STRAUB-OPEN-FLEX Specification STRAUB-OPEN-FLEX 1L o ...

STRAUB-OPEN-FLEX Specification STRAUB-OPEN-FLEX 1L o ...

STRAUB-OPEN-FLEX Specification STRAUB-OPEN-FLEX 1L o ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

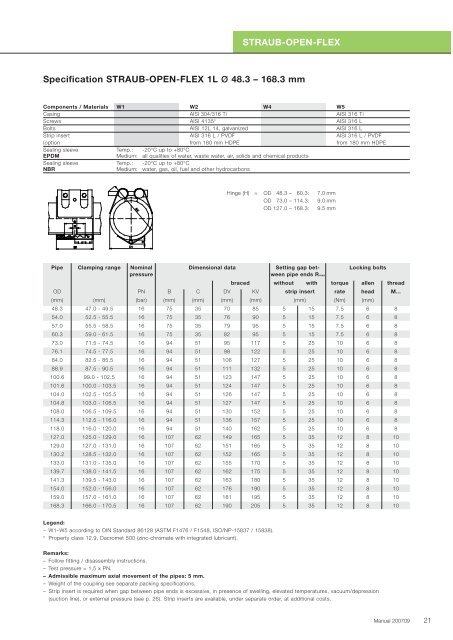

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong><br />

<strong>Specification</strong> <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> ø 48.3 – 168.3 mm<br />

Components / Materials W1 W2 W4 W5<br />

Casing AISI 304/316 Ti AISI 316 Ti<br />

Screws AISI 4135 0 AISI 316 L<br />

Bolts AISI 12L 14, galvanized AISI 316 L<br />

Strip insert AISI 316 L / PVDF AISI 316 L / PVDF<br />

(option from 180 mm HDPE from 180 mm HDPE<br />

Sealing sleeve Temp.: -20°C up to +80°C<br />

EPDM Medium: all qualities of water, waste water, air, solids and chemical products<br />

Sealing sleeve Temp.: -20°C up to +80°C<br />

NBR Medium: water, gas, oil, fuel and other hydrocarbons<br />

Pipe Clamping range Nominal Dimensional data Setting gap bet- Locking bolts<br />

