. Reduced power consumption enables<br />

the PALcom P7 to run for up to twelve hours in<br />

continuous operation without recharging, making unproductive<br />

battery charging breaks a thing of the past. The<br />

innovations of the PALFINGER PALcom P7 span all areas<br />

relating to the interaction between humans and machines.<br />

Two ergonomically optimised strap systems with a<br />

diagonal or waist belt and large areas of padding ensure<br />

the highest level of wearing comfort, even over long periods<br />

of operation.<br />

The perfect balance between further optimised intuitive<br />

control, clear communication of information and maximum<br />

operator comfort sets a new benchmark for crane<br />

remote controls with the PALcom P7. <strong>Crane</strong> operators<br />

therefore reap the benefits of a sustained workload reduction,<br />

maximum safety and a longer battery life.<br />

PaLcom<br />

„<br />

„<br />

„<br />

in terms oF oPeration and<br />

Wearing comFort, i am 100%<br />

haPPy With the PaLcom P7.<br />

“<br />

maXimiLiaN rEitEr, 24, craNE oPErator,<br />

drivES aN mb actroS 2646 WitH a Pk 34002 SH<br />

aNd WorkS at bErGEr bau- uNd iNduStriEbEdarF<br />

GmbH, trauNStEiN.<br />

the neW PaLcom P7 Provides<br />

cLear Feedback that is easy<br />

to understand When aP-<br />

Proaching the Limits With<br />

the crane.<br />

“<br />

markuS moLL, 40, cEo moLL traNSPortE,<br />

GiNGEN/FiLS, traNSPortS traNSFormErS,<br />

cabLE drumS aNd SyStEm comPoNENtS<br />

For tHE ENErGy iNduStry WitH a<br />

ScaNia r500 WitH Pk 34002 SH.<br />

changing to the neW PaLcom<br />

P7 didn't reQuire any sPeciaL<br />

adJustment For me. aLL oPerating<br />

eLements are Positioned<br />

Where they beLong.<br />

“<br />

micHaEL GutiErrEz, 24, traNSPortS<br />

coNStructioN matEriaLS aNd PaLLEt<br />

GoodS WitH HiS maN aNd Pk 34002 SH<br />

For tHE comPaNy bauWarEN maHLEr,<br />

auGSburG.<br />

I have been working with the PALcom P7 for a good two weeks now and am<br />

very pleased with it. Changing from the conventional remote control to the<br />

new PALcom remote control constitutes a huge step forward. Even though I<br />

only recently became acquainted with the new remote control, I can perform<br />

most commands intuitively without looking at the device. The grip and positioning<br />

of the lever have been perfectly designed. I really like the graphic<br />

menu – you can understand the symbols instantly. It's really self-explanatory.<br />

The backlighting on the display means I can read the information easily in any<br />

light. The device also offers a significant improvement in wearing comfort<br />

compared with my old remote control. I truly am 100% happy with the new<br />

device.<br />

The ergonomics of the new crane control are fantastic! I am familiar with the<br />

rotary control knob from my car. I absolutely love using it to control the crane<br />

– it has a true luxury-class feel to it. After only a few days of using it, I have really<br />

got the hang of operating the control. The new display is very easy to read.<br />

Here, I can see the current load and stabilizer conditions on the display. This<br />

is extremely important when approaching the lifting capacity levels.The<br />

backlighting is an excellent feature in our field of work, which often requires<br />

the power to be switched off during assembly. The sensitive control and good<br />

modulation of the PALcom P7 makes working with our heavy and expensive<br />

loads a great deal easier. The wearing comfort is perfect. If I don't need the<br />

remote control, I simply swivel the waist strap around so it sits against my<br />

back.<br />

After using the new PALFINGER remote control for almost three months,<br />

I don't have a bad word to say about it. Changing from the former control<br />

wasn't a big adjustment for me. The new rotary knob in the centre improves<br />

operation during use. I like the display of capacity utilisation and stabilization<br />

