GPI 20 I-Joist - BlueLinx

GPI 20 I-Joist - BlueLinx

GPI 20 I-Joist - BlueLinx

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

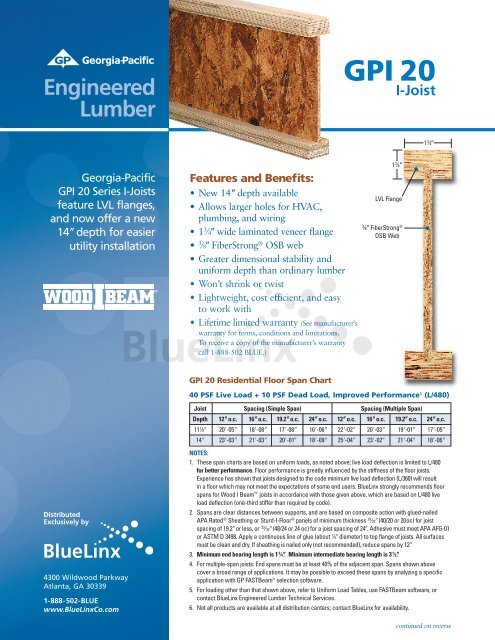

Engineered<br />

Lumber<br />

Georgia-Pacific<br />

<strong>GPI</strong> <strong>20</strong> Series I-<strong>Joist</strong>s<br />

feature LVL flanges,<br />

and now offer a new<br />

14� depth for easier<br />

utility installation<br />

4300 Wildwood Parkway<br />

Atlanta, GA 30339<br />

1-888-502-BLUE<br />

www.<strong>BlueLinx</strong>Co.com<br />

Features and Benefits:<br />

• New 14� depth available<br />

• Allows larger holes for HVAC,<br />

plumbing, and wiring<br />

•1 3 ⁄4� wide laminated veneer flange<br />

• 3 ⁄8� FiberStrong ® OSB web<br />

• Greater dimensional stability and<br />

uniform depth than ordinary lumber<br />

• Won’t shrink or twist<br />

• Lightweight, cost efficient, and easy<br />

to work with<br />

• Lifetime limited warranty (See manufacturer’s<br />

warranty for terms, conditions and limitations.<br />

To receive a copy of the manufacturer’s warranty<br />

call 1-888-502 BLUE.)<br />

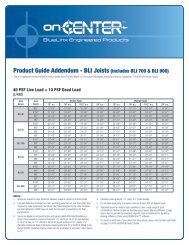

<strong>GPI</strong> <strong>20</strong> Residential Floor Span Chart<br />

<strong>GPI</strong> <strong>20</strong><br />

I-<strong>Joist</strong><br />

LVL Flange<br />

3 ⁄8� FiberStrong ®<br />

OSB Web<br />

40 PSF Live Load + 10 PSF Dead Load, Improved Performance 1 (L/480)<br />

<strong>Joist</strong> Spacing (Simple Span) Spacing (Multiple Span)<br />

Depth 12�� o.c. 16�� o.c. 19.2�� o.c. 24�� o.c. 12�� o.c. 16�� o.c. 19.2�� o.c. 24�� o.c.<br />

11 7 ⁄8� <strong>20</strong>�-05� 18�-08� 17�-08� 16�-06� 22�-02� <strong>20</strong>�-03� 19�-01� 17�-05�<br />

14� 23�-03� 21�-03� <strong>20</strong>�-01� 18�-09� 25�-04� 23�-02� 21�-04� 18�-06�<br />

NOTES:<br />

1. These span charts are based on uniform loads, as noted above; live load deflection is limited to L/480<br />

for better performance. Floor performance is greatly influenced by the stiffness of the floor joists.<br />

Experience has shown that joists designed to the code minimum live load deflection (L/360) will result<br />

in a floor which may not meet the expectations of some end users. <strong>BlueLinx</strong> strongly recommends floor<br />

spans for Wood I Beam joists in accordance with those given above, which are based on L/480 live<br />

load deflection (one-third stiffer than required by code).<br />

2. Spans are clear distances between supports, and are based on composite action with glued-nailed<br />

APA Rated ® Sheathing or Sturd-I-Floor ® panels of minimum thickness 19 ⁄32� (40/<strong>20</strong> or <strong>20</strong>oc) for joist<br />

spacing of 19.2� or less, or 23 ⁄32� (48/24 or 24 oc) for a joist spacing of 24�. Adhesive must meet APA AFG-01<br />

or ASTM D 3498. Apply a continuous line of glue (about 1 ⁄4� diameter) to top flange of joists. All surfaces<br />

must be clean and dry. If sheathing is nailed only (not recommended), reduce spans by 12� .<br />

