Building Automation Controls Catalog 2006 - Trane

Building Automation Controls Catalog 2006 - Trane

Building Automation Controls Catalog 2006 - Trane

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

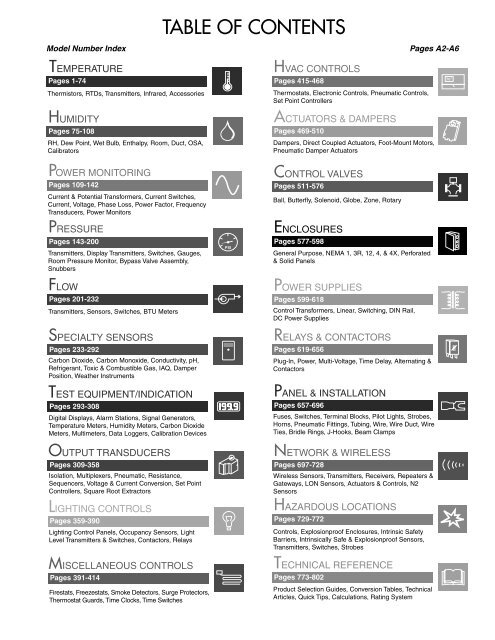

Model Number Index Pages A2-A6<br />

TEMPERATURE<br />

Pages 1-74<br />

Thermistors, RTDs, Transmitters, Infrared, Accessories<br />

HUMIDITY<br />

Pages 75-108<br />

RH, Dew Point, Wet Bulb, Enthalpy, Room, Duct, OSA,<br />

Calibrators<br />

POWER MONITORING<br />

Pages 109-142<br />

Current & Potential Transformers, Current Switches,<br />

Current, Voltage, Phase Loss, Power Factor, Frequency<br />

Transducers, Power Monitors<br />

PRESSURE<br />

Pages 143-200<br />

Transmitters, Display Transmitters, Switches, Gauges,<br />

Room Pressure Monitor, Bypass Valve Assembly,<br />

Snubbers<br />

FLOW<br />

Pages 201-232<br />

Transmitters, Sensors, Switches, BTU Meters<br />

SPECIALTY SENSORS<br />

Pages 233-292<br />

Carbon Dioxide, Carbon Monoxide, Conductivity, pH,<br />

Refrigerant, Toxic & Combustible Gas, IAQ, Damper<br />

Position, Weather Instruments<br />

TEST EQUIPMENT/INDICATION<br />

Pages 293-308<br />

Digital Displays, Alarm Stations, Signal Generators,<br />

Temperature Meters, Humidity Meters, Carbon Dioxide<br />

Meters, Multimeters, Data Loggers, Calibration Devices<br />

OUTPUT TRANSDUCERS<br />

Pages 309-358<br />

Isolation, Multiplexers, Pneumatic, Resistance,<br />

Sequencers, Voltage & Current Conversion, Set Point<br />

Controllers, Square Root Extractors<br />

LIGHTING CONTROLS<br />

Pages 359-390<br />

Lighting Control Panels, Occupancy Sensors, Light<br />

Level Transmitters & Switches, Contactors, Relays<br />

MISCELLANEOUS CONTROLS<br />

Pages 391-414<br />

Firestats, Freezestats, Smoke Detectors, Surge Protectors,<br />

Thermostat Guards, Time Clocks, Time Switches<br />

TABLE OF CONTENTS<br />

PSI<br />

HVAC CONTROLS<br />

Pages 415-468<br />

Thermostats, Electronic <strong>Controls</strong>, Pneumatic <strong>Controls</strong>,<br />