width in percentages as well as the direct menu access. The control is extremely<br />

sensitive, which is very important for us when lifting pallets of plasterboard<br />

to the third floor, for example. Thanks to the diagonal strap, wearing the<br />

remote control remains comfortable even over longer periods. And there is<br />

every reason to be extremely pleased with the long battery life.<br />

10

CRANE <strong>Passion</strong> | Job Report Hörmann<br />

Reaching new<br />

heights<br />

With PALFINGER assembly cranes<br />

Family business Rudolf Hörmann GmbH, based in Buchloe,<br />

Allgäu, is constructing more than 740 commercial, barn and<br />

storage halls across Germany. A fleet of modern PALFINGER<br />

cranes is completing the skilled on-site construction work<br />

right on schedule.<br />

CONSTRUCTING HALLS WITH<br />

HYDRAULIC ASSISTANCE:<br />

HÖRMANN ASSEMBLY OPERATOR SIGI<br />

KIRCHNER SWEARS BY DAILY USE OF<br />

HIS PALFINGER PK 92002 SH ON<br />

FOUR-AXLE MAN CHASSIS.<br />

Both the people and machines at Hörmann, one of Germany's leading hall<br />

construction companies, have to work with maximum flexibility. "Each hall is<br />

unique," reports Thomas Novacek, 47, head of the Timber Construction and<br />

Assembly divisions in the company with 650 employees. The hardworking<br />

Allgäu employees receive dynamic assistancefrom their fleet of PALFINGER<br />

cranes. A total of 13 assembly cranes, some of which are mounted on three<br />

axle, four axle or semi-trailer tractors, are taking on a leading role in the construction<br />

of approximately 740 halls this year.<br />

The new flagship of the Hörmann fleet, a PALFINGER PK 92002 SH, is mounted<br />

on a four-axle MAN chassis that has been specially modified for cranes.<br />

Altogether, 480 hp, a hydraulic drive for the second steering axle and an<br />

additional auxiliary frame to hold a hydraulic stabilizer system with a loadbearing<br />

capacity of 30 tonnes on the front of the vehicle make the heavy MAN<br />

a high-tech substructure for PALFINGER that can be used universally. For example,<br />

the heavy assembly crane with a maximum lifting capacity of 30 tonnes<br />

and electronic high-performance stability control can also slew over the front<br />

of the vehicle – a truly major advantage that time and again proves beneficial,<br />

particularly in confined spaces on rural construction sites.<br />

"Unbelievably simple and extremely sensitive," says Bavarian hall assembly<br />

operator Sigi Kirchner, 42, praising his hydraulic assistant mounted on the<br />

back of the heavy four-axle MAN chassis. In just five days, he and his colleagues<br />

will place a complete hall extension on the foundations. Narrow access<br />

roads, unpaved surfaces and extremely confined working spaces often<br />

placed the highest demands on the assembly team and crane.<br />

„<br />

We have been working with PALFINGER<br />

assembly cranes since 1994. We believe<br />

that PALFINGER is the best brand on the<br />

market for day-to-day operation as well<br />

as maintenance, spare parts service and<br />

value retention.<br />

“<br />

Thomas Novacek, head of the Timber Construction and<br />

Assembly divisions at Rudolf Hörmann GmbH, Buchloe<br />

From unloading the materials and preparing for construction to building the<br />

hall and assembling solar elements on the roof, the premium products from<br />

Austria operated non-stop. "The sensitive control, the electronic active oscillation<br />

suppression system, the continuous slewing system and the fly-jib or overstretchable<br />

knuckle boom fitted on the vehicle perfectly suit our requirements,"<br />

praises Thomas Novacek. In addition, reliability, the closely integrated<br />

service network extending to the swift repair service at the<br />

construction site and ultimately the resale value all cast a<br />

positive light on the Bavarian-Austrian liaison.<br />

<strong>11</strong>

The Company Gross | CRANE <strong>Passion</strong><br />

„<br />

I simply can't afford to use simplistic<br />

technology. For us, PALFINGER is the<br />

non plus ultra when it comes to<br />

loading devices!<br />

“<br />

Rainer Petermann, CEO of the Gross<br />

group from Köngen near Stuttgart<br />

Great<br />

business<br />

With PALFINGER<br />

Europe's largest ADAC partner, the Swabian Gross group, is placing its full<br />