3. Minimum end bearing length is 1 3 ⁄4.�� Minimum intermediate bearing length is 3 1 ⁄2��.<br />

4. For multiple-span joists: End spans must be at least 40% of the adjacent span. Spans shown above<br />

cover a broad range of applications. It may be possible to exceed these spans by analyzing a specific<br />

application with GP FASTBeam ® selection software.<br />

5. For loading other than that shown above, refer to Uniform Load Tables, use FASTBeam software, or<br />

contact <strong>BlueLinx</strong> Engineered Lumber Technical Services.<br />

6. Not all products are available at all distribution centers; contact <strong>BlueLinx</strong> for availability.<br />

1 3 ⁄8�<br />

1 3 ⁄4�<br />

continued on reverse

4300 Wildwood Parkway<br />

Atlanta, GA 30339<br />

1-888-502-BLUE<br />

www.<strong>BlueLinx</strong>Co.com<br />

GEORGIA-PACIFIC, GP, the GEORGIA-PACIFIC logo,<br />

FASTBEAM, FIBERSTRONG and WOOD I BEAM<br />

are owned by or licensed to Georgia-Pacific Wood<br />

Products LLC. APA RATED and STURD-I-FLOOR<br />

are registered trademarks of APA-The Engineered<br />

Wood Association. BLUELINX and the BLUELINX<br />

design are trademarks and registered servicemarks<br />

of <strong>BlueLinx</strong> Corporation.<br />

©<strong>20</strong>07 Georgia-Pacific Wood Products LLC.<br />

All rights reserved. Printed in the U.S.A. 6/07<br />

WBM Lit. Item #122972.<br />

<strong>GPI</strong> <strong>20</strong> Series Section Design Properties<br />

Specifications:<br />

Flange: 1 3 ⁄4� x 1 3 ⁄8�<br />

Web: 3 ⁄8� FiberStrong ® OSB<br />

Available Depths: 11 7 ⁄8�, 14�<br />

Available Lengths: 24�, 28�, 32�, 36�, 40�, 48�<br />

<strong>GPI</strong> <strong>20</strong><br />

I-<strong>Joist</strong><br />

Allowable Allowable Allowable Reactions<br />

EI Moment a,b Shear b<br />

End b,c Intermediate b,d C Weight e<br />

Depth (106 inch2 lbs) (ft-lbs) (lbs) (lbs) (lbs) (10 6 ft-lbs/in) (lbs/ft)<br />

117 ⁄8� 274 3870 1435 1100 2340 0.515 2.6<br />

14� 409 4640 1710 1150 2340 0.607 2.9<br />

NOTES:<br />

a. Allowable moment may not be increased for any code allowed repetitive member use factor.<br />

b. Allowable moment, shear, and reaction values are for normal duration loading and may be increased<br />

for other load durations in accordance with code.<br />

c. Allowable end reaction is based on a minimum bearing length of 1 3 ⁄4� without bearing stiffeners.<br />

For a bearing length of 4�, the allowable end reaction may be set equal to the tabulated shear value.<br />

Interpolation of the end reaction between 13 ⁄4� and 4� bearing is permitted. For end reaction values<br />

over 1,550 lbs., bearing stiffeners are required.<br />

d. Allowable intermediate reaction is based on a minimum bearing length of 3 1 ⁄2�.<br />

e. Weight of joists for dead load calculations. For shipping weights contact <strong>BlueLinx</strong>.<br />

APPROXIMATE DEFLECTION* (Inches) =<br />

W = Uniform Load (lbs/foot)<br />

L = Span (feet)<br />

EI = Stiffness Constant<br />

C = Shear Deflection Constant<br />

*Constants have been adjusted to maintain unit consistency.<br />

22.5 x W x L4 W x L2 +<br />

EI<br />

C