Pleading for open modular architectures - Lirmm

Pleading for open modular architectures - Lirmm

Pleading for open modular architectures - Lirmm

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

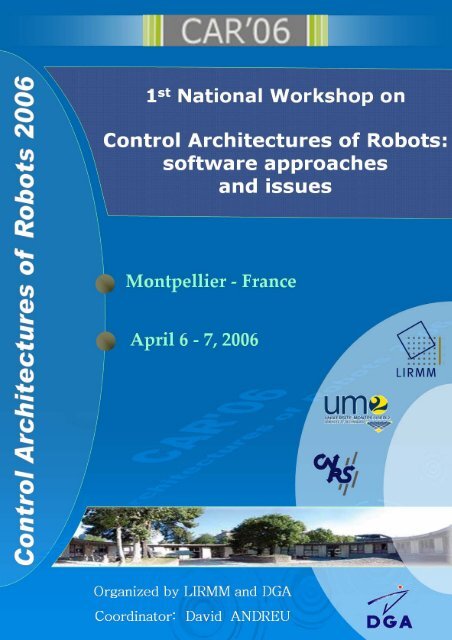

Organization<br />

This first national workshop is aimed at addressing important aspects of robot control<br />

<strong>architectures</strong>, with a specific emphasis on software aspects. It brings together researchers and<br />

practitioners from universities, institutions and industries, working in this field. It intends to be a<br />

meeting to expose and discuss gathered expertise, identified trends and issues, as well as new<br />

scientific results and applications around software control <strong>architectures</strong> related topics, through<br />

plenary invited papers. It consists of 19 invited talks, and 2 round tables.<br />

This 2-day event has been co-organized by LIRMM 1 and DGA 2 . The organizing committee<br />

wishes to thank the following organizations <strong>for</strong> their financial support <strong>for</strong> the workshop:<br />

• LIRMM CNRS-UM2,<br />

• University of Montpellier 2 (UM2),<br />

• STICS Research Department of UM2,<br />

• Robotics Department of LIRMM.<br />

Steering Committee<br />

• David Andreu, LIRMM, University of Montpellier 2, France - andreu@lirmm.fr<br />

• Aurélien Godin, ETAS, DGA, France – aurelien.godin@dga.defense.gouv.fr<br />

Local Organization<br />

Web<br />

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

• Céline Berger, LIRMM, France - berger@lirmm.fr<br />

• Robin Passama, LIRMM, University of Montpellier 2, France – passama@lirmm.fr<br />

• Stéphanie Belin, LIRMM, France - belin@lirmm.fr<br />

1 Laboratoire d’In<strong>for</strong>matique, de Robotique et de Microélectronique de Montpellier : http://www.lirmm.fr<br />

2 Délégation Générale pour l’Armement : http://www.defense.gouv.fr/dga/<br />

4

Theme<br />

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Due to their increasing complexity, nowadays intervention robots, that to say those dedicated <strong>for</strong><br />

instance to exploration, security or defence applications, definitely raise huge scientific and<br />

commercial issues. Whatever the considered environment, terrestrial, aerial, marine or even<br />

spatial, this complexity mainly derives from the integration of multiple functionalities: advanced<br />

perception, planning, navigation, autonomous behaviours, in parallel with teleoperation or robots<br />

coordination enable to tackle more and more difficult missions.<br />

But robots can only be equipped with such functions if an appropriate hardware and software<br />

structure is embedded: the software <strong>architectures</strong> will hence be the main concern of this<br />

workshop.<br />

As quoted above, the control architecture is thus a necessary element <strong>for</strong> the integration of a<br />

multitude of works; it also permits to cope with technological advances that continually offer<br />

new devices <strong>for</strong> communication, localisation, computing, etc. As a matter of fact, it should be<br />

<strong>modular</strong>, reusable, scalable and even readable (ability to analyse and understand it). Besides,<br />

such properties ease the sharing of competencies among the robotics community, but also with<br />

computer scientists and automatics specialists as the domain is inherently a multidisciplinary<br />

one.<br />

Numerous solutions have been proposed, based on the "classical" three layers architecture or on<br />

more "modern" approaches such as object or component oriented programming. Actually, almost<br />

every robot integrates its own architecture; the workshop will thus be a real opportunity to share<br />

reflections on these solutions but also on related needs, especially standardization ones, which<br />

are of particular importance in military applications <strong>for</strong> instance.<br />

Hence, this first national workshop on control <strong>architectures</strong> of robots aims at gathering a large<br />

number of robotics actors (researchers, manufacturers as well as state institutions) in order to<br />

highlight the multiple issues, key difficulties and potential sources of advances.<br />

David Andreu Aurélien Godin<br />

LIRMM DGA<br />

Robotics Department Angers Technical Centre<br />

5

Contents<br />

Organization………………………………………………………………………...……………4<br />

Theme…………………………………………………………………………………….….……5<br />

Program………………………………………………………………………………………..…8<br />

Papers<br />

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Session “Institutions”<br />

DGA-ETAS……………………………………………………………………………………...10<br />

<strong>Pleading</strong> <strong>for</strong> <strong>open</strong> <strong>modular</strong> <strong>architectures</strong> in robotics<br />

A. Godin, O. Evain.<br />

DGA-SPART……………………………………………………………………………………18<br />

Integrating human/robot interaction into robot control <strong>architectures</strong> <strong>for</strong> defence applications<br />

D. Dufourd, A. Dalgalarrondo.<br />

ONERA-CERT………………………………………………………………………………….37<br />

ProCoSA: a software package <strong>for</strong> autonomous system supervision<br />

M. Barbier, J.F. Gabard, D. Vizcaino, O. Bonnet-Torrès<br />

DGA-GESMA……………………………………………………………………….…………..48<br />

Goal driven planning and adaptivity <strong>for</strong> AUVs<br />

H. Ayreault, F. Dabe, M. Barbier, S. Nicolas, G. Kermet.<br />

IFREMER…………………………………………………………………….…………………56<br />

Advanced Control <strong>for</strong> Autonomous Underwater Vehicles<br />

M. Perrier.<br />

Session “Industrials”<br />

THALES…………………………………………………………………………………….…..64<br />

Compared Architectures of Vehicle Control System (Vetronics) and application to an UXV<br />

J.P. Quin.<br />

INTEMPORA………………………………………………………………………………...…72<br />

RT-MAPS: a <strong>modular</strong> software <strong>for</strong> rapid prototyping of real-time multisensor applications.<br />

N. Dulac.<br />

ECA……………………………………………………………………………………………...76<br />

DES (Data Exchange System), a publish/subscribe architecture <strong>for</strong> robotics<br />

C. Riquier, N. Ricard, C. Rousset.<br />

ROBOSOFT……………………………………………………………………………….……85<br />

Modular distributed architecture <strong>for</strong> robotics embedded systems<br />

P. Pomiers, V. Dupourqué.<br />

ECA (CYBERNETIX)………………………………………………………………………….….91<br />

Remote operation kit with <strong>modular</strong> conception and <strong>open</strong> architecture: the SUMMER concept<br />

L. Walle.<br />

6

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Session “Academics”<br />

LVR – Université d’Orléans………………………………………………………………….100<br />

A multi-level architecture controlling robots from autonomy to teleoperation<br />

C. Novales, G. Mourioux, G. Poisson.<br />

LAAS-CNRS…………………………………………………………………………………..120<br />

LAAS architecture: Open Robots<br />

F. Ingrand.<br />

LISYC - Université de Bretagne Occidentale……………………………………………….121<br />

Architectures logicielles pour la robotique et sûreté de fonctionnement<br />

L. Nanatchamda.<br />

INRIA Rhône-Alpes…………………………………………………………………………..131<br />

Orccad, a framework <strong>for</strong> safe control design and implementation<br />

D. Simon, R. Pissard-Gibollet, S. Arias.<br />

LIRMM-CNRS – Université Montpellier 2 ……………………………………….………...145<br />

Overview of a new Robot Controller Development Methodology<br />

R. Passama, D. Andreu, T. Libourel, C. Dony.<br />

LIP6 - Université Pierre et Marie Curie Paris VI………………………..…………….……164<br />

An Asynchronous Reflection Model <strong>for</strong> Object-oriented Distributed Reactive Systems<br />

