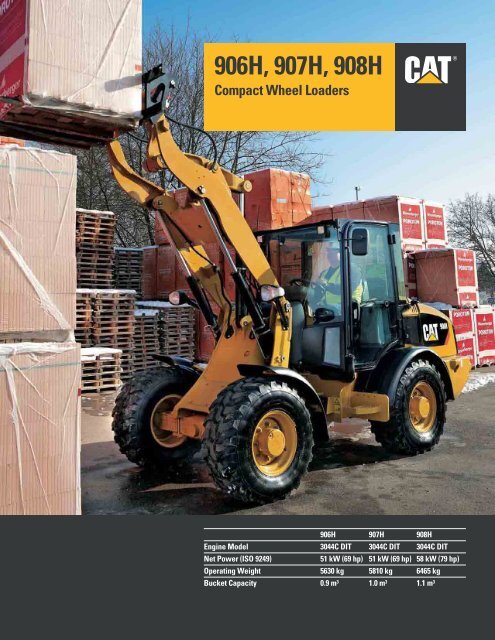

Compact Wheel Loaders 906H, 907H, 908H - Teknoxgroup

Compact Wheel Loaders 906H, 907H, 908H - Teknoxgroup

Compact Wheel Loaders 906H, 907H, 908H - Teknoxgroup

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Caterpillar ® H Series <strong>Compact</strong> <strong>Wheel</strong> LoaderPerformance & Versatility from Caterpillar <strong>Compact</strong> Products.Ease of OperationSimple controls and ergonomicallydesigned low effort joysticks reducefatigue and increase comfort. With achoice of three cab options the operatoris guaranteed all day comfort toenhance jobsite productivity. pg. 5Z-Bar LinkageHigh performance Z-Bar loader linkagedesigned for strength, visibility andversatile attachment usage. Skid steer orhorizontal pin quick coupler allow forrapid work tool changes. pg. 6Power TrainThe hydrostatic driveline developedwith advanced computer simulations,offers two speeds as standard. Theoptional speeder transmission providesa maximum speed of 35 km/h. Heavyduty axles are fitted as standard. 100%diff lock and ride control options areavailable. pg. 8Caterpillar Work ToolsStandard and high flow hydraulics,with a choice of couplers allows theCaterpillar <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> touse a variety of work tools, even thosethat are commonly associated withCaterpillar Skid Steer <strong>Loaders</strong>. pg. 7The new H-Series <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> still maintainCaterpillar's strengths whilst boasting a whole new rangeof features and benefits. In short, a machine that can betrusted to perform.2

Reliability and DurabilityThe same standards and qualitycomponents used in large Caterpillar<strong>Wheel</strong> <strong>Loaders</strong> are applied to the H-Series <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong>. Thesemachines are all you expect from Cat...but in a smaller package. pg. 9ServiceabilityThe design of the H-Series <strong>Compact</strong><strong>Wheel</strong> Loader allows quick and easyservicing. Tilt-up engine hood and sideservice doors give exceptional access tothe major components. S•O•S SM . oilports and pressure test points enableeasy preventative maintenance. pg. 10Customer SupportCaterpillar dealers offer unmatchedcustomer support, excellent warrantyprograms and fast parts availability,resulting in maximum uptime andminimum repair costs. pg. 113

<strong>Compact</strong> <strong>Wheel</strong> Loader H-Series RangeA comprehensive range to suit all applications and environments.<strong>906H</strong>. This low cab machine provides access to more areason site. It is designed with simplicity and cost effectivenessin mind. This model offers great operating capacity andhydraulic flows to work in a wide range of applications.<strong>907H</strong>. With more operating capacity than the <strong>906H</strong> anda higher mounted cab this model can work in applicationswhere clearance is not critical.<strong>908H</strong>. Boasts higher operating capacity, engine horse power,powerful breakout forces, increased axle durability andhydraulic flow allowing it to operate in tougher conditions.4

