steel project list - Kinsley Construction, Inc.

steel project list - Kinsley Construction, Inc.

steel project list - Kinsley Construction, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12<br />

PO Box 2886 � York, PA 17405<br />

For general company<br />

information, contact<br />

one of our offices:<br />

WELLNESS<br />

York, PA: John Sivulka<br />

(717) 741-8373<br />

jsivulka@rkinsley.com<br />

Reading, PA: Jack Hoy<br />

(610) 378-5380<br />

jhoy@rkinsley.com<br />

Maryland: Bruce Rogers<br />

(410) 453-6706<br />

brogers@rkinsley.com<br />

To provide feedback, please contact: Jessica Kaun via phone: (717) 741-8406 or e-mail: jkaun@rkinsley.com<br />

Diabetes is the leading public health crisis of the 21st century, and it continues to grow at epidemic<br />

proportions. Many people who have diabetes don’t even know it. Whether you have diabetes or want<br />

to prevent it, simple lifestyle changes can help you stay healthy. Take action today to control your risk!<br />

DIABETES Know Your Risks, Raise Your Awareness and Take Action.<br />

WORK ON LOSING WEIGHT, IF OVERWEIGHT.<br />

Losing 5 to 7 percent can significantly lower your risk—that’s 10 to 14 pounds for a 200-pound person.<br />

Reduce your number of calories by 250 to 500 per day by decreasing portions and leaving 2 to 3 bites<br />

of food on your plate.<br />

STRIVE TO GET SOME EXERCISE EVERY DAY.<br />

Work up to 30 to 60 minutes of moderate exercise 5 to 7 days a week, such as brisk walking.<br />

MAKE HEALTHY FOOD CHOICES AND EAT REGULAR MEALS AND SNACKS.<br />

Choose high fiber, whole grain foods with at least 3 grams of fiber per serving. Eat 5 to 9 servings of<br />

fresh fruits and vegetables, and drink water and other 0-calorie beverages.<br />

USE OUR PLATE PLANNER TO CONTROL PORTIONS.<br />

2011 | VOLUME 4<br />

THE KINSLEY COMPANIES’ NEWSLETTER<br />

www.rkinsley.com www.kinsleyconstruction.com 717.741.3841 www.rkinsley.com www.kinsleyconstruction.com 717.741.3841<br />

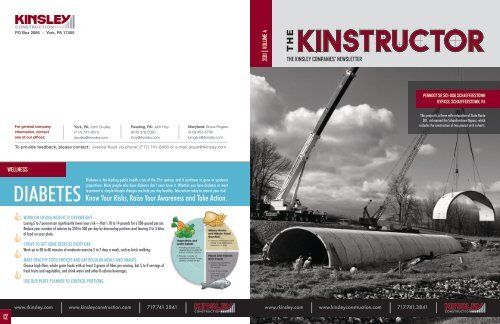

PENNDOT SR 501-006 SCHAEFFERSTOWN<br />

BYPASS, SCHAEFFERSTOWN, PA<br />

This <strong>project</strong> is a three mile relocation of State Route<br />

501, nicknamed the Schaefferstown Bypass, which<br />

includes the construction of two precast arch culverts.

2<br />

PRESIDENT’S LETTER | TOC<br />

BRIGHT SPOTS<br />

A Message from our President & COO<br />

I am a firm believer in the power of positive thinking. I believe that positive<br />

things happen to positive people. In sports, we are told to visualize the shot,<br />

see it happen in your mind, and chances are much better that the shot will be<br />

successful. This theory holds true is all parts of our lives. A good attitude goes<br />

a long way in helping us produce positive outcomes. However, having a good<br />

attitude and staying positive can be a real challenge when we are surrounded<br />

by so much negativity. It seems like all we hear is negative news. So how do<br />

we maintain a good attitude no matter what?<br />

In the book Switch: How to Change Things When Change Is Hard, authors<br />

Chip and Dan Heath contend that even in what seems to be the worst situation<br />

or conditions, there are “Bright Spots.” These are little successes that occur in<br />

the face of many negative situations. If we are vigilant in looking at the entire<br />

situation, we will find the little successes that defy the odds. It is the one inner<br />

city school that, despite all the challenges, produces remarkable results. It is the<br />

one production line that, for some reason, consistently out-performs all the other<br />

lines. It is the one salesperson who produces results when his peers struggle.<br />

The idea is to find and analyze what is working and not waste time and energy<br />

on what is not. Why is that school excelling? What is that salesperson doing<br />

that makes the difference? Once you identify the reasons behind success, those<br />

ideas can be implemented across the organization to improve overall results.<br />

