EcoVap Shipboard Regasification Plant for LNG Carriers - Cryostar

EcoVap Shipboard Regasification Plant for LNG Carriers - Cryostar

EcoVap Shipboard Regasification Plant for LNG Carriers - Cryostar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

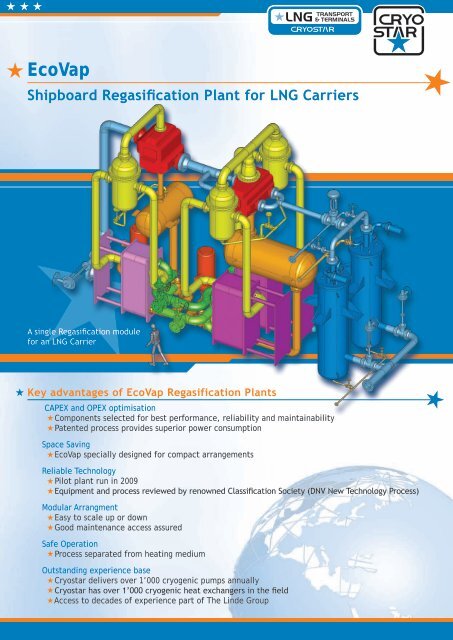

<strong>EcoVap</strong><br />

<strong>Shipboard</strong> <strong>Regasification</strong> <strong>Plant</strong> <strong>for</strong> <strong>LNG</strong> <strong>Carriers</strong><br />

A single <strong>Regasification</strong> module<br />

<strong>for</strong> an <strong>LNG</strong> Carrier<br />

Key advantages of <strong>EcoVap</strong> <strong>Regasification</strong> <strong>Plant</strong>s<br />

CAPEX and OPEX optimisation<br />

Components selected <strong>for</strong> best per<strong>for</strong>mance, reliability and maintainability<br />

Patented process provides superior power consumption<br />

Space Saving<br />

<strong>EcoVap</strong> specially designed <strong>for</strong> compact arrangements<br />

Reliable Technology<br />

Pilot plant run in 2009<br />

Equipment and process reviewed by renowned Classification Society (DNV New Technology Process)<br />

Modular Arrangment<br />

Easy to scale up or down<br />

Good maintenance access assured<br />

Safe Operation<br />

Process separated from heating medium<br />

Outstanding experience base<br />

<strong>Cryostar</strong> delivers over 1’000 cryogenic pumps annually<br />

<strong>Cryostar</strong> has over 1’000 cryogenic heat exchangers in the field<br />

Access to decades of experience part of The Linde Group

Three <strong>LNG</strong> regasification processes available :<br />

Closed Loop Systems<br />

Steam-heated glycol-water intermediate loop<br />

Direct steam-heated water bath vaporizer<br />

Open Loop System<br />

Sea-water heated propane loop<br />

Special features of <strong>Cryostar</strong> regasification units :<br />

Design<br />

Sizing and simulation per<strong>for</strong>med on state-of-the-art software<br />

Layouts chosen <strong>for</strong> compact footprint<br />

Superior access <strong>for</strong> maintenance offered<br />

Simple concept ensures simple control<br />

Flexibility<br />

Redundancy simple to arrange with modular system<br />

IAS integration possible<br />

Customer benefits<br />

<strong>Cryostar</strong> is in the unique position to be able to provide <strong>Regasification</strong> plants, Cargo Handling Compressors<br />

and Heat Exchangers as well as Reliquefaction <strong>Plant</strong>s.<br />

In-house process design as well as rotating machinery manufacture allows optimum matching of<br />

equipment to process.<br />

CRYOSTAR SAS - BP 48 - Zone Industrielle - F-68220 Hésingue - France<br />

Phone: +33 389 70 27 27 - Fax: +33 389 70 27 77 - sales@cryostar.com - www.cryostar.com