Set Point Controllers<br />

ACTUATORS & DAMPERS<br />

Pages 469-510<br />

Dampers, Direct Coupled Actuators, Foot-Mount Motors,<br />

Pneumatic Damper Actuators<br />

CONTROL VALVES<br />

Pages 511-576<br />

Ball, Butterfly, Solenoid, Globe, Zone, Rotary<br />

ENCLOSURES<br />

Pages 577-598<br />

General Purpose, NEMA 1, 3R, 12, 4, & 4X, Perforated<br />

& Solid Panels<br />

POWER SUPPLIES<br />

Pages 599-618<br />

Control Transformers, Linear, Switching, DIN Rail,<br />

DC Power Supplies<br />

RELAYS & CONTACTORS<br />

Pages 619-656<br />

Plug-In, Power, Multi-Voltage, Time Delay, Alternating &<br />

Contactors<br />

PANEL & INSTALLATION<br />

Pages 657-696<br />

Fuses, Switches, Terminal Blocks, Pilot Lights, Strobes,<br />

Horns, Pneumatic Fittings, Tubing, Wire, Wire Duct, Wire<br />

Ties, Bridle Rings, J-Hooks, Beam Clamps<br />

NETWORK & WIRELESS<br />

Pages 697-728<br />

Wireless Sensors, Transmitters, Receivers, Repeaters &<br />

Gateways, LON Sensors, Actuators & <strong>Controls</strong>, N2<br />

Sensors<br />

HAZARDOUS LOCATIONS<br />

Pages 729-772<br />

<strong>Controls</strong>, Explosionproof Enclosures, Intrinsic Safety<br />

Barriers, Intrinsically Safe & Explosionproof Sensors,<br />

Transmitters, Switches, Strobes<br />

TECHNICAL REFERENCE<br />

Pages 773-802<br />

Product Selection Guides, Conversion Tables, Technical<br />

Articles, Quick Tips, Calculations, Rating System<br />

70°

MODEL / SERIES NUMBER INDEX<br />

Model / Series No. Page Model / Series No. Page Model / Series No. Page<br />

1<br />

105 . . . . . . . . . . . . . . . . . . . . . . . .765<br />

189 . . . . . . . . . . . . . . . . . . . . . . . .142<br />

100 SERIES . . . . . . . . . . . . . . . . .663<br />

104ST . . . . . . . . . . . . . . . . . . . . . .674<br />

106EXP . . . . . . . . . . . . . . . . . . . .765<br />

116EXMST . . . . . . . . . . . . . . . . . .765<br />

13F142 . . . . . . . . . . . . . . . . . . . . . .50<br />

140T . . . . . . . . . . . . . . . . . . .749, 750<br />

140T . . . . . . . . . . . . . . . . . . .279, 280<br />

14121-000 . . . . . . . . . . . . . . . . . .598<br />

1500 SERIES . . . . . . . . . . . . . . . .214<br />

1550 SERIES . . . . . . . . . . . .215, 216<br />

160 SERIES . . . . . . . . . . . . . . . . .203<br />

1900-5-MR . . . . . . . . . . . . . . . . . .187<br />

190XSUM . . . . . . . . . . . . . . . . . . .142<br />

1910 SERIES . . . . . . . . . . . . . . . .187<br />

1950G SERIES . . . . . . . . . . . . . . .738<br />

2<br />

21F . . . . . . . . . . . . . . . . . . . . . . . .681<br />

22/07-16 . . . . . . . . . . . . . . . . . . . .326<br />

23F . . . . . . . . . . . . . . . . . . . . . . . .681<br />

24-013 . . . . . . . . . . . . . . . . .189, 190<br />

24-014 . . . . . . . . . . . . . . . . .189, 190<br />

25 SERIES . . . . . . . . . . . . . . . . . .193<br />

200 SERIES . . . . . . . . . . . . . . . . .207<br />

200-IS SERIES . . . . . . . . . . . . . . .754<br />

201A . . . . . . . . . . . . . . . . . . .129, 131<br />

209 SERIES . . . . . . . . . . . . .175, 176<br />

209PF . . . . . . . . . . . . . . . . . . . . . .135<br />

220B . . . . . . . . . . . . . . . . . . . . . . .208<br />

220SS . . . . . . . . . . . . . . . . . . . . . .208<br />

225B . . . . . . . . . . . . . . . . . . . . . . .209<br />

226B . . . . . . . . . . . . . . . . . . . . . . .209<br />

226SS . . . . . . . . . . . . . . . . . . . . . .209<br />

228B . . . . . . . . . . . . . . . . . . . . . . .210<br />

228C . . . . . . . . . . . . . . . . . . . . . . .210<br />

228PV . . . . . . . . . . . . . . . . . . . . . .211<br />

228SS . . . . . . . . . . . . . . . . . . . . . .210<br />

250B . . . . . . . . . . . . . . . . . . . . . . .210<br />

251 SERIES . . . . . . . . . . . . . . . . .666<br />

258 . . . . . . . . . . . . . . . . . . . . . . . .128<br />

260 SERIES . . . . . . . . . . . . .153, 154<br />

269 . . . . . . . . . . . . . . . . . . . . . . . .128<br />

2000 SERIES . . . . . . . . . . . .195, 196<br />

21121 . . . . . . . . . . . . . . . . . . . . . .194<br />

2200 . . . . . . . . . . . . . . . . . . . .459, 460<br />

2200 . . . . . . . . . . . . . . . . . . . .223, 224<br />

2200 SERIES . . . . . . . . . . . . . . . .459<br />

20307 SERIES . . . . . . . . . . . . . . .630<br />

3<br />

3PT3 . . . . . . . . . . . . . . . . . . . . . . .142<br />

3W15US.5 . . . . . . . . . . . . . .525, 526<br />

30-3003D . . . . . . . . . . . . . . .761, 762<br />

33 SERIES . . . . . . . . . . . . . . . . . .606<br />

35A . . . . . . . . . . . . . . . . . . . . . . . .468<br />

310 . . . . . . . . . . . . . . . . . . . . . . . .213<br />

340 SERIES . . . . . . . . . . . . .217, 218<br />

355 SERIES . . . . . . . . . . . . . . . . .132<br />

356 . . . . . . . . . . . . . . . . . . . . .461, 462<br />

357 . . . . . . . . . . . . . . . . . . . . .461, 462<br />

360-3VLV . . . . . . . . . . . . . . . . . . .198<br />

392-SVSR2 . . . . . . . . . . . . . . . . . .406<br />

3000 SERIES . . . . . . . . . . . . . . . .188<br />

3100 . . . . . . . . . . . . . . . . . . . .223, 224<br />

4<br />

4BRT . . . . . . . . . . . . . . . . . . . . . . .684<br />

4CMA . . . . . . . . . . . . . . . . . .123, 124<br />

4CTV . . . . . . . . . . . . . . . . . .121, 122<br />

4GS . . . . . . . . . . . . . . . . . . .249, 250<br />

41F SERIES . . . . . . . . . . . . . . . . .681<br />

460 . . . . . . . . . . . . . . . . . . . . . . . .130<br />

468 . . . . . . . . . . . . . . . . . . . . . . . .142<br />

47B . . . . . . . . . . . . . . . . . . . . . . . .200<br />

47S . . . . . . . . . . . . . . . . . . . . . . . .200<br />

438USA . . . . . . . . . . . . . . . .651, 652<br />

438USA-INT . . . . . . . . . . . . .651, 652<br />

475-FM Series . . . . . . . . . . . . . . .299<br />

490 SERIES . . . . . . . . . . . . . . . . .299<br />

4000 SERIES . . . . . . . . . . . . . . . .211<br />

500T . . . . . . . . . . . . . . . . . . . . . . .112<br />

501T . . . . . . . . . . . . . . . . . . . . . . .112<br />

550 . . . . . . . . . . . . . . . . . . . . .277, 278<br />

550-X . . . . . . . . . . . . . . . . . .747, 748<br />

5530M . . . . . . . . . . . . . . . . . . . . .765<br />

51012218 . . . . . . . . . . . . . . . . . . .671<br />

6H38 . . . . . . . . . . . . . . . . . . . . . . .660<br />

6M30 SERIES . . . . . . . . . . . . . . .665<br />

6W30 . . . . . . . . . . . . . . . . . . . . . .661<br />

600T . . . . . . . . . . . . . . . . . . . . . . .111<br />

601T . . . . . . . . . . . . . . . . . . . . . . .111<br />

603 . . . . . . . . . . . . . . . . . . . . . . . .110<br />

603D . . . . . . . . . . . . . . . . . . . . . . .110<br />

691 SERIES . . . . . . . . . . . . . . . . .599<br />

691-U100 . . . . . . . . . . . . . . . . . . .600<br />

694 SERIES . . . . . . . . . . . . . . . . .601<br />

626600A . . . . . . . . . . . . . . . .227, 228<br />

70-781D-1 . . . . . . . . . . . . . . . . . . .629<br />

70-782D-1 . . . . . . . . . . . . . . . . . . .629<br />

70-783D-1 . . . . . . . . . . . . . . . . . . .629<br />

70-784D-1 . . . . . . . . . . . . . . . . . . .629<br />

A2<br />

747B . . . . . . . . . . . . . . . . . . . . . . .200<br />

747S . . . . . . . . . . . . . . . . . . . . . . .200<br />

781 . . . . . . . . . . . . . . . . . . . . .627, 628<br />

782 . . . . . . . . . . . . . . . . . . . . .627, 628<br />

783 . . . . . . . . . . . . . . . . . . . . .627, 628<br />

784 SERIES . . . . . . . . . . . . .627, 628<br />

7001 . . . . . . . . . . . . . . . . . . . . . . .300<br />

711271 . . . . . . . . . . . . . . . . . .239, 240<br />

89STR . . . . . . . . . . . . . . . . . . . . .674<br />

860D . . . . . . . . . . . . . . . . . . . . . . .151<br />

868 . . . . . . . . . . . . . . . . . . . . . . . .674<br />

868STR . . . . . . . . . . . . . . . . . . . .674<br />

869 . . . . . . . . . . . . . . . . . . . . . . . .674<br />

869STR . . . . . . . . . . . . . . . . . . . .674<br />

878EX . . . . . . . . . . . . . . . . . . . . . .765<br />

879EX . . . . . . . . . . . . . . . . . . . . . .765<br />

880D . . . . . . . . . . . . . . . . . . . . . . .151<br />

885D . . . . . . . . . . . . . . . . . . . . . . .151<br />

8001 . . . . . . . . . . . . . . . . . . . .247, 248<br />

8002 . . . . . . . . . . . . . . . . . . . .247, 248<br />

8003 SERIES . . . . . . . . . . . .247, 248<br />

8205 . . . . . . . . . . . . . . . . . . . .273, 274<br />

8210 SERIES . . . . . . . . . . . .529, 530<br />

821TD10H . . . . . . . . . . . . . .655, 656<br />

8238 SERIES . . . . . . . . . . . .531, 532<br />

8225 . . . . . . . . . . . . . . . . . . . .275, 276<br />

5 9<br />

6<br />

7<br />

9002 . . . . . . . . . . . . . . . . . . . .105, 106<br />

93000 . . . . . . . . . . . . . . . . . . . . . .411<br />

93000 . . . . . . . . . . . . . . . . . . . . . .382<br />

A SERIES . . . . . . . . . . . . . . . . . . .680<br />

A11 SERIES . . . . . . . . . . . . . . . . .398<br />

A15 SERIES . . . . . . . . . . . . .525, 526<br />

A19 . . . . . . . . . . . . . . . . . . . .447, 448<br />

A19AUC-2 . . . . . . . . . . . . . . . . . .757<br />

A21 . . . . . . . . . . . . . . . . . . . . . . . .108<br />

A-300 SERIES . . . . . . . . . . . . . . .194<br />

A319 . . . . . . . . . . . . . . . . . . .447, 448<br />

A350 . . . . . . . . . . .449, 450, 451, 452<br />

A419 SERIES . . . . . . . . . . . .447, 448<br />

A70 SERIES . . . . . . . . . . . . . . . . .401<br />

A70 SERIES . . . . . . . . . . . . .281, 282<br />

ABB SERIES . . . . . . . . . . . . . . . .669<br />

ABW . . . . . . . . . . . . . . . . . . . . . . .683<br />

AC1 . . . . . . . . . . . . . . . . . . . . . . .768<br />

AC1A . . . . . . . . . . . . . . . . . . . . . .768<br />

ACI SERIES . . . . . . . . . . . . . . .33, 34<br />

ACI/RH SERIES . . . . . . . . . . . .93, 94<br />

ACK6F . . . . . . . . . . . . . . . . . . . . .768<br />

AF SERIES . . . . . . . . . . . . . .499, 500<br />

8<br />

A

MODEL / SERIES NUMBER INDEX<br />

Model / Series No. Page Model / Series No. Page Model / Series No. Page<br />