J. Malenfant.<br />

LST - Université de Technologie de Bel<strong>for</strong>t-Montbéliard …...…………………………….183<br />

Reactive Multi-Agent approaches <strong>for</strong> the Control of Mobile Robots<br />

O. Simonin.<br />

VALORIA – Université Bretagne Sud ………………………………………………………192<br />

Horocol language and Hardware modules <strong>for</strong> robots<br />

D. Duhaut, C. Gueganno, Y. Le Guyadec, M. Dubois.<br />

CEMAGREF…………………………………………………………………………………..203<br />

A Real-Time, Multi-Sensor Architecture <strong>for</strong> fusion of delayed observations: Application to<br />

Vehicle Localisation<br />

C. Tessier, C. Cariou, C. Debain, F. Chausse, R. Chapuis, C. Rousset.<br />

List of speakers………………………………………………………………………….……..208<br />

List of participants…………………………………………………………………….………209<br />

7

Program<br />

April 6, 2006<br />

8:30-9:00 Reception (coffee)<br />

Welcome LIRMM-DGA<br />

9:00- 9:30<br />

F. Pierrot (LIRMM Assitant Director)<br />

R. Zapata (Robotics Department Manager)<br />

9:30-12:30 Session « Institutions »<br />

9:30-10:00 DGA-ETAS A. Godin<br />

10:00-10:30 DGA-SPART D. Dufourd<br />

10:30-11:00 Coffee Break<br />

11:00-11:30 ONERA-CERT M. Barbier<br />

11:30-12:00 DGA-GESMA H. Ayreault<br />

12:00-12:30 IFREMER M. Perrier<br />

12:30-14:00 Lunch<br />

14:00-16:30 Session « Industrials »<br />

14:00-14:30 THALES J.P. Quin<br />

14:30-15:00 INTEMPORA N. Dulac<br />

15:00-15:30 ECA C. Rousset<br />

15:30-16:00 ECA(Cybernetix) L. Walle<br />

16:00-16:30 Robosoft P. Pomiers<br />

16:30-17:00 Coffee Break<br />

17:00-18:30<br />

Round table<br />

« Software control architecture: trends and issues »<br />

20:00 Diner<br />

April 7, 2006<br />

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

8:30-9:00 Reception (coffee)<br />

9:00-12:00 Session « Academic »<br />

9:00-9:30 LVR C. Novales<br />

9:30-10:00 LAAS F. Ingrand<br />

10:00-10:30 LISYC L. Nanatchamda<br />

10:30-11:00 Coffee Break<br />

11:00-11:30 INRIA D. Simon<br />

11:30-12:00 LIRMM R. Passama<br />

12:00-14:00 Lunch<br />

14:00-14:30 LIP6 J. Malenfant<br />

14:30-15:00 UTBM O. Simonin<br />

15:00-15:30 VALORIA D. Duhaut<br />

15:30-16:00 CEMAGREF C. Tessier<br />

16:00-16:30 Coffee Break<br />

16:30-18:00<br />

Round table<br />

« Software robot control architecture: what’s going on ? »<br />

8

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Session « Institutions »<br />

9

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

<strong>Pleading</strong> <strong>for</strong> <strong>open</strong> <strong>modular</strong> <strong>architectures</strong><br />

Abstract— Since first researches in the field of robotics <strong>architectures</strong>,<br />

many advances have been achieved. Nowadays softwares<br />

offer <strong>modular</strong> functionalities, which interests will be reminded<br />

in section I, and actually satisfy most of the needs, as shown in<br />

section II. However, none of the mentioned approaches managed<br />

to spread widely or succeeded in gathering works developed<br />

by the very numerous robotics actors, not even those that can<br />

already be considered mature. We argue here that the port of<br />

these works from an architecture to another is a major difficulty<br />

and that only an ef<strong>for</strong>t towards standardisation can help to<br />

overcome this drawback.<br />

I. REASONS FOR DEFENDING MODULAR OPEN DESIGNS<br />

We here define the architecture as the structured<br />

organisation of components (or “framework”), embedded on a<br />

system, that enables their simultaneous and correct execution,<br />

by offering the basic services needed <strong>for</strong> all of them. In this<br />

paper, we will more specifically consider software aspects.<br />

Modularity will be defined as the ability, <strong>for</strong> this software,<br />

to receive new components that were not included in the<br />

original release, thus enabling, a posteriori, to extend its<br />

functionalities. It will be moreover “<strong>open</strong>” if interfaces <strong>for</strong><br />

writing these modules are public, so that a person different<br />

from the developper that originally implemented the code<br />

can produce some. For instance, Linux is such a system, in<br />

which hardware drivers can easily be added by third parties.<br />

And so is Windows: these two characteristics are effectively<br />

not contradictory with commercial or property policies and<br />

do not mean that the original sources must be unveiled.<br />

Recent articles on <strong>architectures</strong> often insist on their <strong>modular</strong>ity.<br />

This must not only be considered a “commercial”<br />

announce but, indeed, softwares that satisfy this property<br />

offer many interests. First of all, as they are able to receive<br />

all sorts of modules, provided that the latter respect the<br />

defined interfaces, they can potentially attract many robotic<br />

actors and their adoption is eased. The direct corollary of<br />

wide-spread <strong>architectures</strong> is to provide this users community<br />

with a common framework, enhancing the possibilities of<br />

sharing and exchanging competencies. As a matter of fact,<br />

it also enables to validate concurrent approaches in the same<br />

conditions/environment <strong>for</strong> more relevant comparison results.<br />

Besides, <strong>modular</strong>ity permits to focus one’s development<br />

only on particular aspects, while working algorithms can be<br />

re-used. Hence, there is no need anymore, when conducting<br />

a specific research, to redevelop an entire system to test it,<br />

but one can take benefit of an already existing complete<br />

Aurélien Godin, Olivier Evain<br />

French Department of Defence<br />

Angers Technical Centre / Vetronics & Robotics Group<br />

{aurelien.godin,olivier.evain}@dga.defense.gouv.fr<br />

10<br />

framework, in which to integrate and evaluate one’s own work.<br />

But interests are not limited to these ones. Indeed, the<br />

vehicle (more generally the plat<strong>for</strong>m) in which the <strong>modular</strong><br />

framework will be embedded will allow a fast integration<br />

of different modules or their easy replacement. This is particularly<br />

interesting <strong>for</strong> all users. Laboratories take benefit<br />

from the flexibility of such structures, manufacturers can<br />

easily provide updates or new functionalities to their clients.<br />

Finally, end-users, such as the Department of Defence, can<br />

both take advantage of such <strong>open</strong>-targets to support their<br />

research programmes and, depending of the mission needs, to<br />

get reconfigurable operational systems. Recently, the French<br />

Ground Army confirmed that the MiniRoC concepts of ground<br />

robots, see [10], presenting such <strong>modular</strong> characteristics, was<br />

of great interest as they would allow soldiers to only take with<br />

them the absolutely necessary modules related to their actual<br />

task.<br />

By extension, if on the one hand <strong>open</strong> <strong>architectures</strong> compel<br />

to con<strong>for</strong>m to given software interfaces, on the other hand they<br />

make no assumptions as regarding to the underlying hardware.<br />

Such frameworks are, ideally, completely independent from<br />

plat<strong>for</strong>ms, processors or electronics. Said another way, they<br />

offer the possibility to evolve as technologies progress : it<br />

remains up-to-date. For end-users essentially, it is a guarantee<br />

of durability and, consequently, it requires to train maintainers<br />

only <strong>for</strong> one type of software. This durability is however<br />

achievable only by ensuring backward compatibility, so that<br />

modules running on older versions of the software can be<br />

executed in latest releases.<br />

For the sake of exhaustivity, the same arguments that<br />

talk in favour of <strong>modular</strong> <strong>architectures</strong> on a single robot<br />

also are valid when tackling the multi-robots context, as<br />

it will help to gather an un-predefined number of agents<br />

within a collaborating team. This property is then known as<br />

extensibility or scalability.<br />

Thus, from the above discussion, the main requirements <strong>for</strong><br />

an architecture to be <strong>modular</strong> can be summarised as:<br />

• permit normalized data exchange through the definition<br />

of public interfaces and common communication mechanisms;<br />

• enable extensibility by making no assumptions on underlying<br />

plat<strong>for</strong>m or candidate peripheral hardware;<br />

• be flexible by making no assumptions on missions that

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

will be given to the robot, since new ones will irremediably<br />

be imagined during system’s life.<br />

As will be discussed in section II, many <strong>architectures</strong><br />

developed <strong>for</strong> about twenty years satisfy these characteritics.<br />

