Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ISSUE 01 | 2008<br />

Naturally healthy<br />

HIPP PACKS BABY FOOD WITH MEYPACK<br />

PACKAGING TECHNOLOGY<br />

THE CUSTOMER MAGAZINE FROM MEYPACK<br />

The big cheese<br />

MEYPACK MACHINE PACKS ARLA WHITE<br />

CHEESE IN DENMARK<br />

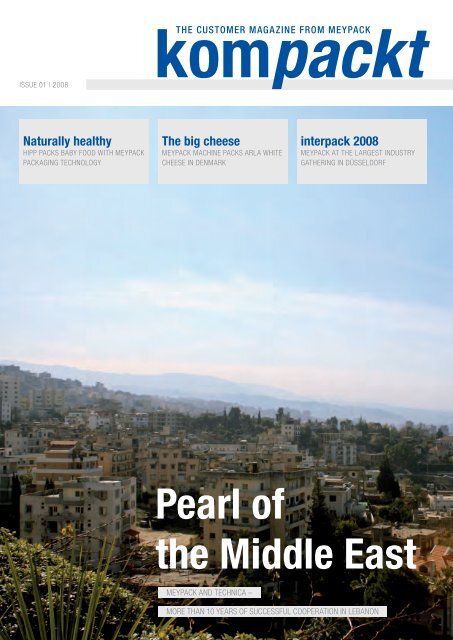

<strong>Pearl</strong> <strong>of</strong><br />

interpack 2008<br />

MEYPACK AT THE LARGEST INDUSTRY<br />

GATHERING IN DÜSSELDORF<br />

<strong>the</strong> <strong>Middle</strong> <strong>East</strong><br />

MEYPACK AND TECHNICA –<br />

MORE THAN 10 YEARS OF SUCCESSFUL COOPERATION IN LEBANON

Peter Böckenholt<br />

Managing Director and Owner<br />

Editorial<br />

Dear Readers,<br />

You are holding <strong>the</strong> fi rst issue <strong>of</strong> <strong>the</strong> “new” old <strong>Meypack</strong> kompackt in<br />

your hands. After more than fi ve years in newspaper format, we have now<br />

decided to fur<strong>the</strong>r develop <strong>the</strong> <strong>Meypack</strong> kompackt into a modern magazine<br />

format. At <strong>the</strong> forefront <strong>of</strong> <strong>the</strong> new kompackt are more detailed stories and<br />

background information about <strong>Meypack</strong>’s customers, partners, projects and<br />

o<strong>the</strong>r interesting topics, such as <strong>the</strong> countries and <strong>the</strong> respective cultures in<br />

which <strong>Meypack</strong> is successful on a worldwide scale. Looking at it that way, <strong>the</strong><br />

kompackt will in turn also become increasingly international as its contents<br />

will consistently refl ect <strong>the</strong> path being forged by <strong>the</strong> dynamically developing<br />

global markets. At <strong>the</strong> same time, we know where our roots are and recognise<br />

<strong>the</strong>ir importance.<br />

Global markets are also being served by <strong>Meypack</strong>’s <strong>Middle</strong> <strong>East</strong> representative<br />

Technica International. For our cover story, <strong>Meypack</strong>’s Export and Marketing<br />

Director Klaus M. Vogel and <strong>the</strong> Communications Consultant Frederik<br />

Bernard travelled far to Beirut to speak with Tony Haddad, CEO <strong>of</strong> <strong>the</strong> company<br />

Technica, about <strong>the</strong> 25th year company jubilee, current projects and <strong>the</strong><br />

company’s cooperation with <strong>Meypack</strong>. Starting on page 04, you can read about<br />

<strong>the</strong> exciting trip taken to a fascinating country perched between optimism<br />

and internal unrest.<br />

Optimism can also be clearly registered in <strong>the</strong> packaging industry: It was<br />

not only <strong>the</strong> impressive export activity that contributed signifi cantly to <strong>the</strong><br />

economic upswing in our country but also, <strong>the</strong> intensive preparations for <strong>the</strong><br />

interpack 2008 have been noticeable in our line <strong>of</strong> business. After <strong>the</strong> Fachpack<br />

and <strong>the</strong> Brau – two very successful trade fairs for <strong>Meypack</strong> at <strong>the</strong> end<br />

<strong>of</strong> 2007 – <strong>the</strong> interpack 2008 (from April 24th to 30th, 2008) is <strong>the</strong> highlight <strong>of</strong><br />

<strong>the</strong> industry. <strong>Meypack</strong> will be presenting its packaging solutions at a stand<br />

conceptualised to refl ect <strong>the</strong> importance <strong>of</strong> this trade fair. Visit us in Hall 14 at<br />

Stand D15.<br />

I hope you enjoy reading <strong>the</strong> articles presented in this “new” kompackt.

04<br />

12<br />

01 | 2008<br />

02 Editorial<br />

04 Beirut: <strong>Pearl</strong> <strong>of</strong> <strong>the</strong> <strong>Middle</strong> <strong>East</strong><br />

Report on <strong>Meypack</strong>’s representative Technica International<br />

Interview with CEO Tony Haddad<br />

10 Naturally healthy – as a tradition<br />

HiPP packs baby food with <strong>Meypack</strong><br />

12 Royally good<br />

Friesland Foods packs nutritious milk and fruit-based<br />

products with <strong>Meypack</strong> technology<br />

14 The big cheese in Denmark<br />

<strong>Meypack</strong> machine packs white cheese for Arla Bov<br />

16 Absolut <strong>Meypack</strong><br />

Absolut Vodka from Åhus, Sweden packed by<br />

<strong>Meypack</strong> machines<br />

18 C<strong>of</strong>fee – a fi ne world <strong>of</strong> its own<br />

<strong>Meypack</strong> proves competence in packing c<strong>of</strong>fee<br />

for DEK, Delica and Café Liegeois<br />

19 Last but not least<br />

Imprint<br />

<strong>Meypack</strong> Verpackungssystemtechnik GmbH<br />

Industriestraße 3<br />

D-48301 Nottuln-Appelhülsen<br />

Tel.: +49 (0) 2509 - 940<br />

Fax: +49 (0) 2509 - 948190<br />

info@meypack.de<br />

www.meypack.com<br />

Conception, compilation, design: www.fbkb.com<br />

Photos: <strong>Meypack</strong> Verpackungssystemtechnik GmbH,<br />

Technica International, HiPP GmbH & Co. KG,<br />

Royal Friesland Foods N.V., V&S Absolut Spirits,<br />

Wild GmbH & Co. KG, istockphoto.com (Eva Serrabassa,<br />

Elzbieta Sekowska, Terence Mendoza, Christine Balderas)<br />

Print-run: 3,000 copies<br />

Frequency: 2 x per year

04 kompackt 1/08<br />

High-tech packaging solutions from<br />

<strong>the</strong> “Switzerland <strong>of</strong> <strong>the</strong> Orient”<br />

25 YEARS OF PERMANENT GROWTH AND MORE THAN 10 YEARS OF COOPERATION WITH<br />

MEYPACK ARE THE SECRETS OF SUCCESS FOR TECHNICA INTERNATIONAL

Lebanon is a country <strong>of</strong> mountains, ocean and in particular, <strong>of</strong><br />

cities. Over <strong>the</strong> last 50 years, most <strong>of</strong> <strong>the</strong> 3.8 million residents <strong>of</strong><br />

Lebanon have been leaving <strong>the</strong> countryside for life in <strong>the</strong> cities,<br />

albeit around half <strong>of</strong> <strong>the</strong>m live in <strong>the</strong> capital Beirut. With 500,000 residents,<br />

Tripoli is <strong>the</strong> second largest city, followed by Zahlé with 200,000, and Sidon<br />