AFS-222 . . . . . . . . . . . . . . . .183, 184<br />

AFS-262 . . . . . . . . . . . . . . . .183, 184<br />

AFS-460 . . . . . . . . . . . .183, 184, 185<br />

AIS . . . . . . . . . . . . . . . . . . . . . . . .302<br />

AL . . . . . . . . . . . . . . . . . . . . . . . . .109<br />

ALD-1 . . . . . . . . . . . . . . . . . . . . . .300<br />

AM . . . . . . . . . . . . . . . . . . . .497, 498<br />

AM-401 SERIES . . . . . . . . . . . . .760<br />

AMP SERIES . . . . . . . . . . . . . . . .204<br />

AOW SERIES . . . . . . . . . . . . . . . .683<br />

APB-28 . . . . . . . . . . . . . . . . . . . . . .48<br />

APW SERIES . . . . . . . . . . . . . . . .679<br />

AQS00660 . . . . . . . . . . . . . . . . . .289<br />

AQS00661 . . . . . . . . . . . . . . . . . .289<br />

ASG . . . . . . . . . . . . . . . . . . . . . . .293<br />

ASW SERIES . . . . . . . . . . . . . . . .682<br />

AT-1100 SERIES . . . . . . . . . . . . .414<br />

AT140A . . . . . . . . . . . . . . . . . . . .602<br />

AT150A . . . . . . . . . . . . . . . . . . . .602<br />

AT150F . . . . . . . . . . . . . . . . . . . . .603<br />

AT175F . . . . . . . . . . . . . . . . . . . . .603<br />

AT87A . . . . . . . . . . . . . . . . . . . . .602<br />

AVS-200 . . . . . . . . . . . . . . . . . . . .206<br />

B<br />

B SERIES FITTINGS . . . . . .689, 690<br />

B120E-P . . . . . . . . . . . . . . . .371, 372<br />

B2 . . . . . . . . . . . . . . . . . . . . .539, 540<br />

B230E-P . . . . . . . . . . . . . . . .371, 372<br />

B277E-P . . . . . . . . . . . . . . . .371, 372<br />

B3 SERIES . . . . . . . . . . . . . .539, 540<br />

B347D-P . . . . . . . . . . . . . . . .371, 372<br />

BA PROBE . . . . . . . . . . . . . . . .37, 38<br />

BA ROOM . . . . . . . . . . . . . . . .35, 36<br />

BA/HSERIES . . . . . . . . . . . . . .95, 96<br />

BAM-1000 . . . . . . . . . . . . . . . . . .668<br />

BKA/1 . . . . . . . . . . . . . . . . . . . . . .662<br />

BKT-1 . . . . . . . . . . . . . . . . . . . . . . .48<br />

BKT-2 . . . . . . . . . . . . . . . . . . . . . . .48<br />

BLV . . . . . . . . . . . . . . . . . . . . . . . .364<br />

BVA-5 . . . . . . . . . . . . . . . . . . . . . .199<br />

C<br />

C SERIES FITTINGS . .691, 692, 693<br />

C500 SERIES . . . . . . . . . . . . . . . .675<br />

C7232 . . . . . . . . . . . . . . . . . .243, 244<br />

CAT SERIES . . . . . . . . . . . . . . . . .684<br />

CBL SERIES . . . . . . . . . . . . . . . .670<br />

CD-420 SERIES . . . . . . . . . . . . . .255<br />

CD50 SERIES . . . . . . . . . . . . . . .510<br />

CD-A . . . . . . . . . . . . . . . . . . .241, 242<br />

CI-200 . . . . . . . . . . . . . . . . . .367, 368<br />

CI-24 . . . . . . . . . . . . . . . . . . . . . . .366<br />

CLC-100 . . . . . . . . . . . . . . . . . . . .294<br />

CN SERIES . . . . . . . . . . . . .647, 648<br />

CONCEPT SERIES . . . . . . .592, 593<br />

CS1150A . . . . . . . . . . . . . . .115, 116<br />

CS1A . . . . . . . . . . . . . . . . . .115, 116<br />

CTW3 . . . . . . . . . . . . . . . . . . . . . .142<br />

CW . . . . . . . . . . . . . . . . . . . .377, 378<br />

CX-100 . . . . . . . . . . . . . . . . .367, 368<br />

CXJ SERIES . . . . . . . . . . . . . . . .766<br />

D<br />

D-3000 . . . . . . . . . . . . . . . . . . . . .505<br />

D-4000 SERIES . . . . . . . . . . . . . .505<br />

DCP-1.5-W . . . . . . . . . . . . . . . . . .611<br />

DCP-250 . . . . . . . . . . . . . . . . . . . .613<br />

DCP-524 . . . . . . . . . . . . . . . . . . . .612<br />

DCPA-1.2 . . . . . . . . . . . . . . . . . . .610<br />

DDN SERIES . . . . . . . . . . . . . . . .365<br />

DH100 SERIES . . . . . . . . . .395, 396<br />

DIGI-42 SERIES . . . . . . . . . . . . . .413<br />

DIN-3F . . . . . . . . . . . . . . . . . . . . .668<br />

DN SERIES . . . . . . . . . . . . . . . . .668<br />

DP3A . . . . . . . . . . . . . . . . . .103, 104<br />

DPA SERIES . . . . . . . . . . . .143, 144<br />

DPW-3VLV . . . . . . . . . . . . . . . . . .198<br />

DPW-692 SERIES . . . . . . . .165, 166<br />

DRS SERIES . . . . . . . . . . . . . . . .405<br />

DS-2B . . . . . . . . . . . . . . . . . .283, 284<br />

DT13 . . . . . . . . . . . . . . . . . . .339, 340<br />

DTFXL Series . . . . . . . . . . .221, 222<br />

DTK SERIES . . . . . . . . . . . . . . . .407<br />

DURADRIVE SERIES . . . . .557, 558<br />

E<br />

E100E . . . . . . . . . . . . . . . . . . . . . .605<br />

E150E . . . . . . . . . . . . . . . . . . . . . .605<br />

E300E . . . . . . . . . . . . . . . . . . . . . .605<br />

E500E . . . . . . . . . . . . . . . . . . . . . .605<br />

EASYCAL . . . . . . . . . . . . . . . . . . .92<br />

EHRH . . . . . . . . . . . . . . . . . . . . . .107<br />

EJB . . . . . . . . . . . . . . . . . . . .763, 764<br />

E-LINK . . . . . . . . . . . . . . . . . . . . .362<br />

ELP . . . . . . . . . . . . . . . . . . . .751, 752<br />

EM . . . . . . . . . . . . . . . . . . . . . . . .378<br />

EN3A . . . . . . . . . . . . . . . . . .103, 104<br />

EP3 . . . . . . . . . . . . . . . . . . . . . . . .467<br />

EPETD8S . . . . . . . . . . . . . . . . . . .758<br />

ES-1051 . . . . . . . . . . . . . . . . . . . . .50<br />

ET SERIES . . . . . . . . . . . . . . . . . .431<br />

EVSI SERIES . . . . . . . . . . . .533, 534<br />

EYM . . . . . . . . . . . . . . . . . . . . . . .767<br />

F<br />

F01 . . . . . . . . . . . . . . . . . . . . . . . .768<br />

F01A . . . . . . . . . . . . . . . . . . . . . . .768<br />

F-1000 SERIES . . . . . .690, 694, 695<br />

F2B-D . . . . . . . . . . . . . . . . . . . . . . .73<br />

A3<br />

F2N-B . . . . . . . . . . . . . . . . . . . . . . .73<br />

F2S-D . . . . . . . . . . . . . . . . . . . . . . .73<br />

F61 SERIES . . . . . . . . . . . . .231, 232<br />

F7 . . . . . . . . . . . . . . . . . . . . . . . . .291<br />

FAS-TEL . . . . . . . . . . . . . . . . . . . .403<br />

FC/FCS SERIES . . . . . . . . . . . . .581<br />

FILN05 . . . . . . . . . . . . . . . . . . . . .464<br />

FLM . . . . . . . . . . . . . . . . . . . . . . .666<br />

FLQ . . . . . . . . . . . . . . . . . . . . . . .666<br />

FS1-6 229, . . . . . . . . . . . . . . . . . .230<br />

G<br />

G2R SERIES . . . . . . . . . . . .623, 624<br />

G7L SERIES . . . . . . . . . . . . . . . .643<br />

GBB . . . . . . . . . . . . . . . . . . .489, 490<br />

GCA SERIES . . . . . . . . . . . .491, 492<br />

GDE . . . . . . . . . . . . . . . . . . .489, 490<br />

GEB . . . . . . . . . . . . . . . . . . .489, 490<br />

GF . . . . . . . . . . . . . . . . . . . . . . . .666<br />

GIB SERIES . . . . . . . . . . . . .489, 490<br />

GLB . . . . . . . . . . . . . . . . . . .489, 490<br />

GM SERIES . . . . . . . . . . . . .497, 498<br />

GMA . . . . . . . . . . . . . . . . . . .491, 492<br />

GMD20 . . . . . . . . . . . . . . . . .245, 246<br />

GMT SERIES . . . . . . . . . . . .253, 254<br />

GMT XP SERIES . . . . . . . . . .745, 746<br />

GMT200 SERIES . . . . . . . . .245, 246<br />

GMW21 . . . . . . . . . . . . . . . .245, 246<br />

GRT . . . . . . . . . . . . . . . . . . . . . . .767<br />

GUBB SERIES . . . . . . . . . . .763, 764<br />

H<br />

H_10K SERIES . . . . . . . . . . . . . . .80<br />

H_1K SERIES . . . . . . . . . . . . . . . .90<br />

H_30K SERIES . . . . . . . . . . . . . . .82<br />

H_31K SERIES . . . . . . . . . . . .83, 84<br />

H08 SERIES . . . . . . . . . . . . . . . . .296<br />

H3B SERIES . . . . . . . . . . . . . . . .737<br />

HC SERIES . . . . . . . . . . . . . . . . .582<br />

HC-101 . . . . . . . . . . . . . . . . . . . . . .76<br />

HC-201 . . . . . . . . . . . . . . . . . . . . . .76<br />

HCT-859-B . . . . . . . . . . . . . . . . . . .59<br />

HCT-881 . . . . . . . . . . . . . . . . . . . .733<br />

HD1K . . . . . . . . . . . . . . . . . . . . . . .89<br />

HD20K . . . . . . . . . . . . . . . . . . .87, 88<br />

HD30K . . . . . . . . . . . . . . . . . . . . . .81<br />

HF20K . . . . . . . . . . . . . . . . . . .85, 86<br />

HGM300 . . . . . . . . . . . . . . . .261, 262<br />

HGM-SZ . . . . . . . . . . . . . . . . . . . .263<br />

HHT2-D . . . . . . . . . . . . . . . . . . . . . .99<br />

HHT2-O . . . . . . . . . . . . . . . . . . . . .99<br />

HHT2-S . . . . . . . . . . . . . . . . . . . . .99<br />

HL600 . . . . . . . . . . . . . . . . . . . . . .742<br />

HM_ 60 . . . . . . . . . . . . . . . . . . . . . .98<br />

HM_ 70 . . . . . . . . . . . . . . . . . . . . . .98

MODEL / SERIES NUMBER INDEX<br />

Model / Series No. Page Model / Series No. Page Model / Series No. Page<br />

HM34 . . . . . . . . . . . . . . . . . . . . . .298<br />

HMW 60 . . . . . . . . . . . . . . . . . . . . .97<br />

HMW 70 . . . . . . . . . . . . . . . . . . . . .97<br />

HO20K . . . . . . . . . . . . . . . . . . .87, 88<br />

HRK . . . . . . . . . . . . . . . . . . . . . . .666<br />

HSP-121BT1RU . . . . . . . . . . . . . .403<br />

HT2D . . . . . . . . . . . . . . . . . . . . . .100<br />

HT2O . . . . . . . . . . . . . . . . . . . . . .100<br />

HT2S . . . . . . . . . . . . . . . . . . . . . .100<br />

HT829 . . . . . . . . . . . . . . . . . .101, 102<br />

HT839 . . . . . . . . . . . . . . . . . .101, 102<br />

HT880 . . . . . . . . . . . . . . . . . .735, 736<br />

HTP . . . . . . . . . . . . . . . . . . . . . . . .733<br />

HW10K . . . . . . . . . . . . . . . . . . . . . .79<br />

HW20K . . . . . . . . . . . . . . . . . . .85, 86<br />

HW-76B . . . . . . . . . . . . . . . . . . . .670<br />

HZLIM SERIES . . . . . . . . . .755, 756<br />

I<br />

ISPL-1 . . . . . . . . . . . . . . . . . . . . . . .48<br />

ISPR2 SERIES . . . . . . . . . . .743, 744<br />

IXLdp . . . . . . . . . . . . . . . . . .739, 740<br />

J<br />

JMP SERIES . . . . . . . . . . . . . . . .291<br />

K<br />

K1 SERIES . . . . . . . . . . . . . . . . . .741<br />

K235 . . . . . . . . . . . . . . . . . . . . . . .666<br />

K-332 . . . . . . . . . . . . . . . . . . . . . .464<br />

K-337 . . . . . . . . . . . . . . . . . . . . . .463<br />

K-339 . . . . . . . . . . . . . . . . . . . . . .463<br />

K-383 . . . . . . . . . . . . . . . . . . . . . .463<br />

K-384 . . . . . . . . . . . . . . . . . . . . . .463<br />