Besides, whereas the framework nature - reactive, deliberative<br />

or hybrid - is often a central concern, we will note here that<br />

<strong>modular</strong>ity is independent from this issue, and that it can be<br />

ensured in all cases.<br />

II. PREVIOUS WORK<br />

A. Evolution in <strong>architectures</strong> conception<br />

In the second half of the 80s’, Brooks introduced an<br />

architecture that can maybe be considered the first <strong>modular</strong><br />

one, [7]. Contrary to common software structures at that time,<br />

which often used sequencial treatments to achieve an action,<br />

an organisation based on layers is proposed. Each layer can<br />

operate in parallel and corresponds to a particular task to be accomplished,<br />

see figure 1. Nowadays designs have inherited this<br />

point of view as modules often implement specific behaviours.<br />

However, in Brooks’ system, layers interactions are based on<br />

the subsumption principle (upper layers can block and replace<br />

outputs of lower ones) and not on a real standardized data<br />

exchange. This may bring to a complex links organisation.<br />

Enhanced exchange schemes are present in most following<br />

works. Modules become real “independent computational<br />

units”, executing concurrently and that can use given communication<br />

services, imposed by the architecture, to exchange<br />

in<strong>for</strong>mation. Compared to the subsumption architecture, the<br />

level of competence (i.e., the priority of the module) is not<br />

fixed a priori since all the blocks are considered equal. The<br />

choice <strong>for</strong> the appropriate output can be made, depending on<br />

the implementation, by a global referee or another module<br />

written by the system designer. DAMN, [18], is a remarkable<br />

Fig. 1. Whereas traditional approaches presented a sequential organisation<br />

(above schema), Brooks proposed a structure where layers, often corresponding<br />

to a given level of competence, can execute in parallel and influence the<br />

global robot behaviour by subsuming outputs of lower ones. Figures are taken<br />

from [7].<br />

11<br />

example of the first category. Each block, called “behaviour”<br />

in the sense of Brooks’, issues votes in favour of a specific<br />

possible action that are then collected by an arbiter (figure 2).<br />

The final effective command is, schematically, a weighted sum<br />

of these votes.<br />

Fig. 2. The DAMN architecture as described in [18].<br />

Another famous approach is the one developed at<br />

GeorgiaTech by Arkin, [5]. The principles are close to those<br />

of DAMN: behaviours, here called “motor schemas”, provide<br />

their commands to a process that sums and normalizes them<br />

using the potential fields method. A sligth difference is however<br />

introduced since a homeostatic control system is added:<br />

this can be thought as a bus that collects state variables from<br />

robot internal sensors and broadcast them to all of the motor<br />

schemas. Resulting monitoring in<strong>for</strong>mation are used both to<br />

influence internal parameters of behaviours and their relative<br />

weights. The structure is synthesized on figure 3.<br />

Fig. 3. AuRA principle. This figure both shows the fusion process between<br />

two motor schemas and the homeostatic control system that regulates the<br />

per<strong>for</strong>mance of the overall architecture.<br />

However, theoretically, <strong>modular</strong>ity does not only apply to<br />

behaviours (i.e., reactive modules) but also to deliberative capabilities<br />

of robots. If the complete AuRA framework already<br />

integrates a planning component (as well as a layer responsible<br />

<strong>for</strong> user-robot interaction that can convey human decisions),<br />

the reasoning capacities are fixed once <strong>for</strong> all. But there exists<br />

practical cases <strong>for</strong> which these capacities are more flexible.

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

An army is a typical example of an efficient organisation in<br />

which deliberative agents are not gathered in a centralized<br />

structure, as each soldier is not only able to act but also<br />

to learn, acquire experience, and use complex reasonings to<br />

succeed in his elementary task. And a robot architecture is, in<br />

some way, comparable: in both cases, an upper objective (the<br />

goal of the robot or of the army) can be achieved by getting<br />

elementary agents (modules or men) to work in a coordinated<br />

fashion (i.e., respecting rules imposed by the architecture or<br />

the hierarchy). Such comparisons naturally lead to propose<br />

new robot frameworks, in which deliberative capacities, and<br />

not only reactive behaviours, are also designed in a <strong>modular</strong><br />

manner.<br />

Albus’ researches on 4-D/RCS 1 have been conducted based,<br />

partly, on these reflexions and lead to a node-oriented architecture.<br />

Each elementary component, called a node, integrates<br />

sensory processings and reactive parts, like “classical” modules,<br />

but can also simultaneously gather modeling, learning and<br />

reasoning capabilities, as shown figure 4. Each node is then<br />

arranged within a global hierarchy modeled on the military<br />

structure. A natural way of implementing this architecture is to<br />

grant more deliberative responsibilities to nodes that are placed<br />

high in the hierarchy, whereas lower nodes are rather dedicated<br />

to in<strong>for</strong>mation processing. Furthermore, by construction, this<br />

framework is multirobot-ready: from a macroscopic point of<br />

view, a robot can itself be considered a node and teams<br />

of robots can hence be constituted the same way nodes are<br />

structured inside each robot. More detailed explanations can<br />

be found in [2].<br />

Fig. 4. A typical 4-D/RCS node.<br />

The emergence of modern programming methods, i.e.<br />

object-oriented (OO) approaches, hugely contributed to ease<br />

the implementation of the above concepts. Inheritance and<br />

related mechanisms (polymorphism, methods over-writing)<br />

are directly useful to derive efficient modules and permit<br />

to easily extend robots capacities, whereas the encapsulation<br />

of properties and methods enables objects to share only the<br />

useful interfaces. But these approaches did not only reveal<br />

1 4-D/RCS is the architecture that is embedded on the Demo III Experimental<br />

Unmanned Vehicle (XUV), a project supported by the American DoD. This<br />

probably explains the origin of the parallel between robots architecture and<br />

military organisation.<br />

12<br />

interesting <strong>for</strong> programmers but also inspired the conception<br />

of recent <strong>architectures</strong>. The most appealing one is probably<br />

CLARAty in which the whole functional layer is thought<br />

as a hierarchy of objects. A simple example is shown on<br />

figure 5, whereas very detailed explanations, including coding<br />

considerations, can be found in [19]. One interest of OOconception<br />

is to provide all the mechanisms to build proper<br />

extensible interfaces, without imposing any limitations on<br />

the way objects are internally implemented. COSARC is a<br />

very recent example of this trend: it uses an extension of<br />

OO-methods (the component-based approach) to define four<br />

types of components which internal structure is described with<br />

Petri Nets, please refer to [4] <strong>for</strong> details. This is a relevant<br />

illustration of the ability of object-based languages to both ease<br />

the development of <strong>open</strong> frameworks, satisfying <strong>modular</strong>ity<br />

requirements, and take benefit from any other recognized<br />

approach <strong>for</strong> the modelisation of components behaviour, here<br />