pressure ween pipe ends R max<br />

braced without with torque allen thread<br />

OD PN B C DV KV strip insert rate head M...<br />

(mm) (mm) (bar) (mm) (mm) (mm) (mm) (mm) (Nm) (mm)<br />

48.3 47.0 - 49.5 16 75 35 70 85 5 15 7.5 6 8<br />

54.0 52.5 - 55.5 16 75 35 76 90 5 15 7.5 6 8<br />

57.0 55.5 - 58.5 16 75 35 79 95 5 15 7.5 6 8<br />

60.3 59.0 - 61.5 16 75 35 82 95 5 15 7.5 6 8<br />

73.0 71.5 - 74.5 16 94 51 95 117 5 25 10 6 8<br />

76.1 74.5 - 77.5 16 94 51 98 122 5 25 10 6 8<br />

84.0 82.5 - 85.5 16 94 51 106 127 5 25 10 6 8<br />

88.9 87.5 - 90.5 16 94 51 111 132 5 25 10 6 8<br />

100.6 99.0 - 102.5 16 94 51 123 147 5 25 10 6 8<br />

101.6 100.0 - 103.5 16 94 51 124 147 5 25 10 6 8<br />

104.0 102.5 - 105.5 16 94 51 126 147 5 25 10 6 8<br />

104.8 103.0 - 106.5 16 94 51 127 147 5 25 10 6 8<br />

108.0 106.5 - 109.5 16 94 51 130 152 5 25 10 6 8<br />

114.3 112.5 - 116.0 16 94 51 136 157 5 25 10 6 8<br />

118.0 116.0 - 120.0 16 94 51 140 162 5 25 10 6 8<br />

127.0 125.0 - 129.0 16 107 62 149 165 5 35 12 8 10<br />

129.0 127.0 - 131.0 16 107 62 151 165 5 35 12 8 10<br />

130.2 128.5 - 132.0 16 107 62 152 165 5 35 12 8 10<br />

133.0 131.0 - 135.0 16 107 62 155 170 5 35 12 8 10<br />

139.7 138.0 - 141.5 16 107 62 162 175 5 35 12 8 10<br />

141.3 139.5 - 143.0 16 107 62 163 180 5 35 12 8 10<br />

154.0 152.0 - 156.0 16 107 62 176 190 5 35 12 8 10<br />

159.0 157.0 - 161.0 16 107 62 181 195 5 35 12 8 10<br />

168.3 166.0 - 170.5 16 107 62 190 205 5 35 12 8 10<br />

Legend:<br />

– W1–W5 according to DIN Standard 86128 (ASTM F1476 / F1548, ISO/NP-15837 / 15838).<br />

0 Property class 12.9, Dacromet 500 (zinc-chromate with integrated lubricant).<br />

Hinge (H) = OD 48.3 – 60.3: 7.0 mm<br />

OD 73.0 – 114.3: 9.0 mm<br />

OD 127.0 – 168.3: 9.5 mm<br />

Remarks:<br />

– Follow fitting / disassembly instructions.<br />

– Test pressure = 1,5 x PN.<br />

– Admissible maximum axial movement of the pipes: 5 mm.<br />

– Weight of the coupling see separate packing specifications.<br />

– Strip insert is required when gap between pipe ends is excessive, in presence of swelling, elevated temperatures, vacuum/depression<br />

(suction line), or external pressure (see p. 26). Strip inserts are available, under separate order, at additional costs.<br />

Manual 200709 21

<strong>Specification</strong> <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> 2 ø 180.0 – 1219.2 mm<br />

Components / Materials W1 W2 W4 W5<br />

Casing AISI 1024, hot-dip galv. AISI 304/316 Ti AISI 316 Ti<br />

Screws AISI 4135 0 AISI 4135 0 AISI 316 L<br />

Bolts AISI 12L 14, galvanized AISI 12L 14, galvanized AISI 316 L<br />

Strip insert (option) AISI 316 L / HDPE AISI 316 L / HDPE AISI 316 L / HDPE<br />

Sealing sleeve Temp.: -20°C up to +80°C<br />

EPDM Medium: all qualities of water, waste water, air, solids and chemical products<br />

Sealing sleeve Temp.: -20°C up to +80°C<br />

NBR Medium: water, gas, oil, fuel and other hydrocarbons<br />

Sealing sleeve Temp.: -20°C up to +180°C<br />

VITON A1 Medien: Medium: ozone, oxygen, acids, gas, oil and fuel (only with strip insert)<br />

L-, LS-, and LU-version in W2 or W5. H-version in W1.<br />

22 Manual 200709<br />

Pipe Clamping range Working pressure Torque rate Locking bolts<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 2 <strong>OPEN</strong>-<strong>FLEX</strong> 2 <strong>OPEN</strong>-<strong>FLEX</strong> 2<br />