trust in intelligent crane technology from PALFINGER to ensure its fleet of<br />

recovery and breakdown vehicles can lift gently and effectively.<br />

The lifting work in vehicle recovery and<br />

transport business must be performed gently and quickly.<br />

The sensitivity of the hook is important to clear blocked<br />

roads as quickly as possible on the one hand, and to avoid<br />

putting people and the expensive vehicles being used in<br />

danger on the other. Headquartered in Köngen, the<br />

Swabian Gross group swears by the innovative, robust<br />

technology of PALFINGER cranes for this reason for its<br />

35 tow and recovery trucks.<br />

The Gross fleet of recovery vehicles is in operation<br />

throughout Europe around the clock, 365 days a year.<br />

As an established technology expert, CEO Rainer<br />

Petermann chose PALFINGER to be the partner company.<br />

"Once I have been won over by a service, then I stick<br />

with it!" says the 52-year-old Gross CEO, describing the<br />

structure of the high-quality vehicle fleet. "PALFINGER<br />

and vehicle body manufacturer TBZ are simply the perfect<br />

combination for us," explains the consummate businessman,<br />

summarising his many years of experience<br />

with countless competitor products. The Austrian premium<br />

products had the edge over the competition not<br />

only in terms of technical implementation but also for<br />

spare parts supply, service and sales advice. Bruno<br />

Nocce, financial expert and member of the management<br />

team at Gross, attests that the reliability in 24-hour<br />

operation as well as the zero external damage rate for<br />

vehicle transportation and the later resale value all clearly<br />

put PALFINGER cranes on top. And it makes sense to<br />

opt for the best product instead of a simply good one in<br />

economic terms as well. The somewhat higher acquisition<br />

costs for the top-class product are amortised<br />

several times over throughout the vehicle's entire<br />

service life. For the practical workers in the Gross group,<br />

working with a PALFINGER crane every day constitutes<br />

an essential component of their success. Recovery truck<br />

driver Patrick Wälde summarises the benefits of his<br />

PALFINGER PK 17500 T. "The intuitive control plays a<br />

major role in ensuring the successful transportation of<br />

cars." For example, even vehicles positioned directly<br />

behind the vehicle platform can be optimally lifted<br />

without swinging. "The extremely sensitive response is<br />

extremely important if a car has to be lifted on from a<br />

confined space using a vehicle recovery yoke!"<br />

Many detailed solutions cast positive light on modern<br />

PALFINGER cranes. For example, the cylinder attached to<br />

the side of the main boom often provides those crucial<br />

extra centimetres when working in confined spaces.<br />

What's more, the response behaviour is optimal straight<br />

away even after a frosty night. "It's clear that PALFINGER<br />

puts a great deal of consideration into operation and<br />

makes use of its consolidated expertise," says Daniel<br />

Beyersdorf, manager of the Gross fleet of cranes and<br />

recognised vehicle recovery expert, praising the characteristics<br />

of the Austrian quality product.<br />

After the last third-party product was taken out of service,<br />

the Gross fleet now rolls out for operation with only<br />

PALFINGER cranes. CEO Rainer Petermann continues to<br />

place his trust in the company's technical expertise and<br />

remains loyal to the best products. When it comes to<br />

cranes, the clever businessman is certain that he has<br />

found a partner for life in PALFINGER.<br />

12

The Gross group:<br />

everything for cars<br />

Thanks to Swabian diligence and perseverance, the filling<br />

station business with a metalworking shop founded<br />

in 1953 by Karl Gross has evolved over three generations<br />

of owners to become a successful group of companies<br />

comprising more than 50 divisions, 400 employees<br />

at 31 locations and 320 trucks. This makes Gross the<br />