Petri Nets.<br />

Fig. 5. This example illustrates the object-oriented design of the functional<br />

layer of CLARAty. Note that, like all moderns frameworks, it also provides a<br />

decision layer, not shown here. But although most other <strong>architectures</strong> split the<br />

executive and planning levels, these functionalities are here gathered within<br />

the same layer, <strong>for</strong> consistency reasons. See [20] <strong>for</strong> a discussion on this<br />

point.<br />

As noted above, the same requirements of <strong>modular</strong>ity and<br />

extensibility are needed in the multi-robots context. Here, the<br />

main constraint is to enable the adjonction and the removal of<br />

agents within the team. If some <strong>architectures</strong>, like 4-D/RCS,<br />

inherently have the capacity to manage several robots, they<br />

should also tackle the “fault-tolerancy” problem. That is to<br />

say, the lost of a robot or of the communication channel,<br />

during the mission, must not induce the failure of the whole<br />

team. Most of the time, specific coordination schemes are<br />

thus added to the upper layers of the <strong>architectures</strong> and run all<br />

the processes needed to manage a team (especially scalability<br />

mechanisms, communication strategies and task allocation).<br />

Among all approaches proposed, let us quote ALLIANCE and

TABLE I<br />

TECHNOLOGY READINESS LEVELS<br />

Low maturity<br />

1 Basic principles of technology observed &<br />

reported<br />

2 Technology concept and/or<br />

application <strong>for</strong>mulated<br />

3 Analytical and laboratory<br />

studies to validate analytical predictions<br />

Medium maturity<br />

4 Component and/or basic sub-system<br />

technology valid in lab environment<br />

5 Component and/or basic sub-system<br />

technology valid in relevant environment<br />

6 System/sub-system technology model or<br />

prototype demo in relevant environment<br />

High maturity<br />

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

7 System technology prototype demo in an<br />

operational environment<br />

8 System technology qualified<br />

through test & demonstration<br />

9 System technology ‘qualified’ through<br />

successful mission operations<br />

M+. The first one mainly focuses on determining an efficient<br />

fault-tolerant scheme: details can be found in [17]. The<br />

second one, [6], offers an alternative based on negociations<br />

between the robots. It has been successfully integrated in the<br />

LAAS-CNRS framework, [1], that hence provides a complete<br />

<strong>open</strong> architecture gathering all functionalities, from reactive<br />

behaviours to decisional capacities, <strong>for</strong> a lonely robot or a<br />

team of agents.<br />

Besides, all above quoted works do not remain pure theorical<br />

concepts. Many of them have been ported on some<br />

vehicles and proved to be relevant potential candidates <strong>for</strong><br />

real applications.<br />

B. Introducing Technology Readiness Levels<br />

Technology Readiness Levels (TRLs) were initially created<br />

by NASA in 1995 and were officialy adopted by the American<br />

Ministry of Defence (MoD) in 2001. This referential aims<br />

at assessing the maturity of technologies so as to reduce<br />

the risks related to acquisition programmes. It consists of<br />

nine levels, of increasing maturity, that apply to individual<br />

technologies (not to entire systems). The TRLs grid, copied<br />

from [8], is given in table I.<br />

Nowadays results and experimentations show that levels<br />

5/6 can currently be reached. 4-D/RCS framework has thus<br />

been ported to the American XUV (Experimental Unmanned<br />

Vehicle) and its ability to host functionnal modules could be<br />

demonstrated. Besides, Albus’ report [3] com<strong>for</strong>ts us in our<br />

evaluation of the maturity of this architecture when asserting<br />

13<br />

that “the tests are designed to determine whether the Demo<br />

III XUVs have achieved technology readiness level six”.<br />

In France, the same encouraging conclusions can be drawn.<br />

All along SYRANO 2 project, industrials have shown their<br />

ability to deploy a <strong>modular</strong> architecture (although proprietary)<br />

on a prototype tank and their capacity to incrementally add<br />

new functionalities when they become available. Demonstrations<br />

with this vehicle took place in the military camp of<br />

Mourmelon, in a quasi-operational context, as related in [16].<br />

Because only teleoperated functions have been used, not all<br />

possibilities of the architecture have been extensively tested,<br />

and these demonstrations “only” correspond to the TRL-5.<br />

However, a vehicle such as Syrano is TRL-6-ready as, in<br />

theory, advanced autonomous modules can be added the same<br />

way. Moreover results achieved by some laboratories com<strong>for</strong>t<br />

this point of view. For instance, experiments conducted by<br />

LAAS-CNRS in autonomous navigation demonstrated the<br />

ability of a robot to automatically explore an unknown area.<br />

During these tests, all functionalities were used: planning,<br />

supervision, autonomous modules management as well as<br />

human-robot interfaces (at least to send mission reports and<br />

receive high level orders from the operator). The multi-robot<br />

scheme is itself under ‘validation’ as, in some current projects,<br />

additional aerial in<strong>for</strong>mation is provided by a Blimp UAV to<br />

assist the robot in its navigation task.<br />

Since 2004, this laboratory has also been running a robot<br />

equipped with the same architecture, [1], in Cité de l’Espace,<br />

Toulouse. This robot serves as a guide <strong>for</strong> visitors, interacting<br />

with them to retrieve their questions, then conducting them to<br />

the desired point. Since people are obviously neither roboticians<br />

nor technicians, the environment of the robot can be<br />

considered operational. This experiment can maybe not claim<br />

the TRL-7 title, which would require huge reliability, but<br />

definitely proves that this level is now achievable.<br />

Of course, qualitatively judging the architecture, on an<br />

experiment that takes into account the whole system, is quite<br />

difficult and its exact contribution to the overall per<strong>for</strong>mance is<br />

hard to deduce. But at least, this means that services expected<br />

from the software are functional and that internal communications<br />

between framework components work. When, moreover,<br />

the architecture has been ported on heterogeneous systems<br />

(the SYRANO one was previously integrated on a robot jeep,<br />

called DARDS, and is reused <strong>for</strong> a future demining system),<br />

it can be argued that <strong>modular</strong>ity and portability have been<br />

validated. In conclusion, based on the observation of above<br />

quoted experiments, giving TRL-6 as the current achieved<br />

maturity level seems relevant.<br />

Some complementary methods also exist to assess the<br />

maturity of a whole system, System Readiness Levels. A brief<br />

review of SRLs ([9] and table II) confirms that these vehicles<br />

have reached levels 6-7, meaning that demonstrations have<br />

been conducted successfully in representative environment.<br />

2 SYRANO is a teleoperated prototype vehicle, with simple autonomous<br />

behaviours, <strong>for</strong> reconnaissance and detection of potential adverse targets. It<br />

aims at evolving in <strong>open</strong> areas.

1 User requirements<br />

defined<br />

2 System requirements<br />

defined<br />

3 Architectural design<br />

refined<br />

TABLE II<br />

SYSTEM READINESS LEVELS<br />

4 Detailed design<br />

is nominally complete<br />

5 Sub-systems verification<br />

in laboratory environment<br />

6 Sub-system verification<br />

in representative integration environment<br />

7 System prototype demonstration<br />

in a representative integration environment<br />

8 Pre-production system completed and demonstrated<br />

in a representative operational environment<br />

9 System proven through successful<br />

representative mission profile<br />

Nevertheless, the previous section raises a major concern,<br />

as it shows that numerous <strong>architectures</strong> have been develop<br />

concurrently: if each one, separatly, does satisfy the <strong>modular</strong>ity<br />

requirements, components developed <strong>for</strong> one of them cannot<br />

be ported to another. A higher level of specification is still<br />

missing that would ensure interoperability, a property of real<br />

importance, especially in a military context. Consequently,<br />

as upcoming programmes can not systematically rely on a<br />

standard, they only correspond to SRL-2. It is thus quite<br />

urgent to emphasize the research ef<strong>for</strong>t on this point, as will<br />

be discussed in section III. We will first focus on a relevant<br />

American example, JAUS, then present some French research<br />

programmes that tackle the issue.<br />

A. American proposals<br />

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

III. TOWARDS STANDARDISATION<br />

1) History: In the last 20 years, a large number of unmanned<br />

systems have been developed by US companies in<br />

response to the American DoD, but most of them are taskspecific<br />

and non-interoperable. There<strong>for</strong>e, in 1994, JAUGS,<br />

an ef<strong>for</strong>t to avoid the pitfalls of “eaches” in an expanding<br />

domain, was initiated. It was still limited to ground systems<br />

(the “G” actually stands <strong>for</strong> “ground”).<br />

In 1998, OUSD (Office of the Under Secretary of Defence)<br />

chartered a working group, consisting of members from the<br />

government, industry and academia, to develop an architecture<br />

<strong>for</strong> unmanned systems. It set itself five targets:<br />

• support all classes of unmanned systems ;<br />

• advocate rapid technology insertion ;<br />

• provide interoperable Operating Control Units (OCUs) ;<br />

• provide interchangeable/interoperable payloads ;<br />

14<br />

• provide interoperable unmanned systems.<br />

The resulting Joint Architecture <strong>for</strong> Unmanned Systems<br />

(JAUS), available <strong>for</strong> use by defence, academic and commercial<br />

sectors, is an upper level design <strong>for</strong> the interfaces within<br />

the domain of unmanned vehicles. It aims at being independent<br />

from technology, computer hardware, operator use and vehicle<br />

plat<strong>for</strong>ms, and isolated from mission. It is a component based,<br />

message-passing framework that specifies data <strong>for</strong>mats and<br />

methods of communication between computing entities of<br />

unmanned systems.<br />

Its final goal is to reduce development and integration<br />

times, ownership cost, and to enable an expanded range of<br />

vendors by providing a framework <strong>for</strong> technology insertion.<br />