Operator StationModern interior, high quality, with an instinctive design.Excellent Visibility. The loader armshave been specifically designed withvisibility to work tools in mind. Lowlevel glazing and fully glazed doorsgives excellent visibility tothe work site.Cab Comfort. The heating and airconditioning system means that acomfortable operating environment canbe maintained. All cabs are pre-wired,making it easier to install future options.Digital LED Display. All models featurea high contrast backlit single pointmachine status cluster, locatedconveniently within the operator's lineof sight.Low Effort Controls. With a choice ofpilot hydraulics designed to make lightwork of using Cat work tools, or thesmooth mechanical controls, you can beassured operator fatigue will be kept ata minimum.Multi Functional Joystick. ContainsFNR (Forward, Neutral, Reverse),travel speed, 3rd Auxilliary hydraulics,diff lock and constant flow controls.Cab Options. With a variety of options itis easy to customize the cab to yourrequirements. A choice of base, comfortand deluxe specification cab trims areavailable. See pg. 13 for available cabfeatures.5

Z-Bar Loader Linkage and CouplersThe ideal linkage system for <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> for excellent visibility.Provides optimal digging forces combined with parallel lift.Z-Bar Design. Each of the Caterpillar <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong>make use of the high performance Z-bar loader design whichhas been optimized for strength, visibility and versatileattachment usage.The Z-bar linkage gives the operator a clear view to the worktool and excellent dump clearance while maintaining goodcycle times and parallel lift.Horizontal Pin Coupler. This quick coupler will pick up thenew range of <strong>Compact</strong> <strong>Wheel</strong> Loader work tools. The coupleralong with the profiled loader arms have been designed to givemaximum visibility to the work tool.A simple joystick function allows for easy engagement anddisengagement of the locking pins.Skid Steer Loader Coupler. The universal skid steer loadercoupler allows the use of many Cat Skid Steer Loader worktools. Using either the standard or high flow hydraulic option,this coupler allows the H-Series <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> tointegrate into a skid steer loader fleet.6

Work ToolsCaterpillar's range of buckets, forks and hydraulically powered Work Tools optimizemachine performance.Caterpillar Offers a Wide Range of WorkTools. To maximize machine utilization,Cat work tools are designed to getthe best out of the machine and deliverexcellent value through highproductivity and long life.The new H-Series <strong>Compact</strong> <strong>Wheel</strong><strong>Loaders</strong> can now pick up even morework tools with the addition of a choiceof couplers.Cat Horizontal Pin Coupler Work Tools.The Caterpillar <strong>Compact</strong> <strong>Wheel</strong> Loaderoffers a comprehensive range of bucketsto suit any environment and specificcustomer needs. The buckets have beenengineered and designed to allow theoperator to gain maximum efficiency.The Caterpillar fork carriage has beendesigned to increase visibility to theforks, allowing the operator to workmuch more efficiently and safely,without compromising durability.Various fork tine lengths are available.Cat Skid Steer Loader Coupler WorkTools. This coupler allows the use of Catskid steer loader work tools.Caterpillar recommends the followingoptions when choosing the Cat skid steerloader coupler:• Return to dig work tool positioner• Work tool wiring harness• Transmission control upgrade• High flow auxiliary hydraulics forhigh flow work toolsAuxiliary Lines and Connectors.The auxiliary lines and connectorsare fitted as standard, meaning theCaterpillar <strong>Compact</strong> <strong>Wheel</strong> Loadercomes ready to work.For a complete list of available worktools please consult your localCaterpillar dealer.7

Power TrainCaterpillar Hystat power train delivers aggressive performance.Two Speed Options. Caterpillar’shydrostatic driveline has two speedoptions, 20 or 35 km/h. High speedroading is achieved using an optionaltwo-speed gearbox. Both optionsfeature smooth inching as standard,with optional speed/rimpull controland hand throttle.Disc Brakes. The speeder version hashydraulically boosted oil immersed discbrakes fitted to the front axle. The nonspeederversion has a hydraulicallyactuated dry disc brake, both offeringsmooth and effective braking.Diff Lock. The Caterpillar <strong>Compact</strong><strong>Wheel</strong> <strong>Loaders</strong> offer 100% diff-lock,in both axles as an option throughoutthe range. Diff-lock can be easilyengaged on the move to allow travelover poor underfoot conditions.Chassis Oscillation. Oscillating chassishelps assure four wheel ground contactfor optimum traction and stability.Ride Control. The ride control systemfurther enhances the already smoothroad handling of the machine, resultingin increased operator comfort andhigher productivity. It is suited forextreme applications where operatorsneed to maintain bucket material loadand have a smooth ride. There arethree modes available; auto, on and off.Recommended for use with the speederoption.8