These Bright Spots can be hard to find and sometimes are very small at first,<br />

which is what makes it so challenging, but it continues to be crucial that we<br />

concentrate on the positives and do not dwell on the negatives.<br />

Change is always hard. Identifying the Bright Spots and identifying why they<br />

work will help everyone to see the benefits and soften the resistance to the<br />

changes needed to succeed.<br />

So, when you wake up in the morning, make the conscious decision to have a<br />

positive attitude, look for good in things, and find the Bright Spots and positive<br />

things will happen to you.<br />

Sincerely,<br />

Jon <strong>Kinsley</strong><br />

President & COO<br />

2011 | VOLUME 4<br />

“In times of change,<br />

you need a brightspots<br />

focus. That is,<br />

you need to look for<br />

the early glimmers<br />

that something is<br />

going right. And when<br />

you find a bright spot,<br />

your mission is to<br />

study it and clone it.”<br />

Contents<br />

03<br />

04<br />

10<br />

10<br />

11<br />

12<br />

– Dan Heath<br />

Virtual <strong>Construction</strong><br />

Vela Field Management Solutions<br />

<strong>Construction</strong> Zone<br />

Division Updates<br />

Safety Matters<br />

New Safety <strong>Inc</strong>entive Program<br />

<strong>Kinsley</strong> Education Center<br />

Effective Communication Through Good<br />

Listening Skills<br />

Sustainability<br />

<strong>Kinsley</strong>'s Role In The LEED ® Certification<br />

of A New Or Renovated Building<br />

Wellness<br />

Diabetes: Know Your Risks, Raise Your<br />

Awareness and Take Action<br />

VIRTUAL CONSTRUCTION<br />

VELA FIELD MANAGEMENT SOLUTIONS | FIELD MOBILITY<br />

If you’re out on one of our jobsites and happen to see some of the staff walking around with iPads, don’t worry – they’re not playing Angry Birds<br />

or updating their status on Facebook. They’re actually deploying some of the latest technology available in the construction industry. It’s called Vela<br />

Mobile and its part of Vela’s Field Management Suite.<br />

WHAT IS VELA? | VELA AT KINSLEY<br />

Vela is a web-based platform that will revolutionize construction<br />

management. Its main purpose is to bring solutions to the field. Before<br />

Vela, when field staff performed safety inspections, quality control<br />

inspections, pre-task check<strong>list</strong>s, or even daily walkthroughs, the staff<br />

member usually carried a notebook or clipboard, intending to take notes<br />

while in the field and then return to the office and type up the notes to<br />

email them to other team members.<br />

With Vela Mobile, a superintendent can take nothing but his iPad into the<br />

field and not only have the ability to perform any one of these tasks, but<br />

also the ability to view and mark up plans. The superintendent can also<br />

attach plans, pictures, and locations to each issue that is created. After<br />

issues are created, reports can be automatically sent out on a daily basis<br />

to each subcontractor notifying them of any issues that need to be resolved<br />

in their scope. Subcontractors will have access through a special portal that<br />

lets them see all the issues they have outstanding with the <strong>project</strong>. They<br />

will also be able to post comments on open issues as well as notify <strong>Kinsley</strong><br />

of work to be inspected. The real kicker is that all of this information<br />

is recorded into one database of information that gives a complete<br />

timeline of the <strong>project</strong> from start to finish. This will dramatically increase<br />

accountability on the jobsite and it’s almost completely autonomous.<br />

Now that you know all the cool<br />

things that Vela can do, let me tell<br />

you how <strong>Kinsley</strong> is implementing this<br />

revolutionary new software. The first<br />

thing we have done is developed a<br />

core team of individuals who will lead<br />

the implementation. <strong>Inc</strong>luded are a<br />

<strong>project</strong> executive, <strong>project</strong> manager,<br />

<strong>project</strong> engineer, superintendent,<br />

and safety representative. We have several large <strong>project</strong>s on which we will pilot this program:<br />

Mt. Vernon, The Gunther at Brewers Hill, Hershey Next Century, and Volvo NE Headquarters.<br />

We have already gone through all our training with Vela and are now ready to get started.<br />

In order to ensure all subcontractors have access to this system, we will also be installing a<br />

Vela/BIM workstation kiosk at each job site. In addition to accessing Vela, we are working<br />

to give all site supervisors the ability to see the coordinated 3D model of the building.<br />

We are very anxious to implement this software and start seeing results.<br />

This is definitely a time of change within the construction industry<br />

and it’s exciting to know that we at <strong>Kinsley</strong> are on the leading edge.<br />