L LS LU H L LS LU H L/LS LU/<br />

OD PS PS PS PS H<br />

(mm) (mm) (bar) (bar) (bar) (bar) (Nm) (Nm) (Nm) (Nm)<br />

180.0 178 - 182 12.0 16.0 – – 10 15 – –<br />

200.0 198 - 202 11.0 15.0 – – 10 15 – –<br />

219.1 217 - 222 10.0 13.5 16.0 2 – 10 15 30 –<br />

250.0 248 - 253 9.0 12.0 16.0 2 – 10 15 30 –<br />

267.0 264 - 270 8.0 11.0 16.0 2 – 15 15 30 –<br />

273.0 270 - 276 8.0 11.0 16.0 2 16.0 2 15 15 30 30<br />

304.0 301 - 307 7.0 10.0 16.0 2 16.0 2 15 20 30 30<br />

323.9 321 - 327 7.0 9.5 16.0 2 16.0 2 15 20 30 30<br />

355.6 353 - 358 6.0 8.5 16.0 2 16.0 2 15 20 30 30<br />

406.4 404 - 409 5.5 7.5 15.0 2 16.0 2 20 20 30 40 2 2 (42 )<br />

457.2 454 - 460 5.0 6.5 13.0 2 16.0 2 20 20 40 40 x M10 x M12<br />

508.0 505 - 511 4.5 6.0 10.0 2 16.0 2 20 25 40 40 with with<br />

558.8 556 - 562 4.0 5.5 9.0 16.0 2 25 25 40 50 socket head socket head<br />

609.6 606 - 613 3.5 5.0 8.0 14.0 2 25 25 40 50 8 mm 10 mm<br />

711.2 707 - 715 – 4.0 7.0 12.0 2 – 30 50 50<br />

762.0 758 - 766 – 4.0 6.5 12.0 2 – 30 50 60<br />

812.8 809 - 817 – 3.5 6.0 11.0 2 – 30 50 60<br />

914.4 910 - 918 – 3.5 5.5 10.0 2 – 35 60 60<br />

1016.0 1012 - 1020 – 3.0 5.0 9.0 2 – 35 60 70<br />

1117.6 1114 - 1122 – 2.5 4.5 8.0 2 – 40 70 70<br />

1219.2 1215 - 1223 – 2.5 4.0 7.0 2 – 40 70 80<br />

Available for all pipe sizes from 180 up to 1219 mm<br />

Legend:<br />

– W1–W5 according to DIN Standard 86128 (ASTM F1476 / F1548, ISO/NP-15837 / 15838).<br />

0 Property class 12.9, Dacromet 500 (zinc-chromate with integrated lubricant).<br />

1 To special order.<br />

2 Casing in two halfs.<br />

DV = Outside diameter of the braced pipe coupling = OD + 27 mm<br />

B = Width of the pipe coupling<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 2L = 138 mm<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 2LS = 139 mm<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 2LU = 141 mm<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 2H = 142 mm<br />

C = Distance between sealing lips = 91 mm<br />

Rmax. = Setting gap between pipe ends<br />

with strip insert = 35 mm<br />

without strip insert = 10 mm<br />

Remarks:<br />

– Follow fitting / disassembly instructions.<br />

– Test pressure = 1,5 x PS.<br />

– Admissible maximum axial movement of the pipes: 10 mm.<br />

– Weight of the repair clamps see separate packing specifications.<br />

– Strip insert is required when gap between pipe ends is excessive, in presence of swelling, elevated temperatures, vacuum/depression<br />

(suction line), or external pressure (see p. 26). Strip inserts are available, under separate order, at additional costs.

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong><br />

<strong>Specification</strong> <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> 3 ø 558.8 – 2032.0 mm<br />

Components / Materials W1 W2 W4 W5<br />

Casing AISI 1024, hot-dip galv. AISI 304/316 Ti AISI 316 Ti<br />

Screws AISI 4135 0 AISI 4135 0 AISI 316 L<br />

Bolts AISI 12L 14, galvanized AISI 12L 14, galvanized AISI 316 L<br />

Strip insert (option) AISI 316 L / HDPE AISI 316 L / HDPE AISI 316 L / HDPE<br />

Sealing sleeve Temp.: -20°C up to +80°C<br />

EPDM Medium: all qualities of water, waste water, air, solids and chemical products<br />

Sealing sleeve Temp.: -20°C up to +80°C<br />

NBR Medium: water, gas, oil, fuel and other hydrocarbons<br />

LS-version in W2 or W5. H-version in W1.<br />

Pipe Clamping range Working pressure Torque rate Locking bolts<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 3 <strong>OPEN</strong>-<strong>FLEX</strong> 3 <strong>OPEN</strong>-<strong>FLEX</strong> 3<br />