& Tyros toge<strong>the</strong>r with between 180,000 and 200,000 residents. The fi gures are,<br />

however, all estimates because <strong>the</strong>re has not been an <strong>of</strong>fi cial census taken<br />

since 1932.<br />

The majority <strong>of</strong> Lebanese speak Arabic. English and French are also widely<br />

spoken and are considered <strong>the</strong> key languages for communication with Europe.<br />

In Lebanon <strong>the</strong>re are 17 recognised religious communities. The largest communities<br />

are <strong>the</strong> Sunnis, Maronite and Schiites. On November 26th, 1941 <strong>the</strong><br />

French General Georges Catroux declared <strong>the</strong> independence <strong>of</strong> Lebanon under<br />

<strong>the</strong> authority <strong>of</strong> <strong>the</strong> Free French government. Elections were held in 1943 and<br />

at <strong>the</strong> end <strong>of</strong> that year, <strong>the</strong> new Lebanese government unilaterally abolished<br />

<strong>the</strong> French mandate. Directly after <strong>the</strong> independence <strong>of</strong> Lebanon, approximately<br />

20,000 men volunteered to serve under <strong>the</strong> command <strong>of</strong> <strong>the</strong> future<br />

president Fouad Chehab where <strong>the</strong>y were integrated into <strong>the</strong> Free French<br />

Army under Charles de Gaulle and contributed to <strong>the</strong> success <strong>of</strong> <strong>the</strong> Allied<br />

Forces in Bir Hakeim and near Monte Cassino in <strong>the</strong> Mediterranean <strong>the</strong>atre<br />

<strong>of</strong> war. After <strong>the</strong> Second World War, <strong>the</strong> independent Lebanon was one <strong>of</strong> <strong>the</strong><br />

founding members <strong>of</strong> <strong>the</strong> United Nations. In 1945, during <strong>the</strong> United Nations<br />

Conference on International Organisation, which laid out <strong>the</strong> foundation for<br />

<strong>the</strong> United Nations, <strong>the</strong> Lebanese delegate Charles Malik – along with Eleanor<br />

Roosevelt – played a dominating role and co-authored essential sections <strong>of</strong> <strong>the</strong>

“Innovation stands <strong>the</strong> test<br />

<strong>of</strong> time” – that is <strong>the</strong> motto <strong>of</strong><br />

Technica International. Since<br />

1997, <strong>the</strong> company has been<br />

working toge<strong>the</strong>r with <strong>the</strong> Westphalian<br />

packaging specialist.<br />

Technica International – made<br />

up <strong>of</strong> over 120 employees who<br />

design and manufacture automation<br />

systems for all sectors <strong>of</strong><br />

industry. The specialists from<br />

Lebanon connect <strong>the</strong> conveyors<br />

with <strong>Meypack</strong> packaging<br />

machines and in this way create<br />

a value-added product for <strong>the</strong>ir<br />

customers.<br />

06 kompackt 1/08<br />

UN-Charter and Universal Declaration <strong>of</strong> Human<br />

Rights. Due to its economic stability and political<br />

neutrality (1949 – 1969), <strong>the</strong> western infl uenced<br />

Lebanon became known as <strong>the</strong> “Switzerland <strong>of</strong> <strong>the</strong><br />

Orient” during <strong>the</strong> 1950s and 1960s. The capital Beirut<br />

was referred to <strong>the</strong> “Paris <strong>of</strong> <strong>the</strong> <strong>Middle</strong> <strong>East</strong>”<br />

until <strong>the</strong> civil war in 1975.<br />

Due to its cosmopolitan culture, <strong>the</strong> high level <strong>of</strong><br />

education (<strong>the</strong>re are at least four elite universities in<br />

Beirut with very long traditions) as well as <strong>the</strong> mix<br />

<strong>of</strong> different religious denominations (for example,<br />

Christians and Muslims have been living side by<br />

side for years) Lebanon is <strong>the</strong> point <strong>of</strong> departure for<br />

trade between <strong>the</strong> European and Arabian worlds;<br />

Beirut has <strong>the</strong> optimal location and function as a<br />

metropolis – with people who understand and live<br />

both <strong>the</strong> western/European and <strong>the</strong> Arabian mentalities.<br />

As a result, <strong>the</strong> country and its capital Beirut<br />

have been accorded a mediating function which<br />

has qualifi ed Lebanon as <strong>the</strong> gateway to <strong>the</strong> <strong>Middle</strong><br />

<strong>East</strong>.<br />

TECHNICA INTERNATIONAL:<br />

A COMPANY – A SUCCESS STORY<br />

Technica International, a machine manufacturer<br />

from Bickfaya, a suburb <strong>of</strong> Beirut, Lebanon, started<br />

as a one man show in 1982 and afterwards with<br />

four staff employees working in a space <strong>of</strong> 36 m²<br />

under <strong>the</strong> direction <strong>of</strong> Tony Haddad in <strong>the</strong> small<br />

town <strong>of</strong> Dora. In 1984, <strong>the</strong> fi rst production hall<br />

was inaugurated. It was also located in Dora and<br />

measured a modest 60 m². As a result <strong>of</strong> <strong>the</strong> war, <strong>the</strong><br />

company moved to Cyprus in 1987. This location is<br />

still active in <strong>the</strong> market. After <strong>the</strong> war, Technica<br />

returned to Lebanon in 1991. In <strong>the</strong> Bickfaya industrial<br />

area, a 600 m² production facility was built<br />

on a 3,700 m² parcel <strong>of</strong> land. In 1992, <strong>the</strong> company<br />

became active in <strong>the</strong> export business and started<br />

its own sales activity in Saudi Arabia. In 1996, <strong>the</strong><br />

facility in Bickfaya/Beirut was expanded into a size<br />

<strong>of</strong> 7,200 m² <strong>of</strong> property and 1,200 m² <strong>of</strong> production<br />

area. In 1997, <strong>Meypack</strong> and Technica began cooperation<br />

for end-packaging lines, which continues to<br />

run successfully to this day. The fi rst project was<br />

Makkah Water in Jeddah, Saudi Arabia. In 1999, a<br />

Technica <strong>of</strong>fi ce was established in Cairo, Egypt.<br />

In <strong>the</strong> year 2000, Technica received <strong>the</strong> <strong>of</strong>fi -<br />

cial “Sales Partner Status” from Procter & Gamble<br />

(P&G) <strong>of</strong> Brussels for all P&G companies worldwide.<br />

Coop eration with P&G started that same<br />

year with <strong>the</strong> fi rst large project for P&G in Cairo.<br />

In 2001, <strong>the</strong> property and <strong>the</strong> production facility at<br />

<strong>the</strong> Beirut location were extended once again, this<br />

time to 11,000 m² and 2,000 m² respectively. In 2003,<br />

Technica received <strong>the</strong> designation as an <strong>of</strong>fi cial<br />

supplier for Danone and executed its fi rst project<br />

for Al Safi Danone in Riyadh, Saudi Arabia in that<br />

same year.