John Clemons | LEED AP BD+C<br />

BIM Program Manager<br />

THE KINSTRUCTOR NEWSLETTER 3

CONSTRUCTION ZONE CONSTRUCTION ZONE<br />

RESTORING THE PAST<br />

THE ORIGINAL BUILDING<br />

The Smyser-Royer building was home to an iron foundry in the<br />

1800s. Iron produced there was used to build the Brooklyn<br />

Bridge, lampposts on Ben Franklin Parkway in Philadelphia<br />

and fences in New Orleans, according to Kevin Schreiber, York’s<br />

economic development director and Redevelopment Authority<br />

coordinator. This historic, pre-Civil War building is located at<br />

32 W. North Street in the City of York.<br />

THE SCHOOL<br />

YorkCounts, a nonprofit quality-of-life group, spearheaded<br />

the effort to create York Academy as a way to attract families<br />

to York City and improve the quality of education. The<br />

school has an International Baccalaureate program, which<br />

is intertwined into teaching methods. Subjects are taught in<br />

an interdisciplinary fashion, with an emphasis on students<br />

asking questions to drive instruction. Foreign language<br />

instruction starts in kindergarten.<br />

4 2011 | VOLUME 4<br />

“The success of this<br />

<strong>project</strong> was a result of<br />

the care and expertise<br />

that <strong>Kinsley</strong> brought to<br />

the <strong>project</strong>.”<br />

Dennis P, Baughman, Ed.D.<br />

President, York Academy Regional<br />

Charter School Board of Trustees<br />

THE EXTERIOR RENOVATION<br />

Before <strong>Kinsley</strong> started work on this 39,400 square foot architectural and historic gem in 2008, the building sat<br />

unoccupied for 10 years and used only as a warehouse space by the previous building owner. <strong>Kinsley</strong> worked with<br />

the architects at LSC Design carefully to maintain this facility’s historic character and architectural details while<br />

adapting this new work with original historic portions of the building that were previously restored. After cleaning<br />

and repointing the entire three-story building as well as completing general building stabilization including a<br />

poured basement floor and a new roof in a historic 1840s style, the <strong>Kinsley</strong> team took extensive measures to match<br />

the new features of the exterior with the existing historic features. Windows that could not be restored were replaced<br />

with vintage windows of similar style. Perhaps the most interesting feature of this restoration was working with the<br />

ornamental ironwork that adorned the building. Over time, some of this antique cast iron was lost and only about<br />

45% of the original metal remained on the building. Rather than removing the remaining cast iron, the <strong>Kinsley</strong><br />

team cleaned several pieces and sent them to be replicated at an iron foundry. The new identical pieces were<br />

attached to the exterior and helped to return the building to its original grandeur.<br />

THE INTERIOR RENOVATION<br />

<strong>Kinsley</strong> made this school possible by agreeing to renovate the space at<br />

the vacated ironworks building. The interior of the facility was designed to<br />

showcase as much of the existing building's timber and brick construction<br />

as possible. LSC was challenged with finding a solution to balance the<br />

acoustical requirements of a classroom environment while keeping the<br />

beauty of the existing structure and materials exposed. By utilizing<br />

ceiling clouds and exposing the wood columns we were able to allow the<br />

students to connect with the historic fabric of facility. An old vault door<br />

was mounted on a brick façade inside the main parents' entrance on the<br />

North Street side as a relic of the school's history. The library and media<br />

center showcase a pulley system from an old mill and exposed woodbeam<br />

rafters. The biggest challenge to this portion of the renovation was<br />

the short schedule. The work had to be expedited in order to have the<br />

building complete for the start of the school year. <strong>Kinsley</strong> was able to<br />

complete the three story fit-out in seven months, including installing an<br />

elevator and two completely new stairwells. <strong>Kinsley</strong> also worked with the<br />

City of York Historical Architectural Review Board (HARB) to bring this<br />

building back to life while maintain its historical integrity. The result is a<br />

unique and visually rich environment for learning.<br />

THE KINSTRUCTOR NEWSLETTER 5

CONSTRUCTION ZONE<br />

6 2011 | VOLUME 4<br />

SITEWORK MD PROJECT LIST<br />

Montgomery College Bioscience Education Center (Germantown, MD)<br />

$9.1 Million dollar site grading, utility, & road construction <strong>project</strong> at the<br />

Germantown campus<br />

C&O Canal (Potomac, MD) – Repair of a breech in the tow path for a National Park<br />

in Potomac Maryland<br />

Locust Point Force Main (Baltimore City, MD) – Replacement of 2,725 LF of 12”<br />

Ductile Iron force main with pump station upgrades and three railroad borings<br />

Washington County Culvert Replacements (Washington County, MD)<br />

Replacement of three culverts in Washington County<br />

Hampton National Historical Site (Towson, MD) – Sitework for a new artifacts<br />

collections building<br />

Greenmount Cemetery (Baltimore City) – Sidewalk removal and restoration for a<br />

historical cemetery in Baltimore City<br />

ATEF/APG Test Track (Aberdeen, MD) – <strong>Construction</strong> of a 4.5 mile Automotive<br />

Vehicle Test and Evaluation Facility for the US Army Corps of Engineers<br />

Morgan State University Academic Quad (Baltimore City, MD) – University<br />

improvements including new site amenities, stone paver walkways, retaining walls,<br />

site lighting, storm drain work, parking lot renovations and an irrigation system<br />