LS H LS H LS H<br />

OD PS PS<br />

(mm) (mm) (bar) (bar) (Nm) (Nm)<br />

558.8 555 - 562 7.0 – 40 –<br />

609.6 606 - 613 6.5 – 40 –<br />

711.2 707 - 715 5.5 – 40 –<br />

762.0 758 - 766 5.0 – 40 –<br />

812.8 809 - 817 5.0 – 50 –<br />

914.4 910 - 918 4.5 – 50 –<br />

1016.0 1012 - 1020 4.0 – 50 –<br />

1117.6 1113 - 1122 3.5 – 50 – 3 (62 ) 62 1219.2 1215 - 1224 3.5 2 8.5 2 50 60 x M12 x M16<br />

1320.8 1316 - 1325 3.0 2 8.0 2 50 60 with with<br />

1422.4 1418 - 1427 3.0 2 7.5 2 60 70 socket head socket head<br />

1524.0 1519 - 1529 2.5 2 7.0 2 60 70 10 mm 14 mm<br />

1625.6 1621 - 1631 2.5 2 6.5 2 60 80<br />

1727.2 1722 - 1732 2.5 2 6.0 2 60 80<br />

1828.8 1824 - 1834 2.0 2 5.5 2 70 90<br />

1930.4 1925 - 1936 2.0 2 5.5 2 70 90<br />

2032.0 2027 - 2037 2.0 2 5.0 2 70 100<br />

Available for all pipe sizes from 558 up to 2032 mm<br />

Legend:<br />

– W1–W5 according to DIN Standard 86128 (ASTM F1476 / F1548, ISO/NP-15837 / 15838).<br />

0 Property class 12.9, Dacromet 500 (zinc-chromate with integrated lubricant).<br />

2 Casing in two halfs.<br />

DV = Outside diameter of the braced pipe coupling = OD + 38 mm<br />

B = Width of the pipe coupling<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 3LS = 210 mm<br />

<strong>OPEN</strong>-<strong>FLEX</strong> 3H = 212 mm<br />

C = Distance between sealing lips = 127 mm<br />

Rmax. = Setting gap between pipe ends<br />

with strip insert = 60 mm<br />

without strip insert = 15 mm<br />

Remarks:<br />

– Follow fitting / disassembly instructions.<br />

– Test pressure = 1,5 x PS.<br />

– Admissible maximum axial movement of the pipes: 15 mm.<br />

– Weight of the repair clamps see separate packing specifications.<br />

– Strip insert is required when gap between pipe ends is excessive, in presence of swelling, elevated temperatures, vacuum/depression<br />

(suction line), or external pressure (see p. 26). Strip inserts are available, under separate order, at additional costs.<br />

Manual 200709 23

Simple, safe, tight –<br />

<strong>STRAUB</strong>-CLAMP ®<br />

NEW

<strong>STRAUB</strong>-CLAMP ® SCE 44.0 – 330.0 mm<br />

One-piece repair clamp<br />

Components Materials<br />

Casing 1.4301 / 304<br />

Screws 1.4301 / 304<br />

Bolts 1.4301 / 304<br />

Sealing sleeve Temp.: -5°C to +25°C<br />

NBR Medium: all water qualities, gas<br />

¯OD<br />

R<br />

200<br />

300<br />

400<br />

KV<br />

DV<br />

<strong>STRAUB</strong>-CLAMP ®<br />

clamp length<br />

DN OD Working Tightening 2 locking 3 locking 4 locking DV on KV on Hex Thread<br />

(mm) pressure* torque bolts bolts bolts largest pipe largest pipe head (mm)<br />