Technica now has sales <strong>of</strong>fi ces in Saudi Arabia,<br />

Egypt and Dubai as well as in o<strong>the</strong>r locations in <strong>the</strong><br />

<strong>Middle</strong> <strong>East</strong>. This refl ects <strong>the</strong> vision <strong>of</strong> Technica:<br />

Technica wants to be <strong>the</strong> fi rst choice for auto mated<br />

solutions in <strong>the</strong> Arab world. It is obvious that this<br />

goal cannot be realised with innovative solutions<br />

and strong partnerships alone but above all, it<br />

is imperative to have a high standard <strong>of</strong> quality.<br />

Therefore, since 1999 Technica has been certifi ed<br />

according to <strong>the</strong> DIN ISO 9001:2000 – an important<br />

criterion in <strong>the</strong> decision making process for large<br />

corporations such as Danone or Procter & Gamble<br />

when deciding to place <strong>the</strong>ir packaging requirements<br />

in Technica’s hands.<br />

On <strong>the</strong> Human resources level, <strong>the</strong> founder and<br />

CEO Tony Haddad implemented a total re-engineering<br />

concept, whereby each team member takes<br />

ownership <strong>of</strong> his job duties, with total responsibility<br />

and accountability. This is applied at all levels<br />

in <strong>the</strong> organization. According to Tony Haddad,<br />

<strong>the</strong> employees identify <strong>the</strong>mselves more strongly<br />

with <strong>the</strong> company and <strong>the</strong>ir tasks. They become<br />

motivated and as a result are signifi cantly more<br />

productive. This was evidenced in 2006 when everyone<br />

pitched in to load <strong>the</strong> last machines onto <strong>the</strong><br />

trucks for transport out <strong>of</strong> <strong>the</strong> country while <strong>the</strong><br />

war was raging; an impressive performance that<br />

can only be explained by a sense <strong>of</strong> total dedication<br />

and commitment.<br />

Multicultural and pulsating,<br />

breathtakingly diverse and<br />

fascinatingly beautiful: Beirut, <strong>the</strong><br />

colourful metropolis <strong>of</strong> Lebanon,<br />

is <strong>the</strong> centre between <strong>East</strong> and West

Technica is active in 23 countries<br />

and has executed nearly 500<br />

projects for over 200 customers.<br />

In 2004, <strong>the</strong> company received<br />

<strong>the</strong> highest Merit Award for<br />

Creativity and Innovation from<br />

<strong>the</strong> Ministry <strong>of</strong> Industry and<br />

<strong>the</strong> Association <strong>of</strong> Lebanese<br />

Industrialists (ALI)<br />

The products <strong>of</strong> Technica International include<br />

transport conveyors for all applications, packaging<br />

solutions (in cooperation with <strong>Meypack</strong>) and<br />

palletisers. Technica also supplies labelling solutions<br />

as well as fi lling lines. Technica provides a<br />

comprehensive after sales service for all solutions,<br />

a reliable spare parts supply as well as a complete<br />

maintenance, modernisation and repair service.<br />

TECHNICA AND MEYPACK: SUCCESSFUL<br />

COOPERATION SINCE 1997<br />

Since its beginnings in 1997, <strong>the</strong> cooperation<br />

between Technica International and <strong>Meypack</strong><br />

has generated some exciting projects. Thanks to<br />

<strong>the</strong> effective teamwork <strong>of</strong> both machine manufacturers,<br />

projects for international customers such<br />

as Al Marai, Danone, Pepsi Cola, APV, Heineken,<br />

Procter & Gamble, Coca-Cola and Nestlé could<br />

be successfully executed.<br />

Within <strong>the</strong> framework <strong>of</strong> this cooperation,<br />

<strong>Meypack</strong> not only just supplies end-packaging<br />

machines such as wrap-around case packers<br />

or shrink wrappers but also ensures after sales<br />

support through its partner company from Lebanon.<br />

For its own projects, Technica designs <strong>the</strong><br />

entire packaging line and connects <strong>the</strong> transport<br />

conveyor system with <strong>the</strong> <strong>Meypack</strong> packaging<br />

ma chines. This is a cooperation that clearly<br />

exceeds <strong>the</strong> normal scope <strong>of</strong> a purely trade and<br />

The Technica team with CEO Tony Haddad<br />

The Technica factory in Bickfaya<br />

distribution business relationship. According to<br />

Klaus M. Vogel <strong>of</strong> <strong>Meypack</strong>, Technica is a strong<br />

partner with its own engineering and design<br />

departments and a reliable production division that<br />

creates completely new applications and solutions<br />

through this integration. That is, however, only one<br />

<strong>of</strong> <strong>the</strong> reasons for <strong>the</strong> continued growth <strong>of</strong> this once<br />

small company from Bickfaya near Beirut.

Interview<br />

INTERVIEW WITH TONY HADDAD, CEO OF<br />

TECHNICA INTERNATIONAL, LEBANON<br />

Tony, you speak about Lebanon<br />

being a gateway between <strong>the</strong><br />

European west and <strong>the</strong> Arab world.<br />

How would you describe that?<br />

Well, I am referring to <strong>the</strong> moderating<br />

position that Lebanon has been playing<br />

between Europe and <strong>the</strong> Arab world<br />

throughout its history. In Lebanon, <strong>the</strong>re<br />

are a large number <strong>of</strong> superbly trained<br />

and educated people who speak Arabic<br />

as well as European languages, in particular<br />

English and French. Fur<strong>the</strong>rmore, in<br />

Lebanon we are exposed to and understand<br />

<strong>the</strong> western mentality and its work<br />

habits. Being part <strong>of</strong> <strong>the</strong> Arab world and<br />

speaking <strong>the</strong> same language, we also are<br />

very close to <strong>the</strong> social and work habits<br />

<strong>of</strong> <strong>the</strong> Arab world. This “Gateway Function”<br />

makes Lebanon an ideal meeting<br />

point between both worlds. That is why<br />

we at Technica have our headquarters<br />

here, from where we can coordinate <strong>the</strong><br />

cooperation with our European partners,<br />

such as <strong>Meypack</strong>, but also from where can<br />

operate our own sales <strong>of</strong>fi ces in countries<br />

such as Saudi Arabia, GCC, Egypt or o<strong>the</strong>r<br />

North African countries. And last but not<br />

least, Lebanon is my homeland and that <strong>of</strong><br />

my family – that certainly also plays a role<br />

in <strong>the</strong> decision to be located here.<br />

2007 is now behind us and we are<br />

now fi rmly into 2008. How would you<br />

describe <strong>the</strong> past year for Technica<br />

and what is <strong>the</strong> outlook for 2008?<br />

For us, <strong>the</strong> year 2007 was a very good<br />

year; or more precisely it was a record year<br />

in <strong>the</strong> company’s 25 year history. We were<br />

able to fur<strong>the</strong>r develop our own ma chines<br />

and secure new cooperation partners.<br />

With partners such as <strong>Meypack</strong>, we were<br />

able to realise projects, a number <strong>of</strong> which<br />

were very big, comprehensive and technologically<br />

sophisticated, such as Al Marai<br />

or Health Water Bottling. Consid ering that,<br />

one can say that 2007 was real export year<br />

for Technica. And 2008 is show ing signs<br />

that this trend will continue.<br />

Tony, what is special about Technica?<br />

What makes you so successful?<br />

I think that <strong>the</strong> key to our success is<br />

that we are not a simple reseller or trading<br />

agent for a company like <strong>Meypack</strong><br />

pack aging machines but ra<strong>the</strong>r that we<br />

have our own engineering and production<br />

expertise. We do not just design and<br />

manufacture transport conveyor systems<br />

but incorporate <strong>the</strong>se in packaging lines<br />

that we <strong>the</strong>n <strong>of</strong>fer as a new complete solution.<br />

In this way, we <strong>of</strong>fer a value-added<br />

product which is not <strong>of</strong>fered by anyone<br />

else in this market. Ano<strong>the</strong>r reason for<br />

our success is <strong>the</strong> high motivation and<br />

<strong>the</strong> good training and education <strong>of</strong> our<br />

employees. We work as a team, with a<br />

sense <strong>of</strong> responsibility towards each o<strong>the</strong>r,<br />

which has contributed to a signifi cant<br />

increase in productivity.<br />

Let’s stick with <strong>the</strong> issue <strong>of</strong> “employee<br />

motivation” – what measures does<br />

Technica and do you undertake to<br />

keep your team motivated to deal with<br />

this enormous growth process?<br />

We invest in our staff, not just with<br />

money but with time and trust. Our<br />

employees receive training regularly on<br />

technical as well as managerial levels. Fur<strong>the</strong>rmore,<br />

we live and work here by <strong>the</strong><br />

principle <strong>of</strong> shared responsibility. Every<br />

member feels responsible for <strong>the</strong> success<br />

<strong>of</strong> his team and consequently for <strong>the</strong> success<br />

<strong>of</strong> <strong>the</strong> whole company. Our teams<br />

take responsibility for fi nding solutions<br />

to new problems and new challenges. In<br />

this context, I no longer feel like a controlling<br />

managing director but ra<strong>the</strong>r play<br />

a moderating role. My leadership style is<br />

to motivate <strong>the</strong> staff to give <strong>the</strong> best <strong>of</strong><br />

<strong>the</strong>mselves, and when results are not as<br />

good as expected, we analyze <strong>the</strong> gap and<br />

design corrective and preventive actions.<br />

We are hard on <strong>the</strong> problem, s<strong>of</strong>t on <strong>the</strong><br />

people. The atmosphere is very open and<br />

transparent. I am convinced that this form<br />

<strong>of</strong> employee management has contributed<br />

signifi cantly to <strong>the</strong> development <strong>of</strong> Technica<br />

and continues to remain essential.<br />

Tony Haddad, thank you very<br />

much for <strong>the</strong> interview.