Winter’s Run Pump Station & Sewer Outfall Replacement (Edgewood, MD)<br />

Upgrade to a Harford County Pump Station including the installation of over 4000<br />

linear feet of sewer pipe, 16 manholes and 2 junction boxes<br />

Fieldside Commons (Aberdeen, MD) – Sitework for a new business park<br />

Leith Walk Elementary School (Baltimore City, MD) – Sitework for an existing<br />

elementary school including earthwork, storm drain installation, water piping,<br />

concrete curbs & sidewalks, asphalt paving, storm water management and sanitary<br />

sewer work<br />

Windlass Overlook Phase 1 (White Marsh, MD) – Sitework for the first 30 lots of a<br />

new residential subdivision<br />

Renaissance Square (Middle River, MD) – Sitework for a 15 acre housing<br />

subdivision including earthwork, utilities and street & alley construction<br />

Snowden Farm (Clarksburg, MD) – Arterial roadway extension for a residential<br />

subdivision in Montgomery County including two structural plate stream culverts<br />

Little Seneca Parkway (Clarksburg, MD) – Arterial roadway extension for a<br />

residential subdivision expansion in Montgomery County<br />

Lake Linganore Villages of Pinehurst (Frederick, MD) – Remove and reconstruct<br />

water, storm, sewer, and road systems in an existing residential development<br />

Urbana Parkway Extended (Urbana, MD) – Arterial roadway for a business park in<br />

Frederick County<br />

Urbana Corporate Center (Urbana, MD) – Site earthwork and infrastructure for<br />

the expansion of an existing corporate center in Frederick County including water,<br />

sewer, storm, and road construction<br />

Urbana North Waste Water Pumping Station (Urbana, MD) – <strong>Construction</strong> of a<br />

new pumping station in Frederick County<br />

"In spite of the weak economy, last year was the first time in three years the Maryland Site Division reported<br />

increased sales in both the Timonium and Hagerstown offices. Due to everyone working more efficiently<br />

and monitoring their jobs closely, we were able to obtain respectable profit margins while experiencing<br />

this revenue growth along with the geographical expansion we have been undertaking that stretches our<br />

resources. As we enter the second quarter of 2012, we are optimistically <strong>project</strong>ing even further growth this<br />

year based on the substantial backlog we currently experience in addition to the favorable number of bid<br />

requests we are receiving. The big challenge for this year will be to maintain or increase profit levels in what<br />

is still a very competitive market. Currently the majority of the work managed out of the Timonium office is<br />

public sector work. This work consists of <strong>project</strong>s for The National Park Service, US Army Corps of Engineers,<br />

Baltimore City Department of Public Works, Baltimore City Public Schools, and Harford County Department<br />

of Public Works. The current backlog in the Hagerstown office is more evenly split between public and<br />

private sector work. In January we began work on a $9.1 million <strong>project</strong> at Montgomery College’s<br />

Germantown Campus. The housing market in Clarksburg remains brisk and as<br />

more developers see our trucks and work in the area we are receiving more<br />

requests to bid."<br />

Mike Royer<br />

MD Sitework Division Manager<br />

C&O CANAL, POTOMAC, MD<br />

<strong>Kinsley</strong> Site has teamed up with Classic Site Solutions to repair a portion of the 180-year-old C&O<br />

Canal in Potomac, Maryland. “Anglers Breach” at mile 12 of the 185 mile long historic canal is<br />

a 150 foot wide washout caused by Hurricane Hanna to the tow path and a 20 foot tall stone<br />

retaining wall separating the canal from the Potomac River. Blasted rock from the canal excavation<br />

was used to build the wall originally in the late 1920s. Any rock that is recovered will be used to<br />

face a new concrete wall to return it to its original historic appearance. Approximately 1,000 feet of<br />

tow path and canal will also be restored using a new liner and drainage system to prevent future<br />

sink holes and breaches. One of the challenges we face under the watchful eye of the Army Corps is<br />

engineering and building a temporary bridge to cross a failing bridge that goes over a 150-yearold<br />

masonry aqueduct that supplies water to Washington, DC. After the canal breach repair is<br />

complete, <strong>Kinsley</strong> Industrial will replace the existing aqueduct bridge with caissons and a reinforced<br />

concrete deck. The <strong>project</strong> is scheduled to be complete in November 2012.<br />

URBANA CORPORATE CENTER, FREDERICK MD<br />

Urbana Corporate Center is one of three <strong>project</strong>s currently under construction for Monocacy Land<br />

Company. The value of the three contracts is worth $10 million, of which $4.5 million is allocated<br />

to the Corporate Center. This development encompasses 48 acres and allows for 8 commercial lots.<br />

This venture also provides road access and utilities to the proposed $200 million Social Security<br />

Administration’s data center.<br />

CONSTRUCTION ZONE<br />

AUTOMOTIVE VEHICLE TESTING & EVALUATION FACILITY (ATEF) PHASE II<br />

The Automotive Vehicle Testing & Evaluation Facility (ATEF) Phase II <strong>project</strong> is located at the Aberdeen Proving Grounds in<br />

