Very Large Diameter Fiberglass Reinforced Polyester (FRP) pipe

Very Large Diameter Fiberglass Reinforced Polyester (FRP) pipe

Very Large Diameter Fiberglass Reinforced Polyester (FRP) pipe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Complete <strong>pipe</strong> System Solutions<br />

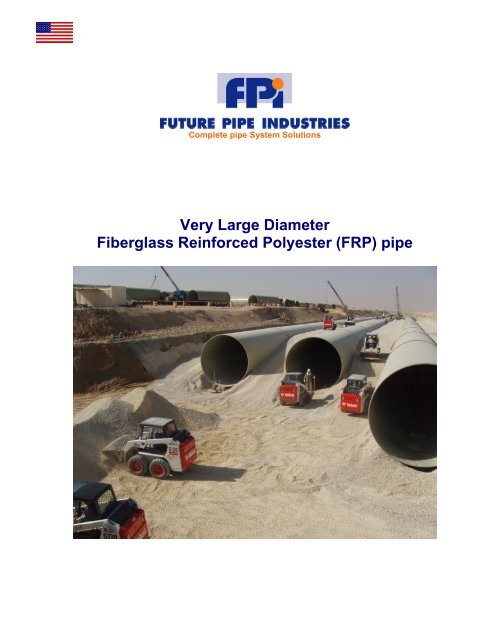

<strong>Very</strong> <strong>Large</strong> <strong>Diameter</strong><br />

<strong>Fiberglass</strong> <strong>Reinforced</strong> <strong>Polyester</strong> (<strong>FRP</strong>) <strong>pipe</strong>

<strong>Very</strong> <strong>Large</strong> <strong>Diameter</strong> <strong>FRP</strong> <strong>pipe</strong> from Future Pipe Industries<br />

Future Pipe Industries produces large diameter <strong>FRP</strong> <strong>pipe</strong> in sizes up to 158” (13 ft) in<br />

diameter. Our Fiberstrong <strong>FRP</strong> <strong>pipe</strong> are the largest commercially produced <strong>pipe</strong><br />

system in the United States; no other <strong>FRP</strong> <strong>pipe</strong> manufacturer comes even close to the<br />

large diameters produced by FPI.<br />

Manufacture<br />

Fiberstrong <strong>pipe</strong> are produced on our own state of art computer-controlled Continuous<br />

filament winding machines that allow <strong>pipe</strong> of any transportable length to be produced.<br />

Pipe produced with this process and equipment are consistently uniform in wall<br />

thickness, composition and physical properties, insuring compliance with applicable<br />

specifications that include AWWA C950, ATSM D 3517 and ASTM D3262. They are<br />

available in sizes from 16” all the way through 158”; all in standard 40’ lengths (other<br />

lengths are available). Pressure classes range from 250 to 100 psig depending on<br />

diameter.

Applications<br />

Fiberstrong large diameter <strong>FRP</strong> <strong>pipe</strong>s find many uses in infrastructure projects such as:<br />

• <strong>Large</strong> potable water transmission <strong>pipe</strong>line ( NSF ® listed )<br />

• Slip lining of corroded large concrete sewer <strong>pipe</strong> & tunnels<br />

• <strong>Large</strong> gravity sewer and storm water drains<br />

• <strong>Large</strong> siphons and culverts<br />

• River & Seawater intakes & outfalls<br />

• Power plant circulating & cooling water lines<br />

• <strong>Large</strong> Power plant penstocks<br />

• <strong>Large</strong> Irrigation <strong>pipe</strong>lines<br />

• <strong>Large</strong> Pump station headers<br />

Joints<br />

For standard buried applications, <strong>pipe</strong> is provided with <strong>FRP</strong> Reka couplings featuring<br />

two elastomeric rubber seals as shown below. These joints allow for angular<br />

deflections ranging from 3.0 degrees up to 0.5 degree depending on <strong>pipe</strong> diameter.<br />

They are easy to assemble and provide a water-tight joint under all normal operating<br />

conditions for all diameters. Internal joint testers are available to eliminate the need for<br />

expensive sectional pressure tests on large diameter <strong>pipe</strong>lines.