K-387 . . . . . . . . . . . . . . . . . . . . . .463<br />

KA-175 SERIES . . . . . . . . . .475, 476<br />

KA-35 SERIES . . . . . . . . . . .473, 474<br />

KAS-175 . . . . . . . . . . . . . . . . . . . .478<br />

KAS-44 SERIES . . . . . . . . . . . . .477<br />

KAS-88 . . . . . . . . . . . . . . . . . . . . .478<br />

KBV SERIES 571, 572, 573, 574, 575,<br />

576<br />

KCO SERIES . . . . . . . . . . . .233, 234<br />

KE375 . . . . . . . . . . . . . . . . . .645, 646<br />

KE900 SERIES . . . . . . . . . .645, 646<br />

KEL71/120 . . . . . . . . . . . . . . . . . .412<br />

KEL72/120 . . . . . . . . . . . . . . . . . .412<br />

KHD . . . . . . . . . . . . . . . . . . . . .77, 78<br />

KHO . . . . . . . . . . . . . . . . . . . . .77, 78<br />

KHR . . . . . . . . . . . . . . . . . . . . .77, 78<br />

KIP SERIES . . . . . . . . . . . . . . . . .202<br />

KLK . . . . . . . . . . . . . . . . . . . . . . .666<br />

KMS SERIES . . . . . . . . . . . . . . . .201<br />

KT-1 . . . . . . . . . . . . . . . . . . . . . . . .48<br />

KT600 . . . . . . . . . . . . . . . . . .423, 424<br />

KTD . . . . . . . . . . . . . . . . . . . . .29, 30<br />

KTEC . . . . . . . . . . . . . . . . . .425, 426<br />

KTO . . . . . . . . . . . . . . . . . . . . .29, 30<br />

KTR* . . . . . . . . . . . . . . . . . . . . .27, 28<br />

KTW . . . . . . . . . . . . . . . . . . . . .29, 30<br />

KV . . . . . . . . . . . . . . . . . . . . . . . .226<br />

KVA-24-NO/NC . . . . . . . . . . . . . .527<br />

KVC SERIES . . . . . . . .513, 517, 518<br />

KVS . . . . . . . . . . . . . . . . . . . . . . .226<br />

KZ SERIES . . . . . . . . .511, 512, †514<br />

L<br />

L4000 SERIES . . . . . . . . . . . . . . .678<br />

L4-CN . . . . . . . . . . . . . . . . . . . . . .753<br />

LD1-24 . . . . . . . . . . . . . . . . . . . . .289<br />

LF . . . . . . . . . . . . . . . . . . . . .499, 500<br />

L-KIT . . . . . . . . . . . . . . . . . . . . . .363<br />

LM . . . . . . . . . . . . . . . . . . . .497, 498<br />

LP-2800 SERIES . . . . . . . . . . . . .361<br />

LP-3500 SERIES . . . . . . . . . .359, 360<br />

LPI-1C . . . . . . . . . . . . . . . . . . . . .303<br />

LPI-1C-A, -G, -R . . . . . . . . . . . . . .304<br />

LPI-3C . . . . . . . . . . . . . . . . . . . . .305<br />

LPI-3C-A, -G, -R . . . . . . . . . . . . . .305<br />

LPI-4 . . . . . . . . . . . . . . . . . . . . . . .306<br />

LPI-5 . . . . . . . . . . . . . . . . . . . . . . .307<br />

LPI-5R . . . . . . . . . . . . . . . . . . . . .307<br />

LP-KIT . . . . . . . . . . . . . . . . . . . . .363<br />

LP-PK . . . . . . . . . . . . . . . . . . . . . .364<br />

LS45M91B11 . . . . . . . . . . . . . . . .270<br />

LU SERIES . . . . . . . . . . . . . .285, 286<br />

LVM . . . . . . . . . . . . . . . . . . .133, 134<br />

LY . . . . . . . . . . . . . . . . . . . . .623, 624<br />

M<br />

M SERIES FITINGS . . . . . . .694, 695<br />

M10/16SFL . . . . . . . . . . . . . . . . . .658<br />

M100 SERIES . . . . . . . . . . .503, 504<br />

M230 SERIES . . . . . . . . . . .167, 168<br />

M230-3VLV . . . . . . . . . . . . . . . . . .198<br />

M-2500 . . . . . . . . . . . . . . . . . . . . . .50<br />

M264 . . . . . . . . . . . . . . . . . . .145, 146<br />

M267MR . . . . . . . . . . . . . . . .157, 158<br />

M30/40 . . . . . . . . . . . . . . . . .149, 150<br />

M4/6 . . . . . . . . . . . . . . . . . . . . . . .657<br />

M4/6SNT . . . . . . . . . . . . . . . . . . .658<br />

M4/8SF . . . . . . . . . . . . . . . . . . . . .658<br />

M4000 . . . . . . . . . . . . . . . . . .501, 502<br />

M6/8 . . . . . . . . . . . . . . . . . . . . . . .657<br />

M6000 . . . . . . . . . . . . . . . . . .501, 502<br />

M7000 . . . . . . . . . . . . . . . . . .501, 502<br />

M8000 . . . . . . . . . . . . . . . . . .501, 502<br />

M9000 SERIES . . . . . . . . . .501, 502<br />

M9000-200 . . . . . . . . . . . . . . . . . .295<br />

A4<br />

M9100 SERIES . . . . . . . . . .479, 480<br />

M9200 SERIES . . . . . . . . . .481, 482<br />

MA6 . . . . . . . . . . . . . . . . . . . . . . .760<br />

MK . . . . . . . . . . . . . . . . . . . .623, 624<br />

MK-3000 . . . . . . . . . . . . . . . . . . . .506<br />

MK-7100 SERIES . . . . . . . . . . . .506<br />

MK7-B SERIES . . . . . . . . . .373, 374<br />

ML SERIES . . . . . . . . . . . . . . . . .545<br />

ML SERIES DCA . . . . . . . . .483, 484<br />

MOB-4 . . . . . . . . . . . . . . . . .409, 410<br />

MOB-8 . . . . . . . . . . . . . . . . . .409, 410<br />

MP6 SERIES . . . . . . . . . . . . . . . .760<br />

MP8000 SERIES . . . . . . . . .563, 564<br />

MPA-2 . . . . . . . . . . . . . . . . . . . . . .136<br />

MPM SERIES . . . . . . . . . . . . . . . .152<br />

MR . . . . . . . . . . . . . . . . . . . .159, 160<br />

MR SERIES . . . . . . . . . . . . .641, 642<br />

MR-604/T . . . . . . . . . . . . . . .409, 410<br />

MR-608/T . . . . . . . . . . . . . . .409, 410<br />

MRH SERIES . . . . . . . . . . . . . .91, 92<br />

MS SERIES . . . . . . . . . . . . . . . . .393<br />

MTL5000 SERIES 769, 770, 771, 772<br />

MTL7000 . . . . . . .769, 770, 771, 772<br />

MX40-6 SERIES . . . . . . . . . .493, 494<br />

MX40-7 SERIES . . . . . . . . . .495, 496<br />

MX8001 . . . . . . . . . . . . . . . . . . . .431<br />

N<br />

N SERIES . . . . . . . . . . . . . . . . . . .590<br />

NEMA 1 LARGE . . . . . . . . . . . . .586<br />

NEMA 1 MEDIUM . . . . . . . . . . . .585<br />

NEMA 1 SMALL . . . . . . . . . . . . . .584<br />

NEMA 12 . . . . . . . . . . . . . . . . . . .591<br />

NEMA 3R . . . . . . . . . . . . . . . . . . .587<br />

NEMA 4 . . . . . . . . . . . . . . . . . . . .588<br />

NEMA 4X . . . . . . . . . . . . . . . . . . .589<br />

NF . . . . . . . . . . . . . . . . . . . . .499, 500<br />

NG2DW1500B . . . . . . . . . . . . . . .290<br />

NM . . . . . . . . . . . . . . . . . . . .497, 498<br />

NVF SERIES . . . . . . . . . . . .547, 548<br />

NVS ERIES . . . . . . . . . . . . .549, 550<br />

O<br />

OS-1 . . . . . . . . . . . . . . . . . . .251, 252<br />

OSA . . . . . . . . . . . . . . . . . . . . .61, 62<br />

OSA* . . . . . . . . . . . . . . . . . . . . . . .32<br />

P<br />

P SERIES . . . . . . . . . . . . . . . . . . .668<br />

P10 SERIES . . . . . . . . . . . . . . . . .192<br />

P2RF SERIES . . . . . . . . . . .625, 626<br />

P32 SERIES . . . . . . . . . . . . . . . . .186<br />

P352 . . . . . . . . . . .449, 450, 451, 452<br />

P51 SERIES . . . . . . . . . . . . .173, 174<br />

P74 . . . . . . . . . . . . . . . . . . . . . . . .191

MODEL / SERIES NUMBER INDEX<br />

Model / Series No. Page Model / Series No. Page Model / Series No. Page<br />

PAM-1 . . . . . . . . . . . . . . . . . . . . . .640<br />

PAM-4 . . . . . . . . . . . . . . . . . . . . . .640<br />

PC642C . . . . . . . . . . . . . . . . . . . .404<br />

PCM SERIES . . . . . . . . . . . .163, 164<br />

PDK . . . . . . . . . . . . . . . . . . . . . . .671<br />

PERF PANEL . . . . . . . . . . . . . . . .580<br />

PF . . . . . . . . . . . . . . . . . . . . .625, 626<br />

PG SERIES . . . . . . . . . . . . . . . . .197<br />

PIL-1 . . . . . . . . . . . . . . . . . . .387, 388<br />

PIL-2 . . . . . . . . . . . . . . . . . . . . . . .632<br />

PLG50 SERIES . . . . . . . . . . . . . .767<br />

PN . . . . . . . . . . . . . . . . . . . . .377, 378<br />

PN-10 . . . . . . . . . . . . . . . . . . . . . . .49<br />

PN-26 . . . . . . . . . . . . . . . . . . . . . . .49<br />

PN-46 . . . . . . . . . . . . . . . . . . . . . . .49<br />

PQ-1001 . . . . . . . . . . . . . . . .271, 272<br />

PRK . . . . . . . . . . . . . . . . . . . . . . .671<br />

PS SERIES . . . . . . . . . . . . . . . . .597<br />

PS5R SERIES . . . . . . . . . . .615, 616<br />

PSM SERIES . . . . . . . . . . . . . . . .618<br />

PSR-1 . . . . . . . . . . . . . . . . . .375, 376<br />

PSR-1-T . . . . . . . . . . . . . . . .375, 376<br />

PSS2 SERIES . . . . . . . . . . .177, 178<br />

PT . . . . . . . . . . . . . . . . . . . . . . . . .200<br />

PT-9000 SERIES .137, 138, 139, 140<br />

PTF . . . . . . . . . . . . . . . . . . . .625, 626<br />

PT-NT4-M . . . . . . . . . . . . . . . . . . .141<br />

PT-NT4-N2 . . . . . . . . . . . . . . . . . .141<br />

PT-NTL-10 . . . . . . . . . . . . . . . . . .141<br />

PTX1 SERIES . . . . . . . . . . .179, 180<br />

PV600 . . . . . . . . . . . . . . . . . . . . . .463<br />

PVI-1 . . . . . . . . . . . . . . . . . . .171, 172<br />

PVI-2 . . . . . . . . . . . . . . . . . . .171, 172<br />

PVM . . . . . . . . . . . . . . . . . . .133, 134<br />

PW2 . . . . . . . . . . . . . . . . . . . . . . .617<br />

PWA SERIES . . . .331, 332, 333, 334<br />

PXZ4 . . . . . . . . . . .343, 344, 455, 456<br />

Q<br />

Q674 . . . . . . . . . . . . . . . . . . .427, 428<br />

QZ SERIES . . . . . . . . . . . . . . . . .672<br />

R<br />

R353 SERIES . . . .449, 450, 451, 452<br />

R-3710 . . . . . . . . . . . . . . . . . . . . .690<br />

R-3710 SERIES . . . . . . . . . . . . . .690<br />

RAD-1 . . . . . . . . . . . . . . . . . . . . .301<br />

RCB-8 . . . . . . . . . . . . . . . . . .385, 386<br />

RCD40 . . . . . . . . . . . . . . . . . . . . .510<br />

RDI-2 . . . . . . . . . . . . . . . . . .707, 708<br />

RDM800 . . . . . . . . . . . . . . . . . . . .264<br />

RDO-2 . . . . . . . . . . . . . . . . .711, 712<br />

RES-1 . . . . . . . . . .327, 328, 329, 330<br />

RET SERIES . . . . . . . . . . . . . . . .579<br />

RFS-4001 . . . . . . . . . . . . . . . . . . .185<br />

RH . . . . . . . . . . . . . . . . . . . .619, 620<br />

RH2LB SERIES . . . . . . . . . . . . . .631<br />

RH-3 . . . . . . . . . . . . . . . . . . .181, 182<br />

RH-3-2 . . . . . . . . . . . . . . . . .181, 182<br />

RI-4 . . . . . . . . . . . . . . . . . . . .709, 710<br />

RI-4-K4 . . . . . . . . . . . . . . . . .717, 718<br />

RIB . . . . . . . . . . . .633, 634, 635, 636<br />

RIB M SERIES . . . . . . . . . . .637, 638<br />

RIB TR SERIES . . . . . . . . . .607, 608<br />

RIB01BDC . . . . . . . . . . . . . . . . . .639<br />

RIB01SBDC . . . . . . . . . . . . . . . . .639<br />