Aberdeen, Maryland. The majority of the proposed work for this <strong>project</strong> consists of constructing a 4.5 mile asphalt track for<br />

our military to test and evaluate military vehicles prior to their use in combat. In order to construct the proposed test track,<br />

<strong>Kinsley</strong>’s top notch dirt crews will have moved over 375,000 cubic yards of dirt. A large portion of this dirt was moved<br />

economically with agricultural type tractors pulling double 18 cubic yard and 21 cubic yard pans behind them. After the<br />

controlled fills have been made and the 27 foot wide track has been constructed, it will be composed of over 170,000<br />

tons of stone material along with over 35,000 tons of asphalt. Along the proposed track are 19 culvert crossings to be<br />

extended, which total over 2,000 feet of concrete reinforced pipe. This <strong>project</strong> is located in a high security area which<br />

makes coordinating access for employees, sub-contractors, and deliveries a challenge. All excavated areas need to be swept<br />

for unexploded ordinance prior to beginning work and during work depending on the depth of excavation. An active Army<br />

airstrip is located in the middle of this <strong>project</strong> which requires <strong>Kinsley</strong>’s field management to be in constant radio contact<br />

with the control tower during earthmoving, stoning and paving operations. <strong>Kinsley</strong> crews must meet very stringent grading<br />

and paving tolerances in the construction of this test track. Thanks to the great teamwork and efforts or everyone involved in<br />

this <strong>project</strong>, we plan to be successfully completed in August of 2012.<br />

THE KINSTRUCTOR NEWSLETTER 7

8<br />

CONSTRUCTION ZONE<br />

SITEWORK PENNSYLVANIA DIVISION<br />

"Our on going <strong>project</strong> <strong>list</strong> shows our ability to be diverse. We’ve<br />

been able to continually adapt to what the market provides.<br />

Our backlog is extensive and there is a steady flow of <strong>project</strong>s to<br />

bid. We look forward to a profitable 2012."<br />

Darren Weaver<br />

PA Sitework Division Manager<br />

SITEWORK PA PROJECT LIST<br />

114 Associates Phico Hop (Mechanicsburg, PA)<br />

Beaver Street Improvements (York, PA)<br />

Codorus Estates Phase II (York, PA)<br />

Columbia Gas, Pine Street (York, PA)<br />

Columbia Gas, South Belvidere Avenue (York, PA)<br />

Country Club Homes, LP Country Club Estates Phase 1 (Mechanicsburg, PA)<br />

CRS Hopewell Expansion Stage 4 (Shippensburg, PA)<br />

DGS Swatara State Park DGS 152-2 Phase 1 (Jonestown/Grantville, PA)<br />

Harkins, the Overlook (Camp Hill, PA)<br />

North Gettysburg Area Trail (Gettysburg, PA)<br />

Ph Glatfelter Company Emergency Basin Liner Project (Spring Grove, PA)<br />

Red Lion ASD Fields Improvements (Red Lion, PA)<br />

Stolzfus Sage Hill Phase 1 Binder, Wearing & Curbs (York, PA)<br />

Stonebridge Crossing Phase 2 (Carroll Township, PA)<br />

Tyler Run, LLC Soil Remediation (York, PA)<br />

Veterans Memorial Gold Star Peace Garden (York, PA)<br />

Western Berks Landfill Relocate Old Trash (Birdsboro, PA)<br />

COLUMBIA GAS WORK<br />

Two years ago, Columbia Gas came to <strong>Kinsley</strong> and asked if we would<br />

be interested in trying our hand at a local <strong>project</strong> in the gas industry.<br />

<strong>Kinsley</strong> started the <strong>project</strong> with a five-man crew and it turned out to<br />

be very successful. Currently, we are operating with 35 people who all<br />

have the very extensive training that is required to work on Columbia<br />

Gas <strong>project</strong>s, and we are looking to add another 10 people to our<br />

crews. We now have nine crews and are operating in the Gettysburg,<br />

Caledonia, Hanover and York areas. We have a three-year contract to<br />

install pipe, place new meters and provide services to homes. With<br />

this current contract, last year we did sixty pipe <strong>project</strong>s and all of the<br />

restoration behind them which includes paving, concrete curb and<br />

sidewalk, and lawn work. We also have a restoration contract for the<br />

next two years that keeps our paving and concrete crews moving. This<br />

contract also takes us to areas as far out as Hagerstown, State College,<br />

Gettysburg, and Bellefonte. <strong>Kinsley</strong> has excelled so much in this field<br />

that we became ranked number three out of nine national players in<br />

this field in less than two years.<br />

We are currently Columbia Gas’s only turnkey contractor<br />

and we are now in negotiations to extend our contract to<br />

2015. Talk about “Setting the Standard!” The <strong>Kinsley</strong> men<br />

and women in the field and behind the scenes have done it<br />

again. Great job!<br />

"<strong>Kinsley</strong> Manufacturing is now recognized as a PCI (Precast/Prestressed Concrete Institute) Certified Erector, putting us among<br />

the other 17 companies nationally who hold this certification. Achieving this designation will allow the division to continue to<br />

pursue and develop growth opportunities within the precast/prestressed concrete market."<br />