PS (bar) (Nm) (mm) (mm) (mm)<br />

44 44 - 48 16 40 +_ 2 200 300 60 117 17 M10<br />

48 48 - 52 16 45 +_ 2 200 300 64 120 17 M10<br />

54 54 - 58 16 45 +_ 2 200 300 70 125 17 M10<br />

60 60 - 67 16 45 +_ 2 200 300 79 127 17 M10<br />

70 70 - 77 16 45 +_ 2 200 300 89 135 17 M10<br />

75 75 - 81 16 60 +_ 3 200 300 95 138 17 M10<br />

82 82 - 89 16 60 +_ 3 200 300 400 101 145 17 M10<br />

87 87 - 95 16 60 +_ 3 200 300 400 107 149 17 M10<br />

88 88 - 95 16 60 +_ 3 200 300 400 110 148 17 M10<br />

95 95 - 104 16 60 +_ 3 200 300 400 116 155 17 M10<br />

108 108 - 118 16 60 +_ 3 200 300 400 120 166 17 M10<br />

113 113 - 123 16 60 +_ 3 200 300 400 135 171 17 M10<br />

118 118 - 128 16 60 +_ 3 200 300 400 140 175 17 M10<br />

120 120 - 131 16 60 +_ 3 200 300 400 143 176 17 M10<br />

132 132 - 142 16 70 +_ 3 200 300 400 154 188 19 M12<br />

135 135 - 145 16 70 +_ 3 200 300 400 157 191 19 M12<br />

139 139 - 149 16 70 +_ 3 200 300 400 161 195 19 M12<br />

145 145 - 155 16 70 +_ 3 200 300 400 167 201 19 M12<br />

159 159 - 170 16 80 +_ 5 200 300 400 182 214 19 M12<br />

167 167 - 178 16 80 +_ 5 200 300 400 190 221 19 M12<br />

176 176 - 187 16 80 +_ 5 200 300 400 199 230 19 M12<br />

193 193 - 203 16/10 80 +_ 5 200 300 400 215 247 19 M12<br />

215 215 - 225 10 80 +_ 5 200 300 400 237 268 19 M12<br />

228 228 - 239 10 85 +_ 5 300 251 281 19 M12<br />

240 240 - 250 10 85 +_ 5 300 262 292 19 M12<br />

261 261 - 271 10 85 +_ 5 300 283 313 19 M12<br />

269 269 - 280 10 85 +_ 5 300 292 321 19 M12<br />

280 280 - 291 10 85 +_ 5 300 303 332 19 M12<br />

315 315 - 325 6 85 +_ 5 300 337 366 19 M12<br />

320 320 - 330 6 90 +_ 9 300 342 371 19 M12<br />

Legend:<br />

– R = Maximum axial length of damaged area Clamp length 200 mm 300 mm 400 mm<br />

– Radial length of damaged area max. 20% of pipe outside diameters R = 50 mm 150 mm 250 mm<br />

The repair clamp must be centred over the damaged area<br />

* Working pressure for gas max 5 bar<br />

Remarks:<br />

– The clamp cannot be used for differing pipe diameters (transitions)<br />

– Test pressure = 1.5 x PS<br />

– Comply with installation instructions

<strong>STRAUB</strong>-CLAMP ® SCZ 88.0 – 440.0 mm<br />

Two-piece repair clamp<br />

Components Materials<br />

Casing 1.4301 / 304<br />

Screws 1.4301 / 304<br />

Bolts 1.4301 / 304<br />

Sealing sleeve Temp.: -5°C to +25°C<br />

NBR Medium: all water qualities, gas<br />

¯OD<br />

R<br />

200<br />

300<br />

400<br />

<strong>STRAUB</strong>-CLAMP ®<br />

clamp length<br />

DN OD Working Tightening 2 locking 3 locking 4 locking DV on KV on Hex Thread<br />