Reliability and DurabilityQuality within, quality throughout.E-Coat Protection. Cat <strong>Compact</strong> <strong>Wheel</strong><strong>Loaders</strong> undergo an extensive 24-Stage‘E-Coat’ process. Zinc based electroplatedundercoat and polyurethanetopcoat provides unmatched corrosionresistant properties.Heavy Duty Axles. The H Series<strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> are fittedwith heavy duty axles, with outboardplanetary reduction gears.Wiring. With heavy-duty wiring, Cat<strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> offer greatelectrical durability. The water resistantsealed connectors prevent dust andmoisture interfering with the electrics.Multicoloured wiring is used to easediagnosis and fault finding.9

ServiceabilitySuperb access to service points for easy maintenance.Ground Level Access. With a highopening, easy to lift up engine hood andside service doors, access to all majorcomponents and service points can beeasily seen and reached safely from theground.S•O•S Valves. Are conveniently locatedin the engine bay for analyzing engineand hydraulic system cleanliness andservice requirements, prolongingmachine life.Caterpillar Air Cleaner. A two stage aircleaner with an inbuilt centrifugal precleaner,including a secondary elementand a visual restriction indicator forbetter service life.Centralized Locations. Auxiliary fuses,diagnostic sockets, isolator and otherregular service points are all locatedtogether for ease of servicing.Hydraulic Filter/Fuel Filter. Verticallymounted, spin on oil filter and fuel filterwith water separator for easy servicing.Oil Cooler. The cooling pack can beopened using a handle in the engine bayto allow easy cleaning.Electronic Technician. Plug in pointallows advanced diagnostics and faultcode investigation using Caterpillarservice tools.10

Customer SupportComplete services provided by the world’s largest dealer network.Unmatched Dealer Support. Excellentequipment management services andfast parts availability – most within 24hours – provide maximum uptime andminimum repair costs.Equipment Maintenance Services.To help optimize machine performanceand reliability. Services include:• Customer Support Agreements• S•O•S oil analysis – can detectpotential faults before they becomemajor problems that cost time andmoney. Amongst a list of benefits,S•O•S can shorten repair time andhelp to manage budgets byforecasting the costs of repair anddowntime. Sample test analysis isdone in a Cat dealers laboratory bytrained technicians utilising the mostmodern technology. Most test resultsare available within 24 hours ofreceipt of the sample.• Maintenance contracts• Scheduled technical inspectionsEquipment Management Services.To help optimize profits.Services include:• Machine and work tool selection• Rental and leasing• Purchasing and financing• Owning and operating costmanagement• Extended warrantiesFor a complete explanation of these servicesplease call your local Caterpillar dealer.11

EngineCat 3044C DIT engine, 4 cylinder,turbocharged, direct injectionRated Power at 2600 rpm <strong>906H</strong> <strong>907H</strong> <strong>908H</strong>Gross power kW/hp 53/72 53/72 60/82Net powerISO 9249 kW/hp 51/69 51/69 58/7980/1296/EEC kW/hp 51/69 51/69 58/79Bore mm 94 94 94Stroke mm 120 120 120Displacement L 3.3 3.3 3.3• All engine horsepower (hp) are metric including front page.• Engine is EU Stage II compliant.Hydraulic System<strong>906H</strong> <strong>907H</strong> <strong>908H</strong>Main relief bar 235 235 2353rd Aux FlowStandard L/min 83 83 83High Flow L/min 125 125 125Hydraulic cycle timeLift secs 5 5 5Lower secs 4 4 4Dump secs 2 2 2Rack Back secs 2.5 2.5 2.5Travel Speeds<strong>906H</strong> <strong>907H</strong> <strong>908H</strong>Speed 1 km/h 7 7 7Speed 2 km/h 20 20 20High Speed km/h 35 35 35ROPS/FOPSCaterpillar cab, Rollover Protective Structure (ROPS) andFalling Objects Protective structure (FOPS)• ROPS meets the following criteria: ISO 3471-1:1994• FOPS meets the following criteria: ISO 3449:1992Sound LevelsExterior Sound. For European Union compliant machineconfigurations, the machine labeled spectator sound powerlevel is measured according to the test procedures andconditions specified in 2000/14/EC.Service Refill Capacities<strong>906H</strong> <strong>907H</strong> <strong>908H</strong>Cooling System L 24 24 24Fuel Tank L 52 78 78Hydraulic System L 84 84 84Engine Oil L 10 10 10Maximum Material DensitiesBased on ISO 7546:1983, and rated operating loads at full turn.Bucket Type General PurposeMulti Purpose Light MaterialModelRated Capacity m 3Dump HeightHorizontal Pin CouplermmSSL CouplermmMaximum Material DensityHorizontal Pin Coupler kg/m 3SSL Coupler kg/m 3Bucket Widthmm<strong>906H</strong> <strong>907H</strong> <strong>908H</strong> <strong>906H</strong> <strong>907H</strong> <strong>908H</strong> <strong>906H</strong> <strong>907H</strong> <strong>908H</strong>0.90 1.00 1.10 0.75 0.75 0.90 1.20 1.20 1.502510 2510 2655 2500 2500 2665 2430 2430 24602395 2395 2540 2470 2470 2630 2395 2395 23451740 1595 1605 2000 2050 1900 1160 1220 10701615 1480 1500 1950 2000 1865 1105 1135 10001880 2035 2060 1880 1880 2060 2080 2080 208012H Series <strong>Compact</strong> <strong>Wheel</strong> Loader specifications