STEEL DIVISION<br />

TOWSON UNIVERSITY STUDENT RECREATION CENTER (TOWSON, MD)<br />

<strong>Kinsley</strong> Manufacturing was contracted as the structural <strong>steel</strong> fabricator and erector for Towson University’s<br />

new $68 million multi-purpose sports arena. The arena is a 60,000 SF cast-in-place concrete and <strong>steel</strong>framed<br />

structure. Some of the notable <strong>steel</strong> features on this <strong>project</strong> include: Ten 202 foot long span trusses,<br />

a cantilevered roof, and hanging <strong>steel</strong> that comprises the executive suites. Fabrication consists of 840 tons of<br />

structural <strong>steel</strong> and 440 tons of trusses. Our field crew’s manpower will peak at 16 ironworkers, 2 foremen,<br />

and 1 superintendant. These individuals will be assisted by our 275-ton and 200-ton crawler cranes. The most<br />

challenging aspect of this <strong>project</strong> is the erection of the trusses. Due to the lack of laydown area and general<br />

space on the construction site, internal coordination has and will be a major factor in setting these trusses.<br />

Using two cranes, the truss will be erected making a flying connection 70 feet in the air, and then the one<br />

crane will disconnect to place the infill beams while the second crane holds the truss for stability.<br />

STEEL PROJECT LIST<br />

1500 North Street Project (Harrisburg, PA) – New 7 story mixed use building fabrication/installation<br />

Penn State Hershey Medical Center’s Children’s Tower (Hershey, PA) – New five story Children’s Tower for Penn State Hershey’s Medical Center installation<br />

Binghamton University (Binghamton, NY) – Fabrication/installation for four new 6-story residence halls<br />

Point Pleasant Elementary (Glen Burnie, MD) – Fabrication/installation addition to an existing school<br />

Towson University Student Recreation Center (Towson, MD) – Fabrication/installation to new arena addition to the existing Student Recreation Center<br />

University of Pittsburgh (Pittsburgh, PA) – New, 5-story addition onto an existing building fabrication/installation<br />

Susquehanna Center (Bel Air, MD) – Fabrication for another <strong>steel</strong> fabricator<br />

Penn State- Bio Research Lab (State College, PA) – New 3-story building fabrication/installation<br />

Montgomery County EMOC (Frederick, MD) – Fabrication for another <strong>steel</strong> fabricator<br />

1800 F St. (Washington, DC) – Fabrication for another <strong>steel</strong> fabricator<br />

SR849-013 Bridge (Perry County, PA) – Bridge beam fabrication<br />

Dover High School (Dover, DE) – Fabrication/installation New High School<br />

Nemours Children’s Hospital (Wilmington, DE) – Fabrication/installation for a 7-story expansion to the existing hospital<br />

YCP- Business Administration Building (York, PA) – Renovations and a 5-story addition to the existing building fabrication/installation<br />

YCP- McKay Nursing Building (York, PA) – Fabrication/installation for renovations and an addition to the existing building<br />

Chester County Hospital (West Chester, PA)- Installation, 5 story addition to the existing hospital<br />

Westbrook Elementary School (Bethesda, MD)-Fabrication and Installation, Addition to the Elementary School<br />

Ryan Butler<br />

Steel Manufacturing Division<br />

Assistant Manager<br />

CONSTRUCTION ZONE<br />

THE KINSTRUCTOR NEWSLETTER 9

SAFETY MATTERS/EDUCATION<br />

NEW SAFETY<br />

INCENTIVE PROGRAM<br />

SAFETY INCENTIVE PROGRAMS have always been a hot topic in the safety profession. Some feel you shouldn’t<br />

have to entice employees to do what is expected of them anyway. Others feel these programs are essential to get<br />

employees to pay attention to safety policies and procedures. OSHA is the latest group to chime in on the subject.<br />

OSHA has launched a national emphasis program on record keeping and they have <strong>list</strong>ed incentive programs as<br />

a possible cause for under-reporting of work-related injuries and illnesses. With increased attention from OSHA,<br />

safety incentive programs are being reevaluated by many companies. Almost all studies on the subject come to<br />

the following conclusions:<br />

1. <strong>Inc</strong>entive award programs need to be changed<br />

periodically or they become stale and lose their<br />

effectiveness.<br />

2. If awards and bonuses are too easy, employees<br />

begin to view them as entitlements, not something<br />

to be earned. These programs tend to backfire and<br />

create more hard feelings rather than promote safe<br />

behaviors and attitudes.<br />

3. Positive recognition for a job well done is a better<br />

motivator than punishment for not meeting<br />

expectations.<br />

4. Awards and recognition need to be timely. Awards<br />

and bonuses distributed at the end of the year have<br />

little effect on day to day behaviors and attitudes<br />

toward safety.<br />

5. Safety incentives can create peer pressure among<br />

work crews. Peer pressure can be good if it<br />

encourages safe behaviors, or it can be negative if it<br />

encourages covering up work-related incidents and<br />

near misses.<br />

10 2011 | VOLUME 4<br />

In light of these findings, <strong>Kinsley</strong> will be restructuring the<br />