2) JAUS specifications: to date, two documents describe the<br />

JAUS architecture: the Reference Architecture specification<br />

(RA), [13], and the Domain Model (DM), [12].<br />

a) Domain model: the analysis conducted in the DM<br />

on the five above targets, along with the study of military<br />

contracts constraints, urged to define five main requirements<br />

on messages within the architecture. Indeed they need to be<br />

independent from: 1. vehicle plat<strong>for</strong>m, 2. mission, 3. computer<br />

resource, 4. technology and 5. operator use. This document is<br />

also a tool with which customers/users can define both near<br />

and far term operational requirements, <strong>for</strong> unmanned systems,<br />

based on mission needs; and by defining far-term capabilities,<br />

the JAUS Domain Model can actually be considered a “road<br />

map” <strong>for</strong> developers to focus research and design ef<strong>for</strong>ts to<br />

support these future requirements.<br />

In a word, the domain model is a common language which<br />

contains three distinct elements : functional capabilities (FC),<br />

in<strong>for</strong>mational capabilities (IC), and device groups (DG). The<br />

first ones, all documented in DM so that to ease dialog<br />

between users and developers, are a set of capabilities with<br />

similar functional purposes. Eleven categories are identified,<br />

that permit to describe the abilities of an unmanned system:<br />

command, manœuvre, navigation, communication, payload,<br />

safety, security, resource management, maintenance, training<br />

and automatic configuration. In parallel with the functional description,<br />

In<strong>for</strong>mational Capabilities provide a representation<br />

Fig. 6. JAUS domain model representation.

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

of what unmanned systems (should) know. They are groupings<br />

of similar types of in<strong>for</strong>mation. Five categories are depicted in<br />

DM: vehicle status, world model, library, logistics, time/date.<br />

Finally, device groups are a classification of sensors and/or<br />

effectors that are used <strong>for</strong> similar functions. Functional and<br />

in<strong>for</strong>mational capabilities may interface with device groups,<br />

but the JAUS domain model does not define these interfaces.<br />

Figure 6 summarises the DM representation.<br />

b) Reference architecture specification: in the development<br />

cycle, the specification of capabilities described in the<br />

DM will always precede those that appear in the RA, whose<br />

main purpose is to detail all functions and messages that<br />

shall be employed to design new components. All currently<br />

defined messages as well as rules that govern messaging are<br />

also depicted in this second document. It is worth noting<br />

that messaging is the sole accepted method to communicate<br />

between components.<br />

The RA specification comprises three parts. First of them,<br />

the architecture framework provides a description of the structure<br />

of JAUS-based systems. Actually, unmanned systems are<br />

seen as a hierarchical topology, shown on figure 7. A system<br />

is a logical grouping of one or more subsystems, which are<br />

independent and distinct units. A node, in such a topology, is a<br />

‘black-box’ containing all the hardware and software necessary<br />

to provide a complete service, <strong>for</strong> example a mobility or<br />

a payload controller. A component is the lowest level of<br />

decomposition in the JAUS hierarchy: it is an executable task<br />

or process. All the components, which may be found within<br />

an unmanned system, are listed in this first part of the RA.<br />

The above defined topology is very flexible since the only<br />

requirement is that a subsystem be composed of component<br />

software, distributed across one or more nodes. Interoperability<br />

between intelligent systems is achieved by defining functional<br />

components with supported messages. There<strong>for</strong>e, the only<br />

constraint to be JAUS-compliant is that all messages that pass<br />

between components, over networks or via airwaves, shall be<br />

JAUS-compatible messages. No other rules are imposed to<br />

system engineers. Besides, messages coming from or/and sent<br />

to non-JAUS components can have their own protocol.<br />

The definition and the <strong>for</strong>mat of those messages are the<br />

objects of the second and the third parts of the RA. In the<br />

second one, message definition, different classes of messages<br />

(command, query, in<strong>for</strong>m, event setup, event notification) and<br />

message composition (classically, a header and a data fields)<br />

are defined. Messaging protocol is also depicted with the<br />

routing strategy, the way to send large data messages, the way<br />

to establish a connection between two components, as well<br />

as some various messaging rules. The third and final part of<br />

the RA, Message Set, presents the details of command code<br />

usage <strong>for</strong> each message (the command code is an in<strong>for</strong>mation<br />

included in the message header).<br />

c) Other documents: additional documents support the<br />

JAUS standards: a Document Control Plan (DCP) and the<br />

Standard Operating Procedures (SOP), [14]. The first one<br />

defines the process to update the JAUS DM and RA whereas<br />

the second one establishes the charter and organisation <strong>for</strong><br />

15<br />

Fig. 7. The reference architecture from JAUS.<br />

the JAUS working group. A compliance plan, [11], transport<br />

plan and user’s handbook are under development.<br />

3) Conclusion on JAUS: JAUS is not an architecture, as<br />

defined at the beginning of this article. It is rather a process<br />

to ease communication between users and developers and to<br />

standardise exchanges of data within software embedded in an<br />

autonomous system. However, nowadays, JAUS is mandated<br />

<strong>for</strong> use by all of the programmes in the Joint Robotics Program<br />

(JRP), [15], and numerous American manufacturers begin<br />

to follow the requirements. For example, the EOD 3 Man-<br />

Transportable Robotic System (MTRS), PackBot, produced by<br />

IRobot, is JAUS-compliant. Moreover, JAUS is now recognized<br />

as a technical committee within the SAE, Aerospace<br />

Council’s Aviation Systems Division (ASD), which name is<br />

AS-4 Unmanned Systems.<br />

B. French government ef<strong>for</strong>t<br />

For several years now, French DoD has been preparing a<br />

number of studies to get standards to emerge, so that future<br />

<strong>architectures</strong> embedded in military demonstrators be ready <strong>for</strong><br />

interoperability needs. In the ground robotics field, two major<br />

research programmes have been, or are about to be, launched.<br />

At the end of year 2005, the “Démonstrateur BOA” programme<br />

was notified to an industrial group (TGS: Thales,<br />

GIAT Industries, SAGEM). Roughly, BOA is the equivalent of<br />

the American Network Centric Warfare. It aims at proposing<br />

new organisations <strong>for</strong> ground <strong>for</strong>ces (including aerial devices<br />

operating to their profit) with a high degree of interoperability<br />

between the different units, through advanced communication<br />

means. UGVs and mini-UAVS will naturally be part of this<br />

structure since they represent a privileged way to retrieve<br />

in<strong>for</strong>mation, even during high-intensity actions, without exposing<br />

soldiers, enabling new combat strategies such as indirect<br />

firing, see figure 8. Missions which they should respond to are<br />

manifold and heterogeneous, from urban fighting, to logistics<br />

or reconnaissance. Hence, the challenge:<br />

3 explosive ordnance disposal

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Fig. 8. Official illustration of the BOA concept, showing candidate systems,<br />

data exchanges between them and consequent achievable missions.<br />

• integrating unmanned vehicles communications in an<br />

already very constraint electromagnetic environment;<br />

• enabling in<strong>for</strong>mation sharing between robots and with<br />

human units;<br />

• getting highly reconfigurable robots/UAVs so that they<br />

can quickly be adapted to the actual mission.<br />

The third point can only be achieved through the use of a<br />

<strong>modular</strong> architecture. Moreover, since BOA is still a prospective<br />

concept, all possible missions are probably not exhaustively<br />

identified; finally, some specific functions, dealing with<br />

autonomous capacities of ground vehicles, will be provided<br />

by other programmes, the actors of which are not necessarily<br />

involved in BOA. These two supplementary aspects imply that<br />

the software framework be also <strong>open</strong>, to allow the desired<br />

extensibility. But the second above point is maybe the most<br />

critical. The diversity of in<strong>for</strong>mation sources, and the number<br />

of actors that will access them, then encourages to adopt<br />

standards <strong>for</strong> data exchanges.<br />

As a consequence, the DoD insisted on the architecture<br />

part of the robots and vehemently required that <strong>modular</strong>ity<br />

be achieved at all levels (software as well as hardware), that<br />

interfaces be <strong>open</strong> and can be communicated to third parties.<br />