most important ADAC partner company in Europe and<br />

sees it take on a wide range of transport tasks on behalf<br />

of the Daimler Group, including the transportation of<br />

prototypes, test vehicles and vintage cars for the museum<br />

by truck. The slogan of the bustling Swabian company,<br />

"We do everything for cars", is perfectly fitting.<br />

SWEARING BY THE PALFINGER<br />

BRAND ALONE: GROSS CEO<br />

RAINER PETERMANN (LEFT) AND<br />

MEMBER OF THE MANAGEMENT<br />

TEAM BRUNO NOCE.

atELiEr<br />

mÉcaNiquES<br />

doStErt<br />

a comPaNy carEEr cLoSELy<br />

LiNkEd WitH PaLFiNGEr<br />

Ateliers mécaniques Dostert has served as primary importer of PALFINGER<br />

products in Luxembourg for 40 years – a success story written by a tradition<br />

of innovation.

CRANE <strong>Passion</strong> | Dostert<br />

LUXEMBOURG TECHNOLOGY TEMPLE:<br />

THE NEW DOSTERT COMPANY PREMISES FROM<br />

FRANZ DOSTERT OFFERS LOTS OF SPACE FOR SERVICE,<br />

SALES AND MODIFICATION. THE EXTENSIVE SPART<br />

PARTS WAREHOUSE IS LOCATED IN THE UNDER-<br />

GROUND HALL.<br />

For Franz Dostert, true meaning has just<br />

been given to the ancient Greek philosophical<br />

saying "everything flows". Special hydraulic<br />

solutions define his working life, which has<br />

closely linked him to PALFINGER for 40 years<br />

now. Ever since his childhood, the Director of<br />

the family business Ateliers mécaniques Dostert<br />

has been acquainted with the mechanical<br />

and hydraulic business of his family.<br />

So it's no surprise that the likeable company<br />

boss enthusiastically got to work as a qualified<br />

journeyman at the designer's desk and<br />

workbench in the historical workshop building<br />

located in Hunsdorf, a small town of 8,000 residents, when he<br />

was just 16 years old. At the young age of 21, he took over management<br />

of the company from his uncle who had fallen ill, and this was<br />

the year that the first PALFINGER crane made its entrance.<br />

Franz Dostert can still remember his first rendezvous with the Austrian<br />

crane very well. The extremely talented mechanics expert immediately<br />

recognised the technical finesse of the first PALFINGER<br />

crane and has since served as primary importer<br />

of the Austrian products for Luxembourg, which<br />

currently has a population of around 500,000. In<br />

the beginning, five to six cranes were distributed<br />

to the customers each year, whereas now around<br />

35 PALFNGER cranes, numerous truck-mounted<br />

forklifts and hookloaders leave the historic<br />

halls in Rue Franz Dostert.<br />

Together with his son and Junior Director<br />

Charles, 35, Franz Dostert also deals with special<br />

customer requirements, modifications and chassis<br />

adaptations. PALFINGER has always been the<br />

designated partner of choice for the 61-year-old<br />

company Director. He believes that the Austrian-Luxembourgish alliance<br />

is unbeatable, in terms of both the technology and people.<br />

"The global PALFINGER family is unique. There is a genuine friendship<br />

among the dealers – it's not all just about the shareholder<br />

value!" says Franz Dostert, affirming the values of the long-standing<br />

alliance.<br />

Making an appearance at the EMEA Sales Conference in Luxembourg<br />

A partnership now stretching over 40 years links PALFINGER to<br />

our Luxembourg dealer Franz Dostert. Together with the fact that<br />

the Dostert company moved into a new building this year and<br />

that PALFINGER was optimally branded in a lighthouse project at<br />

the same time, this was reason enough to make an appearance<br />

at the <strong>2014</strong> EMEA Sales Conference in Luxembourg.<br />

The opening ceremony for the new Franz Dostert workshop was<br />

without doubt the emotional highlight of the event. In addition to<br />

a heartfelt speech given by Management Board member Wolfgang<br />

Pilz, old friends and employees gave their congratulations<br />

on the anniversary in the form of video messages. Hannes <strong>Palfinger</strong><br />