Pipes can be provided with plain ends for butt-wrap joints. High axial strength<br />

<strong>pipe</strong>s can also be supplied for installations where restrained joints are required and<br />

thrust blocks cannot be utilized as shown below.<br />

Advantages of Fiberstrong large diameter <strong>FRP</strong> <strong>pipe</strong><br />

Excellent corrosion resistance<br />

<strong>FRP</strong> <strong>pipe</strong> is inert and will not corrode from all known and naturally occurring soil and<br />

ground water conditions. Because the <strong>pipe</strong> is inherently corrosion resistant, it is<br />

maintenance free; requiring no periodic coating or lining. For sanitary sewer service,<br />

Fiberstrong <strong>pipe</strong> meets the stringent chemical resistance requirements of ASTM D3262.<br />

Electrically inert<br />

Because <strong>FRP</strong> <strong>pipe</strong> are non-metallic, they do not require any cathodic protection<br />

systems nor are they affected by stray electrical currents and can be safely installed in<br />

the vicinity of cathodically protected steel <strong>pipe</strong>lines.<br />

Long life and low life-cycle cost<br />

Fiberstrong <strong>FRP</strong> <strong>pipe</strong> have a minimum 50 year design life. Invariably <strong>FRP</strong> <strong>pipe</strong> provide<br />

owners with the lowest life-cycle costs when compared to conventional large diameter<br />

<strong>pipe</strong> such as steel or concrete <strong>pipe</strong>, due to its long life, and maintenance-free and<br />

corrosion-free service.

Light weight<br />

Fiberstrong <strong>FRP</strong> <strong>pipe</strong> are light weight and easy to handle. They weigh ¼th the weight of<br />

steel <strong>pipe</strong> and 1/10th the weight of concrete <strong>pipe</strong> per foot. Most <strong>pipe</strong> sections can be<br />

handled on-site with a small excavator or small crane. When used off-shore, it is<br />

common to pre-assemble 3 x 40’ <strong>pipe</strong> sections as shown below to allow 120’ of <strong>pipe</strong> to<br />

be installed underwater in one underwater operation, significantly reducing installing<br />

costs.<br />

Excellent hydraulic characteristics<br />

The smooth inner bore of Fiberstrong <strong>FRP</strong> <strong>pipe</strong> (Hazen Williams ‘C’ factor = 150) results<br />

in very low friction losses and reduced pumping costs. In most projects, a smaller <strong>FRP</strong><br />

<strong>pipe</strong> diameter will provide the same flow as a larger Concrete or cement lined steel <strong>pipe</strong>.<br />

Unlike conventional <strong>pipe</strong>s, the flow characteristics of <strong>FRP</strong> <strong>pipe</strong> remain the same year<br />

after year.<br />

Long lengths & fast installation<br />

<strong>Large</strong> diameter Fiberstrong <strong>FRP</strong> <strong>pipe</strong> is available in standard 40 foot (12 m) laying<br />

lengths. In open areas, installation rates of more than 1000 ft (300 m) per day with one<br />

crew are typical with the standard Reka couplings. Unlike steel <strong>pipe</strong>, Fiberstrong <strong>FRP</strong><br />

<strong>pipe</strong> does not require expensive and time consuming welding.<br />

ISO 9001 accreditation<br />

FPI’s Gulfport, MS plant is certified to operate a quality management system meeting<br />

the requirements of ISO 9001:2000. It’s your assurance of a reliable, dependable and<br />

quality product.

Complete piping system<br />

Our large diameter product line is complete; including fittings such as elbows, tees,<br />

reducers and flanges in <strong>pipe</strong> sizes and pressure classes produced.

Experience<br />

The Future Pipe group is the undisputed global leader in very large diameter <strong>FRP</strong> <strong>pipe</strong><br />

production, with tens of thousands of feet of <strong>pipe</strong> from 100” to 158” installed in mostly<br />

pressure service. Some of the world’s largest power plants rely on FPI’s <strong>FRP</strong> <strong>pipe</strong> for<br />

their sea water intakes and cooling water requirements.

Complete <strong>pipe</strong> System Solutions<br />

Gulfport, Mississippi factory<br />

12450 Glascock Drive<br />

Bernard Bayou Industrial Estate<br />

Gulfport, MS 39503<br />

Tel : (228) 604-0060<br />

Fax : (228) 604-0051<br />

e-mail : gulfport@future-<strong>pipe</strong>.com<br />

Houston, Texas factory & US central Sales office<br />

11811 Proctor Road<br />

Houston, TX 77038<br />

Tel : (+1-281) 847-2987<br />

Fax : (+1-281) 847-1931<br />

e-mail : sales-houston@future-<strong>pipe</strong>.com<br />

In Europe contact<br />

Future Pipe Industries BV<br />

J.C. Kellerlaan 3<br />

7770 AG Hardenberg<br />

The Netherdlands<br />

Tel : (+31) 52-288-811<br />

Fax: (+31) 52-288-441<br />

e-mail : info@future<strong>pipe</strong>.nl<br />

Future Pipe Group factory locations<br />

USA, Holland, Dubai, Abu Dhabi, Saudi Arabia, Oman, Qatar, Lebanon, Egypt,<br />

Future Pipe sales office locations<br />

Houston, London, Madrid, Paris, Hardenberg, Abu Dhabi, Beirut, Cairo, Dammam, Doha, Dubai<br />

Muscat, Bangkok, Singapore,<br />

www.future<strong>pipe</strong>.com/usa