employee Safety <strong>Inc</strong>entive Program this year. We still<br />

feel that incentives are an important part of our Safety<br />

Program, but also want to change things up a little to<br />

reenergize the program.<br />

One of <strong>Kinsley</strong>’s new safety program incentives are the<br />

Safety Recognition Awards. The Safety Department will<br />

recognize outstanding safety performance on job sites or<br />

among work crews with these awards. Safety Recognition<br />

Awards may include lunches, gift certificates, t-shirts, or<br />

similar items. Recognition Awards will be awarded to<br />

crews going above and beyond the normal safety rules<br />

and policies.<br />

In addition to the Safety Recognition Awards, we have also<br />

instituted Safety Prizes, a Weekly Drawing, and a Grand<br />

Prize Drawing.<br />

We hope the new prizes and awards will reenergize our<br />

Safety <strong>Inc</strong>entive Program. The goal of the program is to<br />

increase employee’s awareness and participation in the<br />

safety program, not just win<br />

prizes. With safer job sites,<br />

we all win.<br />

William McCaffrey, CSP<br />

Director of Safety<br />

SETTING THE STANDARD FOR<br />

EFFECTIVE COMMUNICATION<br />

THROUGH GOOD LISTENING SKILLS<br />

In the last issue of the Kinstructor, <strong>Kinsley</strong> President and<br />

COO Jon <strong>Kinsley</strong> reminded us that communication is key<br />

to our success as a company. As we focus on heightening<br />

our communication skills, it is crucial to focus on <strong>list</strong>ening,<br />

the often forgotten partner to speaking in the exchange of<br />

information. When we communicate with our co-workers,<br />

clients, and subcontractors, we are both speakers and <strong>list</strong>eners<br />

in every instance of communication.<br />

Communication is “the act of transmitting or conveying<br />

information or ideas.” When we communicate verbally, a<br />

speaker focuses on conveying the information, and a <strong>list</strong>ener<br />

focuses on receiving the information. Typically, we place a<br />

higher value on our role as the speaker because it is important<br />

to us that our ideas are heard, but our role as the <strong>list</strong>ener is<br />

equally as important for useful communication to occur. As an<br />

effective <strong>list</strong>ener, our role is to understand what is being said<br />

and to respond appropriately.<br />

Instructors at <strong>Kinsley</strong> Education Center use various methods<br />

to assure that the information they are teaching has been<br />

understood. For instance, testing and feedback from class<br />

evaluations enable instructors to refine the classroom content<br />

and to develop new methods for teaching procedures, safety<br />

practices and skills.<br />

We encourage you to try out several of the hints below to see<br />

how making a few changes in your <strong>list</strong>ening style can result in<br />

communication that is more effective.<br />

BENEFITS OF GOOD LISTENING SKILLS ON THE JOB:<br />

• Better understanding of assignments and expectations<br />

• <strong>Inc</strong>reased rapport with co-workers, supervisors,<br />

subcontractors, and clients<br />

• Greater work proficiency in a team-based environment<br />

• Improved ability to resolve problems with customers,<br />

co-workers, and supervisors<br />

HELPFUL HINTS TO IMPROVE YOUR LISTENING SKILLS:<br />

• Maintain good eye contact<br />

• Speak back what has been said by paraphrasing and get<br />

confirmation from the speaker that you have understood<br />

• Ask questions, clarify points, and summarize speaker’s<br />

comments<br />

• Allow the speaker to finish – do not interrupt<br />

• Do not formulate your response before the speaker has<br />

made their original point<br />

When information or ideas from a speaker are successfully<br />

received through good <strong>list</strong>ening skills, the communication<br />

results in positive outcomes and goals being met. This is a<br />

win-win scenario for everyone.<br />

Article by Bonnie Brown<br />

KINSLEY'S ROLE<br />

IN THE LEED ®<br />

CERTIFICATION OF A<br />

NEW OR RENOVATED<br />

BUILDING<br />

SUSTAINABLE SITES<br />

<strong>Construction</strong> Activity Pollution Prevention<br />

This is a prerequisite involving the compliance with federal, state<br />

and local laws and requirements in addition to following the<br />

civil engineer’s <strong>project</strong> specific erosion and dust control plans.<br />

Being a prerequisite, it doesn’t count as a credit but is required<br />

to be qualified for any other credits within this category.<br />

Site Development: Protect and Restore Habitat<br />

During site operations <strong>Kinsley</strong> must stay within the Limit of<br />

