Download the data sheet - Cryostar

Download the data sheet - Cryostar

Download the data sheet - Cryostar

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

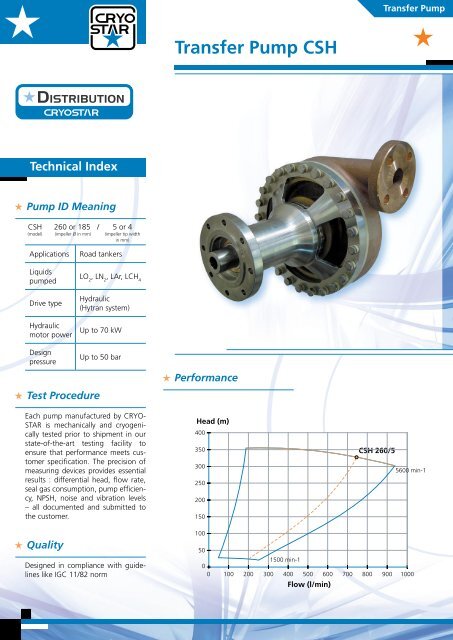

Transfer PumpTransfer Pump CSHTechnical IndexPump ID MeaningCSH 260 or 185 / 5 or 4(model) (impeller Ø in mm) (impeller tip widthin mm)ApplicationsLiquidspumpedDrive typeHydraulicmotor powerDesignpressureRoad tankersLO 2, LN 2, LAr, LCH 4Hydraulic(Hytran system)Up to 70 kWUp to 50 barPerformanceTest ProcedureEach pump manufactured by CRYO-STAR is mechanically and cryogenicallytested prior to shipment in ourstate-of-<strong>the</strong>-art testing facility toensure that performance meets customerspecification. The precision ofmeasuring devices provides essentialresults : differential head, flow rate,seal gas consumption, pump efficiency,NPSH, noise and vibration levels– all documented and submitted to<strong>the</strong> customer.Head (m)400350300250200150CSH 260/55600 min-1QualityDesigned in compliance with guidelineslike IGC 11/82 norm10050001500 min-1100 200 300 400 500 600 700 800 900 1000Flow (l/min)

Possible arrangementsDimensions in mmDimensions in inchWeight without hydraulic motorm: 165 pound / 75KgFeaturesThe hydraulic pump is driven by <strong>the</strong> truck’s powertake-off via <strong>the</strong> truck gearbox which includes anelectric piloted flow control valve to allow adjustmentof <strong>the</strong> cryogenic pump speedHydraulic couplings are supplied with fast couplers inorder to easily disconnect <strong>the</strong> vehicle tractorThe hydraulic circuit is protected by a safety valveinstalled on <strong>the</strong> hydraulic pump in order to preventoverloading of <strong>the</strong> Hytran systemControl system: a manometer is installed on <strong>the</strong> highpressure hydraulic circuit to monitor <strong>the</strong> pressure of<strong>the</strong> complete hydraulic system.At constant speed, <strong>the</strong> cryogenic pump flow can beadjusted via <strong>the</strong> discharge line valveThe pump is protected by a non return valve, installedon a parallel circuit in order to prevent an suddenlyflow shutdown1 The pump shaft is mechanically sealed with a<strong>Cryostar</strong> composite faced seal, capable of providingup to 4 times <strong>the</strong> wearing life of conventional carbonfaced mechanical seal.2 Closed impeller with axial suction and radialdischarge. Impeller balance is achieved hydraulicallyto minimize <strong>the</strong> axial load on <strong>the</strong> bearings3 Bronze helical inducer results in low NPSHrequirements with hydraulic optimal conception.2OptionsDifferential pressure switch(protection against dry running)Cool down temperature probeLeak detection temperature probePurged sealComplete skid mounted assembly13For more details please contact your local <strong>Cryostar</strong> representativeCRYOSTAR Automation tel : +33 (0) 5 65 80 20 20 info@cryostar.comCRYOSTAR Brazil tel : +55 11 5092 5262 brazil@cryostar.comCRYOSTAR China tel : +86 571 8536 8331 china@cryostar.comCRYOSTAR France tel: +33 (0) 3 89 70 27 27 info@cryostar.comCRYOSTAR Singapore tel : +65 6276 7441 singapore@cryostar.comCRYOSTAR UK tel : +44 1709 702 777 uk@cryostar.comCRYOSTAR USA East tel : 1-800-483-1052 usa@cryostar.comCRYOSTAR USA West tel : +1 (562) 903-1290 usa@cryostar.comCRYOSTAR USA - Houston Office tel : +1 (713) 661-6000 usa.houston@cryostar.comwww.cryostar.com