Georg Hipp founded <strong>the</strong><br />

company “Nährmittel Hipp” in<br />

Pfaffenh<strong>of</strong>en on July 1st, 1932.<br />

In <strong>the</strong> mid-1950s, HiPP was <strong>the</strong><br />

fi rst company in Germany to<br />

industrially produce baby food in<br />

tins and since 1959/60 has been<br />

selling its baby food in glass jars<br />

due to hygienic considerations.<br />

In 1964, Georg Hipp’s son Claus<br />

Hipp entered <strong>the</strong> business and<br />

took over <strong>the</strong> reigns in 1967.<br />

10 kompackt 1/08<br />

Without a doubt – <strong>the</strong> longestablished<br />

company HiPP<br />

is one <strong>of</strong> <strong>the</strong> real trailblazers<br />

when it comes to aspects <strong>of</strong> environmental protection,<br />

sustainability and biological responsibility.<br />

After all, it is no wonder – <strong>the</strong> company began as a<br />

small rural enterprise and a bakery. Over 50 years<br />

ago, <strong>the</strong> company HiPP committed itself to organic<br />

farming. With great care and extremely high expectations<br />

<strong>of</strong> quality, Claus Hipp personally gives his<br />

word that his products are healthy, biologically<br />

valuable and <strong>of</strong> <strong>the</strong> best quality; products, that are<br />

consistantly and traditionally grown and produced<br />

in harmony with nature.<br />

HIPP GIVES AN ORGANIC GUARANTEE<br />

The organic guarantee given by HiPP embodies<br />

both a seal and set <strong>of</strong> rules for maintaining <strong>the</strong><br />

high standards <strong>of</strong> quality that HiPP sets for itself,<br />

which go above and beyond <strong>the</strong> criteria set by <strong>the</strong><br />

Federal Ministry for Consumer Protection, Food<br />

and Agriculture to receive <strong>the</strong> <strong>of</strong>fi cial organic seal.<br />

HiPP only uses organic raw materials that have<br />

been grown according to <strong>the</strong> regulations set out in<br />

<strong>the</strong> EC regulations for organic farming. Above and<br />

beyond that, to ensure 100% quality, all raw materials<br />

used by HiPP are strictly tested (for example<br />

for contaminants, pollutants) before <strong>the</strong>y are processed.<br />

In order to detect and identify pollutants<br />

and contaminants, HiPP utilises a testing databank<br />

that can recognise over 850 <strong>of</strong> <strong>the</strong>se harmful<br />

substances. Only after all <strong>of</strong> <strong>the</strong>se control tests have<br />

Assuming responsibility<br />

for <strong>the</strong> environment and<br />

for life: HiPP<br />

BIOLOGICALLY VALUABLE PRODUCTS, FIRST CLASS QUALITY AND THE<br />

SUSTAINABLE TREATMENT OF THE ENVIRONMENT HAVE ALWAYS BEEN HIGH<br />

ON THE HIPP AGENDA<br />

been passed does a product receive <strong>the</strong> recognised<br />

HiPP organic seal.<br />

The strict and controlled processing <strong>of</strong> <strong>the</strong> HiPP<br />

products is matched by equally meticulous and<br />

careful vegetable cultivation. Growing <strong>the</strong> vegetables<br />

is carried out only in <strong>the</strong> most natural manner<br />

– syn<strong>the</strong>tic pesticides are strictly forbidden. This<br />

traditional style <strong>of</strong> cultivation however requires<br />

a high degree <strong>of</strong> manual labour (which in some<br />

areas is expidited by mechanised support, such as<br />

in weeding). To prevent <strong>the</strong> growth <strong>of</strong> weeds, <strong>the</strong><br />

company resorts to employing traditional farming<br />

methods. For example, plants that tickle <strong>the</strong><br />

pallettes <strong>of</strong> pesky pests are planted around <strong>the</strong><br />

perimeter <strong>of</strong> <strong>the</strong> fi elds to divert <strong>the</strong>ir attention<br />

from vegetables growing in <strong>the</strong> fi elds. To prevent<br />

late blight in potatos, rock powders are sprinkled<br />

upon <strong>the</strong>m to fortify <strong>the</strong>m and bind moisture. HiPP<br />

is also adamantly against any form <strong>of</strong> fertilisation.<br />

The notorious mold and pest infestation that<br />

so <strong>of</strong>ten plagues carrots is fought with a natural<br />

weap on: wind. Carrots are planted in a windy location,<br />

enabling <strong>the</strong> wind to blow through <strong>the</strong> rows<br />

and keep <strong>the</strong> crops swept clean.<br />

PROTECTING THE ENVIRONMENT: SUSTAINABLE<br />

ENVIRONMENTAL MANAGEMENT FROM HIPP<br />

Whoever places such a high priority on producing<br />

biologically valuable products is also highly<br />

engaged in working for a sustainable environment.<br />

For over 50 years, HiPP has been actively

supporting environmental protection – which has<br />

manifested into a comprehensive environmental<br />

management. Since 1995, HiPP has been documenting<br />

its activities in an annual environmental<br />

report and has since <strong>the</strong>n been validated according<br />

to EMAS (eco-management and audit scheme) and<br />

certifi ed according to DIN ISO 14001 since 1997.<br />

HiPP has received many awards for its environmental<br />

management, most recently in 2006 with<br />

<strong>the</strong> B.A.U.M. Environmental Award (German Environmental<br />

Management Association).<br />

HIPP TODAY: SUSTAINABLE, INTERNATIONAL<br />

– AND WITH MEYPACK PACKAGING TECHNOLOGY<br />

Already active in 1899 and <strong>of</strong>fi cially founded in<br />

1932, <strong>the</strong> company HiPP sells approximately 230<br />

products in all corners <strong>of</strong> <strong>the</strong> world. The company<br />

has production facilities and cultivation areas<br />

in Germany, Austria, Hungary, Croatia and <strong>the</strong><br />

Ukraine. Over 1,000 employees ensure that <strong>the</strong><br />

products produced by HiPP continue to be <strong>of</strong> <strong>the</strong><br />

highest quality and are at one with nature.<br />

on this machine, <strong>the</strong> frequently necessary machine<br />

changeovers have been simplifi ed as much as possible.<br />

Out <strong>of</strong> consideration for <strong>the</strong> environment, particular<br />

attention was placed on an energy effi cient<br />

shrink tunnel. As a result, this shrink tunnel is not<br />

powered by electricity, as is ususally <strong>the</strong> case, but<br />

ra<strong>the</strong>r by gas. A second machine <strong>of</strong> <strong>the</strong> same type<br />

will be put into operation at <strong>the</strong> HiPP production<br />

facility in Hungary.<br />

For <strong>the</strong> production facilities in Austria, <strong>Meypack</strong><br />

installed a double lane, high speed VP 530-2 SW 90<br />

TM 60-2 tray-shrink wrapper in <strong>the</strong> second half <strong>of</strong><br />