Disturbance. The Limit of Disturbance is defined 40 feet beyond<br />

the building perimeter, 10 feet beyond surface walkways,<br />

patios, parking, and utilities less than 12 inches in diameter,<br />

15 feet beyond roadway curbs and main utility trenches.<br />

Heat Island Effect: Non-Roof<br />

Although this is mainly design driven, material cut sheets and<br />

as-built drawings may be required from <strong>Kinsley</strong> to achieve this<br />

credit. The term "heat island" describes surface areas that are<br />

hotter than nearby rural areas. They can be minimized by utilizing<br />

architectural and/or site components to shade a percentage of<br />

the site. Also, utilizing a solar reflectance index (SRI) of at<br />

least 29 on a percentage of all hard surfaces (including roofs)<br />

contributes towards the credit. SRI is a measure of a material’s<br />

ability to reject solar heat. <strong>Kinsley</strong> furnishes and installs only<br />

the specified materials having the required reflectance values.<br />

ENERGY AND ATMOSPHERE<br />

Fundamental & Enhanced Commissioning<br />

Fundamental commissioning is a prerequisite in the E&A<br />

category that involves verifying that the <strong>project</strong>’s energy-related<br />

systems are installed, calibrated and perform according to the<br />

requirements set forth by the owner and engineer. In order to<br />

fulfill the enhanced credit, the commissioning process must<br />

begin early in the design phase and additional activities will<br />

be required of the contractors. Everybody, especially MEP<br />

contractors, must do their part to achieve this credit.<br />

MATERIALS & RESOURCES<br />

<strong>Construction</strong> Waste Management<br />

Before the <strong>project</strong> begins, the <strong>Kinsley</strong> team will develop a plan<br />

that will identify the types of debris or trash that we will likely<br />

create and where it will go when it leaves the job site. We must<br />

think twice before throwing something away. The only way we<br />

can earn credit points is to keep as much material as we can<br />

from going to the landfill.<br />

Materials Reuse (reuse of building materials, decreasing<br />

the demand for virgin materials)<br />

Recycled Content (requirement for recycled content<br />

percentage within building materials)<br />

Regional Materials (increasing the demand for materials<br />

manufactured, harvested or extracted within the region)<br />

Rapidly Renewable Materials (materials that are<br />

manufactured from raw material that can be harvested within a<br />

10-year cycle or less) – This credit usually involves more work<br />

on the designer’s part but the contractor will need to be sure<br />

to follow the plans and specifications as well as submit the<br />

necessary documentation.<br />

Certified Wood<br />

To earn this point, at least 50% of all the wood used on the<br />

<strong>project</strong> must be Forest Stewardship Council (FSC) certified,<br />

meaning, it has come from a forest where management<br />

practices have been held to strict standards set forth by the<br />

certifier. Also, everyone who has handled the wood before it<br />

SUSTAINABILITY<br />

It is extremely important that the <strong>Kinsley</strong> team take<br />

ownership of the LEED process to assist the owner and design<br />

team in obtaining the desired level of certification.<br />

What role does <strong>Kinsley</strong> play in the LEED certification of a new or renovated building? During preconstruction, the design team is responsible for approximately 60% of the available<br />

credit points and during the construction phase, <strong>Kinsley</strong> is responsible for the remaining 40% targeted credits. It is extremely important that the <strong>Kinsley</strong> team take ownership of<br />

the LEED process to assist the owner and design team in obtaining the desired level of certification. The following are a few typical construction phase credits:<br />

reached the job site must have a certificate from FSC for their<br />

part in the manufacturing process.<br />

<strong>Construction</strong> IAQ Management Plan<br />

This plan will ensure the reduction of air quality problems that<br />

can occur during the construction or renovation, which in turn<br />

improves the wellbeing of the workers and building occupants.<br />

Smoking, protection of the ventilation system, storage of<br />

material on site, and housekeeping are all items that must be<br />

addressed within this plan. The <strong>Kinsley</strong> team develops the plan<br />

to achieve this credit.<br />

Low-Emitting Materials<br />

With these credits, it’s important that each contractor on site<br />

uses only the specified materials for this <strong>project</strong>. They were<br />

specified because of their relatively low VOC content. VOCs<br />

(Volatile Organic Compounds) are emitted as gases from certain<br />

solids or liquids, typically at room temperature. VOCs include a<br />

variety of chemicals, some of which may have short- and longterm<br />

adverse health effects.<br />

Taking ownership of the LEED process and being held accountable<br />

for the results can be summed up by <strong>Kinsley</strong> superintendent,<br />

Mike Goodling, “After you get your feet wet and understand<br />

the process, it is not all that time consuming. Little things<br />

that you take for granted need to be documented, like<br />

taking measurements and weights of recycled materials<br />

to be reused in the building.”<br />

John Clemons<br />

LEED AP BD+C<br />

BIM Program Manager<br />

Flight 93 Memorial Sitework<br />

THE KINSTRUCTOR NEWSLETTER 11