(mm) pressure* torque bolts bolts bolts largest pipe largest pipe head<br />

PS (bar) (Nm) (mm) (mm) (mm)<br />

88 88 - 108 16 60 +_ 3 200 300 400 117 186 17 M10<br />

100 100 - 120 16 60 +_ 3 200 300 400 132 197 17 M10<br />

108 108 - 128 16 60 +_ 3 200 300 400 140 204 17 M10<br />

114 114 - 134 16 60 +_ 3 200 300 400 146 209 17 M10<br />

120 120 - 140 16 70 +_ 3 200 300 400 152 215 17 M10<br />

130 130 - 150 16 70 +_ 3 200 300 400 162 228 19 M12<br />

140 140 - 160 16 70 +_ 3 200 300 400 172 237 19 M12<br />

159 159 - 180 16 80 +_ 5 200 300 400 192 255 19 M12<br />

168 168 - 189 16 80 +_ 5 200 300 400 201 264 19 M12<br />

190 190 - 210 16 80 +_ 5 200 300 400 222 284 19 M12<br />

210 210 - 230 10 80 +_ 5 200 300 400 242 303 19 M12<br />

218 218 - 238 10 80 +_ 5 200 300 400 252 312 19 M12<br />

240 240 - 260 10 85 +_ 5 200 300 400 272 332 19 M12<br />

269 269 - 289 10 85 +_ 5 200 300 400 301 360 19 M12<br />

282 282 - 302 10 85 +_ 5 200 300 400 314 373 19 M12<br />

315 315 - 335 10/6 85 +_ 5 200 300 400 347 405 19 M12<br />

322 322 - 344 6 85 +_ 5 300 400 356 413 19 M12<br />

337 337 - 358 6 85 +_ 5 300 400 370 427 19 M12<br />

347 347 - 367 5 95 +_ 5 300 400 379 436 19 M12<br />

365 365 - 385 5 95 +_ 5 400 397 453 19 M12<br />

410 410 - 430 5 95 +_ 5 400 442 498 19 M12<br />

420 420 - 440 5 95 +_ 5 400 452 508 19 M12<br />

Legend:<br />

– R = Maximum axial length of damaged area Clamp length 200 mm 300 mm 400 mm<br />

– Radial length of damaged area max. 20% of pipe outside diameters R = 50 mm 150 mm 250 mm<br />

The repair clamp must be centred over the damaged area<br />

* Working pressure for gas max 5 bar<br />

Remarks:<br />

– The clamp cannot be used for differing pipe diameters (transitions)<br />

– Test pressure = 1.5 x PS<br />

– Comply with installation instructions<br />

DV<br />

KV

<strong>STRAUB</strong>-CLAMP ® -repair clamps<br />

One and two-piece clamps for the safe, reliable repair of gas, water and drainage pipes made from a<br />

range of materials.<br />

Applications<br />

<strong>STRAUB</strong>-CLAMP ® repair clamps for safely and<br />

reliably sealing damaged pipes made from a range of<br />

materials (steel, cast iron, ductile cast iron, fibre<br />

cement, PVC). Available in sizes from DN 40 to<br />

DN 400. Also obtainable as a two-piece version,<br />

<strong>STRAUB</strong>-CLAMP ® repair clamps with the standard<br />

NBR sealing sleeve can be used on water,<br />

drainage pipes and gas.<br />

Working instructions<br />

<strong>STRAUB</strong>-CLAMP ® provides a safe, reliable way of<br />

sealing damaged pipes.<br />

The repair clamp must be at least as long as the<br />

outside diameter of the pipe being repaired.<br />

Prepare the pipe surfaces in accordance with the<br />

general installation requirements (refer to<br />

<strong>STRAUB</strong>-CLAMP ® installation instructions).<br />

Gas: permitted working pressure 5 bar ( DN 300 on request<br />

Straub Werke AG, Rohrverbindungen, Straubstrasse 13, 7323 Wangs, Switzerland<br />

Phone +41 81 725 41 00, Fax +41 81 725 41 01, www.straub.ch, straub@straub.ch<br />