The interoperability constraints were tackled by explicitely<br />

asking <strong>for</strong> the adoption of a standard <strong>for</strong> data exchanges:<br />

JAUS, if obviously not imposed, was quoted as an acceptable<br />

solution, so that to clearly illustrate DoD expectations. Finally,<br />

it is worth noting that in<strong>for</strong>mation provided by unmmanned<br />

vehicles are often of the same nature (localisation, detection<br />

or intelligence data) than those conveied by Battlefield<br />

Management Systems, that will be of primordial importance<br />

in BOA. Robots are then natural candidates to feed these<br />

systems and analyzing data structures used <strong>for</strong> the latter can<br />

also be a relevant source of inspiration.<br />

Although all previous examples are taken from ground<br />

robotics fields, the <strong>open</strong> <strong>modular</strong> architecture is actually an<br />

important subject <strong>for</strong> the near future UAV systems. Currently,<br />

the French DoD is conducting two studies in parallel. The aim<br />

16<br />

<strong>for</strong> both is: “definition of an <strong>open</strong>, standardised, <strong>modular</strong> and<br />

evolutionary architecture <strong>for</strong> a generic and interoperable UAV<br />

system”.<br />

The problematic of an UAV system is large and very complex<br />

because of the multiple interfaces including the onboard<br />

(aircrafts, payloads, airworthiness, air traffic management. . . ),<br />

ground (command, control and exploitation station, recovery,<br />

launch. . . ) and system (communications, certification, subsystem<br />

interfaces, real time synchronization, critical software. . . )<br />

constraints. The studies cover, from the time being, the three<br />

different UAVs system categories: tactical, MALE (Medium<br />

Altitude Long Endurance) and HALE (High Altitude Long<br />

Endurance). The main technical axes of the studies can be<br />

summed up with the following:<br />

• define the best configurable and generic architecture;<br />

• improve the system’s per<strong>for</strong>mances regarding new hard<br />

or software technologies;<br />

• interchangeability of payloads within the “plug and play”<br />

concept;<br />

• obtain secure, certifiable and everlasting architecture.<br />

An “<strong>open</strong>, standardized, <strong>modular</strong> and evolutionary”<br />

architecture is the challenge <strong>for</strong> the future French UAV<br />

systems programmes. Thanks to this, the interoperability will<br />

exist throughout the UAV system’s total cycle life (15 to 20<br />

years).<br />

However, one can still argue that these ef<strong>for</strong>ts towards<br />

standardisation are limited either to ground or to aerial vehicles,<br />

and that one still lacks a federative framework. This is<br />

mainly the goal of the OISAU research programme. Initiated<br />

by ground robotics experts of the DoD, this study <strong>for</strong> “<strong>open</strong><br />

and interoperable autonomous systems” actually introduces no<br />

assumptions concerning the type of the candidate plat<strong>for</strong>ms,<br />

that can either be aerian, ground or even marine vehicles. For<br />

the first time, it explicitely gathers within a lone coherent<br />

programme all the requirements presented above, asking that<br />

the resulting architecture enable :<br />

• plat<strong>for</strong>m and hardware independency;<br />

• cost reduction thanks to standardisation (thus allowing<br />

acquisition and maintenance savings);<br />

• easy integration and replacement of functional modules;<br />

• ability to incrementally proceed to these integration or<br />

replacement to allow systems evolution.<br />

This programme is probably of a primordial importance in<br />

an ef<strong>for</strong>t to get operational robots, that can be introduced in<br />

armed <strong>for</strong>ces.<br />

IV. CONCLUSION<br />

Indeed, many reasons, technical, commercial or practical,<br />

lead to increase the <strong>modular</strong>ity of robots <strong>architectures</strong>. Along<br />

the past ten years, a number of solutions has been proposed<br />

and <strong>open</strong> extensible frameworks are actually available to<br />

robots developers and users. Some of these concepts have even<br />

been successfully ported on real systems, demonstrating their<br />

relevance and maturity.

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

However, the robotics community still lacks a real federative<br />

standard to get unmanned systems interoperable. As a matter<br />

of fact, following the American JAUS example, and since<br />

interoperability is of crucial importance <strong>for</strong> the introduction<br />

of robots within armed <strong>for</strong>ces, the French DoD has decided<br />

to support the development of new normative frameworks.<br />

Besides, this ef<strong>for</strong>t concerns all fields of robotics, from ground<br />

to aerial vehicles, and is at the heart of current research<br />

programmes. A major objective of these works is to increase<br />

the technology and system readiness levels, i.e. to get more<br />

mature and reliable robots.<br />

But, if <strong>modular</strong>ity and standardisation are necessary conditions<br />

<strong>for</strong> <strong>architectures</strong> to meet all the above discussed<br />

requirements, they are not sufficient. Until now, robots are<br />

not completely autonomous systems and, even in the future,<br />

a supervisory control will be at least kept. Nevertheless there<br />

still remains work to determine which role humans deserve and<br />

which level of autonomy will be granted to robots. And the<br />

conclusions of such a work will impact the needed exchanges,<br />

data structures and interfaces that have to take place between<br />

the framework components. That is, the basic characteristics<br />

that enable <strong>modular</strong>ity will deeply depend on the role of the<br />

human in unmanned systems.<br />

ACKNOWLEDGMENT<br />

We would like to thank Agnès Lechevallier, French DoD,<br />

<strong>for</strong> her contribution on the UAV part.<br />

Special thanks go to Jérôme Lemaire, head of our department,<br />

<strong>for</strong> his help and valuable advice on the content of this<br />

paper.<br />

Also note that research works quoted in this paper would<br />

probably deserve much more attention than the one that could<br />

be granted here. They have all bring relevant results, when no<br />

breakthrough, to the field of control <strong>architectures</strong>. Please refer<br />

to the original articles <strong>for</strong> details and in-depth discussions on<br />

their specificities.<br />

REFERENCES<br />

[1] R. Alami, R. Chatila, S. Fleury, M. Ghallab and F. Ingrand, An<br />

Architecture <strong>for</strong> Autonomy, International Journal of Robotics Research,<br />

17(4), April 1998.<br />

17<br />

[2] J.S. Albus, 4-D/RCS: A Reference Model Architecture <strong>for</strong> Demo III, NIS-<br />

TIR 5994, National Institute of Standards and Technology, Gaithersburg,<br />

MD, March 1997.<br />

[3] J.S. Albus, Metrics and Per<strong>for</strong>mance Measures <strong>for</strong> Intelligent Unmanned<br />

Ground Vehicles, in proceedings of the Per<strong>for</strong>mance Metrics <strong>for</strong> Intelligent<br />

Systems (PerMIS) workshop, 2002.<br />

[4] D. Andreu and R. Passama, COSARC: COmponent based Software<br />

Architecture of Robot Controllers, in proceedings of the CAR’06 workshop,<br />

Montpellier, April 2006.<br />

[5] R. Arkin and T. Balch, AuRA: Principles and practice in review, Journal<br />

of Experimental and Theoretical Artificial Intelligence, vol. 9, no. 2-3,<br />

pp. 175-188, 1997.<br />

[6] S.C. Botelho and R. Alami, M+: a scheme <strong>for</strong> multi-robot cooperation<br />

through negotaited task allocation and achievement, in proceedings of<br />

IEEE International Conference on Robotics and Automation, vol. 2, pp.<br />

1234-1239, Michigan, May 1999.<br />

[7] R.A. Brooks, A robust layered control system <strong>for</strong> a mobile robot, IEEE<br />

Journal of Robotics and Automation, vol. RA-2, no. 1, pp. 14-23, April<br />

1986.<br />

[8] Future Business Group, Technology Readiness Levels (TRLs) guidance,<br />

FBG/36/10, January 11th 2005.<br />

[9] Future Business Group, System maturity assessment using System Readiness<br />