and Management Board member Martin Zehnder were also<br />

among the well-wishers in the cheerful audience. Of course,<br />

alongside this icebreaker on the agenda, the three days of the<br />

event also offered a wealth of content and provided the invited<br />

dealers with current information about the markets, marketing<br />

activities, dealer standards and service projects as well as all relevant<br />

information for crane, hookloader, MBB and Epsilon products.<br />

Following an extremely compact and informative agenda, a<br />

social evening event in Luxembourg old town, a fantastic and<br />

above all productive event drew to a close in style.<br />

PALFINGER FAMILY MAKE AN APPEARANCE IN LUXEMBOURG:<br />

(From left to right) Martin Zehnder, Wolfgang PilZ,<br />

Hubert Meschnark, Hannes <strong>Palfinger</strong>, Franz Dostert,<br />

Felix Strohbichler.<br />

15

doStErt | CRANE PAssIoN<br />

„<br />

essentiaLLy, We do things that<br />

others can't. there is no such<br />

Word as "can't" at our comPany.<br />

hydrauLics even characterise<br />

our thoughts!<br />

“<br />

FraNz doStErt, dirEctor oF atELiErS mÉcaNiquES<br />

doStErt, HuNSdorF iN LuXEmbourG<br />

For example, his holiday agenda features extremely<br />

frequent visits to his foreign PALFINGER importer colleagues.<br />

The exceptional design engineer, who has received<br />

several innovation awards, believes the global<br />

exchange of information is extremely important. Dostert is<br />

now the oldest living PALFINGER importer, which doesn't<br />

stop the enterprising expert from setting the course for<br />

expansion for the company's future with an impressive<br />

new construction in Rouscht, Bissen.<br />

on the spacious new company premises, Franz Dostert<br />

wants to enhance performance potential with an in-house<br />

sandblasting facility, paint shop and hydro jet cutting system<br />

system. The representative PALFINGER customer<br />

area and an extensive spare parts warehouse in the fully<br />

underground, spacious hall are leading the innovative<br />

workshops of the Dostert family company to a new era of<br />

the company's 130 years of history. A semi-trailer tractor<br />

lifting platform with a lifting capacity of 60 tonnes, abundant<br />

parking spaces and an in-house TÜV testing facility<br />

complete the comprehensive offer, which had always suffered<br />

from problems with space at the old location. The<br />

likeable senior Director and his 38 employees in the new,<br />

ultramodern PALFINGER branch will have no problem<br />

bidding farewell to the historic workshop in Hunsdorf,<br />

where Franz Dostert witnessed the fascination surrounding<br />

shaped metal in the forge when he was just a child.<br />

However, Franz Dostert does not want to forget the company's<br />

history after moving into the modern facilities. The<br />

historic forge, where founder of the company Bernard<br />

Dostert shaped the first metal parts in 1884, will remain in<br />

Hunsdorf as a company museum.<br />

driviNG ForcE For iNNovatioN<br />

For morE tHaN 130 yEarS<br />

Dostert's company history can<br />

be traced back to the French<br />

Revolution. 1884 is the official<br />

founding year of the mechanical<br />

Dostert workshops in Hunsdorf,<br />

Luxembourg, where Bernard<br />

Dostert ran a blacksmith<br />

and wheelwright's workshop,<br />

from which an in-house vehicle<br />

construction facility was born over the decades.<br />

Construction of truck tipper bodies and the manufacture<br />

of pumps and cylinders began in 1936. The<br />

year 1946 saw the arrival of an innovative waste<br />

collection vehicle with a tipper container for compacting<br />