Ten good reasons to opt for <strong>STRAUB</strong>-CLAMP ®<br />

1. Ideal for repairing large damaged areas up<br />

to 250 mm long.<br />

2. The large-surface waffle profile reduces<br />

the required tightening torque, extending<br />

the life of the rubber.<br />

3. One size (OD) spans a wide range<br />

(up to 20 mm).<br />

4. Integrated ergonomic hand grips for easy<br />

handling.<br />

5. No loose screws or parts when opening.<br />

Both the one-piece and two-piece repair<br />

clamps are complete units.<br />

6. High level of corrosion resistance. Modern<br />

manufacturing methods, including pressure<br />

jointing, prevent changes in the material<br />

structure and stresses in the material.<br />

7. The entire repair clamp is made from stainless<br />

steel.<br />

8. The stainless steel screws are coated with<br />

Delta Seal, ensuring smooth tightening to the<br />

specified torque.<br />

9. Installation with standard tools (torque wrench<br />

with hex socket) – without extensions.<br />

10. Swiss quality product<br />

Liability Disclaimer<br />

The information contained herein may include inaccuracies or typographical errors. In addition, changes are periodically made to this<br />

information. Straub may make such changes to this information at any time without notice to the user.<br />

SC 200701 E

Fast, easy, practical –<br />

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> ® <strong>1L</strong> GT

Data sheet <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> GT<br />

Pipe coupling with joint and outlet socket<br />

Non axial restraint pipe coupling for all pipe materials<br />

Components /<br />

Materials<br />

W1 W2 W4 W5<br />

Casing 1.4571 (V4A) / 1.4301 (V2A) 1.4571 (V4A)<br />

Screws 1.7220 0 1.4404 / 1.4435 (V4A)<br />

Bolts 1.0737, galvanised 1.4404 / 1.4435 (V4A)<br />

Strip insert<br />

(optional)<br />

Sealing collar<br />

EPDM<br />

Sealing collar<br />

NBR<br />

Pipe Clamping<br />

range<br />

unavailable unavailable<br />

Temp.: -20°C to +70°C<br />

Medium: all qualities of water, wastewater, air, solids, and chemical products<br />

Temp.: -20°C to +70°C<br />

Medium: water, gases, oil, fuel (solid, liquid or gaseous) as well as other hydrocarbons<br />