Levels guidance, FBG/43/01/01, v3.2, February 16th 2006.<br />

[10] L. Gillet and Y.L. Lunel, Des robots pour assister le combattant<br />

débarqué en zone urbaine : les démonstrateurs MiniRoC, L’armement,<br />

no. 85, March 2004.<br />

[11] JAUS, The Joint Architecture <strong>for</strong> Unmanned Systems, Compliance<br />

Specification, v. 1.1, March 10th 2005.<br />

[12] JAUS, The Joint Architecture <strong>for</strong> Unmanned Systems, Domain Model,<br />

volume I, v. 3.2, March 10th 2005.<br />

[13] JAUS, The Joint Architecture <strong>for</strong> Unmanned Systems, Reference Architecture<br />

SPecification, volume II, parts 1-3, v. 3.2, August 13th 2004.<br />

[14] JAUS, The Joint Architecture <strong>for</strong> Unmanned Systems, Standard Operating<br />

Procedures, v. 1.5, October 10th 2002.<br />

[15] JRP, Joint Robotics Program, Master Plan, FY2005.<br />

[16] J.G. Morillon, O. Lecointe, J.-P. Quin, M. Tissedre, C. Lewandowski,<br />

T. Gauthier, F. Le Gusquet and F. Useo, SYRANO: a ground robotic<br />

system <strong>for</strong> target acquisition and neutralization, in proceedings of SPIE<br />

Aerosense, Unmanned Ground Vehicle Technology V, vol. 5083, pp.<br />

38-51, September 2003.<br />

[17] L.E. Parker, ALLIANCE: An Architecture <strong>for</strong> Fault Tolerant Multi-Robot<br />

Cooperation, IEEE Transactions on Robotics and Automation, vol. 14,<br />

no. 2, pp. 220-240, 1998.<br />

[18] J.K. Rosenblatt, DAMN: A Distributed Architecture <strong>for</strong> Mobile Navigation,<br />

in proceedings of the 1995 AAAI Spring Symposium on Lessons<br />

Learned from Implemented Software Architectures <strong>for</strong> Physical Agents,<br />

H. Hexmoor & D. Kortemkamps (Eds.), Menlo Park, CA:AAAI Press.<br />

[19] R. Volpe, I.A.D. Nesnas, T. Estlin, D. Mutz, R. Petras and H. Das,<br />

CLARAty: Coupled Layer Architecture <strong>for</strong> Robotic Autonomy, technical<br />

report, Jet Propulsion Laboratory, December 2000.<br />

[20] R. Volpe, I.A.D. Nesnas, T. Estlin, D. Mutz, R. Petras and H. Das, The<br />

CLARAty architecture <strong>for</strong> robotic autonomy, in proceedings of IEEE<br />

Aerospace Conference, Montana, March 2001.

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Integrating human / robot interaction into robot control<br />

<strong>architectures</strong> <strong>for</strong> defense applications<br />

Delphine Dufourd a and André Dalgalarrondo b<br />

a DGA / Service des Programmes d’Armement Terrestre<br />

10, Place Georges Clemenceau, BP 19, 92211 Saint-Cloud Cedex, France<br />

b DGA / Centre d’Essais en Vol, base de Cazaux<br />

BP 416, 33260 La Teste, France<br />

ABSTRACT<br />

In the near future, military robots are expected to take part in various kinds of missions in order to assist<br />

mounted as well as dismounted soldiers: reconnaissance, surveillance, supply delivery, mine clearance, retrieval<br />

of injured people, etc. However, operating such systems is still a stressful and demanding task, especially when<br />

the teleoperator is not sheltered in an armoured plat<strong>for</strong>m. There<strong>for</strong>e, effective man / machine interactions and<br />

their integration into control <strong>architectures</strong> appear as a key capability in order to obtain efficient semi-autonomous<br />

systems. This article first explains human / robot interaction (HRI) needs and constraints in several operational<br />

situations. Then it describes existing collaboration paradigms between humans and robots and the corresponding<br />

control <strong>architectures</strong> which have been considered <strong>for</strong> defense robotics applications, including behavior-based teleoperation,<br />

cooperative control or sliding autonomy. In particular, it presents our work concerning the HARPIC<br />

control architecture and the related adjustable autonomy system. Finally, it proposes some perspectives concerning<br />

more advanced co-operation schemes between humans and robots and raises more general issues about<br />

insertion and a possible standardization of HRI within robot software <strong>architectures</strong>.<br />

Keywords: Ground robotics, human robot interaction, control <strong>architectures</strong>, defense applications, reconnaissance<br />

robot.<br />

1. INTRODUCTION<br />

Given recent advances in robotics technologies, unmanned ground systems appear as a promising opportunity <strong>for</strong><br />

defense applications. In France, teleoperated vehicles (e.g. AMX30 B2DT) will soon be used <strong>for</strong> mine breaching<br />

operations. In current advanced studies launched by the DGA (Délégation Générale pour l’Armement i.e. the<br />

French Defense Procurement Agency) such as PEA Mini-RoC (Programme d’Etudes Amont Mini-Robots de<br />

Choc) or PEA Démonstrateur BOA (Bulle Opérationnelle Aéroterrestre), robotics systems are considered <strong>for</strong><br />

military operations in urban terrain as well as in <strong>open</strong> environments, in conjunction with mounted or dismounted<br />

soldiers. To fulfill the various missions envisionned <strong>for</strong> unmanned plat<strong>for</strong>ms, the needs <strong>for</strong> human / robot<br />

interaction (HRI) increase so as to benefit from the orthogonal capacities of both the man and the machine.<br />

In section 2, we list several missions considered <strong>for</strong> military land robots and explain related issues concerning<br />

HRI. In section 3, we present an overview of existing paradigms concerning HRI and describe a few existing<br />

applications in the field of defense robotics. In section 4, we focus on an example concerning reconnaissance<br />

missions in urban warfare and present the work on the HARPIC architecture per<strong>for</strong>med at the Centre d’Expertise<br />

Parisien of the DGA. Finally, in section 5, we raise more general questions about the introduction of HRI into<br />

control <strong>architectures</strong> and about a potential standardization of these interactions, be<strong>for</strong>e concluding in section 6.<br />

2.1. Missions <strong>for</strong> military robots<br />

2. OPERATIONAL CONTEXT<br />

Unmanned ground systems can now be considered as key technologies <strong>for</strong> future military operations. Firstly,<br />

they remove humans from harms way by reducing their exposition on the battlefield. Moreover, they can provide<br />

various services and avoid humans dull, dirty or difficult tasks such as surveillance or heavy load carrying. More<br />

generally, in the future, they should be used as <strong>for</strong>ce multipliers and risk reducer in land operations.<br />

Further author in<strong>for</strong>mation:<br />

D.D.: E-mail: delphine.dufourd@dga.defense.gouv.fr, phone: +33 (0)1 47 71 45 86<br />

A.D.: E-mail: andre.dalgalarrondo@dga.defense.gouv.fr, phone: +33 (0)5 57 15 47 62<br />

18

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

Figure 1. A prospective view of future French network centric warfare.<br />

As a result, the range of missions <strong>for</strong> unmanned ground systems in the defense and security field is widening.<br />

Among them, let us mention reconnaissance and scout missions, surveillance, target acquisition and illumination,<br />

supply delivery, mule applications, obstacle clearance, remote manipulation, demining, explosive ordnance<br />

disposal, retrieval of injured people, communication relays, etc. These missions include different time steps from<br />

planning and deployement, mission fulfilment with human supervision and possible re-planning to reployment<br />

and maintenance, as well as training sessions. They take place on various terrains, ranging from structured urban<br />

environments to destructured (destroyed) places and ill-structured or unstructured <strong>open</strong> areas. Moreover, defense<br />

operations present a few specificities compared to civil applications. Unmanned vehicles will often have to deal<br />

with challenging ill-known, unpredictable, changing and hostile environments. In urban warfare <strong>for</strong> instance,<br />

robots will face many incertainties and they will have to intermix with friends, foes and bystanders. As a partner<br />

or as an extent of a warfighter, a robot must also con<strong>for</strong>m to different constraints and doctrines: he must neither<br />

increase the risk <strong>for</strong> the team – which stands <strong>for</strong> ”surprise effect” cancelling and trap triggering <strong>for</strong> instance –<br />

nor impose an important workload to the human supervisor. Moreover, some decisions such as engaging a target<br />

cannot be delegated to a robot: it is crucial that man stay in the loop in such situations. Finally, robots will be<br />

inserted into large organizations (systems of systems designed <strong>for</strong> network-centric warfare – cf. Fig. 1) and will<br />

have to co-operate with other manned or unmanned entities, following a command hierarchy. There<strong>for</strong>e, efficient<br />

and scalable man / machine collaboration appears as a necessity.<br />

2.2. Why introduce HRI into military operations ?<br />

On the one hand, it is desirable that robots should operate as autonomously as possible in order to reduce the<br />

workload of the operator and to be robust to communication failures with the control unit. For example, rescue<br />

operations at the World Trade Center per<strong>for</strong>med using the robots developped <strong>for</strong> the DARPA (U.S. Defense<br />