waste on the market. In 1974, current Director<br />

Franz Dostert took on the role as primary<br />

importer of PALFINGER products for Luxembourg,<br />

which he continuously expanded together with his<br />

son Charles. In <strong>2014</strong>, Ateliers mécaniques moved<br />

to the new location in Rouscht, Bissen, where the<br />

company's activities are being further expanded.<br />

Bernard Dostert<br />

bELLoWS aNd ForGE:<br />

in 130 years, dostert has evolved from<br />

what started as a Blacksmith and wheelwright's<br />

workshop into a high-tech<br />

specialist.<br />

16

CRANE <strong>Passion</strong> | Mounting Competence Center<br />

EXPERTISE<br />

in a compact design<br />

PALFINGER presents new compact crane assembly kit for 3.5-tonne<br />

vehicles at IAA. The lightweight loader cranes stand out from the crowd<br />

with short assembly times and PALFINGER quality.<br />

The PALFINGER Mounting Competence<br />

Centre (MCC), known for crane<br />

projects in the high-end performance<br />

range, is now demonstrating its<br />

strengths with small vehicles as well.<br />

The experts from Lengau, Austria,<br />

present their latest development –<br />

an assembly kit that can be used to<br />

install compact cranes on lightweight<br />

3.5-tonne transporters much more<br />

easily and cost-effectively.<br />

Until now, comparatively high assembly<br />

and installation costs in relation to<br />

the vehicle purchase price have represented<br />

a market hurdle for these<br />

compact all-rounders on the loading<br />

platform. The head of MCC Gernot<br />

Pichorner and his experts worked together<br />

with their sales colleagues to<br />

survey dealers and customers in<br />

depth. Their aim was to clarify the<br />

requirements profile for lightweight<br />

loader cranes in this Europe-wide<br />

vehicle class. Based on this, the<br />

PALFINGER developers created an<br />

extremely assembly-friendly kit that<br />

can be configured for the standard<br />

models of leading suppliers in this<br />

segment.<br />

SIMPLE PRINCIPLE: THE COMPACT PC<br />

LOADER CRANES ARE EASY TO ASSEM-<br />

BLE WITH NO NEED FOR INTERVEN-<br />

TION ON THE CHASSIS AND ARE AVAIL-<br />

ABLE FOR ALL STANDARD 3.5-TONNE<br />

TRANSPORTERS.<br />

„<br />

WITH THE NEW COMPACT CRANE<br />

ASSEMBLY KIT, WE OFFER A "PLUG-<br />

AND-USE" ASSEMBLY SOLUTION THAT<br />

GUARANTEES ALL-ROUND PALFINGER<br />

QUALITY AT REASONABLE COSTS.<br />

“<br />

GERNOT PICHORNER, HEAD OF ASSEMBLY<br />

AND INFRASTRUCTURE, PALFINGER PLANT IN LENGAU<br />

The design of the PALFINGER PC crane does not feature<br />

an additional auxiliary frame to reduce the payload or<br />

additional welding or drilling work on the chassis. Only the<br />

longitudinal profile of the platform substructure and the<br />

screen-printed wear floor of the platform is cut out for<br />

crane assembly. The new crane kit does not need any<br />

further interventions on the chassis or the ladder frame<br />

construction of the platform.<br />

The 120-millimetre high, extremely compact cross-rail for<br />

the stabiliser support system is assembled separately<br />

from the crane and is fixed to the chassis using screw and<br />

clamp connections like a hydraulic crane. "This design<br />

means that the crane can be assembled, retrofitted or<br />

transferred to a new chassis without any problems,"<br />

states Gernot Pichorner, explaining the innovative assembly<br />

concept that yields benefits for a wide range of customers.<br />

The lightweight KTL dip-painted PALFINGER<br />

crane is much easier to assemble and can be constructed<br />

in appropriately qualified workshops. The new<br />