RIB02BDC . . . . . . . . . . . . . . . . . .639<br />

RIB02SBDC . . . . . . . . . . . . . . . . .639<br />

RIB21CDC . . . . . . . . . . . . . . . . . .639<br />

RIBT PILOT SERIES . . . . . .633, 634<br />

RIBT POWER SERIES . . . . .635, 636<br />

RIBX SERIES . . . . . . . . . . . .117, 118<br />

RIBXG . . . . . . . . . . . . . . . . . . . . .114<br />

RIBXK SERIES . . . . . . . . . . . . . .114<br />

RIBX-V SERIES . . . . . . . . . .119, 120<br />

RJ . . . . . . . . . . . . . . . . . . . . . . . . .590<br />

RL . . . . . . . . . . . . . . . . . . . . . . . . .109<br />

RLD-134A . . . . . . . . . . . . . .267, 268<br />

RLD-5 . . . . . . . . . . . . . . . . . .265, 266<br />

RO-4 . . . . . . . . . . . . . . . . . . .713, 714<br />

RPM-1 . . . . . . . . . . . . . . . . . .161, 162<br />

RPS . . . . . . . . . . . . . . . . . . . . . . .194<br />

RPT-K . . . . . . . . . . . . . . . . . .721, 722<br />

RR . . . . . . . . . . . . . . . . . . . .715, 716<br />

RR SERIES . . . . . . . . . . . . .619, 620<br />

RR-7 . . . . . . . . . . . . . . . . . . .383, 384<br />

RR-9 . . . . . . . . . . . . . . . . . . .383, 384<br />

RSSDN . . . . . . . . . . . . . . . . .649, 650<br />

RST-K . . . . . . . . . . . . . . . . . .719, 720<br />

RTC-2P . . . . . . . . . . . . . . . . .441, 442<br />

RTE SERIES . . . . . . . . . . . .653, 654<br />

RT-R . . . . . . . . . . . . . . . . . . .701, 702<br />

RT-R-K . . . . . . . . . . . . . . . . .717, 718<br />

RT-S . . . . . . . . . . . . . . . . . . .705, 706<br />

RT-U . . . . . . . . . . . . . . . . . . .703, 704<br />

RT-U-K . . . . . . . . . . . . . . . . . . . . .717<br />

RUT-G . . . . . . . . . .723, 724, 725, 726<br />

S<br />

S SERIES ACTUATORS . . .487, 488<br />

S SERIES FITTINGS . . . . . . . . . .696<br />

S101144 . . . . . . . . . . . . . . . . . . . . .70<br />

S-120/277/347E-P . . . . . . . .371, 372<br />

S15 . . . . . . . . . . . . . . . . . . . .525, 526<br />

S241HC . . . . . . . . . . . . . . . . . . . . .69<br />

S469 . . . . . . . . . . . . . . . . . . . . . . . .70<br />

S60 . . . . . . . . . . . . . . . . . . . .525, 526<br />

SAK4 . . . . . . . . . . . . . . . . . . . . . .659<br />

SAK6 . . . . . . . . . . . . . . . . . . . . . .659<br />

A5<br />

SC SERIES ENCLOSURES . . . . .583<br />

SC SERIES HORNS . . . . . . . . . . .672<br />

SCS1.5A . . . . . . . . . . . . . . . .115, 116<br />

SCS1150A . . . . . . . . . . . . . .115, 116<br />

SCT SERIES . . . . . . . . . . . . . . . .113<br />

SD-01 . . . . . . . . . . . . . . . . . . . . . .194<br />

SD-1300 SERIES . . . . . . . . . . . . .509<br />

SD-6 . . . . . . . . . . . . . . . . . . . . . . . .49<br />

SDI SERIES . . . . . . . . . . . . . . . . .212<br />

SENTRY 100 SERIES . . . . . . . . .125<br />

SENTRY 200 SERIES . . . . . . . . .126<br />

SENTRY 200-A SERIES . . . . . . .127<br />

SH . . . . . . . . . . . . . . . . . . . . .621, 622<br />

SH17 SERIES . . . . . . . . . . . . . . .381<br />

SLS SERIES . . . . . . . . . . . . . . . .614<br />

SM-501 SERIES . . . . . . . . . .391, 392<br />

SR SERIES . . . . . . . . . . . . .621, 622<br />

SS SERIES . . . . . . . . . . . . . .379, 380<br />

SSPL-1 . . . . . . . . . . . . . . . . . . . . . .48<br />

SSS-1000 SERIES . . . . . . . . . . . .205<br />

ST120 SERIES . . . . . . . . . . . . . . .676<br />

ST20 . . . . . . . . . . . . . . . . . . . . . . .297<br />

ST-A . . . . . . . . . . . . . . . . . . . . . . . .13<br />

ST-A* . . . . . . . . . . . . . . . . . . . . . . .14<br />

ST-AV81H . . . . . . . . . . . . . . . . . . . .40<br />

ST-AV81R . . . . . . . . . . . . . . . . .41, 42<br />

ST-AV85H . . . . . . . . . . . . . . . . . . . .40<br />

ST-AV85R . . . . . . . . . . . . . . . . .41, 42<br />

ST-AV91H . . . . . . . . . . . . . . . . . . . .39<br />

ST-AV91R . . . . . . . . . . . . . . . . .41, 42<br />

STB, STB-H . . . . . . . . . . . . . . . . .675<br />

ST-D . . . . . . . . . . . . . . . . . . . . . . . .15<br />

ST-D* . . . . . . . . . . . . . . . . . . . . . . .16<br />

ST-FZ . . . . . . . . . . . . . . . . . . . .17, 18<br />

ST-O . . . . . . . . . . . . . . . . . . . . .21, 22<br />

ST-R* . . . . . . . . . . . . . . . . . . . . . . .26<br />

ST-R*S . . . . . . . . . . . . . . . . . . . . . .24<br />

ST-R*SC . . . . . . . . . . . . . . . . . . . . .24<br />

ST-R� . . . . . . . . . . . . . . . . . . . . . . .25<br />

ST-R�R . . . . . . . . . . . . . . . . . . . . . .25<br />

ST-R�S . . . . . . . . . . . . . . . . . . . . . .23<br />

ST-R�SC . . . . . . . . . . . . . . . . . . . . .23<br />

ST-S . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

ST-S* . . . . . . . . . . . . . . . . . . . . . . .10<br />

ST-S*E . . . . . . . . . . . . . . . . . . . . .3, 4<br />

ST-S*EW . . . . . . . . . . . . . . . . . .2, 3, 4<br />

ST-S*K . . . . . . . . . . . . . . . . . . . . .5, 6<br />

ST-S*P . . . . . . . . . . . . . . . . . . . . .7, 8<br />

ST-S�E . . . . . . . . . . . . . . . . . . . . . . .2<br />

ST-T90EW . . . . . . . . . . . . . . . .51, 52<br />

ST-T90K . . . . . . . . . . . . . . . . . .51, 52<br />

ST-T91E . . . . . . . . . . . . . . . . . .53, 54<br />

ST-T91K . . . . . . . . . . . . . . . . . .53, 54<br />

ST-U . . . . . . . . . . . . . . . . . . . . . . . .11<br />

ST-W . . . . . . . . . . . . . . . . . . . . .19, 20

MODEL / SERIES NUMBER INDEX<br />

Model / Series No. Page Model / Series No. Page Model / Series No. Page<br />

ST-X . . . . . . . . . . . . . . . . . . . . . . .730<br />

T<br />

T1 SERIES . . . . . . . . . . . . . . . . . .667<br />

T-100 SERIES . . . . . . . . . . .687, 688<br />

T-1000 . . . . . . . . . . . . . . . . . . . . .325<br />

T-141 . . . . . . . . . . . . . . . . . . .687, 688<br />

T155 . . . . . . . . . . . . . . . . . . .437, 438<br />

T158 . . . . . . . . . . . . . . . . . . . . . . .439<br />

T167 . . . . . . . . . . . . . . . . . . .437, 438<br />

T168 . . . . . . . . . . . . . . . . . . . . . . .440<br />

T168 SERIES . . . . . . . . . . . . . . . .439<br />

T170 . . . . . . . . . . . . . . . . . . .435, 436<br />

T25 . . . . . . . . . . . . . . . . . . . .433, 434<br />

T26 . . . . . . . . . . . . . . . . . . . .433, 434<br />

T30/40 SERIES . . . . . . . . . .149, 150<br />

T4000 SERIES . . . . . . . . . . .457, 458<br />

T46 . . . . . . . . . . . . . . . . . . . .433, 434<br />

T5U . . . . . . . . . . . . . . . . . . . . . . . . .58<br />

T6051B1006 . . . . . . . . . . . . . . . . .758<br />

T63U . . . . . . . . . . . . . . . . . . . . . . . .58<br />

T6570 . . . . . . . . . . . . . . . . . . . . . .429<br />

T6575 . . . . . . . . . . . . . . . . . . . . . .430<br />

T6984 . . . . . . . . . . . . . . . . . .443, 444<br />

T7300F2010 . . . . . . . . . . . . .419, 420<br />

T7984 . . . . . . . . . . . . . . . . . .445, 446<br />

T81U . . . . . . . . . . . . . . . . . . . . . . . .57<br />

T8570 SERIES . . . . . . . . . . . . . . .429<br />

T8575 SERIES . . . . . . . . . . . . . . .430<br />

T85U . . . . . . . . . . . . . . . . . . . . . . . .58<br />

T874 . . . . . . . . . . . . . . . . . . .427, 428<br />

T90U . . . . . . . . . . . . . . . . . . . . .51, 52<br />

T91H . . . . . . . . . . . . . . . . . . . . .55, 56<br />

T91L . . . . . . . . . . . . . . . . . . . . .55, 56<br />

T91U . . . . . . . . . . . . . . . . . . . . .55, 56<br />

TB . . . . . . . . . . . . . . . . . . . . .377, 378<br />

TB8220 . . . . . . . . . . . . . . . . .421, 422<br />

TC-100 . . . . . . . . . . . . . . . . . . . . .397<br />

TC-105 . . . . . . . . . . . . . . . . . . . . .397<br />

TC-1100 SERIES . . . . . . . . . . . . .432<br />

TCC-111 . . . . . . . . . . . . . . . . . . . . .49<br />

TCC-12 . . . . . . . . . . . . . . . . . . . . . .49<br />

TDRSOXP . . . . . . . . . . . . . .655, 656<br />

TDRSRXP . . . . . . . . . . . . . .655, 656<br />

TE-6300 . . . . . . . . . . . . . . . . . . . . .68<br />

TE-63xx . . . . . . . . . . . . . . . . . . . . .67<br />

TF142 . . . . . . . . . . . . . . . . . .399, 400<br />

TG500 . . . . . . . . . . . . . . . . . . . . .414<br />

TH8000 . . . . . . . . . . . . . . . . .421, 422<br />

THERA SERIES . . . . . . . . . . . . . .528<br />

TK-1000 . . . . . . . . . . . . . . . .459, 460<br />

TK-5000 SERIES . . . . . . . . . . . . .459<br />

TL . . . . . . . . . . . . . . . . . . . . .377, 378<br />

TM99A . . . . . . . . . . . . . . . . . . . . .297<br />

TP1-M . . . . . . . . . . . . . . . . . .235, 236<br />

T-PB SERIES . . . . . . . . . . . . . . . .609<br />

TR SERIES . . . . . . . . . . . . . .389, 390<br />

TR10K . . . . . . . . . . . . . . . . . . . . . .50<br />

TRANSZORB . . . . . . . . . . . . . . . .408<br />

TS SERIES . . . . . . . . . . . . . . . . . .664<br />

TS-200 SERIES . . . . . . . . . . . . . .411<br />

TS-200 SERIES . . . . . . . . . . . . . .382<br />

TS-470 SERIES . . . . . . . . . . . . . .269<br />

TSA . . . . . . . . . . . . . . . . . . .399, 400<br />

TT111H-0800 . . . . . . . . . . . . . . . . .69<br />

TT211 . . . . . . . . . . . . . . . . . .731, 732<br />

TT-801 . . . . . . . . . . . . . . . . . . .63, 64<br />

TT-807 . . . . . . . . . . . . . . . . . . .63, 64<br />

TT-809 . . . . . . . . . . . . . . . . . . .65, 66<br />

TT859 . . . . . . . . . . . . . . . . . . . . . . .60<br />

TT881 . . . . . . . . . . . . . . . . . .733, 734<br />

TWS SERIES . . . . . . . . . . . . . . . .673<br />

TY7321A1009 . . . . . . . . . . . . .71, 72<br />

U<br />

U3889 . . . . . . . . . . . . . . . . . . . . . .135<br />

UAT-1 . . . . . . . . . . . . . . . . . .335, 336<br />

UAT-2 . . . . . . . . . . . . . . . . . .335, 336<br />

UCK . . . . . . . . . . . . . . . . . . . . . . .292<br />

UCM-420A . . . . . . . . . . . . . .453, 454<br />

UCM-420A . . . . . . . . . . . . . .345, 346<br />

UCO-44 . . . . . . . . . . . . . . . .319, 320<br />

UCO-44T OPTION . . . . . . . .319, 320<br />

UCP-242 . . . . . . . . . . . . . . . .311, 312<br />

UCP-322 . . . . . . . . . . . . . . . .313, 314<br />

UCP-422 . . . . . . . . . . . . . . . .315, 316<br />

UCP-522 . . . . . . . .321, 322, 323, 324<br />

UCP-622 . . . . . . . .321, 322, 323, 324<br />