Operating SpecificationsMachine with full fuel tank, ROPS cab, 75 kg operator, horizontal pin coupler (HP) or skid steer loader coupler (SSL)and general purpose bucket (GP).Coupler typeTyre sizeOperating weight (ISO 6016:1998)Rated bucket capacity (ISO 7546:1983)Hydraulic lift capacity, maximum (ISO 14397-2)Breakout force, bucket (ISO 14397-2)Rated operating load at full turn, bucket (ISO 14397-1)Straight tipping load, bucket (IS0 14397-1)Full turn static tipping load, bucket (ISO 14397-1)Rackback, transport positionRated operating load at full turn, forks (EN 474-3, firmand level ground, 1.25 stability and 500 mm load center)Rated operating load at full turn, forks (EN 474-3, firmand level ground, 1.25 stability and 500 mm load center)(transport 100 mm above ground)<strong>906H</strong> <strong>907H</strong> <strong>908H</strong>HP SSL HP SSL HP SSL405/70 R18 405/70 R18 405/70 R20kg 5630 5630 5810 5810 6465 6465m 3 0.9 0.9 1.0 1.0 1.1 1.1kN 34 32 34 32 38 35kN 51 42 51 42 57 47kg 1565 1450 1595 1480 1765 1650kg 4055 3775 4245 3950 4440 4155kg 3130 2900 3190 2960 3530 329552° 52° 52° 52° 52° 52°kg 2150 2030 2200 2080 2500 2320kg 2695 2670 2760 2735 3035 2945Cab FeaturesStandard Cab Features Base Cab* Comfort Cab Deluxe Cab CanopyTwo access doors✔ ✔ ✔Fixed steering column✔✔Adjustable steering columnVinyl suspension seat✔✔✔Cloth suspension seat, arm restCloth, electric air suspension, arm/head rest,lumbar support and heated back seat✔✔✔Left window – fixedLeft window – slidingRight window – sliding✔✔✔✔Heated rear window✔ ✔ ✔Coat hook✔ ✔ ✔ ✔Cabin light✔ ✔ ✔Sun visor✔ ✔ ✔ ✔Radio-ready kit (wiring, speaker, aerial and grilles)✔✔External mirror – knock back✔ ✔ ✔ ✔Heater✔ ✔ ✔Optional Cab FeaturesCat radio/CD/MP3/WMA✔ ✔ ✔Rear blind✔ ✔ ✔Internal mirror✔ ✔ ✔ ✔Storage tray✔ ✔ ✔ ✔Storage box✔ ✔ ✔ ✔Heater and air conditioning✔ ✔ ✔Radio-ready kit (wiring, speaker, aerial and grilles)* Base cab available only on the <strong>906H</strong>✔H Series <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> specifications13