Advanced Research Projects Agency) TMR (Tactical Mobile Robotics) program showed that it was difficult <strong>for</strong><br />

a single operator to ensure both secure navigation <strong>for</strong> the robot and reliable people detection. 1<br />

On the other hand, technology is not mature enough to produce autonomous robots which could handle<br />

the various military situations on their own. Basic capacities that have been shown on many robots include<br />

obstacle detection and avoidance, waypoint and goal oriented navigation, detection of people, detection of threats,<br />

in<strong>for</strong>mation retrieval (image, sound), localization and map building, exploration or coordination with other<br />

robots. Most of them can be implemented on a real robot with a good reliability in a reasonably difficult<br />

environnement but it is not enough to fulfill military requirements. For instance, so far, no robot has been able<br />

to move fully autonomously in the most difficult and unstructured arenas of the NIST (US National Institute<br />

of Standards and Technologies) in the context of search and rescue competitions. 2 Moreover, some high-level<br />

doctrines and constraints (such as discretion) may be difficult to describe and <strong>for</strong>malize <strong>for</strong> autonomous systems.<br />

Finally, humans and robots have complementary capabilities 3 : humans are usually superior in perception<br />

(especially in environment understanding), in knowledge management and in decision making while robots can<br />

be better than humans in quantitative low-level perception, in precise metric localization and in displacement<br />

in confined and cluttered space. Above all, robots can stand dull, dirty and dangerous jobs. There<strong>for</strong>e, it seems<br />

19

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

that today’s best solutions should rely on a good collaboration between humans and robots e.g. when robots act<br />

as autonomously as possible but remain under human supervision.<br />

2.3. What kind of HRI is needed <strong>for</strong> military operations ?<br />

The modalities concerning human / robot interaction may vary depending on the situation, the mission or<br />

the robotic plat<strong>for</strong>m. For instance, during many demining operations, the teleoperation of the robot could be<br />

per<strong>for</strong>med with a direct view of the unmanned vehicle. However, the teleoperation of a tracked vehicle like the<br />

French demonstrator SYRANO (Système Robotisé d’Acquisition et de Neutralisation d’Objectifs) is per<strong>for</strong>med<br />

with an Operator Control Unit (OCU) set up in a shelter which could be beyond line of sight if the transmission<br />

with the robot is ensured. In urban environment, the dismounted soldier in charge of the robot may need to<br />

protect himself and to operate the robot under stressful conditions either in close proximity or at a distance<br />

varying from a few meters to hundreds of meters. Concerning the effectors and the functions controlled by the<br />

human / robot team, some missions could imply precise remote manipulation with a robotic arm or the use of<br />

specific payloads (pan / tilt observation sensors, diversion equipments such as smoke-producing devices...) while<br />

others would only include effectors <strong>for</strong> the navigation of the plat<strong>for</strong>m. Finally, some missions may be per<strong>for</strong>med in<br />

a multi-robot and multi-entities context, using either homogeneous or heteregenous vehicles, with issues ranging<br />

from authority sharing to multi-robot cooperation and insertion into network-centric warfare organizations.<br />

There<strong>for</strong>e, defining general HRI systems <strong>for</strong> robots in defense applications may be quite challenging.<br />

3. EXISTING HUMAN / ROBOT INTERACTION SYSTEMS<br />

3.1. Overview of existing paradigms <strong>for</strong> HRI<br />

Many paradigms have been developed <strong>for</strong> human robot interaction. They allow various levels of interaction with<br />

different levels of autonomy and dependance. To introduce our work concerning the HARPIC architecture as<br />

well as related work in the defense field, we attempt to briefly list below the main paradigms from the least<br />

autonomous (teleoperation) to the most advanced (mixed-initiative) where humans and robots can co-operate<br />

to determine their goals and strategies.<br />

Teleoperation is the most basic and mature mode. In this mode the operator has full control of the robot<br />

and must assume total responsibility <strong>for</strong> mission safety and success. This mode is suitable in complicated or<br />

unexpected situations which no algorithm can deal with. In return this mode often means a heavy workload <strong>for</strong><br />

the teleoperator who needs to focus his attention on the ongoing task. With Supervisory control 4 the operator<br />

(called the supervisor) orders a subordonate (the robot) to achieve a predefined plan. In this paradigm, the<br />

robot is merely a tool executing tasks under operator monitoring. This interaction mode can adapt to low level<br />

bandwith and high level control but needs constant vigilance from the operator who must react in case of failures<br />

(to per<strong>for</strong>m manual mission re-planning <strong>for</strong> example). This mode is only suitable <strong>for</strong> static environments where<br />

planning is really effective. Behavior-based teleoperation 5 replaces fine-grained control by robot behaviors which<br />

are locally autonomous. In comparison to supervisory control, this paradigm brings safety and provides the<br />

robot with the opportunity to react to its own environment perception (e.g. to avoid obstacles). Thus, it allows<br />

the operator to be more negligent. Adjustable autonomy 6 refers to the adjustment of the level of autononomy<br />

which has been initiated by the operator, by another system or by the system himself and while the system<br />

operates. The goal of this paradigm is generally to increase the negligence time allowed to the operator while<br />

maintaining the robot to an acceptable safety and effectiveness level. In Traded control 7 the operator controls<br />

the robot during one part of the task and the robot behaves autonomously during the other part of this task.<br />

This paradigm may lead to an equivalent of the kidnapped robot problem. While the robot is controlled by the<br />

operator, it can loose its situation awareness and face difficulties when coming back to autonomous control. In<br />

Shared control, 8 part of the robot functions are autonomous and the remaining are controlled by the operator.<br />

It is important to notice that this mode requires constant attention from the operator. If the robot is only in<br />

charge of some safety mechanisms, this paradigm is equivalent to the safeguarded teleoperation. Mixed-initiative 9<br />

is characterized by a continuous dialogue between the operator and the robot where both of them share decision<br />

and responsibility. Collaborative control 10 may be described as a restrictive implementation of mixed-initiave.<br />

In this approach, the human robot dialogue is mainly reduced to a predefined set of questions and answers.<br />

All this paradigms may be considered as subsets of the human / robot teaming domain with important<br />

overlapping. There<strong>for</strong>e, many robotic experimentations use a mix of these paradigms, including our work on<br />

HARPIC and related projects described in the next section.<br />

20

First National Workshop on Control Architectures of Robots - April 6,7 2006 - Montpellier<br />

3.2. Existing applications concerning defense applications<br />

Most applications <strong>for</strong> military unmanned ground vehicles are based on existing control <strong>architectures</strong> and the<br />

HRI mechanisms often reflect this initial approach. Most of these <strong>architectures</strong> are hybrid, but some of them<br />

are more oriented towards the deliberative aspect while others focus mostly on their reactive components. As<br />

a result, HRI mechanisms are sometimes more oriented towards high level interaction at the planning phase<br />

(deliberative) while others tend to be more detailed at the reactive level.<br />

For instance, the small UGV developed by the Swedish Royal Institute of Technology 11 <strong>for</strong> military operations<br />

in urban terrain is inspired from the SSS (Servo, Subsumption, Symbolic) hybrid architecture. The individual<br />

components correspond to reactive behaviors such as goto, avoid, follow me, mapping, explore, road-follow and<br />

inspect. During most tasks, only a single behavior is active but when multiple behaviors are involved, a simple<br />

superposition principle is used <strong>for</strong> command fusion (following the SSS principles). The activation or desactivation<br />