4-stage Gas Compressor - Cryostar

4-stage Gas Compressor - Cryostar

4-stage Gas Compressor - Cryostar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

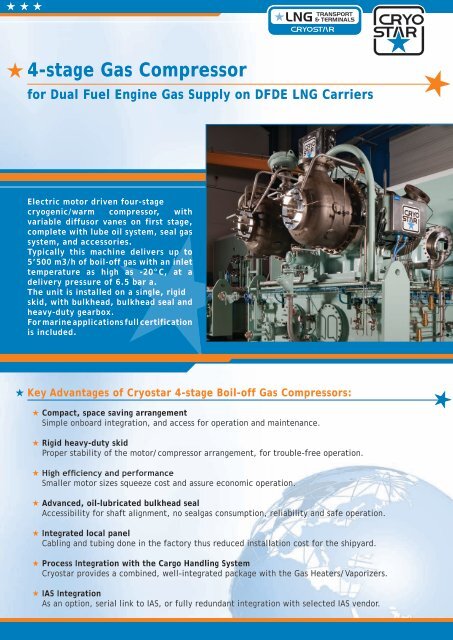

4-<strong>stage</strong> <strong>Gas</strong> <strong>Compressor</strong><br />

for Dual Fuel Engine <strong>Gas</strong> Supply on DFDE LNG Carriers<br />

Electric motor driven four-<strong>stage</strong><br />

cryogenic/warm compressor, with<br />

variable diffusor vanes on first <strong>stage</strong>,<br />

complete with lube oil system, seal gas<br />

system, and accessories.<br />

Typically this machine delivers up to<br />

5’500 m3/h of boil-off gas with an inlet<br />

temperature as high as -20°C, at a<br />

delivery pressure of 6.5 bar a.<br />

The unit is installed on a single, rigid<br />

skid, with bulkhead, bulkhead seal and<br />

heavy-duty gearbox.<br />

For marine applications full certification<br />

is included.<br />

Key Advantages of <strong>Cryostar</strong> 4-<strong>stage</strong> Boil-off <strong>Gas</strong> <strong>Compressor</strong>s:<br />

Compact, space saving arrangement<br />

Simple onboard integration, and access for operation and maintenance.<br />

Rigid heavy-duty skid<br />

Proper stability of the motor/compressor arrangement, for trouble-free operation.<br />

High efficiency and performance<br />

Smaller motor sizes squeeze cost and assure economic operation.<br />

Advanced, oil-lubricated bulkhead seal<br />

Accessibility for shaft alignment, no sealgas consumption, reliability and safe operation.<br />

Integrated local panel<br />

Cabling and tubing done in the factory thus reduced installation cost for the shipyard.<br />

Process Integration with the Cargo Handling System<br />

<strong>Cryostar</strong> provides a combined, well-integrated package with the <strong>Gas</strong> Heaters/Vaporizers.<br />

IAS Integration<br />

As an option, serial link to IAS, or fully redundant integration with selected IAS vendor.

4-Stage and 2-Stage relative performances : discharge pressure & flow range<br />

Pressure for 100% engine load<br />

6.5 bara<br />

Approximate curves<br />

4.5 bara<br />

~ < 2 bara<br />

-120°C<br />

-100°C -80°C -60°C<br />

-40°C -20°C 0°C 20°C 40°C<br />

Design Capacity & Rangeability<br />

Recycle 4-<strong>stage</strong> Cryo 40 ~ 100%<br />

Traditional 2-<strong>stage</strong> Cryo 25 ~ 100%<br />

0 1’300 2’600 3’900 5’200 6’500 m3/h<br />

4-Stage BOG <strong>Compressor</strong> operation envelope – key facts:<br />

Full 6.5 bara pressure from -140 to -20 degC WITH NO SPRAY PRECOOLING REQUIRED !<br />

HEEL-OUT OPERATION possible to DF engines<br />

And also<br />

Massflows down to 500 kg/h are possible<br />

More than 4 bara at +40 degC<br />

No VFD speed control<br />

Limited recycling<br />

Water cooling<br />

No continuously running pumps for spray precooling<br />

Retrofit of 4-<strong>stage</strong> compressor in place of 2-<strong>stage</strong> compressors is also feasible<br />

Applications:<br />

For LNG carriers,<br />

as Fuel <strong>Gas</strong> compressor to maintain the cargo tank pressure while supplying boil-off gas as fuel to the dual<br />

fuel engines and/or gas combustion unit during the voyage.<br />

For land - based plants<br />

these units are supplied as Cryogenic <strong>Compressor</strong>s, without bulkhead and designed according to API617 if<br />

required (with separate lube oil system for special purpose oil systems).<br />

CRYOSTAR SAS - BP 48 - Zone Industrielle - F-68220 Hésingue - France<br />

Phone: +33 389 70 27 27 - Fax: +33 389 70 27 77 - sales@cryostar.com - www.cryostar.com