PALFINGER crane kit entails only around a third of the<br />

time required to assemble other types of crane, which<br />

translates into a significant cost advantage.<br />

Three power classes, ranging from the lightweight<br />

PALFINGER PC 1500 with 1.4 metre tonnes and a lifting<br />

capacity of up to 990 kilograms and the PC 2700 to the<br />

PC 3800 with 3.7 metre tonnes and a maximum lifting<br />

capacity of 2.000 kilograms cover the wide-ranging fields<br />

of application on the transporter platform. An electrohydraulic<br />

pump assembly or a hydraulic pump driven by the<br />

engine V-belt with a magnetic clutch is used to drive the<br />

fully hydraulic compact crane. With the new compact<br />

crane assembly kit, PALFINGER has enabled operators<br />

of lightweight commercial vehicles to benefit from the<br />

usual PALFINGER quality, even with all their sensitivity to<br />

costs.<br />

17

International | CRANE <strong>Passion</strong><br />

Construction work with PALFINGER<br />

Solar energy<br />

for Ghana<br />

PALFINGER is playing a prominent role in a nationwide solar energy project<br />

for rural regions in the West African nation of Ghana.<br />

Use solar energy! The Ghanaian<br />

government is running a campaign<br />

under this slogan, with the primary<br />

aim of bringing electricity to rural<br />

regions in the West African country.<br />

Today, around half of all Ghanaians<br />

work in agriculture. Their main activities<br />

are growing cocoa, coffee, tea<br />

and coconuts and extracting natural<br />

rubber. The Ghana Cocoa Board has<br />

been running a long-term project<br />

since 2008 to install solar-powered<br />

street lighting and build houses supplied<br />

with solar energy in rural areas.<br />

The first solar street lights erected<br />

with the help of a PALFINGER loader<br />

crane were constructed in a small<br />

farming village without electricity<br />

around three hours from the capital<br />

Accra. So far, <strong>11</strong>,000 solar-powered<br />

street lights have been installed in<br />

western Ghana, which is around the<br />

Construction:<br />

same size as the UK.<br />

Solar street lights are assembled<br />

using the PK 8500 and the<br />

In areas without an electricity supply<br />

manipulator PZM 0500.<br />

grid, lighting not only plays an important<br />

role in terms of safety in the evening. The sun goes down early in the evening<br />

in the tropical coastal land throughout the year, and so the artificial light<br />

from solar-powered street lights means that people can continue working or<br />

trading on markets or simply carry on with their social activities. The extra light<br />

improves people's quality of life in the rural western region of the country.<br />

A crane structure specially adapted by PALFINGER at the Austrian Mounting<br />

Competence Centre (MCC) is being used to erect the many solar lamp posts.<br />

As well as the loader crane, which has been adjusted for the application together<br />

with a manipulator from the PALFINGER Equipment Centre, the new<br />

two-axle vehicle has a loading platform for transporting the lamp posts and<br />

solar light modules. In addition to the street light project of the Ghana<br />

Cocoa Board, the electricity supply for private households and small businesses<br />

is also being consistently expanded in Ghana. The Ghanaian government is<br />

using free-of-charge, environmentally friendly power supplied by the sun to<br />

run a lighthouse project that is a prime example of sustainable energy production<br />

in the rural infrastructure of the Third World. A PALFINGER loader crane is<br />

