Paints and Coatings - P2 InfoHouse

Paints and Coatings - P2 InfoHouse

Paints and Coatings - P2 InfoHouse

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

132 <strong>Paints</strong> & <strong>Coatings</strong><br />

chronic <strong>and</strong> cumulative threats to<br />

health as solvents, their caustic<br />

nature dictates use of proper<br />

safety equipment mch as goggles,<br />

face masks <strong>and</strong> protective cloth-<br />

ing.<br />

Industry spokesmen suggest<br />

that caustic cleaning solution is<br />

recycled among many of those<br />

plants that use this cleaning<br />

method. Waste rinsewater, on the<br />

other h<strong>and</strong>, is typically sewered.<br />

Some paint formulators success-<br />

fully muse waste rinsewater in<br />

the production of water-based<br />

paints without impairing paint<br />

quality.! Such water recycling<br />

applications are rare.<br />

H Accordrng to a study of the<br />

United States paint m<strong>and</strong>actur-<br />

ing industry by Burns <strong>and</strong> Roe<br />

Industrial Services Corp.<br />

(Paramus, New Jersey), if the<br />

s00,OOO gallons of wastewater<br />

produced daily by the entire paint<br />

m<strong>and</strong>acturing industry in the<br />

United Stah were treated by<br />

conventional chemical precipita-<br />

tion <strong>and</strong> settling, it would yield a<br />

sludge volume of 120,OOO gallons<br />

per day.I5<br />

On the other h<strong>and</strong>, if8096 of the<br />

wastewater generated is recycled<br />

industry-wide, this would shrink<br />

the total wastestream to 160,000<br />

gallons per day.15 This assumes<br />

that 20% of the total wastewater<br />

volume would be incompatible for<br />

reuse because of colour <strong>and</strong> for-<br />

mulation restrictions.<br />

Recycling wastewater is antici-<br />

pated to be the cheapest treatment<br />

option because it greatly reduces<br />

the volume of wastewater requir-<br />

ing costly chemical precipitation<br />

<strong>and</strong> sludge disposing procedures.<br />

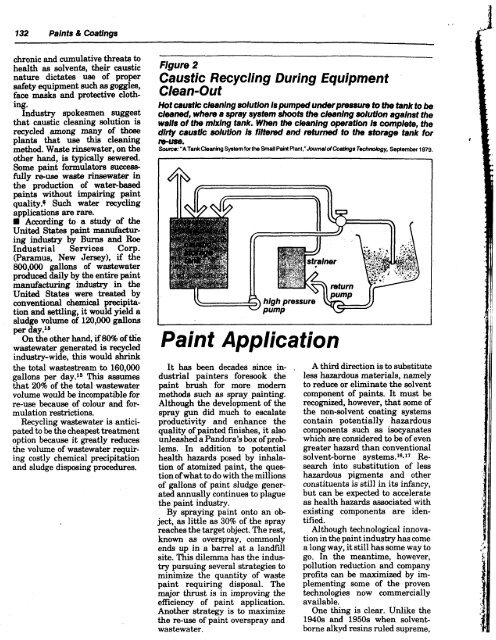

Flgure 2<br />

Caustic Recycling During Equipment<br />

Clean-Out<br />

Hot caustic cleaning solutlon Is pumped under pressure to the tank to be<br />

cleaned, where a spray system shoots the cleaning solution against the<br />

walls of the mixlng tank. When the cleaning operation is complete, the<br />

dirty caustic solutlon Is flitamd <strong>and</strong> mtumed to the storage tank for<br />

"e.<br />

Sou~:"ATankCleanlngSystemforthe Small Pain!Piant,"Joumddcodnga Tecdmibgy, September 1979.<br />

II fr \\<br />

II II<br />

Paint Application<br />

It has been decades since in-<br />

dustrial painters foresook the<br />

paint brush for more modern<br />

methods such as spray painting.<br />

Although the development of the<br />

spray gun did much to escalate<br />

productivity <strong>and</strong> enhance the<br />

quality of painted finishes, it also<br />

unleashed a P<strong>and</strong>ora's box of prob-<br />

lems. In addition to potential<br />

health hazards posed by inhala-<br />

tion of atomized paint, the ques-<br />

tion of what to do with the millions<br />

of gallons of paint siudge gener-<br />

ated annually continues to plague<br />

the paint industry.<br />

By spraying paint onto an ob<br />

ject, as little as 30% of the spray<br />

reaches the target object. The rest,<br />

known as overspray, commonly<br />

ends up in a barrel at a l<strong>and</strong>fill<br />

site. This dilemma has the indus-<br />

try pursuing several strategies to<br />

minimize the quantity of waste<br />

paint requiring disposal. The<br />

major thrust is in improving the<br />

efficiency of paint application.<br />

Another strategy is to maximize<br />

the re-use of paint overspray <strong>and</strong><br />

wastewater.<br />

,<br />

A third direction is to substitute<br />

less hazardous materials, namely<br />

to reduce or eliminate the solvent<br />

component of paints. It must be<br />

recognwd, however, that some of<br />

the non-solvent coating systems<br />

contain potentially hazardous<br />

components such as isocyanates<br />

which are considered to be of even<br />

greater hazard than conventional<br />

solvent-borne systems.16.17 Re-<br />

search into substitution of less<br />

hazardous pigments <strong>and</strong> other<br />

cuiiyiitilents is atill in its infancy,<br />

but can be expected to accelerate<br />

as health hazards associated with<br />

existing components are iden-<br />

tified.<br />

Although technological innova-<br />

tion in the paint industry has come<br />

a long way, it still has some way to<br />

go. In the meantime, however,<br />

pollution reduction <strong>and</strong> company<br />

profits can be maximized by im-<br />

plementing some of the proven<br />

technologies now commercially<br />

available.<br />

One thing is clear. Unlike the<br />

1940s <strong>and</strong> 1950s when solvent-<br />

borne alkyd resins ruled supreme,