2007. The machine packs jars and glass bottles containing<br />

baby food and children’s food into various<br />

sized packs. Depending upon <strong>the</strong> chosen task, <strong>the</strong><br />

products can be packed in trays with or without<br />

fi lm as well as just in fi lm as multi-packs. Due to <strong>the</strong><br />

large number <strong>of</strong> different products being packed On a running conveyor: Baby food in glass jars packed on a <strong>Meypack</strong> VP 530-2 SW 90 TM 60-2

Chocomel is <strong>the</strong> hot chocolate<br />

that is prepared with <strong>the</strong><br />

Senseo® machine. The hot<br />

chocolate capsule is placed in a<br />

special Chocomel capsule holder<br />

that is compatible with <strong>the</strong><br />

Senseo® machine.<br />

Located in Meppel, in <strong>the</strong> Ne<strong>the</strong>rlands,<br />

<strong>the</strong> multinational company<br />

Royal Friesland Foods N.V. develops,<br />

produces and sells a wide range <strong>of</strong> diary products<br />

and fruit beverages for both private and pr<strong>of</strong>essional<br />

consumers as well as for <strong>the</strong> food industry.<br />

The company is committed to producing high<br />

quality products that can be part <strong>of</strong> a healthy diet;<br />

products, made from milk or fruit that can be<br />

consumed at any time <strong>of</strong> <strong>the</strong> day. After all, every<br />

person is dependent upon a balanced diet, consisting<br />

<strong>of</strong> vitamins, carbohydrates and minerals. Only<br />

through an optimal combination and regular daily<br />

consumption can a person remain healthy, fi t and<br />

spared from symptoms <strong>of</strong> nutritional defi ciency.<br />

Friesland Foods produces and sells <strong>the</strong> convenience<br />

food products suitable for an active life in all parts<br />

<strong>of</strong> <strong>the</strong> world. Toge<strong>the</strong>r with <strong>the</strong> companies Campina<br />

and Unilever, Friesland Foods has developed a logo<br />

to identify healthy food products. Products containing<br />

reduced levels <strong>of</strong> fat, sugar and salt carry<br />

<strong>the</strong> slogan “Ik kies bewust.”<br />

Royally good<br />

FRIESLAND FOODS STANDS FOR NUTRITIONAL MILK AND FRUIT PRODUCTS –<br />

AND PUTS ITS TRUST IN END-PACKAGING FROM MEYPACK<br />

Friesland Foods is an association with 10,700<br />

members, including primarily Dutch agriculturalists<br />

who are both suppliers <strong>of</strong> and shareholders<br />

in <strong>the</strong> company. Since 1879, <strong>the</strong> company has<br />

grown continuously through mergers and takeovers.<br />

Today, Royal Friesland Foods is one <strong>of</strong> <strong>the</strong> 10<br />

largest dairy companies in <strong>the</strong> world.<br />

DOUBLE HIGH SPEED FOR FRIESLAND FOODS<br />

A <strong>Meypack</strong> end-packaging system consisting <strong>of</strong><br />

two machines was installed at <strong>the</strong> German production<br />

facility <strong>of</strong> Friesland Foods; it belongs to Royal<br />

Friesland Foods N.V., which is headquartered in<br />

<strong>the</strong> Ne<strong>the</strong>rlands. <strong>Meypack</strong> delivered a combined<br />

packaging system in <strong>the</strong> summer <strong>of</strong> 2007 for <strong>the</strong><br />

facility in Kalkar. On a specially designed VP 511<br />

with a custom designed paddle chain infeed and<br />

“pick & place” elements, <strong>the</strong> Chocomel brand <strong>of</strong> hot<br />

chocolate capsules is packed in groups <strong>of</strong> ei<strong>the</strong>r 4 or<br />

8 into folding boxes. After exiting <strong>the</strong> VP 511, <strong>the</strong><br />

lying boxes are erected by an erecting conveyor and

“Pick & Place”: VP 511 packs hot chocolate capsules in folding boxes<br />

<strong>the</strong>n packed into ei<strong>the</strong>r wrap-around cases or trays<br />

by a VP 451 K tray & wrap-around case packer.<br />

Both machines are made completely <strong>of</strong> stainless<br />

steel and built according to <strong>the</strong> proven <strong>Meypack</strong><br />

CleanDesign ® Construction Principle.<br />

Two additional machines <strong>of</strong> <strong>the</strong> same type will<br />

be installed this year at <strong>the</strong> production facility in<br />

Kalkar.<br />

FRIESLAND FOODS<br />

AT HOME IN MARKETS<br />

WORLDWIDE<br />

The most important markets for Friesland<br />

Foods include Europe, <strong>the</strong> <strong>Middle</strong> <strong>East</strong>, Asia and<br />

West Africa. The company is extremely successful<br />

in <strong>the</strong>se international markets with products such<br />

as condensed milk, milk powder, soya milk, pasteurised<br />

milk, butter, cheese, c<strong>of</strong>fee cream, yogurt<br />

drinks, energy drinks, milk & fruit snacks as well<br />

as fruit juices. The needs <strong>of</strong> <strong>the</strong>se various regions<br />

are <strong>of</strong> course not all identical. In Europe, Asia and<br />

Africa, <strong>the</strong>se milk products are extremely popular<br />

with consumers and are primarily behind <strong>the</strong><br />

company’s sales increases.<br />

Royal Friesland Foods employees approx. 15,300<br />

people (12,300 in 2004), a majority <strong>of</strong> whom work<br />

outside <strong>of</strong> <strong>the</strong> Ne<strong>the</strong>rlands. The leading brands <strong>of</strong><br />

<strong>the</strong> company are Appelsientje, Bonnet, Chocomel/<br />

Cécémel, Completa, CoolBest, Debic, DubbelFrisss,<br />

Dutch Lady, Extran, Frico, Foremost, Friesche Vlag,<br />

Frisian Flag, Fristi, Milli, NoyNoy, Peak, Pöttyös<br />

Túró Rudi, Rainbow and Taksi.<br />

On June 7th, 2004 Her Majesty<br />

Queen Beatrix granted <strong>the</strong><br />

former Friesland Coberco Dairy<br />

Food Holding N.V. <strong>the</strong> right<br />

to use <strong>the</strong> title ”Koninklijk“<br />

(meaning royal). From this date<br />

onward, <strong>the</strong> holding company<br />

has been known as Koninklijke<br />

Friesland Foods N.V.

Olympia Snac<br />

4 onions [250g<br />

clo<br />

Arla Bov is a company belonging<br />

to Arla Foods amba <strong>of</strong> Denmark.<br />

Behind <strong>the</strong> company Arla Foods<br />

amba are <strong>the</strong> Swedish company<br />

Arla and <strong>the</strong> Danish company<br />

MD Foods. Since <strong>the</strong> year 2000,<br />

<strong>the</strong>se two companies have been<br />

jointly presenting <strong>the</strong>mselves in<br />

<strong>the</strong> market under <strong>the</strong> name <strong>of</strong><br />

Arla Foods amba.<br />

14 kompackt 1/08<br />

Arla Foods is one <strong>of</strong><br />

<strong>Meypack</strong>’s biggest customers,<br />

with installations in Denmark,<br />

Sweden and England. The most<br />

recent project was realised in<br />

Denmark at Arla Bov, a company belonging to Arla<br />

Foods amba. Behind <strong>the</strong> company Arla Foods amba<br />

are <strong>the</strong> Swedish company Arla and <strong>the</strong> Danish<br />

company MD Foods. Since <strong>the</strong> year 2000, <strong>the</strong>se two<br />

companies have been jointly presenting <strong>the</strong>mselves<br />

in <strong>the</strong> market under <strong>the</strong> name <strong>of</strong> Arla Foods amba.<br />

Arla Foods is a Swedish-Danish dairy corporation<br />

with its headquarters in Viby, near Århus, in Denmark.<br />

With over 20,000 employees, <strong>the</strong> company is<br />

<strong>the</strong> largest producer <strong>of</strong> dairy products in Europe<br />

and is one <strong>of</strong> <strong>the</strong> largest dairies in <strong>the</strong> world.<br />