also playing an important on-site assembly role in this project.<br />

18

couNtry rEPort<br />

braziL<br />

tHrEE aPPLicatioN SoLutioNS<br />

with one vehicle –<br />

PALFINGER do Brasil set this<br />

efficient and affordable crane<br />

solution in motion in collaboration<br />

with the energy group<br />

AEL sul. PALFINGER is assembling<br />

a combined loader and<br />

working crane on a locallyproduced<br />

truck. The crane<br />

uses a hook device for carrying<br />

cargo, which can be<br />

replaced with a high-voltageisolated<br />

workman basket<br />

where necessary. This allows<br />

service personnel to work<br />

effectively, both when the<br />

power is switched off and<br />

when connected to the 46 kV high-voltage mains supply, without having<br />

to change vehicle.<br />

uSa<br />

PaLFiNGEr NortH amErica is launching the new generation<br />

of PW loader cranes on the major Us sales market.<br />

The PW 32001 and PW 35001 sH models make an<br />

impression on the demanding North American market<br />

with their continuous slewing mechanism with two rotary<br />

actuators. The two actuators have been hydraulically pretensioned<br />

against each other, and thus reduce the crane's<br />

rotation play to a minimum – an invaluable advantage<br />

during usage with large outreaches. The double rotary<br />

actuator ensures a high rotation torque and very precise<br />

crane movements. The compact set-up dimensions allow<br />

for maximum available loading space compared with<br />

competitor products.<br />

PEru<br />

at tHE Foot oF tHE<br />

HimaLayaS<br />

tHE PEruviaN PaLFiNGEr<br />

importer Zapler has ac-<br />

quired an important client in the form of the south Ameri-<br />

can mining company Cerro Verde. The mining group runs<br />

one of the largest open-pit copper mines in the south<br />

American country. Zapler has assembled a PALFINGER<br />

PK 76002 EH on a truck chassis to carry out servicing and<br />

maintenance work on the electricity pylon network. As<br />

well as carrying out servicing tasks in the copper mine in<br />

Arequipa, the PALFINGER truck also transports pylons to<br />

the group's other mining locations. Cerro Verde is so impressed<br />

with the performance capacity of PALFINGER<br />

products that – alongside ten of its own crane vehicles –<br />

around 70% of all third-party vehicles used by Cerro Verde<br />

today are equipped with PALFINGER loader and assembly<br />

cranes.<br />

bHutaN, where's that again? Bhutan lies at the foot of the Himalayas<br />

surrounded by India, Nepal and Tibet. A PK 100002 was sold here,<br />

which was waiting to be set up and approved. Michael Mödlhammer<br />

(Head of Training) flew out there on 23 November 2013 to add the finishing<br />

touches to the crane. The crane was sold by the local PALFINGER<br />

dealer in the country. Its main use will be to construct hydroelectric<br />

power stations, which will supply Bhutan and neighbouring India with<br />

electricity.<br />

19

LiFEtimE EXcELLENcE<br />

PaLpackage comfort<br />

HIGHER oPErator comFort<br />

tHE bESt StabiLity coNtroL<br />

SyStEm For SmaLL<br />

LoadEr craNES<br />

without extra charge and with free<br />

work light.<br />

all models from pk 4501 to<br />

pk 12502 sh can be equipped<br />

with the palpackage comfort. the<br />

package includes the intelligent<br />

hpsc stability control system and<br />

a halogen work light. this offer is<br />

valid for all orders from the 1 st april<br />

to the 31 st december <strong>2014</strong>.<br />

please ask your dealer about the<br />

price advantage for your loader<br />

crane.<br />

HPSc – HiGH<br />

PErFormaNcE<br />

StabiLity coNtroL<br />

≥ Maximum lifting capacity<br />

at any point of the stability<br />

control curve<br />

≥ Maximum flexibility in loader<br />

crane use due to variable<br />

stabilizer positioning<br />

≥ A maximum of comfort and<br />

safety even during crane<br />

operation where space is<br />

restricted<br />

≥ Highest operator comfort<br />

thanks to clearly laid out<br />

display on the operator´s<br />

console and on the display<br />

of the radio remote control<br />

≥ Avoiding of faulty operations<br />

thanks to an automatic shut-off<br />

in extreme conditions<br />

HaLoGEN Work LiGHt<br />

≥ High performance halogen<br />

work light – factory mounted<br />

≥ Compact dimensions<br />

≥ Heavy Duty Glass Fibre<br />

Reinforced Housing and lens<br />

made of high strength glass<br />

≥ optimised light output<br />

(1750lm / 24V and 1450 / 12V),<br />

anti-vibration dampening<br />

WWW.PaLFiNGEr.com/PaLPackaGEcomFort<br />

KP-CRANEP<strong>11</strong>+E