UCS-121 . . . . . . . . . . . . . . . .347, 348<br />

UCS-221 . . . . . . . . . . . . . . . .349, 350<br />

UCS-421 . . . . . . . . . . . . . . . .351, 352<br />

UCS-621 . . . . . . . . . . . . . . . .353, 354<br />

UFT-1 . . . . . . . . . . . . . . . . . .219, 220<br />

UMM-1 . . . . . . . . . . . . . . . . .341, 342<br />

UMM-2 . . . . . . . . . . . . . . . . .341, 342<br />

UMX-4 . . . . . . . . . .355, 356, 357, 358<br />

UMX-8 . . . . . . . . . .355, 356, 357, 358<br />

US* . . . . . . . . . . . . . . . . . . . . . . . . .32<br />

US� . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

V<br />

V SERIES 565, 566, 567, 568, 569, 570<br />

V11 SERIES . . . . . . . . . . . . .465, 466<br />

V200, V300 . . . . . .513, 514, 515, 516<br />

V-3000 . . . . . . . . . . . . . . . . .563, 564<br />

V5011 . . . . . . . . . . . . . . . . . .541, 542<br />

V5013 SERIES . . . . . . . . . . .541, 542<br />

V5860 SERIES . . . . . . . . . . .523, 524<br />

VA301C . . . . . . . . . . . . . . . .259, 260<br />

VA301EM . . . . . . . . . . . . . . .257, 258<br />

A6<br />

VA-7000 SERIES . . . . . . . . .561, 562<br />

VASQN8X . . . . . . . . . . . . . . . . . . .256<br />

VB SERIES .551, 552, 553, 554, 555,<br />

556<br />

VB2 . . . . . . . . . . . . . . . . . . . .535, 536<br />

VB3 SERIES . . . . . . . . . . . .535, 536<br />

V-BAR 700 . . . . . . . . . . . . . . . . . .225<br />

VD-1300 SERIES . . . . . . . . .507, 508<br />

VERSA-CAB . . . . . . . . . . . . . . . .594<br />

VG1000 SERIES . . . . . . . . .537, 538<br />

VG7000 SERIES . . . . . . . . .559, 560<br />

VGF SERIES . . . . . . . . . . . . .543, 544<br />

VM SERIES . . . . . . . . . . . . .521, 522<br />

VPI SERIES . . . . . . . . . . . . . . . . .308<br />

VT SERIES . . . . . . . . . . . . . .519, 520<br />

VTI . . . . . . . . . . . . . . . . . . . .337, 338<br />

W<br />

W30 SERIES . . . . . . . . . . . .169, 170<br />

W30-3VLV . . . . . . . . . . . . . . . . . .198<br />

W351 . . . . . . . . . .449, 450, 451, 452<br />

W92S SERIES . . . . . . . . . . . . . . .644<br />

W9AS . . . . . . . . . . . . . . . . . . . . . .644<br />

WB . . . . . . . . . . . . . . . . . . . . . . . . .74<br />

WB3A . . . . . . . . . . . . . . . . . . . . . .103<br />

WB3A SERIES . . . . . . . . . . . . . . .104<br />

WCO-1B . . . . . . . . . . . . . . . .237, 238<br />

WD-1B . . . . . . . . . . . . . . . . . . . . .287<br />

WD-2-T . . . . . . . . . . . . . . . . . . . . .288<br />

WEL-B . . . . . . . . . . . . . . . . . . . . . .73<br />

WEL-S . . . . . . . . . . . . . . . . . . . . . .73<br />

WMB-1 . . . . . . . . . . . . . . . . . . . . . .50<br />

WMB-2 . . . . . . . . . . . . . . . . . . . . . .50<br />

WPS SERIES . . . . . . . . . . . . . . . .677<br />

WS . . . . . . . . . . . . . . . . . . . . . . . . .74<br />

WS SERIES . . . . . . . . . . . . .369, 370<br />

X<br />

XLdp SERIES . . . . . . . . . . .147, 148<br />

Y<br />

Y63 . . . . . . . . . . . . . . . . . . . . . . . .604<br />

Y65 . . . . . . . . . . . . . . . . . . . . . . . .604<br />

Y66 . . . . . . . . . . . . . . . . . . . . . . . .604<br />

Z<br />

ZGR01 . . . . . . . . . . . . . . . . . . . . . .50<br />

ZPS SERIES . . . . . . . . . . . .155, 156<br />

ZS-260 . . . . . . . . . . . . . . . . . . . . .759

TEMPERATURE

PRODUCTS<br />

Check out the NEW<br />

ACI Series BAS/HVAC<br />

Temperature Sensor on<br />

page 33!<br />

Executive<br />

Space<br />

Surface-Mount<br />

Space<br />

Stainless Steel<br />

Flush<br />

TEMPERATURE<br />

10,000<br />

2252<br />

ST-S3E ST-S21E<br />

S85E ST-S91E<br />

ST-S3P ST-S21<br />

S85P ST-S91<br />

ST-S3 ST-S2<br />

ST-S91<br />

SERVICES<br />

See our helpful Sensor<br />

Resistance Chart on<br />

page 1!<br />

ST-<br />

SOLUTIONS<br />

We offer the variety of<br />

temperature products you<br />

need to meet most temperature<br />

sensing applications.<br />

MODEL/SERIES PAGE<br />

Sensor Selection Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<br />

THERMISTORS AND RTD SENSORS<br />

ACI Series — Room, Duct, OSA, Immersion Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33<br />

AS — Platinum RTD Temerparture Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61<br />

BAPI Series — Room, Duct, OSA, Immersion Sensors and Transmitters . . . . . . . . . .35, 37<br />

KTR* — Low Cost Decorator Room Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . .27<br />

KTD*, KTO*, KTW* — Low Cost Duct, Immersion, OSA Sensors . . . . . . . . . . . . . . . . . . . .29<br />

S101144, S469 — Thermal Ribbon RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70<br />

S241HC — High Temperature Smoke Stack and Boiler RTD Probes . . . . . . . . . . . . . . . . .69<br />

ST-A* — All-Purpose Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13<br />

ST-AV*H — Flexible RTD Duct Averaging Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .39, 40<br />

ST-AV*R — Rigid RTD Duct Averaging Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41<br />

ST-D* — Duct Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15, 44<br />

ST-FZ* — Averaging Thermistor Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17<br />

ST-O* — Outdoor Air Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .21,44<br />

ST-R*/ST-R*R — Encapsulated Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . .25<br />

ST-R*S/ST-R*SC — Encapsulated Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . .23<br />

ST-S* — Stainless Steel Flush Mount Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . .9<br />

ST-S*E — Executive Decorator Zone Thermistor and RTD Sensors . . . . . . . . . . . . . . . .2,43<br />

ST-S*K — New Elegant Decorator Zone Thermistor and RTD Sensors . . . . . . . . . . . . . . . .5<br />

ST-S*P — Room Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7<br />

ST-U* — Universal Mount Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . .11, 44<br />

ST-W* — Immersion Thermistor and RTD Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .19, 44<br />

TE-6300 — Nickel Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67<br />

US* — Universal Mount Thermistor and RTD Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

RTD TRANSMITTERS<br />

OSA* — Outside Air Thermistor and RTD Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

ST-T90E — Fixed Range Room Temperature Transmitter . . . . . . . . . . . . . . . . . . . . . . . . .51<br />

ST-T91E — Room Sensor/Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53<br />

T5U, T63U, T85U — 1000� Rangeable Transmitters Balco, Nickel, Platinum . . . . . . . . . .58<br />

T81U — Rangeable Transmitter for 100� 385 Curve RTDs . . . . . . . . . . . . . . . . . . . . . . . .57<br />

T90U — Fixed Range Duct, Immmersion, OSA Temperature Transmitters . . . . . . . . . . . . .51<br />

T91 — Rangeable Transmitter for 1000� 375 Curve RTDs . . . . . . . . . . . . . . . . . . . . . . . . .55<br />

TT111 — High Temperature RTD Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69<br />

TT-801/TT-807 — Transmitters for Platinum RTDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63<br />

TT-809 — Transmitter for 1000� RTDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65<br />

TT859 — Space Temperature Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59<br />

INFRARED TRANSMITTERS<br />

TY-7321A1009 — Infrared Radiant Room Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . .71<br />

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47-50<br />

Sensor Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45-47<br />

Wells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73, 74<br />

Indicates New Products

TEMPERATURE<br />

SENSOR SELECTION CHART<br />

INSTALLATION<br />

APPLICATION<br />

Decorative<br />

space<br />

Executive<br />

space<br />

Surface-mount<br />

space<br />

Stainless steel<br />

flush<br />

Universal mount<br />

and accessories<br />

All-purpose<br />

mount<br />

Duct mount<br />

Averaging flex<br />

averaging rigid<br />

Immersion<br />

(with well)<br />

Outside air<br />

Stainless<br />

sheath<br />

Encapsulated<br />

sensor<br />

Low-cost<br />

room sensor<br />

Low-cost<br />

universal mount<br />

Low-cost plastic<br />

outside air<br />

Low-cost<br />

metal duct<br />

Low-cost<br />

metal immersion<br />

Low-cost<br />

metal OSA<br />

10,000Ω Type III<br />

2252Ω Type II<br />

3000Ω Type II<br />

THERMISTORS<br />

10,000Ω Type II<br />

100,000Ω Type II<br />

20,000Ω Type IV<br />

100Ω Platinum 385<br />

PLATINUM RTDs<br />

1000Ω Platinum 385<br />

ST-S3K ST-S21K ST-S22K ST-S24K ST-S27K ST-S42K ST-S81K ST-S85K ST-S91K<br />

ST-S3E ST-S21E ST-S22E ST-S24E ST-S27E ST-S42E ST-S81E ST-S85E ST-S91E<br />

ST-S3P ST-S21P ST-S22P ST-S24P ST-S27P ST-S42P ST-S81P ST-S85P ST-S91P<br />

ST-S3 ST-S21 ST-S22 ST-S24 ST-S27 ST-S42 ST-S81 ST-S85 ST-S91<br />

ST-U3 ST-U21 ST-U22 ST-U24 ST-U27 ST-U42 ST-U81 ST-U85 ST-U91<br />

ST-A3 ST-A21 ST-A22 ST-A24 ST-A27 ST-A42 ST-A81 ST-A85 ST-A91<br />

ST-D3 ST-D21 ST-D22 ST-D24 ST-D27 ST-D42 ST-D81 ST-D85 ST-D91<br />

ST-FZ3 ST-FZ21 ST-FZ22 ST-FZ24 ST-FZ27 ST-FZ42 ST-AV81H ST-AV85H ST-AV91H<br />

ST-AV81R ST-AV85R ST-AV91R<br />

ST-W3 ST-W21 ST-W22 ST-W24 ST-W27 ST-W42 ST-W81 ST-W85 ST-W91<br />

ST-O3 ST-O21 ST-O22 ST-O24 ST-O27 ST-O42 ST-O81 ST-O85 ST-O91<br />

ST-R3S ST-R21S ST-R22S ST-R24S ST-R27S ST-R42S ST-R81S ST-R85S ST-R91S<br />

ST-R3 ST-R21 ST-R22 ST-R24 ST-R27 ST-R42 ST-R81 ST-R85 ST-R91<br />

KT-R3R KT-R21R KT-R22R KT-R24R KT-R27R KT-R42R KT-R81R KT-R85R KT-R91R<br />

US-3 US-21 US-22 US-24 US-27 US-42 US-81 US-85 US-91<br />

OSA-3 OSA-21 OSA-22 OSA-24 OSA-27 OSA-42 OSA-81 OSA-85 OSA-91<br />

KTD3 KTD21 KTD22 KTD24 KTD27 KTD42 KTD81 KTD85 KTD91<br />

KTW3 KTW21 KTW22 KTW24 KTW27 KTW42 KTW81 KTW85 KTW91<br />

KTO3 KTO21 KTO22 KTO24 KTO27 KTO42 KTO81 KTO85 KTO91<br />

1000Ω Platinum 375<br />

SENSOR TYPE TEMPERATURE SENSOR DESCRIPTION TYPICAL SENSOR USER<br />

3 10,000Ω thermistor @ 77˚F, Type III material AET, American Automatrix, Andover, Carrier, Delta, Invensys,<br />