Denmark, Sweden and Great Britain are among<br />

<strong>the</strong> company’s most important markets. Over 70%<br />

<strong>of</strong> <strong>the</strong> turnover is generated in <strong>the</strong>se three countries.<br />

Besides Denmark, Sweden and Great Britain,<br />

Arla Foods has subsidiaries in <strong>the</strong> most important<br />

export markets.<br />

MILK AND CHEESE PRODUCTS PACKED<br />

BY MEYPACK PACKAGING SOLUTIONS<br />

Fresh white<br />

cheese from<br />

Arla Bov <strong>of</strong><br />

Denmark<br />

<strong>Meypack</strong> installed a VP 453<br />

inline case packer at <strong>the</strong> facility<br />

in Krusa. This machine, constructed<br />

entirely <strong>of</strong> stainless<br />

steel, packs <strong>the</strong> beloved Arla<br />

white cheese sold in rounded, rectangular containers<br />

into trays with lids. A specially designed<br />

infeed system guarantees that <strong>the</strong> containers are<br />

fed into <strong>the</strong> machine gently and without <strong>the</strong> use<br />

Gently packed thanks to pressure-free infeed <strong>of</strong> <strong>the</strong> products

<strong>of</strong> pressure. With this “tray-lid”-application, <strong>the</strong> lid<br />

is positioned inside <strong>the</strong> tray and depending upon<br />

<strong>the</strong> customer’s wishes, can simply be inserted or<br />

secured additionally with adhesive. The machine is<br />

equipped with motorised adjustment points, which<br />

enable <strong>the</strong> machine to be automatically changedover<br />

within an extremely short time and ensure<br />

that <strong>the</strong> format settings remain unchanged.<br />

WHITE CHEESE OR FETA CHEESE – THAT IS THE<br />

BIG QUESTION<br />

Feta has its origins as a cheese produced and<br />

stored in salt brine. That means that in <strong>the</strong> process<br />

<strong>of</strong> producing <strong>the</strong> sheep’s milk cheese (sometimes<br />

goat’s milk cheese), <strong>the</strong> whey (<strong>the</strong> watery part <strong>of</strong><br />

<strong>the</strong> milk) is separated without pressure from <strong>the</strong><br />

curd (cheese), which ripens in a salt brine. This also<br />

bestows <strong>the</strong> feta cheese with its typical, intensive<br />

taste. Up until <strong>the</strong> year 2007, similar types <strong>of</strong> cheese<br />

from o<strong>the</strong>r countries were being sold as “feta” in<br />

<strong>the</strong> European Union, even though <strong>the</strong> majority were<br />

produced from cow’s milk. According to a decision<br />

handed down by <strong>the</strong> European Commission, only<br />

white cheese produced in Greece from sheep’s milk<br />

or goat’s milk and ripened in salt brine is allowed<br />

to carry <strong>the</strong> name feta.<br />

Feta enjoys a long tradition in Greece. Since time<br />

immemorial, feta has been considered a delicacy<br />

and a coveted item <strong>of</strong> trade, not <strong>the</strong> least because<br />

Protected from all sides: VP 453 packs white cheese in trays with lids<br />

it has been touted as an aphrodisiac with strength<br />

enhancing characteristics. Feta has also been used<br />

as an <strong>of</strong>fering to <strong>the</strong> gods. The art <strong>of</strong> producing<br />

cheese was built up and refi ned by Roman slaves.<br />

The Romans developed a large array <strong>of</strong> baked<br />

goods containing cheese and diverse variations <strong>of</strong><br />

cheese salads. Even <strong>the</strong> Roman legionnaires carried<br />

feta cheese along with olives, bread and raisins as<br />

provisions in <strong>the</strong>ir fi eld packs.<br />

Since <strong>the</strong> 19th Century and particularly in<br />

Europe, cheese production has been subject to<br />

scientifi c research and innovation, especially to<br />

improve <strong>the</strong> shelf life <strong>of</strong> cheese. Often in close<br />

cooperation with cheese craftsmen, engineers have<br />

developed cutting frames, beaters, curd separators,<br />

electrical cutting devices and agitators, huge vats<br />

and boilers, cooling units and o<strong>the</strong>r aids used in<br />

producing cheese at industrial capacity.<br />

CONVENIENT AND PRACTICAL – MEYPACK’S<br />

“WASH-DOWN” CONCEPT FOR SIMPLE CLEANING<br />

It goes without saying that especially in <strong>the</strong><br />

dairy industry, <strong>the</strong> purity <strong>of</strong> <strong>the</strong> entire production,<br />

fi lling and packaging line plays an immensely<br />

important role. In order to cope with <strong>the</strong> regularly<br />

scheduled cleaning processes, <strong>the</strong> <strong>Meypack</strong> packaging<br />

machine was produced in a “wash-down”<br />

version. This means that bearings and guides<br />

have been built <strong>of</strong> rust-free stainless steel and <strong>the</strong><br />

hot-melt applicator has been equipped with special<br />

hose connections and nozzles that are protected<br />

from water spray. This technically sophisticated<br />

packaging machine has been rounded out with a<br />

high capacity ZM 600 magazine for <strong>the</strong> tray and lid<br />

blanks.<br />

<strong>Meypack</strong> Representative Denmark:<br />

Weimar Nicolaisen A/S<br />

Hjulmagervej 11 A<br />

7100 Vejle<br />

Denmark<br />

Tel.: +45 (0) 3886 - 3533<br />

Fax: +45 (0) 3886 - 1606<br />

info@weimar-nicolaisen.dk<br />

www.weimar-nicolaisen.dk<br />

Contact person: Briand Andersen

The V&S Group is a Swedish<br />

distiller with its headquarters<br />

in Stockholm. “Absolut Vodka”<br />

is <strong>the</strong> most important and most<br />

well-known brand produced by<br />

<strong>the</strong> V&S Group. The company<br />

is one <strong>of</strong> <strong>the</strong> largest producers<br />

<strong>of</strong> spirits in Europe and one <strong>of</strong><br />

<strong>the</strong> ten largest companies in <strong>the</strong><br />

alcohol industry worldwide. The<br />

CEO is Bengt Baron.<br />

16 kompackt 1/08<br />

If one were to pose <strong>the</strong> question from<br />

where a large brand with cult status and<br />

worldwide recognition has its roots, one<br />

would not immediately think <strong>of</strong> <strong>the</strong> small, idyllic<br />

town <strong>of</strong> Åhus in sou<strong>the</strong>rn Sweden. For over 100<br />

years, <strong>the</strong> V&S distillery has made this town its<br />

home, producing its internationally renowned and<br />

respected brand <strong>of</strong> “Absolut”. V&S has achieved<br />

this not only by producing a fi rst class product but<br />

also with excellent marketing. Early on, <strong>the</strong> Swedish<br />

company placed high priority on <strong>the</strong> design <strong>of</strong><br />