DimensionsDimensions shown are based on the machine equipped with general purpose bucket and standard tires.All dimensions are approximate.172458 9 111716151023418126 131419202122231 Cab Height2 Ground Clearance3 <strong>Wheel</strong>base4 Overall Length with Bucket5 Reach at Max Dump Height6 Dig Depth7 Max Dump Height8 Load Over Height9 Hinge Pin at Max Height10 Departure Angle (degrees)11 Overall Length with Forks12 Reach at Ground Level13 Max Reach14 Fork Depth Below Ground (Above Ground)15 Fork Height at Max Reach16 Max Fork Height17 Fork Reach at Max Height18 Turning Radius Over Bucket19 Turning Radius Inside Tire20 Width Over Bucket21 Tire Gauge22 Machine Width23 Articulation Angle24 Dump Angle at Max HeightWith horizontal pin couplerWith SSL coupler<strong>906H</strong> <strong>907H</strong> <strong>908H</strong> <strong>906H</strong> <strong>907H</strong> <strong>908H</strong>mm mm mm mm mm mm2465 2585 2650 2465 2585 2650300 300 340 300 300 3402170 2170 2170 2170 2170 21705435 5435 5595 5585 5585 5760710 710 760 810 810 85580 80 85 90 90 952510 2510 2655 2395 2395 25403035 3035 3225 3025 3025 32153230 3230 3410 3230 3230 341034° 34° 34° 34° 34° 34°5915 5915 6015 5945 5945 6150720 720 790 750 750 9251215 1215 1310 1265 1265 144525 25 70 (45) (45) (30)1425 1425 1450 1490 1490 15253090 3090 3225 3160 3160 3300445 445 460 505 505 5954400 4475 4510 4445 4515 45602240 2240 2080 2240 2240 20801880 2035 2060 1880 1880 20601420 1420 1570 1420 1420 15701840 1840 1985 1840 1840 198539° 39° 39° 39° 39° 39°45° 45° 45° 45° 45° 45°

Standard EquipmentStandard and optional equipment may vary by region. Consult your Caterpillar dealer for details.TransmissionTransmission, 20 km/h with standardaxlesTransmission inching functionHydrostatic driveLoaderHydraulic horizontal pin quick coupleror Skid steer quick couplerProportional auxiliary hydraulic circuitLoader arm float functionConnect under pressure hydraulic quickconnectorParallel lift Z-bar loaderEngine3044C DIT Stage II compliantTwo stage air cleaner with visualindicatorCat Extended Life CoolantLockable engine compartmentsEasy quick release fuel filter/waterseparatorEngine oil drain valveClosed circuit breatherElectricalMaster isolatorHeavy duty battery, 12 VEngine cold starter aidAlternator 90 AService point connector for electronicdiagnostics (ET)GeneralE-coat paint primerPressure test pointsRecovery hitch and pinScheduled oil sampling S•O•S portsLockable fuel filler capAll CabsMultifunction joystick with directioncontrolProportional auxiliary controlTwo external mirrors - knock backWarning indicators for major systemsWiper/washer front & rearEasy clean cab floorOperator EnvironmentRadio ready kit inc. speakers(not in base cab)Two doorsPersonal storageCup holderSun visorRear screen defrostROPS & FOPSWrist restRetractable seat belt (2 inch)Cabin lightAuxiliary power socketsCoat hookPressurized cabOn board digital display clusterHeater with window, side and feet ventsSound suppressionOptional EquipmentOptional equipment may vary. Some combinations of options may not be possible. Consult your Caterpillar dealer for details.TransmissionTransmission control upgrade100% Differential Lock on both axles,selectable on the moveRide controlSpeeder, 35 km/hLoaderHigh flow auxiliary hydraulicsLoad check valvesReturn to dig work tool positionerEngineEngine block heater 120 VEngine oil drain valve (non spill ecodrain)Cat extended life coolant (-50 °C)ElectricalBack up alarmMachine Security System (MSS)Rotating beaconWork tool wiring harnessWorking lights, two front and two rearGeneralTire options including heavy duty tiresFluidsBiodegradable hydraulic oilWork ToolsFor all work tools and standard/highflow options (consult your Caterpillardealer)Operator EnvironmentAir conditioningRetractable seat belt (3 inch)Cat radio/CD/MP3/WMACanopyBase cab for <strong>906H</strong>Comfort and deluxe cabsMechanical joystick (available onlyfor <strong>906H</strong>)Radio ready kit for base cab (wiring,speakers, aerial and grille)Rear blindStorage tray or lockable boxInternal mirrorFor a summary of available optionsplease refer to cab features pg. 13H Series <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong> specifications15

<strong>906H</strong>, <strong>907H</strong>, <strong>908H</strong> <strong>Compact</strong> <strong>Wheel</strong> <strong>Loaders</strong>HEHL3619 (06/2007) hrFor more complete information on Cat products, dealer services, and industry solutions, visit us on the web atwww.cat.comMaterials and specifications are subject to change without notice. Featured machines in photosmay include additional equipment. See your Caterpillar dealer for available options.© 2007 Caterpillar -- All rights reservedCAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the POWER EDGE trade dress as well ascorporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.®