Paints and Coatings - P2 InfoHouse

Paints and Coatings - P2 InfoHouse

Paints and Coatings - P2 InfoHouse

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

142 <strong>Paints</strong> i3 <strong>Coatings</strong><br />

improve the adhesion of the metal-<br />

lic layer. Frequently, the base coat<br />

is 100% solids UV-curable paint<br />

that is spray-applied. Conven-<br />

tional solvent-based paints are<br />

used only if required by the pro-<br />

duct specifications. UV-curable<br />

paints offer an advantage over the<br />

more conventional air-dry or<br />

bake-dry paints in that they sig-<br />

nificantly reduce energy require-<br />

ments.<br />

Depending on the product<br />

specifications, the top coat may<br />

vary from solvent-borne<br />

urethanes to UV-curables. Rainey<br />

concedes that problems still exist<br />

with UV-curable topcoats in view<br />

of their poor adhesion to the metal<br />

film. Improving the performance<br />

st<strong>and</strong>ards of low-polluting top<br />

coats is just one of the challenges<br />

that Varian Associates hopes to<br />

solve in the coming decade.<br />

Varian’s Florence plant, which<br />

opened late in 1980, will apply a<br />

metallic finish using the sputter-<br />

coating technique to appliances,<br />

furniture <strong>and</strong> plumbing compo-<br />

nents fabricated of plastic. The<br />

types of plastic to be coated at the<br />

new plant will centre mainly on<br />

acrylonitrile-butadiene-styrene<br />

(ABS) plastics <strong>and</strong> some poly-<br />

propylene plastics. Varian As-<br />

sociates has demonstrated that<br />

other sputterable plastics include<br />

polystyrene, nylon, phenylene-<br />

oxide-based resin, polycarbonate,<br />

acrylic, thermoplastic, acetal <strong>and</strong><br />

p~lyurethane.~~<br />

According to Rainey, sputter-<br />

coating economics might not be as<br />

good today as more conventional<br />

painting methods, but it is gener-<br />

ally competitive with electroplat-<br />

ing. Unlike electroplating which<br />

is a proven technology, sputter-<br />

coating is a newcomer to the<br />

finishing world.<br />

Rainey speculates that in five<br />

years, sputtercoating will be two<br />

times cheaper than electro-<br />

plating.39 Unlike electroplating,<br />

which requires complex <strong>and</strong> costly<br />

pretreatment steps to prepare<br />

the substrate for plating, the<br />

sputtercoating process is<br />

relatively simple.<br />

Powder Coating<br />

In the powder coating process,<br />

specially formulated fusible paint<br />

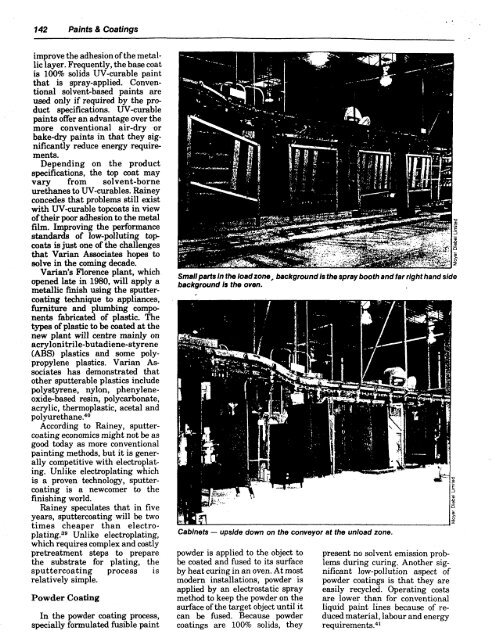

Small parts in the load zone, background is the spray booth <strong>and</strong> far right h<strong>and</strong> side<br />

background Is the oven.<br />

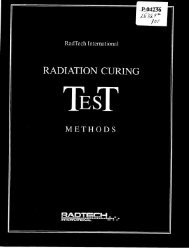

Cabinets - upside down on the conveyor at the unload zone.<br />

powder is applied to the object to<br />

be coated <strong>and</strong> fused to its surface<br />

by heat curing in an oven. At most<br />

modem installations, powder is<br />

applied by an electrostatic spray<br />

method to keep the powder on the<br />

surface of the target object until it<br />

can be fused. Because powder<br />

coatings are 10Wo solids, they<br />

,.<br />

present no solvent emission prob-<br />

lems during curing. Another sig-<br />

nificant low-pollution aspect of<br />

powder coatings is that they are<br />

easily recycled. Operating costs<br />

are lower than for conventional<br />

liquid paint lines because of re-<br />

duced material, labour <strong>and</strong> energy<br />

req~irements.~~