<strong>the</strong> bottle and made this a central focus <strong>of</strong> every<br />

campaign – worldwide.<br />

The distillery’s long history in this relatively<br />

small town has left a considerable yet in no way<br />

overbearing mark on <strong>the</strong> townscape <strong>of</strong> Åhus. One<br />

recognises <strong>the</strong> dominance <strong>of</strong> <strong>the</strong> company but sees<br />

that <strong>the</strong> structures have grown slowly over <strong>the</strong><br />

years, such as <strong>the</strong> two 30 metre high towers that<br />

High spirits<br />

from Åhus<br />

THE CLASSIC YET COOL BRAND “ABSOLUT VODKA”<br />

– WITH OVER 100 YEARS OF TRADITION – PUTS ITS<br />

TRUST IN MEYPACK’S PACKAGING TECHNOLOGY<br />

soar above <strong>the</strong> city and stand as <strong>the</strong> town’s landmark,<br />

visible even from a distance.<br />

THE SECRET RECIPE OF “ABSOLUT VODKA”:<br />

CONCENTRATING ON THE ESSENTIALS<br />

In 1979, V&S wanted to enter <strong>the</strong> American market<br />

– with <strong>the</strong> brand “Absolut”. After carrying out<br />

countless design studies, <strong>the</strong> company decided to<br />

run with a simplifi ed bottle design and a simplifi ed<br />

product brand (Absolut) as well as with a simplifi ed<br />

campaign for <strong>the</strong> US market. In hindsight, this proved<br />

to be a very wise decision, which has contributed<br />

signifi cantly to <strong>the</strong> worldwide success <strong>of</strong> <strong>the</strong><br />

brand “Absolut Vodka.” Reduction and simplicity<br />

formed <strong>the</strong> core message behind <strong>the</strong> brand. It is<br />

about vodka. Period. “Absolut Vodka.” Pure vodka.<br />

A team <strong>of</strong> designers, including <strong>the</strong> renowned Swedish<br />

designer Hans Brindfors, was responsible for<br />

this successful marketing concept. Mr Brindfors

was also responsible for <strong>the</strong> marketing campaigns<br />

<strong>of</strong> IKEA, Arla and Kelloggs, among o<strong>the</strong>rs.<br />

V&S ABSOLUT SPIRITS –<br />

A TRADITION OF DISTILLING SINCE 1879<br />

V&S Absolut Spirits has been producing “Absolut<br />

Vodka” from grain in <strong>the</strong> southwestern Swedish<br />

town <strong>of</strong> Åhus since 1879. The company places a high<br />

priority on <strong>the</strong> premium quality <strong>of</strong> its products as<br />

well as on <strong>the</strong> purity <strong>of</strong> its vodka. Today, “Absolut”<br />

is <strong>the</strong> fourth largest brand <strong>of</strong> spirits in <strong>the</strong> world.<br />

The product and <strong>the</strong> brand were developed by <strong>the</strong><br />

Swede Lars Olsson Smith in 1879.<br />

“Absolut Vodka” has become well-recognised<br />

internationally thanks to its unique bottle design<br />

and <strong>the</strong> simple brand name “Absolut.” The design<br />

<strong>of</strong> <strong>the</strong> bottle resembles a Swedish medicine bottle.<br />

The Swedish government took control <strong>of</strong> <strong>the</strong><br />

alcohol industry in 1917. Shortly <strong>the</strong>reafter, vodka<br />

was being sold across <strong>the</strong> country under <strong>the</strong> name<br />

“Absolut Renat Brännvin.” In <strong>the</strong> 1970s, <strong>the</strong> name <strong>of</strong><br />

<strong>the</strong> relatively unmodern brand was shortened to<br />

“Renat Brännvin.” In 1979, <strong>the</strong> former name “Absolut”<br />

was re-introduced and <strong>the</strong> brand was modernised<br />

to become what is now known worldwide as<br />

<strong>the</strong> premium brand “Absolut.”<br />

QUALITY MEETS QUALITY: “ABSOLUT VODKA”<br />

PACKED BY A MEYPACK PACKAGING MACHINE<br />

In 2007, a second production facility named<br />

“Absolut Satellit” was completed in Åhus. The<br />

entire project was run by Hakan Nilsson and his<br />

engineer ing team. One part <strong>of</strong> <strong>the</strong> new project is a<br />

brand new bottling line including a <strong>Meypack</strong> high<br />

Over 100 years <strong>of</strong> tradition: The V&S distillery in Åhus, Sweden<br />

Fully automatic partition insertion system <strong>of</strong> <strong>the</strong> VP 531<br />

speed VP 531 packaging machine equipped with a<br />

fully automatic partition insertion system.<br />

This case packer packs <strong>the</strong> well-known “Absolut”<br />

bottles, ranging in size from 700 ml up to 1,750<br />

ml, into ei<strong>the</strong>r 3x2 or 3x4 formations. To protect<br />

<strong>the</strong> bottles, <strong>the</strong> machine has been equipped with a<br />

servo-pusher dividing system to gently divide <strong>the</strong><br />

products into formation as well as three fully automatic<br />

partition inserters.<br />

The VP 531 case packer that packs <strong>the</strong> glass bottles<br />

into wrap-around cases is also outfi tted with<br />

an automatic blank loading station, which removes<br />

<strong>the</strong> blanks from <strong>the</strong> pallet and feeds <strong>the</strong>m automatically<br />

into <strong>the</strong> blank magazine.<br />

<strong>Meypack</strong> Representative Sweden:<br />

Advanced Packaging Nordeuropa AB<br />

Peppargränd 11<br />

13536 Tyresö<br />

Sweden<br />

Tel.: +46 (0) 8 - 6496994<br />

Fax: +46 (0) 8 - 6491170<br />

btn@advanced-packaging.net<br />

www.advanced-packaging.net<br />

Contact person: Bart Ten Napel

18 kompackt 1/08<br />

The fi ne world <strong>of</strong> savouring c<strong>of</strong>fee<br />

MEYPACK PROVES ITS COMPETENCE IN PACKING COFFEE<br />

FOR DEK, DELICA AND CAFÉ LIEGEOIS<br />

At <strong>the</strong> latest since its introduction to Europe in<br />

<strong>the</strong> 15th Century, c<strong>of</strong>fee has been one <strong>of</strong> <strong>the</strong> most<br />

widely spread delicacies. By 1517, <strong>the</strong> fi rst cafés<br />

were already operating in Istanbul. After strong<br />

opposition from <strong>the</strong> Islamic clergy and states, <strong>the</strong><br />

fi rst European c<strong>of</strong>fee house was opened in Europe<br />

in 1554. Between 1645 and 1689, c<strong>of</strong>fee houses were<br />

opened in Venice, Oxford, Marseilles, Paris, Bremen,<br />

Berlin, Hamburg, Regensburg, Leipzig and London.<br />

The fi rst Viennese c<strong>of</strong>fee house was established in<br />

1683 after 500 sacks <strong>of</strong> c<strong>of</strong>fee were looted during<br />

fi ghting against <strong>the</strong> Turks. From this point onwards,<br />

fi ne c<strong>of</strong>fee houses spread to all <strong>of</strong> <strong>the</strong> large cities<br />

<strong>of</strong> Europe and <strong>the</strong> world. C<strong>of</strong>fee consumption by<br />

<strong>the</strong> upper echelons <strong>of</strong> society spread and in doing<br />

so, c<strong>of</strong>fee became an important trading good along<br />

with spices, herbs and precious metals, although it<br />

was subject to strict import and trade regulations.<br />

THE COFFEE TRADE – BOTH THEN AND NOW A<br />

GLOBAL MEGA MARKET<br />

Today, c<strong>of</strong>fee is grown in over 50 countries<br />

around <strong>the</strong> world and is – despite its massive drop<br />

in price – still very important economically. After<br />

oil, c<strong>of</strong>fee is <strong>the</strong> second most important trading<br />

product, with Brazil being <strong>the</strong> world’s largest c<strong>of</strong>fee<br />

producer with an annual volume <strong>of</strong> over 2,000 million<br />

tonnes <strong>of</strong> c<strong>of</strong>fee beans. Behind Brazil, <strong>the</strong> o<strong>the</strong>r<br />

largest c<strong>of</strong>fee producers include Vietnam, Indonesia,<br />

Columbia, Mexico and India. 70% <strong>of</strong> <strong>the</strong> world’s<br />

c<strong>of</strong>fee still comes from small scale enterprises that<br />

sell <strong>the</strong>ir production to bulk buyers. The most<br />

important purchasing countries include Germany,<br />

<strong>the</strong> USA, France, Japan and Italy.<br />

MEYPACK’S COMPETENCE IN<br />

THE END-PACKAGING OF COFFEE PRODUCTS<br />

Over <strong>the</strong> past years, <strong>Meypack</strong> has successfully<br />

realised many individual end-packaging solutions<br />

for <strong>the</strong> c<strong>of</strong>fee industry. For example, at Deutsche<br />