(Siebe), Teletrol, York<br />

21 2252Ω thermistor @77˚F, Type II material Anderson Cornelius, JCI (A319)<br />

22 3000Ω thermistor @77˚F, Type II material Alerton, ASI, ATS, Snyder General<br />

24 10,000Ω thermistor @77˚F, Type II material Alerton, Automated Logic, T.A.C. (CSI), Triangle Microsystems, <strong>Trane</strong><br />

27 100,000Ω thermistor @77˚F, Type II material Siemens (Landis and Staefa)<br />

42 20,000Ω thermistor @77˚F, Type IV material Honeywell (XL)<br />

81 100Ω platinum RTD @ 32˚F, 385 curve Transmitter available for any user<br />

85 1000Ω platinum RTD @ 32˚F, 385 curve JCI, Siemens, <strong>Trane</strong> (transmitter available for any user)<br />

91 1000Ω platinum RTD @ 32˚F, 375 curve JCI, Siemens (transmitter available for any user)<br />

5 1000Ω Balco RTD @ 70˚F Invensys (Siebe) (transmitter available for any user)<br />

1<br />

TEMPERATURE

TEMPERATURE<br />

2<br />

TEMPERATURE<br />

EXECUTIVE ROOM THERMISTOR AND RTD SENSORS<br />

ST-S*E, ST-S*EW SERIES<br />

DESCRIPTION<br />

The Precon ST-S*E and ST-S*EW Series Executive<br />

Room Sensors provide precision room temperature<br />

sensing for building automation systems. The active<br />

sensing element is made of a highly stable, precision<br />

thermistor material or platinum RTD.<br />

FEATURES<br />

• Lifetime warranty<br />

• ±0.36°F (±0.2°C) thermistor accuracy<br />

• ±1°F (±0.53°C) RTD accuracy<br />

• Wide selection of thermistor and RTD curves<br />

• Vented housing for quick temperature response<br />

• Adaptable with many options<br />

• Traditional beige or white covers<br />

• Durable plastic housing and base plate<br />

• Easy to mount to wall or back box<br />

APPLICATION<br />

The executive enclosure is designed to be wall-mounted<br />

indoors where appearance is important. The separate<br />

base plate may be mounted directly to the drywall<br />

or on a standard electrical outlet box without adapters.<br />

The cover is secured with tamper-resistant hex screws.<br />

Where moisture is a concern, the moistureproof XB<br />

option is required.<br />

SPECIFICATIONS<br />

Sensing element Thermistor (thermal resistor)<br />

RTD (resistance temperature device)<br />

Accuracy<br />

Thermistor ±0.36°F (0.2°C)<br />

RTD ±1°F (0.53°C)<br />

Sensor types available<br />

Thermistor 2.252 k, 3 k, 10 k, 20 k, 100 k�<br />

RTD Platinum 100�, 385 curve<br />

Platinum 1000�, 385 curve<br />

Platinum 1000�, 375 curve<br />

Temp range 35° to 140°F (2° to 60°C)<br />

Temp response<br />

Thermistor Negative temperature coefficient<br />

RTD Positive temperature coefficient<br />

Sensitivity See Sensor Resistance Charts<br />

in the “Technical Reference”<br />

section<br />

OPTIONS<br />

ST-S*E-XA-XME-XPL-XTD<br />

ST-S*EW<br />

• Custom logos<br />

• Setpoint adjustment (400�, 3 k�, 20 k�)<br />

• Moistureproof with 8' (2.44m) lead<br />

• Gray decorator faceplate<br />

• External communication jack<br />

• Internal RJ11 communication jack<br />

• Membrane momentary switch<br />

• Analog temperature display (ST-S3E)<br />

• Digital temperature display (ST-S3E)<br />

• NIST traceable<br />

• LED status lamp<br />

TM<br />

A Division of Kele, Inc.<br />

Stability<br />

Thermistor 0.24°F (0.13°C) over five years<br />

RTD

TEMPERATURE<br />

EXECUTIVE ROOM THERMISTOR AND RTD SENSORS<br />

ST-S*E, ST-S*EW SERIES<br />

DIMENSIONS<br />

in<br />

(cm)<br />

2.37<br />

(6.02)<br />

0.88<br />

(2.22)<br />

WIRING/OPTIONS<br />

Communication<br />

Bus Terminal<br />

For XJ<br />

Option<br />

XJ2 Internal<br />

RJ11 Jack<br />

XA Setpoint Adjust<br />

Potentiometer<br />

1.43<br />

(3.63)<br />

Cover Hooks<br />

0.75<br />

(1.90)<br />

Mounting Holes<br />

typical<br />

Board Hooks<br />

Wire-Way<br />

Hole<br />

Cover Securing Screws<br />

OUT<br />

IN<br />

P S<br />

1.87<br />

(4.76)<br />

Make electrical connections to the sensor using the terminal block provided in accordance with the installation wiring<br />

diagram for the job and with national and local electrical codes. Though the sensor itself does not require shielded cable,<br />

some controllers and microprocessors do; check with the controller supplier.<br />

LED<br />

POT<br />

SENSOR<br />

+<br />

-<br />

COMP EXT<br />

SENS SENS<br />

Sensor<br />

Mounted to<br />

Cover<br />

0.63<br />

(1.58)<br />

3.31<br />

(8.40)<br />

Option Board Terminations<br />

(multiple options shown)<br />

4.50<br />

(11.43)<br />

XJ1 External Jack<br />

Setpoint Adjust<br />

Sensor Terminals<br />

LED Terminals 24 VAC/VDC<br />

Jumper Pins for momentary<br />

pushbutton option allow<br />

locating the N.O. contacts<br />

across the (S) sensor or<br />

the setpoint (P) pot<br />

Controller Temp<br />

Sensor (standard)<br />

Option XB (8'/2.4m lead) – do not terminate inside the enclosure.<br />

Internal<br />

Option<br />

Wiring<br />

Sensor<br />

Mounted to Cover<br />

Standard<br />

Terminations<br />

ST-S*E<br />

Note: The above drawing shows all options. The actual configuration will vary depending on the options selected.<br />

See Sensor Options in this section for option wiring pin-out connections.<br />

3.23<br />

(8.20)<br />

Front View<br />

3.23<br />

(8.20)<br />

Bottom View<br />

1.20<br />

(3.05)<br />

4.50<br />

(11.43)<br />

2.75 (6.99)<br />

Front View<br />

2.75 (6.99)<br />

Bottom View<br />

ST-S*E ST-S*EW<br />

1.20<br />

(3.05)<br />

3<br />

TEMPERATURE

TEMPERATURE<br />

4<br />

TEMPERATURE<br />

EXECUTIVE ROOM THERMISTOR AND RTD SENSORS<br />

ST-S*E, ST-S*EW SERIES<br />

TYPICAL MOUNTING<br />

Toggle bolts or other direct wall-mount screws can be used where conduit is<br />

not required. Adapters are not required when mounting directly to electrical<br />

outlet boxes.<br />

Basic model comes with screw terminal block, white decorator faceplate, two<br />

#6-32 screws for handibox mounting, and two #6 x 1" screws for direct wall<br />

mounting. Cover screws are #6-32 with a 1/16 allen key head.<br />

White<br />

Faceplate<br />

(standard)<br />

Plate<br />

Mounting<br />

Screws<br />

Wire Access<br />

Hole<br />

Cover<br />

Mounting<br />

1/16 Allen Screws<br />

Optional Customer-<br />

Supplied Handibox<br />

The sensor should be mounted approximately 5' (12.7 cm) above the floor,<br />

on an interior wall, away from any heating or cooling generating devices.<br />

XJ2<br />

Internal<br />

Communication<br />

Jack<br />

under the<br />

cover<br />

ORDERING INFORMATION<br />

TYPICAL COVER WITH MULTIPLE OPTIONS<br />

DEC<br />

XK<br />

Custom Logo<br />

(your company logo)<br />

MODEL DESCRIPTION<br />

ST-S3 10,000Ω executive thermistor @ 77°F (25°C), Type III material (gray leads)<br />

ST-S21 2252Ω executive thermistor @ 77°F (25°C), Type II material (green leads)<br />

ST-S22 3000Ω executive thermistor @ 77°F (25°C), Type II material (blue leads)<br />

ST-S24 10,000Ω executive thermistor @ 77°F (25°C), Type II material (yellow leads)<br />

ST-S27 100,000Ω executive thermistor @ 77°F (25°C), Type II material (gray leads)<br />

ST-S42 20,000Ω executive thermistor @ 77°F (25°C), Type IV material (green leads)<br />

ST-S81 100Ω executive RTD @ 32°F (0°C), 385 platinum curve (yellow leads)<br />

ST-S85 1000Ω executive RTD @ 32°F (0°C), 385 platinum curve (blue leads)<br />

ST-S91 1000Ω executive RTD @ 32°F (0°C), 375 platinum curve (green leads)<br />

E Executive beige enclosure with wide back plate<br />

EW Executive white enclosure with narrow back plate<br />

OPTIONS (See page 37 for option details)<br />

XA* Setpoint adjustment with 10 kΩ to 30 kΩ, resistance input<br />

XA10K* Setpoint adjustment with 1 kΩ to 3 kΩ, resistance input<br />

XA2K* Setpoint adjustment with 1kΩ to 1.4 kΩ, resistance input<br />

XB Moistureproof with 8' (2.44m) lead, no terminal block provided<br />

XGR Gray decorator faceplate (tan faceplate standard)<br />

XJ1* External communication jack (related adapter CC-RJ11AD)<br />

XJ2* † Internal RJ11 communication jack<br />

XK Custom logo<br />

XM** Momentary switch wired N.O. to terminal block (N.C. available)<br />

XME Membrane momentary switch wired only N.O. to terminal block, tan faceplate only<br />