Nominal<br />

pressure<br />

Type Dimension Setting gap<br />

between<br />

pipe ends<br />

Rmax.<br />

Torque<br />

rate<br />

(Nm)<br />

Locking bolts<br />

OD<br />

PS G1 G2 B C DV KV<br />

(mm) (mm) (bar)<br />

(mm) (mm) (mm) (mm)<br />

(mm)<br />

73.0 71.5 – 74.5 16 ¼” ½” 94 51 95 110 5 10 6 8<br />

76.1 74.5 – 77.5 16 ¼” ½” 94 51 98 115 5 10 6 8<br />

84.0 82.5 – 85.5 16 ¼” ½” 94 51 106 120 5 10 6 8<br />

88.9 87.5 – 90.5 16 ¼” ½” 94 51 111 125 5 10 6 8<br />

100.6 99.0 – 102.5 16 ¼” ½” 94 51 123 140 5 10 6 8<br />

101.6 100.0 – 103.5 16 ¼” ½” 94 51 124 140 5 10 6 8<br />

104.0 102.5 – 105.5 16 ¼” ½” 94 51 126 140 5 10 6 8<br />

104.8 103.0 – 106.5 16 ¼” ½” 94 51 127 140 5 10 6 8<br />

108.0 106.5 – 109.5 16 ¼” ½” 94 51 130 145 5 10 6 8<br />

114.3 112.5 – 116.0 16 ¼” ½” 94 51 136 150 5 10 6 8<br />

127.0 125.0 – 129.0 16 ¾” 1” 107 62 149 165 5 12 8 10<br />

129.0 127.0 – 131.0 16 ¾” 1” 107 62 151 165 5 12 8 10<br />

130.2 128.5 – 132.0 16 ¾” 1” 107 62 152 165 5 12 8 10<br />

133.0 131.0 – 135.0 16 ¾” 1” 107 62 155 170 5 12 8 10<br />

139.7 138.0 – 141.5 16 ¾” 1” 107 62 162 175 5 12 8 10<br />

141.3 139.5 – 143.0 16 ¾” 1” 107 62 163 180 5 12 8 10<br />

154.0 152.0 – 156.0 16 ¾” 1” 107 62 176 190 5 12 8 10<br />

159.0 157.0 – 161.0 16 ¾” 1” 107 62 181 195 5 12 8 10<br />

168.3 166.0 – 170.5 16 ¾” 1” 107 62 190 205 5 12 8 10<br />

Legend: - W1–W5 is according to DIN Standard 86128 (ASTM F1476 / F1548, ISO/NP-15837 / 15838).<br />

0 Property class 12.9, Dacromet 500 (zinc-chromate with integrated lubricant).<br />

Remarks: - Follow fitting/disassembly instructions.<br />

- Test pressure = 1.5 x nominal pressure PS<br />

- Admissible maximum axial movement of the pipes: 5 mm<br />

- Strip inserts cannot be fitted on all couplings with outlets.<br />

- <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> 2LGT on request (outlet G1: ¾" G2: 1“)<br />

- Weight: 73.0 – 114.3 mm = <strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> + 0.2 kg / 114.3 – 168.3 mm = <strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> + 0.3 kg<br />

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> ® <strong>1L</strong> GT<br />

Allen<br />

head<br />

Thread<br />

M…

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> ® <strong>1L</strong> GT<br />

We present non axial restraint pipe<br />

connection, compensator, and distributor in<br />

one in the form of the <strong>STRAUB</strong>-<strong>OPEN</strong>-<br />

<strong>FLEX</strong> <strong>1L</strong> GT.<br />

The <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> GT<br />

connects any metal pipe without the need to<br />

adapt the pipe ends. It is light, spacesaving,<br />

and has good damping properties.<br />

This makes it the right pipe coupling for<br />

construction and civil engineering, supply<br />

and disposal as well as for industrial<br />

pipeline construction.<br />

The <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> GT combines all the advantages of the well-known original<br />

with the added benefit of a lateral outlet. Further benefits and a wide range of applications<br />

also exist thanks to this additional outlet.<br />

Connection possibilities<br />

Threaded fittings and <strong>STRAUB</strong> pipe couplings or any other type of pipe connection such as<br />

press fitting, welding nipples, etc.<br />

Installation <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> <strong>1L</strong> GT<br />

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> ® <strong>1L</strong> GT<br />

Note: Our <strong>STRAUB</strong>-METAL-GRIP is also available in the GT-version.

Areas of application<br />

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> ® <strong>1L</strong> GT<br />

For example:<br />

� sampling<br />

� drainage<br />

� venting<br />

… or as a measuring-point for<br />

� pressure<br />

� temperature<br />

� flow rate<br />

� operating checks<br />

… or as a pre-configured<br />

connection for:<br />

� additional loads<br />

� plant extension<br />

� additional workplaces, etc.<br />

Remarks:<br />

� Subject to technical alterations<br />

� In order to illustrate the wide-ranging application potential, some of the images on the data sheet<br />

comprise the <strong>STRAUB</strong>-METAL-GRIP-GT.<br />

� Also available as <strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> 2L GT on request<br />

Straub Werke AG, Rohrverbindungen, Straubstrasse 13, 7323 Wangs, Schweiz<br />

Tel. +41 81 725 41 00, Fax +41 81 725 41 01, www.straub.ch, straub@straub.ch<br />

ST00232_0909<br />

<strong>STRAUB</strong>-<strong>OPEN</strong>-<strong>FLEX</strong> ® <strong>1L</strong> GT