Extrakt Kaffee GmbH (DEK) a <strong>Meypack</strong> case<br />

packer and shrink wrapper end-package jars <strong>of</strong><br />

c<strong>of</strong>fee, while at <strong>the</strong> Swiss company Delica, bags <strong>of</strong><br />

c<strong>of</strong>fee are packed in wrap-around cases. And at <strong>the</strong><br />

Belgian company Café Liegeois, an array <strong>of</strong> different<br />

sized bags containing c<strong>of</strong>fee pads receive <strong>the</strong>ir<br />

end-packaging on <strong>Meypack</strong> machines. All <strong>of</strong> <strong>the</strong><br />

systems have a high degree <strong>of</strong> fl exibility thanks to<br />

fast format changeovers and a packaging process<br />

that is very gentle on products. And <strong>the</strong>se projects<br />

have something else in common: DEK, Delica and<br />

Café Liegeois are all repeat customers, with <strong>Meypack</strong><br />

machines already part <strong>of</strong> <strong>the</strong>ir machine inventories.<br />

After all, <strong>Meypack</strong> packaging machines are<br />

able to pack in display trays, which are extremely<br />

important for <strong>the</strong> c<strong>of</strong>fee industry because <strong>of</strong> <strong>the</strong>ir<br />

utility at <strong>the</strong> point <strong>of</strong> sale in <strong>the</strong> supermarket.

Last but<br />

not least<br />

Technology <strong>of</strong>fensive 2008<br />

MEYPACK PRESENTS OPTIMISED<br />

PACKAGING MACHINE SOLUTIONS AT THE<br />

INTERPACK 2008<br />

At <strong>the</strong> interpack 2008, <strong>the</strong> Westphalian<br />

machine manufacturing specialist<br />

<strong>Meypack</strong> will be highlighting its concepts<br />

to guarantee <strong>the</strong> highest possible<br />

fl exibility through automation and it<br />

will be demonstrating its popular FTS-B-<br />

HD 32 bag closing machine with its new<br />

pneumatics.<br />

At its trade fair<br />

stand, <strong>Meypack</strong> will<br />

be exhibiting its<br />

VP 501 case packer<br />

equipped with fully<br />

auto matic adjustment<br />

points. This machine is<br />

designed to process shaped bottles made<br />

<strong>of</strong> plastic, PET and HDPE. The machine<br />

can process up to seven different bottles<br />

– and that in more than 20 formats. The<br />

machine’s strengths lie in its special lane<br />

dividing system designed specifi cally for<br />

shaped bottles as well in <strong>the</strong> controlled<br />

guiding <strong>of</strong> <strong>the</strong> products from <strong>the</strong> infeed<br />

all <strong>the</strong> way up to <strong>the</strong> packing <strong>of</strong> <strong>the</strong> products<br />

in <strong>the</strong> wrap-around cases. The fully<br />

automatic format adjustments enable fast<br />

and precise machine changeovers. Thanks<br />

to <strong>the</strong> fully automatic changeovers, <strong>the</strong><br />

saved formats and adjustment values can<br />

be reliably and accurately reproduced<br />

time and again. There are also innovations<br />

in <strong>Meypack</strong>’s bag closing technol-<br />

<strong>Meypack</strong> palletisers<br />

for <strong>the</strong> “Deutsche SiSi<br />

Werke” from WILD<br />

To <strong>the</strong> beat: The PKO’s servo-motorised turning station<br />

Two palletising solutions – a PKO and<br />

a PK 110 – were installed by <strong>Meypack</strong> for<br />

two packaging lines at <strong>the</strong> “Deutsche SiSi<br />

Werke” in Heidelberg, Germany. At an<br />

output <strong>of</strong> 6,000 single packets per hour,<br />

packets <strong>of</strong> <strong>the</strong> well-known children’s fruit<br />

juice drink brand, Capri-Sonne®, are fed<br />

Personnel<br />

Anja Sieh<strong>of</strong>f joined <strong>the</strong> sales<br />

team for Germany, Switzerland and<br />

Austria on November 1st, 2007. She<br />

is responsible for project management<br />

and sales support and is <strong>the</strong> fi rst point<br />

<strong>of</strong> contact for <strong>the</strong> external sales force. Ms<br />

Sieh<strong>of</strong>f is taking on <strong>the</strong> area <strong>of</strong> responsibility<br />

carried out by Waltraud Virow, who<br />

entered into partial retirement at <strong>the</strong> end<br />

<strong>of</strong> January 2008, after 17 years as a valued<br />

member <strong>of</strong> <strong>the</strong> sales department.<br />

ogy. The popular FTS-B-HD 32 has been<br />

re-engineered to simplify cleaning and<br />

maintenance. This machine continuously<br />

closes multi-layered paper bags using <strong>the</strong><br />

proven FTS technique. The machine now<br />

has improved electronics and pneumatics.<br />

In addition, <strong>the</strong> cable and hose guides<br />

have been overhauled and re-arranged,<br />

which facilitates care, cleaning and maintenance.<br />

At <strong>the</strong> interpack 2008, <strong>the</strong> FTS-B-<br />

HD 32 will display its fl exibility by closing<br />

strippable bags.<br />

into <strong>the</strong> machine lying<br />

fl at in ei<strong>the</strong>r two rows<br />

(PKO) or four rows (PK<br />

110) and are <strong>the</strong>n erected<br />

by a star wheel erector. Via<br />

a servo-motorised grouping<br />

und turning station,<br />

<strong>the</strong> products are <strong>the</strong>n multipacked<br />

and palletised onto Euro pallets,<br />

industrial pallets, ½-pallets and ¼-pallets.<br />

WILD is <strong>the</strong> world’s leading private<br />

producer <strong>of</strong> natural ingredients for <strong>the</strong><br />

food and beverage industries. Since 1969,<br />

<strong>the</strong> “Deutsche SiSi Werke” have been<br />

producing <strong>the</strong> popular children’s drink<br />

Capri-Sonne®, <strong>the</strong> world’s most successful<br />

beverage brand for children. Packed in<br />

drink packets, <strong>the</strong> juice drink is produced<br />

in 18 countries and enjoyed in over 100.<br />

You will fi nd more about this exciting project in <strong>the</strong> next issue<br />

<strong>of</strong> <strong>the</strong> kompackt.<br />

Waltraud Virow Anja Sieh<strong>of</strong>f Brian Gannon Reiner Müller<br />

In Export, Reiner Müller joined <strong>the</strong><br />

sales team one year ago in preparation for<br />

<strong>the</strong> impending and well-deserved retirement<br />

<strong>of</strong> Brian Gannon, who left <strong>the</strong> company<br />

at <strong>the</strong> end <strong>of</strong> 2007 after 35 years <strong>of</strong><br />

service. Reiner Müller is primarily active<br />

in supporting Export Director Klaus M.<br />

Vogel in external sales activities.<br />

DATES<br />

APRIL 24TH TO 30TH, 2008<br />

interpack, Düsseldorf, Germany<br />

SEPTEMBER 30TH TO OCTOBER 2ND, 2008<br />

POWTECH, Nuremberg, Germany<br />

NOVEMBER 12TH TO 14TH, 2008<br />

BRAU Beviale, Nuremberg, Germany

<strong>Meypack</strong> Verpackungssystemtechnik GmbH<br />

Industriestraße 3 · D-48301 Nottuln-Appelhülsen · Tel.: +49 (0) 2509 - 940 · Fax: +49 (0) 2509 - 948190 · info@meypack.de<br />

Kiebitzweg 18 · D-22869 Schenefeld / Hamburg · Tel.: +49 (0) 40 - 839020 · Fax: +49 (0) 40 - 8309482 · info@meypack.de<br />

www.meypack.de