XPL* Red LED lamp externally powered 24 VAC/VDC<br />

XN1 NIST certificate, one reference point, 32°F (0°C)<br />

XN2 NIST certificate, two reference points, 32°/158°F (0°/70°C)<br />

XTA Analog temperature display, 50° to 90°F ±1°F<br />

XTC Digital temperature display, 15° to 32°C ±1°C, battery powered (one year nominal)<br />

XTD Digital temperature display, 60° to 90°F ±1°F, battery powered (one year nominal)<br />

XZ Three-wire RTD connections (Type 81 only)<br />

ST-S3 E XB XGR Example: ST-S3-E-XB-XGR 10,000Ω Type III moistureproof executive sensor zone with<br />

gray faceplate and an executive beige enclosure with wide back plate<br />

* Circuit board option<br />

** Cannot be mounted in conjunction with *options<br />

† XJ2 option may not be combined with the XTD or XTC option<br />

RELATED PRODUCTS<br />

CC-RJ11AD Adapter cable for XJ1 option with female RJ11 8-pin connector<br />

79-1 Replacement battery for XTD and XTC option<br />

KT1 Mounting screwdriver 1/16" Allen key<br />

10-531 Wall adaptor plate 7" x 5.25" (for ST-S*EW)<br />

F<br />

90<br />

80<br />

70<br />

60<br />

50<br />

INC<br />

XJ1<br />

External Communication<br />

Jack for use with handheld<br />

terminals, requires adapter<br />

cable. CC-RJ11AD<br />

XTA (ST-S*E only)<br />

Analog Temperature Display<br />

50° to 90°F<br />

XTD (ST-S*E only)<br />

(not shown)<br />

Liquid Crystal Temperature<br />

Indication 60° to 90°F (15° to 32°C) ±1°F<br />

XM<br />

Exposed Momentary Push<br />

Button (cannot be used with<br />

XA, XJ1, or XJ2 options)<br />

XME<br />

Concealed Membrane<br />

Momentary Push Button<br />

XPL<br />

Red LED Indicator Lamp<br />

XA<br />

Setpoint Adjust to provide a<br />

10 kΩ to 30 kΩ resistance<br />

input<br />

(1-3 kΩ and 1-1.4 kΩ available)

TEMPERATURE<br />

DECORATOR ROOM TEMPERATURE SENSOR, THERMISTOR AND RTD<br />

ST-S * K SERIES<br />

DESCRIPTION<br />

The ST-S*K Series Room Temperature Sensor is a<br />

cost-effective room temperature sensor. The thermistor<br />

is made of a very stable, pre-aged material that offers<br />

the reliability needed in control systems. The platinum<br />

RTD comes in 100� and 1000� and is compatible with<br />

most HVAC systems.<br />

FEATURES<br />

• Lifetime warranty<br />

• Attractive new design<br />

• ±0.36°F (0.2°C) thermistor accuracy<br />

• ±1.0°F (0.53°C) RTD accuracy<br />

• Durable housing<br />

• White color<br />

• Thermistor or RTD<br />

• Locking cover screws<br />

OPTIONS<br />

• Setpoint slide adjust<br />

• Momentary override switch<br />

• RJ11 communication jack<br />

• NIST certificate<br />

• 24V LED lamp<br />

• OEM models available<br />

• Custom logos<br />

APPLICATION<br />

The ST-S*K Series is designed to be wall mounted<br />

indoors where appearance and accuracy are important.<br />

The sensor may be mounted directly to the drywall or<br />

on standard electrical boxes. It comes in all common<br />

thermistors or RTDs. Options may be mixed and<br />

matched for each application.<br />

SPECIFICATIONS<br />

Sensing elements Thermistor (thermal resistor)<br />

RTD (resistance temperature device)<br />

Accuracy ±0.5°F (0.28°C)<br />

Sensor types<br />

Thermistor @ 77°F 2.252k, 3k, 10k, 20k, 100 k�<br />

RTD @ 32°F Platinum 100�, 385 curve<br />

Platinum 1000�, 385 curve<br />

Platinum 1000�, 375 curve<br />

Temp range 35° to 140°F (2° to 60°C)<br />

Temp response NTC - Thermistors, PTC - RTDs<br />

Sensitivity See Sensor Resistance Charts in<br />

the “Technical Reference” section<br />

Stability<br />

Thermistor 0.24°F (0.13°C) over five years<br />

RTD

TEMPERATURE<br />

TEMPERATURE<br />

DECORATOR ROOM TEMPERATURE SENSOR, THERMISTOR AND RTD<br />

ST-S * K SERIES<br />

MOUNTING AND SENSOR ONLY WIRING<br />

Toggle bolts or other direct wall-mount screws can be used where<br />

back box is not required. Adapters are not required when mounting<br />

directly to electrical outlet boxes.<br />

Basic model comes with screw terminal block, white decorator faceplate,<br />

two #6-32 screws for handibox-mounting, and two #6 x 1" screws<br />

for direct wall-mounting. Locking cover screws are #6-32 with a 1/16"<br />

Allen key head, installed as needed.<br />

Wire Access<br />

Hole<br />

Mounting Back Plate<br />

Mounting<br />

Screws<br />

Option Board Clip<br />

6<br />

Self-Latching<br />

Cover<br />

ST-S3K XN1<br />

Cover<br />

Locking<br />

1/16" Allen Screws<br />

Installed as needed<br />

To BAS<br />

Controller<br />

The sensor should be mounted approximately 5' (1.5m) above the floor,<br />

on an interior wall, out of the sun, and away from any heating or cooling<br />

generating devices.<br />

Note: Adjust option requires option board removal to mount back plate.<br />

WIRING<br />

Communication<br />

Bus Terminal<br />

XJ2 Internal<br />

RJ11 Jack<br />

XA Setpoint<br />

Adjust<br />

Potentiometer<br />

ORDERING INFORMATION<br />

Out<br />

RELATED PRODUCTS<br />

KT1 Mounting screwdriver 1/16" Allen key<br />

10-531 Sensor adaptor plate 7" x 5.25"<br />

In<br />

P S<br />

Pot<br />

Sensor<br />

LED<br />

Comp<br />

Sens<br />

Ext<br />

Sens<br />

Sensor Mounted<br />

to Cover<br />

Setpoint Adjust<br />

Sensor Terminals<br />

LED Terminals<br />

24 VAC/VDC<br />

Jumper Pins for<br />

Momentary Pushbutton<br />

Option allow locating<br />

the N.O. contacts<br />

across the sensor<br />

(S) or the setpoint (P)<br />

Controller Temp<br />

Sensor (standard)<br />

Optional Board Terminations<br />

(multiple options shown)<br />

MODEL DESCRIPTION<br />

ST-S3K 10,000Ω decorator thermistor @ 77°F (25°C), Type III material (gray leads)<br />

ST-S21K 2252Ω decorator thermistor @ 77°F (25°C), Type II material (green leads)<br />

ST-S22K 3000Ω decorator thermistor @ 77°F (25°C), Type II material (blue leads)<br />

ST-S24K 10,000Ω decorator thermistor @ 77°F (25°C), Type II material (yellow leads)<br />

ST-S27K 100,000Ω decorator thermistor @ 77°F (25°C), Type II material (gray leads)<br />

ST-S42K 20,000Ω decorator thermistor @ 77°F (25°C), Type IV material (green leads)<br />

ST-S81K 100Ω decorator RTD @ 32°F (0°C), 385 platinum curve (yellow leads)<br />

ST-S85K 1000Ω decorator RTD @ 32°F (0°C), 385 platinum curve (blue leads)<br />

ST-S91K 1000Ω decorator RTD @ 32°F (0°C), 375 platinum curve (green leads)<br />

OPTIONS (See page 37 for option details)<br />

XA* Setpoint adjustment (10 kΩ to 30 kΩ, resistance input, tan faceplate only)<br />

XA10K* Setpoint adjustment (1 kΩ to 3 kΩ, resistance input, tan faceplate only)<br />

XA2K* Setpoint adjustment (1 kΩ to 1.4 kΩ, resistance input, tan faceplate only)<br />

XB Moistureproof with 8' (2.44m) lead (no terminal block provided)<br />

XJ2* Internal RJ11 communication jack<br />

XK Custom logo<br />

XM Momentary switch wired normally open to terminal block (N.C. available)<br />

XPL* Red LED lamp (externally powered 24 VAC/VDC)<br />

XN1 NIST traceable for one-point certification 32°F (0°C)<br />

XN2 NIST traceable for two-point certification 32°/158°F (0°/70°C)<br />

XZ Three-wire RTD connections (Type 81 only)<br />

Example: ST-S3K-XN1 10,000Ω Type III decorator sensor with NIST certificate<br />

* Circuit board option

TEMPERATURE<br />

SURFACE-MOUNT ROOM THERMISTOR AND RTD SENSORS<br />

ST-S* P SERIES<br />

DESCRIPTION<br />

The Precon ST-S*P Series Surface-Mount Room<br />

Sensors provide precision room temperature sensing<br />

for building automation systems. The active sensing<br />

element is made of a highly stable, precision thermistor<br />

material or platinum RTD.<br />

FEATURES<br />

• Lifetime warranty<br />

• ±0.36°F (±0.2°C) thermistor accuracy<br />

• ±1°F (±0.53°C) RTD accuracy<br />

• Wide selection of thermistor and RTD curves<br />

• Vented housing for quick temperature response<br />

• Adaptable with many options<br />

• Traditional tan cover with aluminum faceplate<br />

• Durable plastic housing and base plate<br />

• Easy to mount to wall or back box<br />

APPLICATION<br />

The wall-mounted enclosure is designed to be mounted<br />

indoors vertically or horizontally. The separate base<br />

plate may be mounted directly to the drywall or a standard<br />

electrical outlet box with adapters. The cover is<br />

secured with tamper-resistant hex screws. Where<br />

moisture is a concern, the moistureproofing XB option<br />

is required.<br />

SPECIFICATIONS<br />

Sensing element Thermistor (thermal resistor)<br />

RTD (resistance temperature device)<br />

Accuracy<br />

Thermistor ±0.36°F (0.2°C)<br />

RTD ±1°F (0.53°C)<br />

Sensor types available<br />

Thermistor 2.252k, 3k, 10k, 20k, 100 k�<br />

RTD Platinum 100�, 385 curve<br />

Platinum 1000�, 385 curve<br />

Platinum 1000�, 375 curve<br />

Temp range 35° to 140°F (2° to 60°C)<br />

Temp response<br />

Thermistor Negative temperature coefficient<br />

RTD Positive temperature coefficient<br />

Sensitivity See Sensor Resistance Charts<br />

in the “Technical Reference”<br />

section<br />

OPTIONS<br />

• Custom logos<br />

• Setpoint adjustment<br />

• Moistureproof with 8' (2.44m) lead<br />

• Momentary switch override<br />

• NIST traceable<br />

Stability<br />

Thermistor 0.24°F (0.13°C) over five years<br />

RTD

TEMPERATURE<br />

8<br />

TEMPERATURE<br />

SURFACE-MOUNT ROOM THERMISTOR AND RTD SENSORS<br />

ST-S* P SERIES<br />